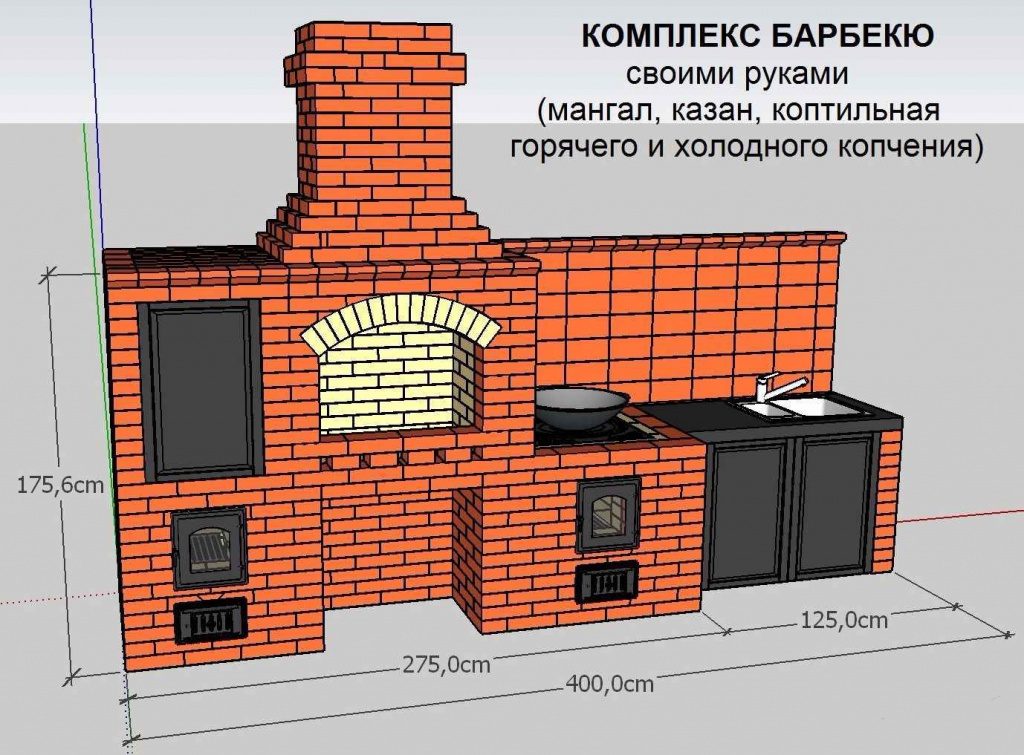

Important points

Before you build a smokehouse of any kind, you need to think carefully about everything and draw up a plan, according to which it will be much easier to make a structure without missing anything. So, you need to think about the place where the brick smokehouse will be located. Remember: it should not interfere in the backyard and cause feelings of discomfort either for you or for the neighbors behind the fence. Next, think about your choice of material. Of course, many people today can build a smokehouse from the same tin barrel. But if you want to use the smokehouse for a long time, then a brick smokehouse is the best option.

Let's figure out what kind of smoking you want the smokehouse: cold or hot. Depending on this, drawings will be drawn up, so think carefully about which type is preferable to you. Also, think about what products you will smoke, because it is for them that the structure will be built. And as a rule, some products are quite demanding and have smoking characteristics.

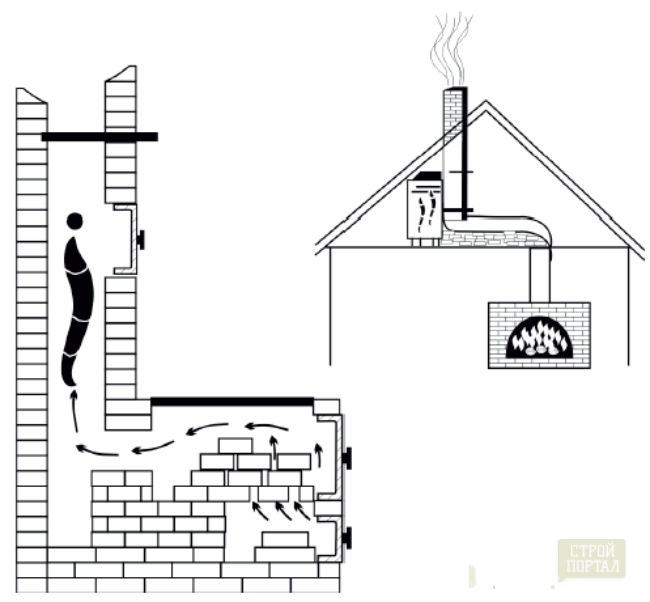

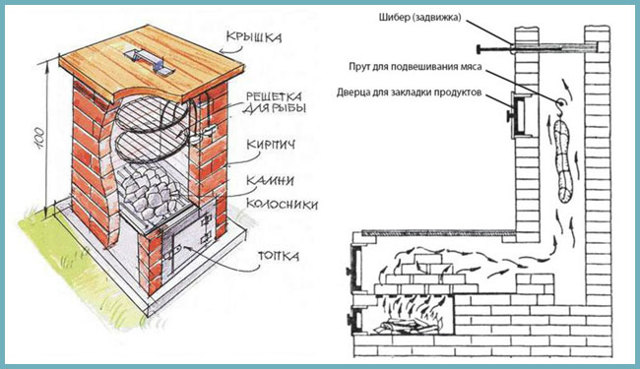

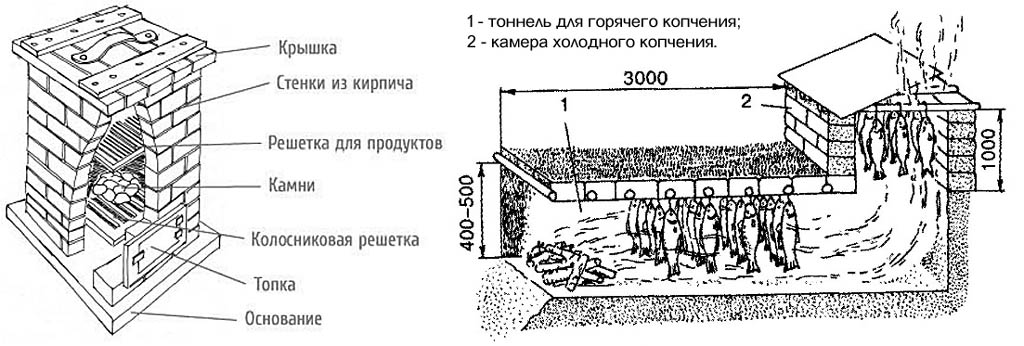

As for the design of the smokehouses. then it also has its own differences and features. For a hot smokehouse, you will need to equip the ignition center directly under the chamber. In designs for cold smoking, the ignition center is built to the side, and an elongated chimney is led directly to the chamber.

