Mounting

Calculation of materials

The total number of Euro screws depends on the mounting area. You can count them yourself. The main thing to consider is the following information about fastening hardware.

When drilling holes, the edge and center distance must be strictly observed.

- The minimum distance from the edge is equal to twice the depth of the element being fastened. The fastener must not be installed very close to the edge.

- The maximum distance between the axes is equal to four times the depth of the material to be fixed. It is not worth screwing in further than this value.

Often, buyers have difficulty, they cannot decide on the number of pieces. Since the manufacturer sells confirmations by weight.

- In this case, special calculators available on the Internet will help. If you enter the type of hardware, standard, diameter, length and weight into the program, it will calculate how many kilograms of hardware are in the specified quantity.

- There is another calculator in which you just need to indicate the size of the screws and the mass, and it will give you the number of pieces. There is also a reverse calculation (from pieces to kilograms).

We will describe below which drill is suitable for the confirmation and how to mount them.

Jig for drilling holes for confirmation

Technology

It takes a little skill to connect parts with a confirmator. You need to be familiar with the features of the Euroscrew and the quality of the bonded material. Confirmation is used mainly for fiberboard, chipboard, plywood, chipboard and wood.

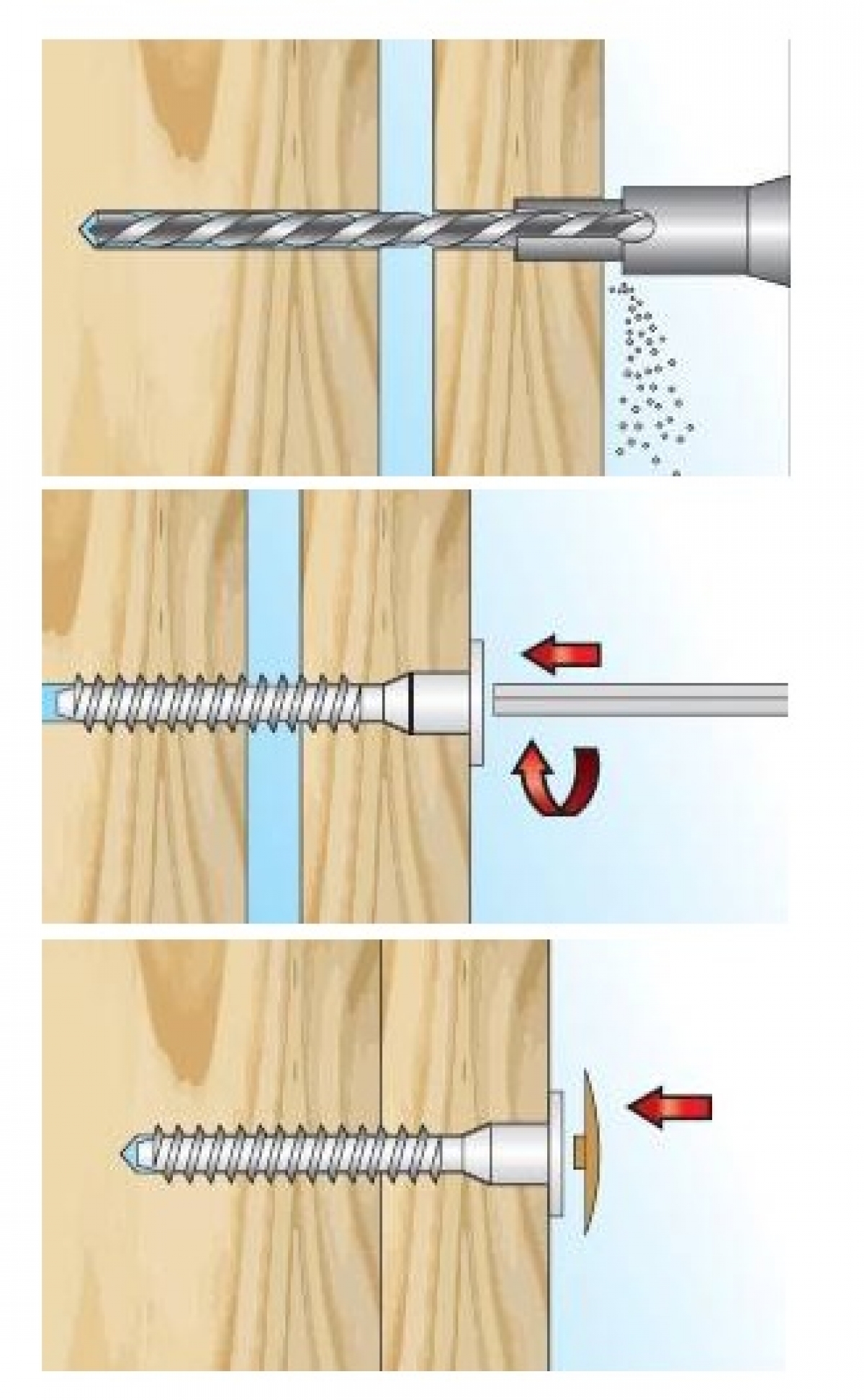

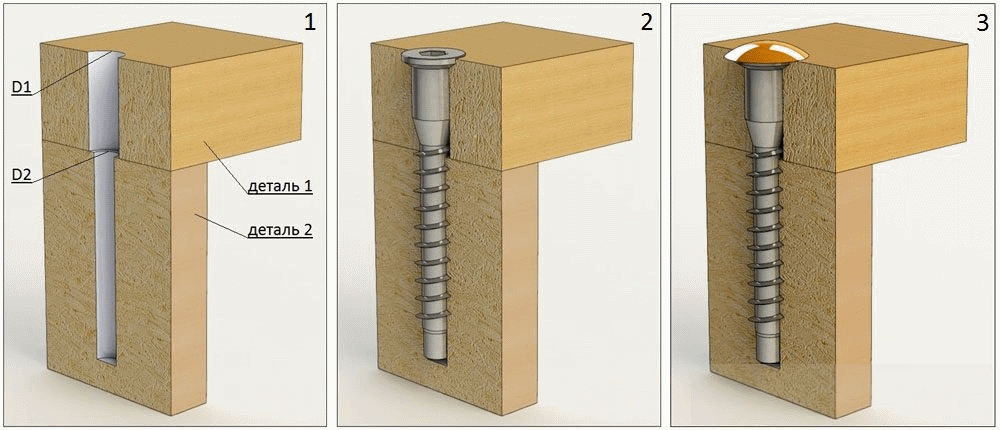

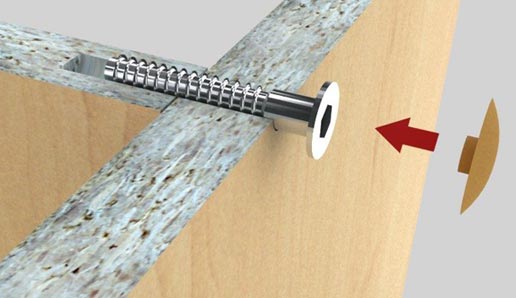

The connection is formed as follows: the smooth part and the head are in the through hole, and the threaded part is in the blind. In this case, the first hole is a through hole, which is located on the front of the first part. And the second hole is in the second part and it is blind.

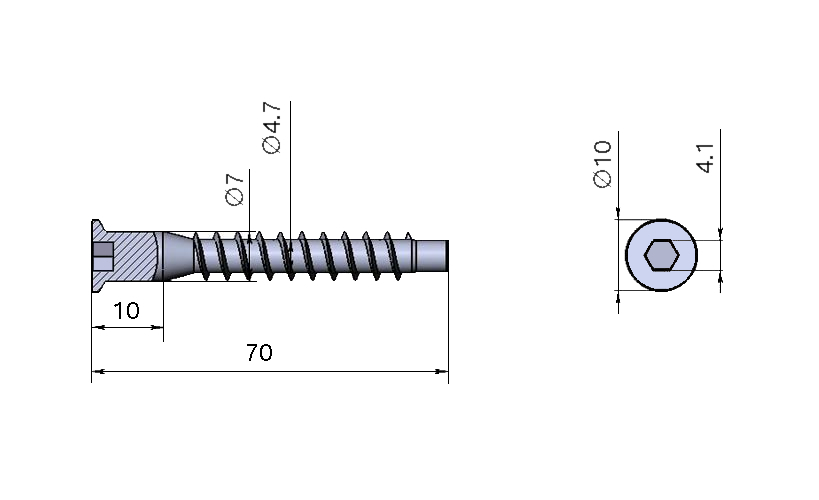

The installation process looks simple. For the confirmation, you need to prepare 2 special holes: the first - for the threaded part, the second - for the smooth non-threaded part. If we take, for example, the most common confirmation size of 7 mm, then in this case for the threaded part you need a 5 mm drill, and for non-threaded 7 mm.