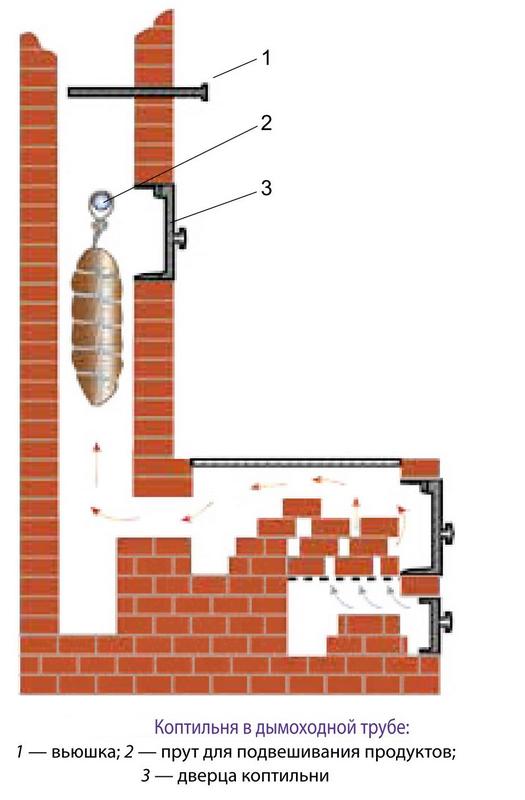

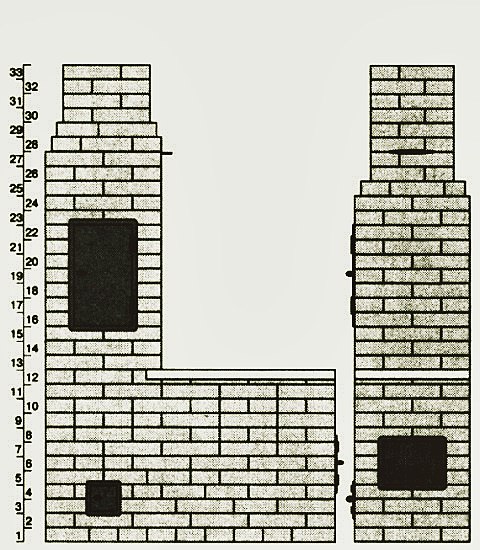

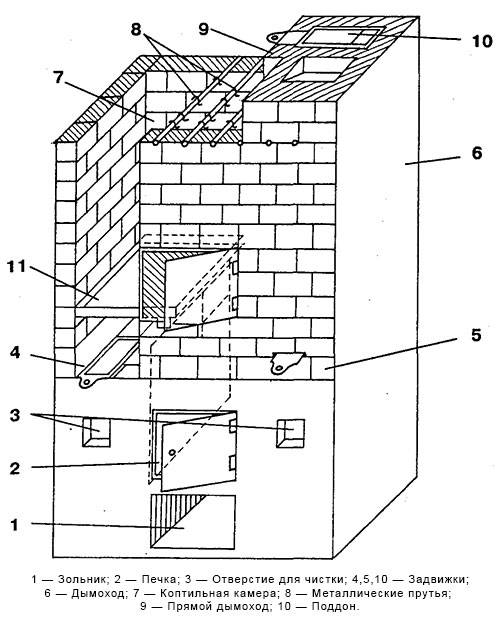

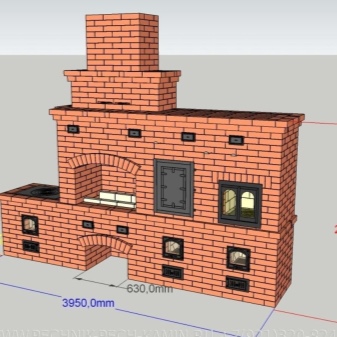

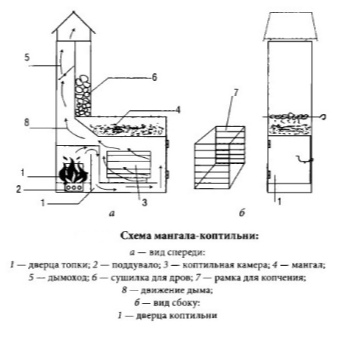

Diagram of a brick smokehouse

An important point for building a good smokehouse is the use of clay, and not cement mortar, for coating wood parts. This is due to the fact that clay is a natural, natural material, which affects the smell of products cooked in the smokehouse.

It is best to build a chimney from bricks, although the metal version will be cheaper. To protect against precipitation, it is worth placing a metal cap over the pipe. It will also affect the smell and taste of meat or fish.

A good solution would be to install a removable tray in the smoking compartment. This will make it possible to remove residual fat that drips from the food during the cooking process. If this is not done, then over time, unpleasant tastes and smells of old burnt fat will be added. Projections can be made to accommodate removable grates to hold food pieces instead of hanging them on hooks.

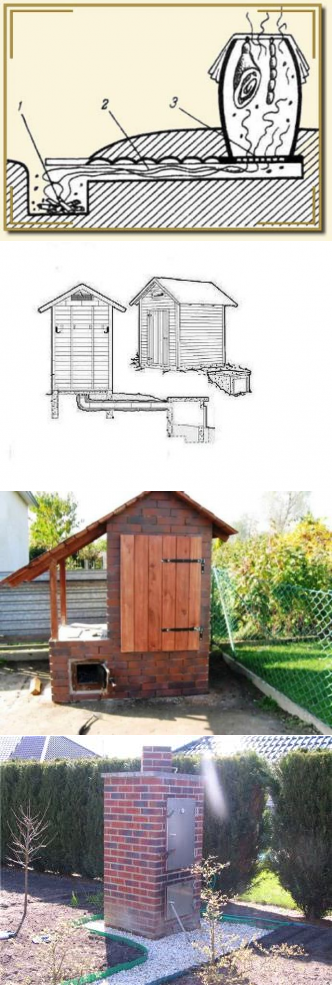

Smokehouse from an iron barrel for cold smoking

One of the easiest ways to make a cold-smoked smokehouse with your own hands is to make it from an iron or wooden barrel. The instructions for its manufacture are as simple as possible. In private households or in summer cottages, there are always barrels of iron or old wooden tubs that have served their time - that's what they can be used as a smoking chamber, connecting them with a chimney and a firebox.

The only nuance or feature of the arrangement of such a smokehouse is to ensure the tightness of the barrel. Iron can be boiled with a welding machine, using patches of a similar or similar material in composition or without them. A wooden barrel can be pulled off with new hoops and covered with natural impregnations

Particular attention should be paid to the joints of such a smoking chamber with a chimney - there should be no smoke leakage from it

Smokehouses from old barrels and tubs often become a real designer decoration of the yard. Original fences are erected around the smoking chamber, the firebox is laid out of bricks, the chimney is hidden inside the ground, and an unusual but functional corner of the garden is obtained.

Basic tips for setting up

During the work and creation of the smokehouse, you need to follow certain recommendations in order to cope with the task perfectly. These include the following:

- During the creation of the walls of the structure, it is necessary to well fix the metal rods on which the products are laid. As a rule, the number of these elements in a small-sized smokehouse is 8 pieces. Moreover, they are fixed at different heights.

- The smokehouse is often equipped with a special filter, for which a standard burlap is used. For it, it will be necessary to fix additional metal rods on which it will fit, therefore, the presence of this element in the smokehouse should be provided even at the stage of creating drawings. During the operation of the equipment, the burlap should be periodically moistened with water.

- A lid must be laid on top of the structure, and it can be made by hand. It is best if it is metal, for which a sheet of suitable metal is taken and the desired element is cut out of it.

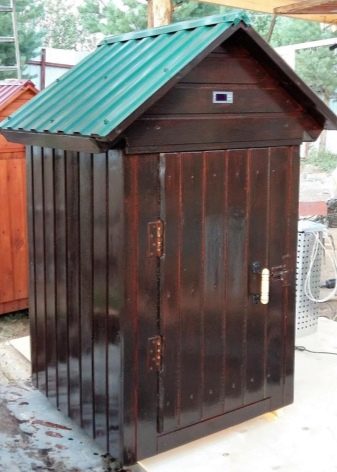

- If you intend to create a fairly large smokehouse, then it is recommended to watch a special video that will show this process. It is best if the design is presented in the form of a small house. It must be closed by a door and all equipment must be properly positioned.

Thus, a hot or cold smoked smokehouse can be easily created in-house. At the same time, you can realize all your ideas and desires in order to get a device that is correctly located, convenient for constant use and has the necessary parameters. As a result, you can always have the opportunity to cook delicious and unsurpassed smoked products that will be fragrant and delicious. Since all the work is done independently, the equipment costs will be minimal.

Smokehouse from the refrigerator Smokehouse for fish dishes

Do-it-yourself smokehouse: manufacturing procedure

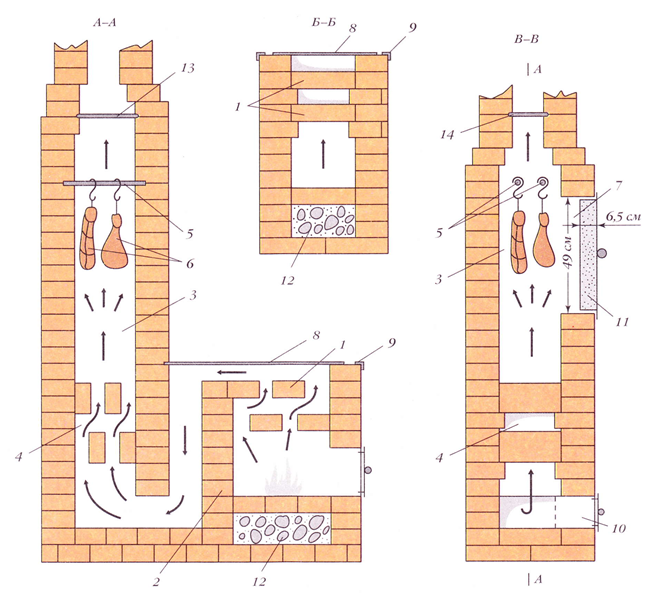

Most often, relatively small brick objects are built in private backyards for smoking food. Despite the fact that working with small forms naturally takes less time and effort than building large and "sophisticated" ovens, the manufacturing principle for both cases is the same. Therefore, considering here the project of creating a small smokehouse, it is worth remembering that it can be safely applied in the construction of a large facility. First of all, a place is laid in the ground under the smokehouse, where in the future there will be a chimney 35 cm wide, 25 cm high and length from 250 cm to 300 cm.To do this, it is necessary to dig a trench at least 300 cm long, 55 cm wide and 35 cm deep. The bottom of the recess is thoroughly rammed, then laid with a stone layer so that two bricks are placed along the length end-to-end. To maintain the integrity and strength of the brick base, it is made using a clay-based mortar.

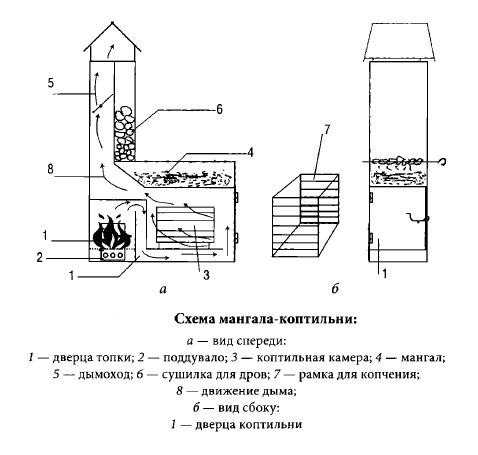

Diagram of a homemade hot smoked smokehouse.

Then a red brick chimney is laid out (note that silicate stone is not suitable for these purposes). According to the rules, the smoking chamber should be located at the end of the chimney. In this case, the smoking section should always be located above (at least minimally) the stove, which should be placed at the beginning of the channel. Therefore, when installing the specified object, it should be provided that the chimney channel from the furnace to the smoking chamber ascends at an angle of 8-9 °. When laying the walls of the chimney, the brick is placed on the edge with the same dressing of the seams along all the rows. The result should be two vertical brick rows 25 cm high. Then the resulting channel is closed from above. It is better to do this not with any auxiliary and not very suitable metal sheet for this role, but with the same brick.To simplify the task, it is recommended to make the top floor in the form of a house. It should be remembered that the chimney duct should not enter the smoking chamber installed at the end of the "stove-duct-chamber" chain by more than 25-30 cm. After all operations have been completed, in accordance with the accepted rules, the brick chimney is covered with earth. The powder should reach the level of the smoking chamber, while its thickness should be approximately 14-16 cm.