- There is one more positive moment in the installation of the confirmation. There is a special drill for confirmation, which has a stepped thread. With its help, you can prepare a hole for a euroscrew in one step.

- To even more reliably connect the parts, a dowel is added to the mount.

So, the following tools will be needed to fasten the parts with a confirmant:

- Hexagon.

- Two drills of different diameters (5 and 7 mm) or a confirmation drill.

Installation rules

For many who first encounter confirmations, a natural question arises regarding which holes to drill for the used Euro screw and how this procedure is generally performed.

Problems with how to drill holes, if you have already worked with a drill and imagine the principle of its operation, should not arise.

Before installing the confirmation in the furniture case, it is required to make the appropriate markings. To apply it, you will need a jig or a template. With their help, you can significantly speed up work, as well as achieve a high level of accuracy. If you are doing simple markup, you will not need a conductor (template).

For the correct installation of the confirmation, it is recommended to find out in advance about the material of the furniture itself, as well as about the design features of the euro screw. A total of 3 holes are needed:

- under the threaded screw part;

- for the smooth part of the eurohead;

- under the hat.

A drill of the corresponding diameter is used for each hole. It is the time it takes to create several holes that make you spend much more time assembling furniture.

But there is a solution. It is presented in the form of a special drill, which is intended specifically for confirms. Finding it in Leroy Merlin or in any other furniture accessories store will not be difficult. The peculiarity of the special drill is that it allows you to prepare 3 different holes at once in one go. This is due to the design of the drill itself.

Drilling and installation

Step by step we will consider the procedure for drilling a hole with the subsequent installation of a confirmation in it.

To assemble furniture using Euro screws, you need to prepare special holes. The process involves the following actions:

- First, a hole is drilled for the screed (confirmation). Drills with a diameter of 4 to 7 millimeters are often used here;

- Due to a stepped cutter or just a special drill for a confirmation, it is possible to significantly facilitate the procedure;

- The cutter is fixed to the drill. This makes it possible to correctly form a hole in two components at the same time;

- For the threaded part of the confirmation, the diameter should be 5 millimeters, and the diameter of the hole for the head itself is already 7 millimeters;

- On the first furniture element, a through-type hole is made, since the smooth part of the special head and the hat itself will be located there;

- In the second part, a blind hole is made, where the internal thread is formed by drilling the threaded part of the Euro screw in the end part;

- To ensure the most accurate connection, furniture elements can be fixed using machines, furniture vices and other devices. This prevents possible shifts.

When drilling, try to use a drill or screwdriver that can rotate at the highest adjustable speed possible. This will ensure the creation of the most accurate, even and quality holes.

It is difficult to imagine the assembly of modern cabinet furniture without the use of confirmations. This is the most modern type of hardware that allows you to significantly speed up and simplify the furniture assembly process.

The use of confirmations allows you to abandon corners, screws and other fasteners that do not have the most attractive appearance, and are also inferior to the Euro screw in terms of reliability.

Confirmation is not just a whim or a fashion. This is a truly versatile and effective solution in furniture production. And we are in many ways lucky that now we have the opportunity to assemble furniture with the help of such fasteners.

What do you think about confirmations and have you had to work with them? Who assembled ready-made furniture and used such fasteners? And who had to make the holes for the confirmation himself? Share your experience and your opinion.

Thank you all for your attention! Subscribe, leave comments and ask relevant questions!

When designing and assembling furniture, the confirmation is the main fastening furniture element. It is with his help that the main parts from chipboard are connected that we have designed on paper.