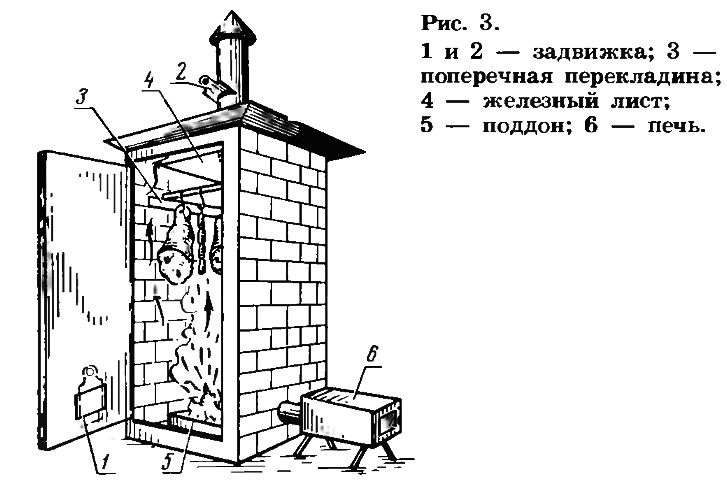

As for the manufacture of a large-sized smokehouse, experts advise making it in the form of a decorative house.

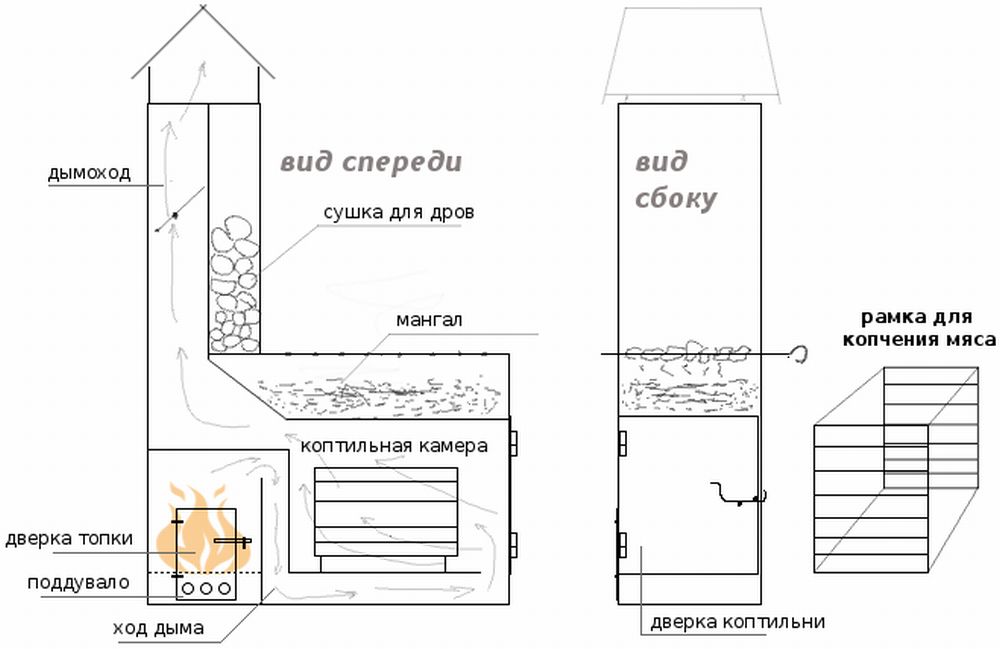

It also consists of an oven, a smoking chamber with a frame for laying out meat and fish and a chimney. Cold smoking will provide an additional smoke generator.

Drawing of a grill-smokehouse with a water seal.

In the upper, outer part of the device, you can arrange a barbecue for cooking barbecue. This element can be either independent of the heating source of the smokehouse, or receive heat directly from the smoking chamber. To do this, the brazier will have to be placed strictly above the chamber and provide in the scheme for direct heating of the bottom of the brazier from the smoking chamber.

It will not be superfluous to provide in the project and the presence in the chimney area of a special compartment for drying firewood with hot smoke. A valve should be installed in the chimney itself. By closing or opening it the passage of smoke in the channel, it will be possible to accordingly regulate the temperature of the smoke and the speed of its passage in the pipe. Thanks to this, you can achieve a uniform color shade of appetizing smoked meats.

Since a relatively large smokehouse, as a rule, is designed for large volumes of meat or fish delicacies, an impressive amount of melted fat will be formed during their preparation. It will drain down under the smoking frame, therefore it is strongly recommended to place a special tray in this place to accumulate and remove waste fat.

Construction process

After choosing a drawing, purchasing materials and checking / borrowing the necessary tools from neighbors, you can proceed to construction.

Pouring the foundation

- Using a bayonet shovel, a hole is made 40-45 cm deep.

- Formwork and reinforcement made of rods, wire and other things are being installed.

- A rubble stone mixed with rubble is poured into the dug hole, poured with cement.

Attention! The number of foundation layers depends on the planned size of the grill with a smokehouse. A new layer can be added once a day.

- The foundation is leveled using a level.

- The base is waterproofed with polyethylene and left to dry for 48 hours.