Design features

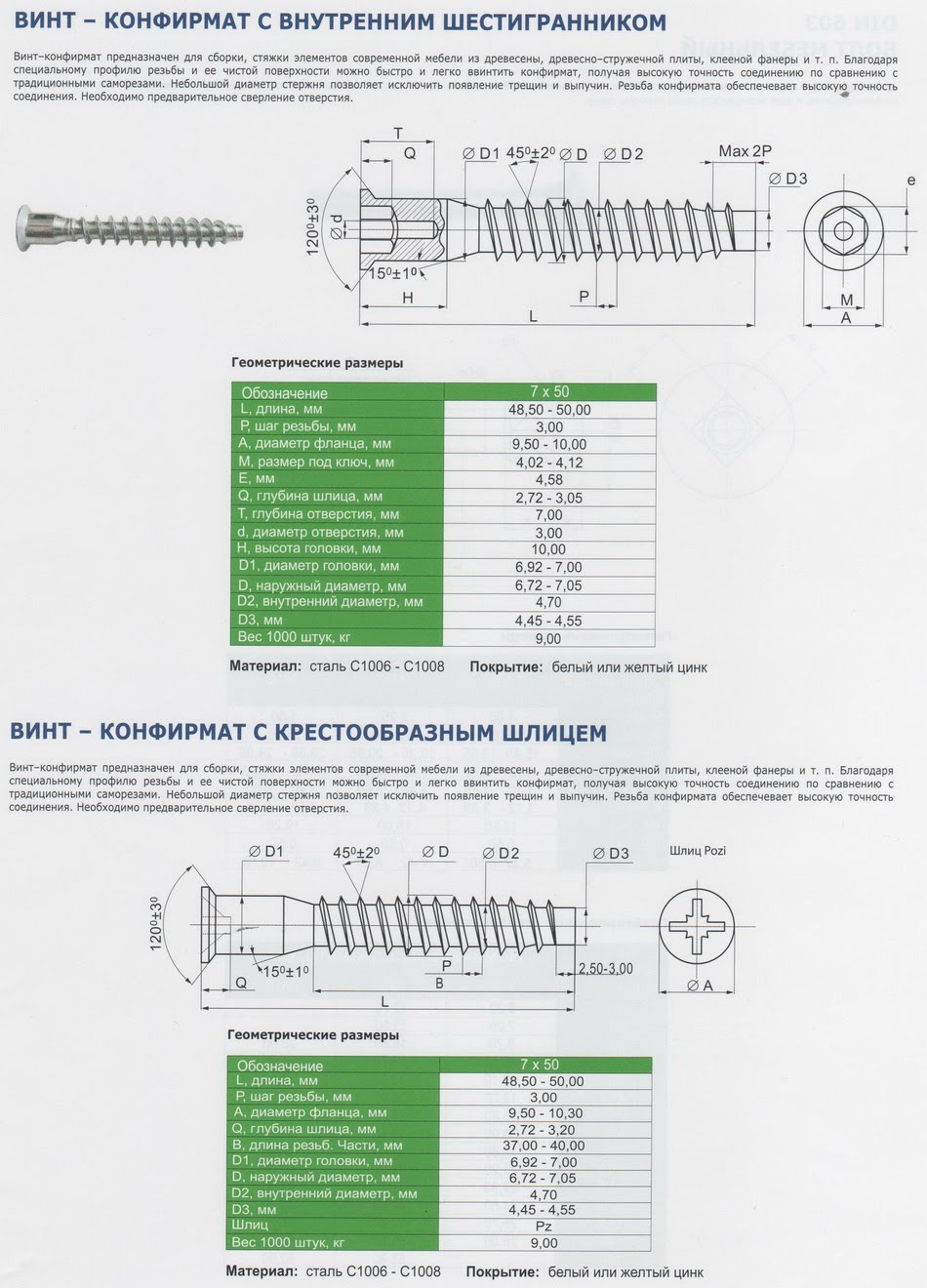

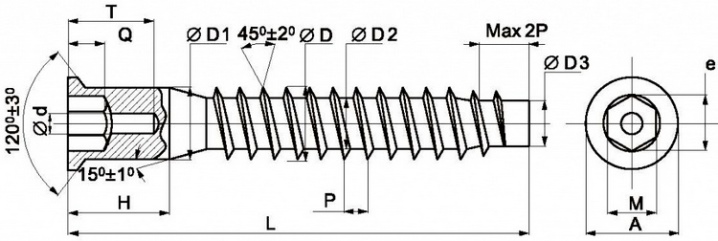

Euro screws for joining furniture parts are a one-piece tie. In fact, they are the same screws, only their body is more massive. The thread for confirmations has a wide pitch, the head is elongated, the head has a secret design. The tool slots are different. Some are suitable for a curved screwdriver, others for a hex wrench. Unlike other hardware, the ends of the Euro screws have a straight cut with a round section.

The use of a hexagon confirmation is considered more practical and reliable. After connecting the parts together, you can additionally tighten them using a hex bit, screwdriver, drill or special wrench.Fasteners for a Phillips screwdriver cannot provide such a reliable fastening, since it will not be possible to tighten the parts tightly. Subsequently, this will affect the strength of the structure, it can loosen and lose stability.

Confirmates are used to connect parts made from:

- MDF;

- Chipboard;

- wood;

- plywood.