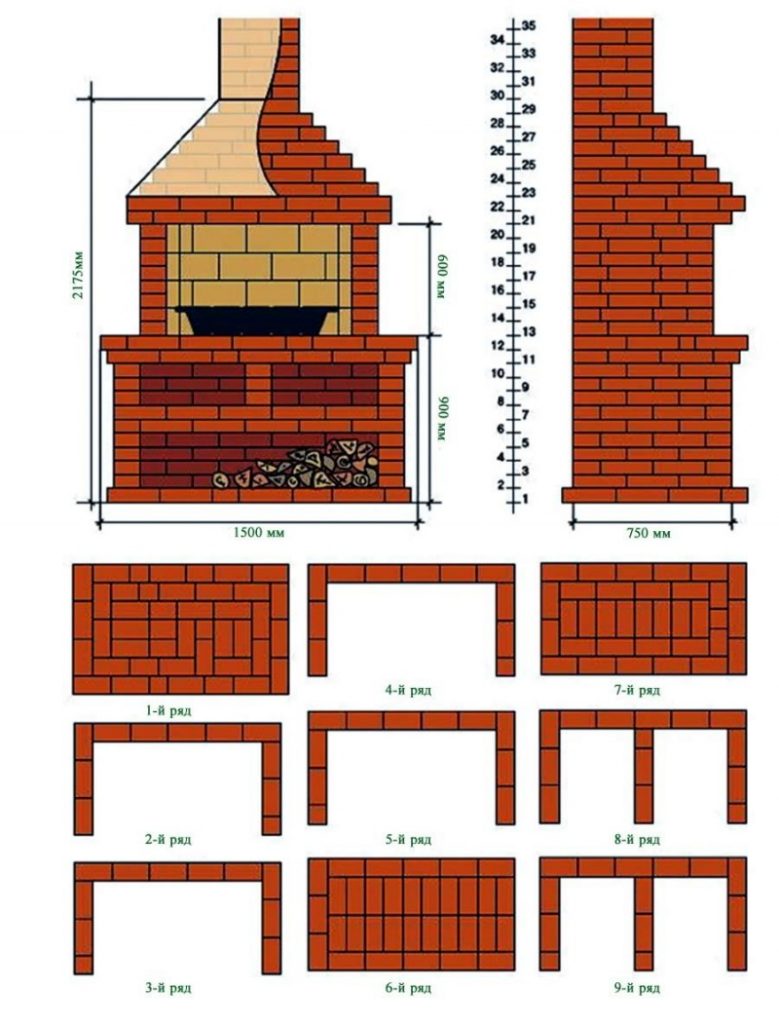

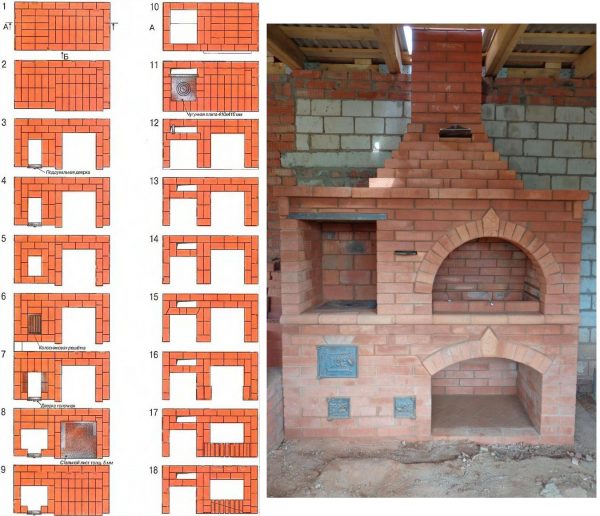

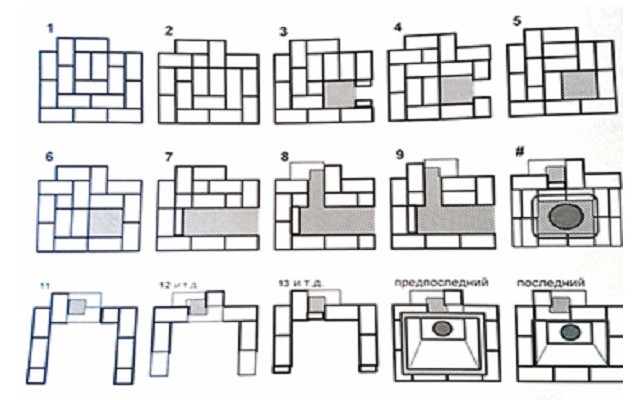

Construction of order

The first row is laid without using a bonding mixture. Thanks to this, the working surface is marked, the methods of laying bricks are calculated, the need for halves for construction.

Barbecue construction

- Sand, slaked lime, cement are mixed in a ratio of 3: 1: 1. Water is added while stirring the mixture until the consistency of thick sour cream is obtained.

- The first row is laid from the corners of the future barbecue with a smokehouse. After completing each row, using a plumb bob and a level, their evenness is checked.

Attention! A day before the brick is laid, it must be moistened with water, otherwise it will pull it out of the cement, reducing the level of its strength

- A minimum of 8 rows are allocated for storage of firewood - located in a warm, dry place, they will retain the ideal quality for creating charcoal.

- The hearth of the barbecue is built of bricks or a stainless steel barbecue is installed inside the structure. The firebox is made according to the drawing, always with a blower or ash pan to provide the coals with sufficient air.

- If the niches of the barbecue are rectangular, corners from a flock for lintels are provided. In the case of arched niches, templates are made from plywood or boards, and a key brick is placed in the center to fasten the structure.

- The walls of the openings are laid out by 0.5-0.6 m for an arched ceiling or 0.7-0.8 m for a rectangular one.

- 2 more rows of bricks are laid out on top of the lintel.

For the external arrangement of the barbecue, only fireclay bricks are suitable, for the external cladding anything is used

Building a cold smoked smokehouse

The construction of the smokehouse resembles the construction of a barbecue, only its firebox is located underground.

- A 4 m long trench is dug between the smoking cabinet and the firebox, into which a pipe is laid or a brick air duct is built.

- At the site of the construction of the smoking cabinet, a hole is being dug under its foundation.

- A firebox with a depth of 1.5 m and a width of 1 m is laid out of bricks. Inside, you need to coat the firebox with clay to ensure tightness. At a distance of 10 cm from the bottom, drainage is done, the air duct is supplied from the bottom.

- For the construction of a smoking cabinet, a foundation is poured into the dug hole (usually 1.5-2 times the volume of the furnace).

- The air duct is connected through the roof.

- The ground around the cabinet is compacted to maintain the appearance of the platform and the strength of the unit.

The process of creating a small smokehouse

As a rule, if it is supposed to form a structure that will be intended for personal private use, and at the same time it is not supposed to constantly engage in the smoking process, then a small structure that will perfectly cope with the tasks is ideal for the site.

Its construction will be easily done by hand, and this procedure will not take much time or require significant effort.

However, even when building a small structure, it is important to know what nuances and requirements should be taken into account during work. It is advisable to watch various videos that are freely available on the Internet, and it is there that you can clearly see exactly how the construction should be implemented

The whole process is divided into the following stages:

Initially, it is important to prepare drawings, according to which all the work will be carried out. You can do them yourself, for which it is advisable to study the training video, and you can also download ready-made schemes from the Internet or order an exclusive project from specialists

The first option is considered the most optimal, since it will not require monetary costs, and you can also make a structure with your own efforts that will have the desired shape, size and other parameters.

In the ground, in close proximity to the already prepared area, it is necessary to make a special recess intended for laying the chimney. It is needed so that smoke and other smoking products are efficiently and quickly removed from the structure. It can, like the smokehouse itself, be made of bricks. For this, it is advisable to use red clay brick, which is resistant to high temperatures, and also does not emit any harmful substances when heated, unlike silicate brick.

At the end of the chimney channel, you can start forming the smoking chamber. It should have a height of about 150 cm. The laying of this element should be carried out on the edge, since this option is considered the most suitable for creating a high-quality and reliable structure. The video of this masonry can be viewed on the Internet.

The masonry process begins with the fact that a trench 40 cm deep and 60 cm wide is pulled out. During work, the firebox must not be allowed to be located above the chamber in the future. In this case, it is best if the construction process itself will be implemented on the rise, since then there will be no need to take any action. However, if the structure is located on level ground, it is necessary to make a slope for the chimney channel. The bottom of the trench must be well tamped with your own hands, after which the brick laying itself begins. In this case, along the length, two bricks must be laid end-to-end.It is best to build a structure using a clay mortar that can easily withstand heat and is considered to be of good quality.

The next stage in creating a cold and hot smoked smokehouse is to lay the walls. They are laid on a brick base made in advance. Laying is only necessary on the edge of the material. Also, the binding of the seams is mandatory and the same in all rows. The height of the wall should be approximately 30 cm.

The top of the channel must then be closed, for which a brick is also used. This should be done with a house, not a flat roof. In this case, do-it-yourself brick laying is carried out end-to-end along the length. It is advisable to perform this work using clay mortar, and it is also recommended to watch the video of this process in advance so that there are no violations and problems. During this work, various gaps or unnecessary voids may appear, which must be quickly repaired.

Only at the end of the execution of the chimney can one proceed with the installation of the cold and hot smoking chamber itself

It is important to implement this process in such a way that the channel goes deep into the chamber by about 30 cm.

As soon as the smoke channel is completely dry, you can fill up all the elements with soil up to the smoking chamber itself.

Thus, it is not too difficult to make a high-quality, reliable and optimal-sized smokehouse for cold and hot smoking. However, it is advisable to study the corresponding video in detail anyway, as well as follow the instructions exactly.

Brick smokers for different types of smoking

The design of the brick smokehouse depends on the expected processing temperature of the products. You can build any of these installations yourself.

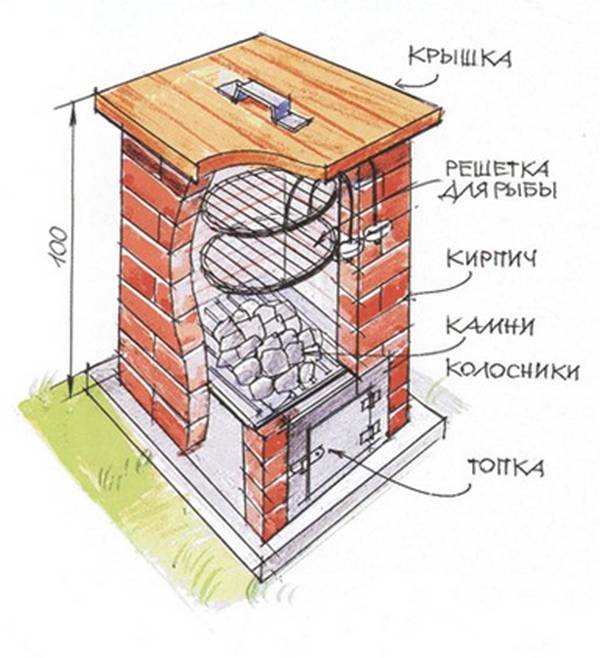

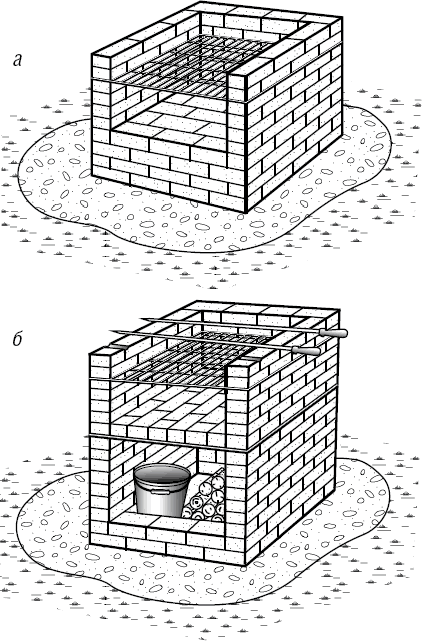

Smokehouse made of hot smoked bricks

In these structures, the firebox is located directly under the smoking chamber. The simplest installation option is a brick box with a door. From above it is covered with a sheet of metal. In the walls there are guides or fasteners for the installation of grates with food and a tray for collecting fat.

When smoking, a saucepan or frying pan with embers is placed on the bottom of the chamber, onto which wet sawdust and wood chips are poured. They heat up, smoke is emitted and goes to the food.

In more complex structures, the firebox is separated from the chamber and is located under it. The fire heats the bottom of the smokehouse with the poured sawdust, and the smoke from the combustion of the wood comes out through a separate chimney.

Do-it-yourself hot smoked smokehouse

Hot-smoked brick smokehouse scheme

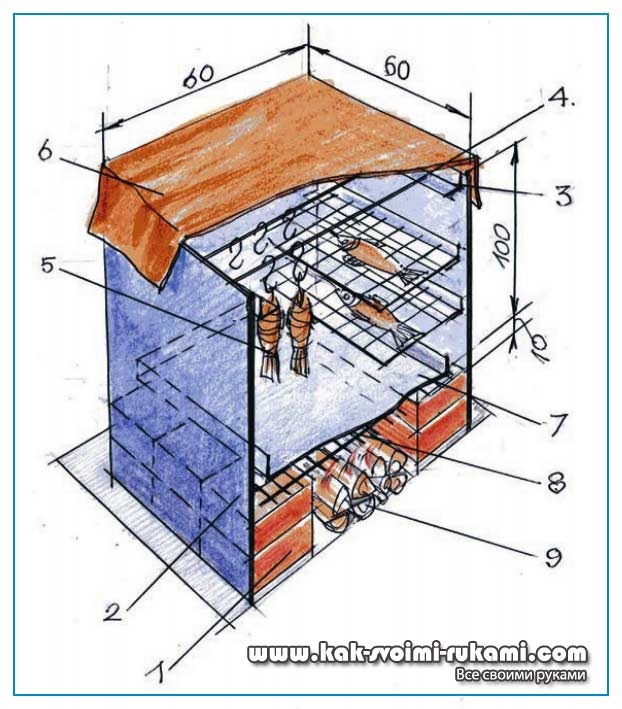

Cold smoked brick smoker

DIY cold smoking oven

- a hole is made in the wall of a brick box with a door through which a chimney and a smoke generator with an ejector are connected;

- the firebox is built separately and is connected to the chamber by a horizontal brick channel;

- the smoking chamber is built above the chimney outlet.