Euro screws can replace standard angle brackets. They easily withstand all bending loads. This feature allows confirms to perform not only fastening, but also a frame-forming function. To mask the fasteners, plastic plugs (diameter 12 mm) are used, similar to the general color of interior items. They are made of plastic. Also on sale there are special round-shaped stickers. The thickness of the plugs does not exceed 0.4 mm. They can be chosen in the same shade as the furniture itself. Interior items acquire a finished look, the euro screws on them become invisible. Self-adhesive elements are more common, they are convenient, easy to use.

Varieties of furniture connections

Two types of fastening can be used to assemble furniture:

- furniture screws;

- confirmations.

Confirmation is one of the varieties of furniture screws, it is also called a screw tie, euro screw and euro screw.

Confirmation is one of the varieties of furniture screws, it is also called a screw tie, euro screw and euro screw.

The self-tapping screw has a sharp end and a small thread pitch, while the confirmat has a wider pitch and a larger diameter of the rod. The first type is most often used when collecting interior items from solid wood, plain and laminated chipboard, MDF.

This type of fastener, such as a self-tapping screw, is a type of metal screw with a screw thread and a pointed or flat end.

This type of fastener, such as a self-tapping screw, is a type of metal screw with a screw thread and a pointed or flat end.

The confirmat has recently been more widely used, it differs from the self-tapping screw first of all by the expansion after the end of the thread during the transition to the part with the fastening head. In such a simple way, a higher quality of the screed is achieved.

Elements such as furniture confirmations are in great demand due to the incredible accuracy of their fit and ease of use.

Elements such as furniture confirmations are in great demand due to the incredible accuracy of their fit and ease of use.

If the self-tapping screw can be screwed into the panel with a regular screwdriver without previously prepared holes, this will not work with the confirmation.

To install it, you will need a hex wrench or a drill with a special attachment.

To install it, you will need a hex wrench or a drill with a special attachment.

Universal screws

Screws for furniture allow you to get an acceptable quality of the screed and a neat connection, but when working with this type, you cannot make mistakes. A slight misalignment when fixing such fasteners - and both fastened elements can be damaged.

Self-tapping screws do not withstand repeated unscrewing from the same hole, therefore, if an error is made at the preparation stage, you will have to drill out the place for the fastening element again.

The head of the element has a notch (straight, cross or polygonal) for twisting it into the canvas.

The head of the element has a notch (straight, cross or polygonal) for twisting it into the canvas.

Also, most often, the diameter of the self-tapping screw is inferior to the confirmation, therefore, the equally reliable and durable tightening of the parts together is not achieved.

A screwdriver is used to quickly connect parts of a cabinet or other object for elements with a sharp end.

A screwdriver is used to quickly connect parts of a cabinet or other object for elements with a sharp end.

Depending on the material, the screw can be metallic, black or gold. Thanks to this, such fasteners can be easily masked without additional elements, only due to their own color.

Self-tapping screws are used to fasten parts without prepared holes or with them. Due to the thread, the screw can be easily screwed into a wooden panel or chipboard.

Self-tapping screws are used to fasten parts without prepared holes or with them. Due to the thread, the screw can be easily screwed into a wooden panel or chipboard.

Confirmates

As already mentioned, confirmations are able to provide a higher quality of the screed. A rather significant drawback of this type of fastener is the impossibility of using it with a material of small depth.It is this factor that limits the use of confirmation, however, in most cases, they are used for cabinets, tables, headsets and countless other types of interior items.

Confirmates allow you to fasten together several parts made of natural wood.

Confirmates allow you to fasten together several parts made of natural wood. Only high quality carbon steel is used for its production. Has an anti-corrosion coating based on zinc, nickel or brass.

Only high quality carbon steel is used for its production. Has an anti-corrosion coating based on zinc, nickel or brass.

The shape of the confirmation head is selected according to individual preferences. The only caveat is that if you plan to cover the surface of the cap, you should select the elements corresponding to its shape.

How to choose the right one

For the correct selection of a furniture screw, it should be taken into account in what material it will be installed. The choice of head will depend on the applied force and space, which will be available when screwing

It is also important to choose not only the type of head, but also the pattern for the tool used.

With the correct selection of the bit, a firm grip of the fastener with the screwing tool is ensured. Only in this case the screws smoothly, evenly enter wooden plates, drywall, chipboard, MDF.