Smoking installations with a chimney in the ground are built at the top on the slope of a hill or ravine:

- below, at a distance of 10m, a firebox with grate bars and a blower 50x50x50cm is being built;

- a 15x15cm ditch is dug in the ground, one of the ends of which is adjacent to the chimney of the furnace, and the other is under the smokehouse;

- from above, the ditch is covered with sheets of metal, slate or boards, leaving the upper end uncovered at a distance of 15 cm;

- when wood is burning in the firebox, smoke passes through the ditch, cooling down at the same time, and enters the chamber to the food.

Cold smoked smokehouse

Scheme of a cold smoked brick smokehouse

Types of brick smokers and their features

There are two types of devices for the preparation of meat products, fish and poultry by the method of processing with smoke:

- hot smoking design - allows you to cook delicacies with a rich smoke smell and delicate tissue structure;

- cold smoking device - meat products are obtained with a delicate aroma and a denser structure than in the previous version.

Hot-smoked brick smokehouse

Hot-smoked brick smokehouse

The devices are also used for smoking vegetables, fruits and vegetables, nuts. When planning a brazier-smokehouse with your own hands, it should be borne in mind that each of the construction options is distinguished by design features and the temperature of the working environment in the smoking chamber.

For cold smoking

In a cold-smoked brick structure, a special supply is provided for supplying smoke to the smoking chamber, the hearth is located at a distance. The direct effect of hot streams on products is excluded. The smoke generated by smoldering sawdust and shavings moves through a channel 1.5-2 meters long and enters the smokehouse.

Features of the design of cold smoking:

- two main building blocks in the form of a chamber and a firebox are connected by a chimney, the length of which varies from 1-2.5 m;

- smoke flows enter the chamber in a cooled state;

- harmful substances in the composition of the smoke settle on the walls of the supply channel.

The key design feature is the complete combustion of flue gases in the process of moving streams along an elongated chimney. Cold processing of food will take from a couple of hours to several days, depending on the recipe. Finished products have a long shelf life. If, during the preparatory stage, the technology conditions are met, taking into account the characteristics of salting, cold smoked products are stored for up to 12 weeks in a cellar or refrigerator.

For hot smoking

The design provides for a smoking chamber directly above the hearth. On the upper tier of the brick chamber, a system of gratings and hooks is being erected, the lower surface is made using a metal sheet.

Features of hot smoking:

- a fire is made in the hearth under the camera;

- sawdust, shavings and chips on a metal base in the chamber are heated under the influence of the flame in the firebox;

- hot smoke is generated, which is directed to the workpieces and penetrates into the fiber structure.

The process of hot processing food lasts depending on the recipe and provides a period from 30 minutes to several hours. The finished products are distinguished by high taste with a rich smoke smell and delicate structure. Hot smoked products are not stored for a long time, the shelf life is limited to 2-3 days in a refrigerator.

Features of a multifunctional two-mode smokehouse

One of the key advantages of a brick smokehouse is the ability to adapt the structure for both hot and cold smoking. Craftsmen manage to design a device as part of a barbecue complex with the supply of smoke streams from a brazier or hearth under a cauldron, if a cold smoking process is planned. For the processing of products in a hot way, a separate firebox is provided under the smoking chamber.

Multifunctional two-mode smokehouse

Multifunctional two-mode smokehouse

Another way to create a dual-mode design involves the possibility of adjusting the draft in the chimney pipe. To create a high-temperature processing mode, the traction force in the smoke exhaust duct is limited with the help of a valve, and intensive firewood combustion is ensured in the firebox. If cold smoking is planned, a small fire is provided in the hearth; with a wide diameter of the chimney, conditions are created for sufficient cooling of the streams.

Operating tips

A cold smoked smokehouse at home is convenient and practical. But when using the device, you must follow the safety rules:

- avoid contact with flammable materials;

- do not touch hot surfaces with an unprotected hand;

- do not install the structure on an unstable base;

- do not allow water to enter the wiring and the compressor of the smoke generator;

- do not use sawdust with traces of paint, varnish, impregnation;

- do not leave small children unattended;

- do not install a smokehouse near a residential building to prevent smoke;

- control the temperature to prevent overheating;

- do not handle expired products.

Smokehouse at a safe distance from home

The chimney and the chamber must be periodically cleaned of carbon deposits, the grates and hooks must be washed with detergents. It is advisable to leave a non-working smokehouse slightly ajar for ventilation.

Preparation of food

Lard, game, fish or meat are prepared in a certain way before smoking, since the products are processed with smoke at low temperature. Smoking has preservative properties and prolongs the shelf life, but this does not happen immediately, but gradually. So that during a long process the delicacy does not deteriorate, preliminary salting is required.

Salting fish before smoking

Cut the bacon into 7-15 cm pieces, soak in a marinade of water, salt and spices. The brine must be concentrated for a raw egg to float. Keep in the refrigerator. After 3-5 days, take out the bacon, dry it and put it in a smokehouse for further processing for 1-2 days at a temperature of 30 ° C.

The fish must first be gutted and washed. Place in a bowl, sprinkle with plenty of salt. After 2-3 days, remove, rinse thoroughly in running water and soak for 1-2 days. Then the fish should be allowed to weather well in a draft to a semi-moist state. The time depends on the size and structure of the pulp. Smoke for 2 days at a temperature of 30-40 ° C.

The meat is salted dry, wet or in a combination. Keep in the refrigerator under pressure from 5-7 days, up to 2-3 weeks. Then the semi-finished product is dried for about 5 days in a draft and sent to smoke for 2-3 days.

Choice of materials

Smokehouses are made from different materials. They can be made of wood, brick, and even from an old barrel. It is worth considering in more detail the designs for their manufacture.

Brick

Outwardly, a brick smokehouse resembles a small house, which can, among other things, become an excellent decoration for a personal plot. But before purchasing materials, you need to make drawings and, based on them, buy materials. This will require:

- bricks or blocks of foam concrete;

- combustion chamber or silicate brick;

- cast-iron door for her firebox;

- double-glazed windows for natural light, while the windows must be made from the north side;

- sand and cement for mortar;

- wooden beam for the truss system;

- corrugated board or metal roofing;

- chimney;

- door.

Wooden

There is another material used for the smoking chamber - this is natural wood, which is not only an environmentally friendly product, but also a material that does not emit harmful substances. To create a home smokehouse, wood species such as oak or cherry are suitable. The main thing is that they have a structure that will not be afraid of any negative influences of nature.

To make it, you need to purchase the following materials:

- bars;

- boards up to ten centimeters wide, the thickness of which will be one centimeter;

- boards for roof slopes;

- permeable roofing material;

- firebox brick;

- solution;

- waterproofing;

- chimney pipe;

- a sheet of metal to put in front of the firebox.

Preparatory work

This stage implies the choice of the type of smoking, since this determines the design of the device. In this particular case, it is planned to build a "hot" smokehouse with a firebox under the smoking chamber and without arranging a smoke supply. The choice of location is no less important, since the structure, regardless of size and shape, requires compliance with fire safety standards. The process of a stationary brick smokehouse involves the release of a large amount of soot and smoke, as well as the presence of fire. To avoid any possibility of fire, inhalation of combustion products, it should be located at a distance from residential buildings, as well as utility structures. This rule also applies to green spaces.The area where the smokehouse is being erected should be free of bushes and trees; the ideal option would be to arrange a small area, which is similar to what is done when setting up a barbecue. Such a solution will look as aesthetically pleasing and organic as possible.

How to make a hot-smoked brick smokehouse with your own hands

The process of building a smokehouse from old or new bricks is divided into stages. First, they study step-by-step actions, and then start work. Main steps:

- preparation of tools, materials and site;

- arrangement of the foundation;

- masonry;

- arrangement of a chimney;

- check and commissioning.

Foundation

On a plot of land prepared and cleared of debris and plants, a base is equipped. For the foundation, a hole is dug in the ground with a depth of 20-30 cm. Crushed stone and sand are poured, reinforcement rods are laid with a mesh and poured with concrete.

It is also recommended to use a ready-made reinforced concrete slab 20 cm wide as a base.

It is also recommended to use a ready-made reinforced concrete slab 20 cm wide as a base.

Masonry

On the prepared base, they begin to order the brick smokehouse according to the masonry drawing. A layer of cement mortar is applied to the foundation and the first tier is laid.

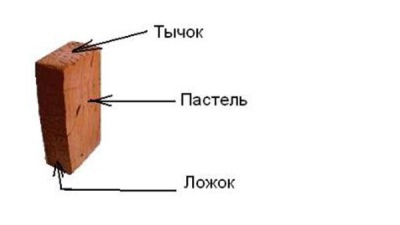

A warning! Professionals call the butt in width of the brick a butt, the base - pastel and the side in length - spoons.

The size of the foundation is made larger than the total area of one row of pastel bricks

The size of the foundation is made larger than the total area of one row of pastel bricks

A layer of concrete is applied separately so that there is a margin of 1 cm. The brick is laid on the mortar, cement is previously applied to the poke. This technique allows vertical joints to be filled immediately.

Each brick on the first tier is laid according to the level and markings. This will help to avoid unevenness in further laying. The size of the seams is 12 mm. Laying starts from the corners. The chamber is equipped with a heat-resistant thermometer. Ordering scheme:

At the ends, the brick of the lower tier is overlapped

At the ends, the brick of the lower tier is overlapped

Smoke inlet

Do-it-yourself brick mini-smoker is supplied with a chimney. To equip it, a hood is put on the camera, a pipe is brought to it. A damper must be installed in the pipe to regulate the temperature in the smoking chamber.

Commissioning

Before using a small brick smokehouse, built with your own hands in steps, the structure is checked. Fire up the firebox, place food. Wait time for the camera to warm up and watch the temperature rise

Also pay attention to the smoke in the chamber. If necessary, the flow of smoke is regulated by a damper

Correctly assembled structure will delight households with delicious aromatic food.

Correctly assembled structure will delight households with delicious aromatic food.

The second option for making a brick smokehouse

This method is highly practical and very convenient. Its main difference is the presence of two smoking chambers:

- Cold smoked.

- Hot smoked.

The design also includes a firebox together with a chimney. Firewood is burned in the firebox, the resulting flue gases escape through the chimney. Moreover, they first go to the hot smoking section, then go into the chimney.

To carry out cold smoking, you need to have a metal container, where sawdust is pre-poured. It should be installed above the firebox of the smokehouse.

Sawdust begins to smolder at high heat. Smoke is emitted and the smoking operation begins. A variety of products are smoked with this smoke in the cold smoking section. The smoke leaves the chamber through the chimney.

Important nuances

It is necessary to correctly calculate the amount of building materials for the work process, because this will greatly facilitate the work.

To make a quality smokehouse and avoid mistakes, professional masters advise you to adhere to the following rules:

a new row must always start from the corner of the structure;

joints between bricks should not exceed 12 mm, later they are fastened with mortar;

for optimal thermal insulation, the zone 2–3 rows, where the ash chamber is usually located, are covered with pebbles;

to clean the lower channel of the chimney, it is necessary to make a door at the level of 3 and 4 rows of bricks;

pay special attention to the narrowing and dissection of the chimney (when laying 6-12 rows);

the uniformity of heating of the furnace slab depends on the correct laying of bricks of the 8-11th row;

at the level of 23 rows, it is supposed to hang products, therefore, along with the masonry, two metal rods are installed;

a hole for a chimney pipe measuring 13x13 cm is made from halves of a brick.

The ordering should be carried out in compliance with the dressing. For the stability of the structure, the seams of the lower rows are covered with bricks. Each row must be checked with a level, it also applies to already erected walls. Experienced craftsmen sometimes even check individual bricks if there is a suspicion of drops.

It is undesirable to make a metal chimney near your own smokehouse, although it will cost less. It is better to use refractory bricks, because the smell and taste of the cooked dishes depends on it. All parts of the smokehouse made of wood are also processed not with cement, but with a clay solution.

Where is the best place to place a brick smoker?

location of the smokehouse on the site

When choosing a place for the stove, you need to think over everything and take into account down to the smallest detail. Since in this article we are considering exclusively brick smokehouses, then this structure will be oval and permanent, which means that at the slightest desire it will not be possible to move or put it in another place (if it is necessary to change the location of the smokehouse, then it will have to be disassembled and build virtually from scratch).

And that is why the location of the smoking oven must be ideal. Such a place should be: large, comfortable, located at the same time close to your home, but also at some distance so that you do not breathe smoke and combustion elements during the smoking process

It is also important to remember that smoking smoke can harm not only your health, but also the buildings and living plants that are on the site. Therefore, the place for the oven must be sufficiently distant.

I will repeat once again - the place for the smokehouse must be chosen carefully and all possible nuances must be taken into account.