Some important nuances that will help buyers of fasteners much better navigate their variety, as well as make the right choice:

- color - screws of the same batch must be kept in the same color scheme. This indicates that all products have undergone the same processing in similar conditions, and also have the appropriate strength, corrosion resistance;

- parameter - the sizes of one batch of products should not visually differ from each other, and also comply with standards;

- step - the load between the threads should be evenly distributed;

- hole - the slot should be characterized by clarity, symmetry, and be deep enough;

- marking - the standard designation of screws is a number in which the first number is the size of the thread diameter, the second is the length of the product from its very head to its sharp tip.

In order to efficiently assemble and install furniture elements, you need to use such a convenient, affordable assistant in fastening work, such as a screw. This type of furniture screed will not only simplify the assembly and installation procedure, but will also be invisible after the installation process is completed, due to its unique structure. All structures and foundations fixed with such fasteners will retain their shape, appearance, properties for a long time.

Advantages and disadvantages of wood screws

To build a solid, reliable structure, it is important to choose high-quality material and suitable fasteners. Almost all buildings and materials made of wood are assembled using self-tapping screws.

There are different types of fasteners that differ depending on where they are used. Self-tapping screws for wood have an incomplete thread, which gives their advantages when using them:

- A self-tapping screw forms a hole using a thread in which it is securely fixed (unlike nails).

- Due to the incomplete thread, the upper element is securely fastened.

- Multi-purpose indoor use.

- There are various forms of thread: groove, special cutting edges, sawtooth threads at the point. The combination of several elements allows parts to be assembled without cracking. Even when curling close to the edge.

- The presence of special slots under the head, necessary to drown the self-tapping screw, without puncturing the wood.

- A special cutter is provided at the end of the hole, which prepares and drills it.

The variety of fasteners

The disadvantages include the fact that self-tapping screws are not universal, namely:

- Some are used for mounting only small structures.For example, phosphated fasteners are suitable only for fixing lightweight structures (with self-tapping screws, drywall sheets are attached to a wooden crate or metal profile). It is not safe to assemble heavy structures with it. Also, this type is prone to corrosion.

- A self-tapping screw with a press washer and universal self-tapping screws cut wood. It is difficult to pull the parts tightly with them, which leaves gaps. Cracking of the material may occur.

- Self-tapping screw with a hex head (wood grouse). Requires hole preparation for mounting. It is used for fastening wooden blocks of heavy structures. Some of them are equipped with a press washer, if not, then it is advisable to put it. Coated with white zinc as a corrosive coating.

- Confirmates. Also require hole preparation. They are used in the manufacture of furniture.

With the correct selection of fasteners and their skillful use, the shortcomings are not only smoothed out, they completely disappear.

What it is?

The furniture confirmation has another name - the Euro screw, it is made of an alloy with the addition of a zinc coating, so the hardware looks shiny and attractive, and most importantly, it does not corrode.

The production of furniture hardware is established in Russia, and today it is one of the most demanded products, without which it is impossible to imagine the assembly of modern furniture of any type.

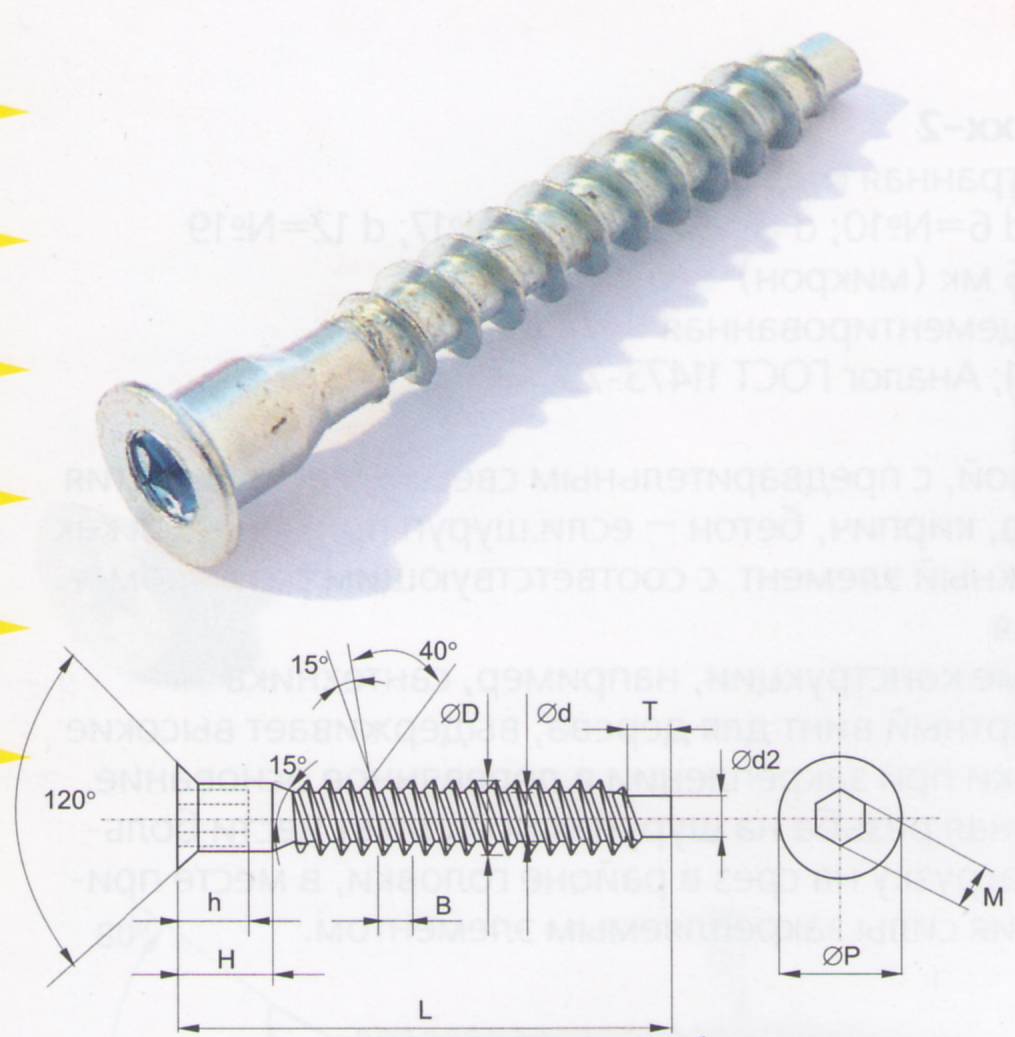

In appearance, the confirmat looks like a small self-tapping screw, equipped with a thread, thanks to which it has the ability to be screwed into the end part of the furniture blank. The confirmat has a leg and a flat head, on which slots are made for a Phillips or hex screwdriver. Most often, it is the hexagonal notch that can be seen on the cap, while the slots for the cross are very rare. The core part of the hardware, in addition to the thread, has a blunt end, therefore, in order to install the confirmat into the cavity of the furniture blank, preliminary drilling of the bore hole will be required.

Certain features are characteristic of the furniture Euro screw.

- The thread on the leg of the hardware is quite massive, and the edges of such a thread have a wide projection relative to the axis of the leg. In the lower part, there are several turns of a conical type with a small notch.

- The confirmation rod has a rather large area, which makes it possible to evenly distribute the load on the furniture parts to be connected, therefore, the finished product (after assembly) has a high degree of stability during operation.

- The Euro screw has the same diameter of the rod and the smooth part, this allows the hardware to be reliably and tightly held in the thickness of the material fixed with it.

- All Euro screws are made only of high-strength carbon steel and have an anti-corrosion coating, which can be made of zinc, brass or nickel. The most common are galvanized silver confirms.

- The product is a Euroclass hardware, therefore it must be manufactured only in an industrial environment, and is also subject to quality control, which is reflected in the certificates.

The furniture Euro screw, like any product for connecting purposes, has both its advantages and some disadvantages.

Positive sides:

- hardware is quite simple to mount not only in industrial, but also in domestic conditions;

- the flat head of the European screw allows you to connect parts in series, one after another;

- to fix furniture blanks with a confirmat, no special equipment is required;

- hardware is able to firmly and reliably attract parts of the furniture structure to each other;

- materials, connected to each other by a Euro screw, are able to withstand many cycles of significant loads during operation.

Negative sides:

- when two furniture pieces are connected, a flat metal head of the confirmation will be visible on the surface, so it has to be covered with special plugs made of plastic, similar in color to the shade of the furniture;

- It is not recommended to disassemble the assembled furniture parts, since after such a procedure the connection becomes unreliable, and the very design of the confirme's thread does not withstand repeated screwing and unscrewing.

Varieties

The more demanded and popular samples used in the production, assembly, installation of furniture pieces include:

Also in the furniture industry, a number of characteristic screws are used with blunt ends, large threads adapted for chipboard, specific heads. One of these products is a galvanized steel screw that allows you to attach chipboard sheets at an angle of 90 degrees.

Universal screw

The product is presented in the form of a rod in the form of a cylinder with various types of heads and external threads. Its main task is to fasten individual assembly elements inside furniture structures. The top of this screw can be of different shapes:

- a countersunk head of the product, which, after twisting, completely sinks and does not protrude above the materials to be fastened, its scope is the installation of shelves, handles, hinges, guide rails for drawers;

- the semi-countersunk head, due to the smooth transition from the rod to the thread at the moment of twisting, goes into the material, as well as the counterpart;

- a semicircular head, the horizontal plane and the inner base of the surface of the semicircular head of which, during installation, additionally creates pressure on the fastened material, increasing the strength of the structure unit, thereby eliminating its deformation.

The presence of a special thread makes it possible to easily fix the screw even in the hardest types of wood. Hardware slots can be simple and cruciform. Products with a cross recess have a number of irrefutable advantages:

- a screwdriver or drill is instantly fixed in the head;

- only one screwdriver is useful;

- the installation process in hard-to-reach places is carried out without much effort.

When using universal screws, you must arm yourself with a screwdriver, screwdrivers with replaceable nozzles. For a high-quality connection of materials, in the process of screwing in the screws, drill holes, the diameter of which will be 70% of the thickness of the hardware, and also choose the right drill.

Confirmation

These products have another name - Euro screws, which in modern furniture production are considered a more popular type of fastening and fixing devices, since they are among the most reliable, inexpensive furniture joints. Such products are resistant to mechanical stress and fracture.

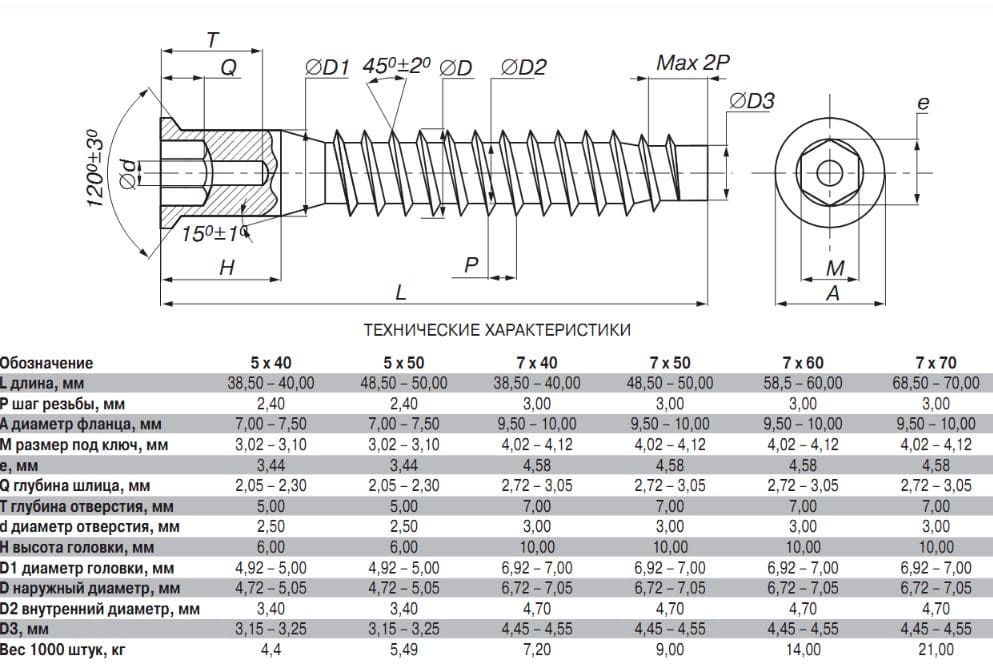

Confirmate is used to connect structures made of materials such as wood, laminated chipboard, plywood, chipboard. In many cases, screws with dimensions of 5x50 mm and 7x50 mm are used. In addition to fastening parts, euro screws replace the usual corner, performing a body-forming function, while withstanding all bending loads. To make cabinet furniture look aesthetically pleasing, confirmations are supplemented with plugs made of plastic. They mask the visible part of the cap to match the color of the furniture product.

Distinctive features of these fasteners are coarse thread, blunt tip, cylindrical head, hex slot. When assembling structures, furniture screws for a hexagon do not require special skills, specialized equipment.

The screw tie is performed using a hex bit, a screwdriver, a special key, and a drill. Do not use products made with a Phillips screwdriver. This technology will not allow the connecting elements to be tightly tightened. As a result, the structure will become loose.

Peculiarities

Furniture drill for confirmation is a type of replaceable elements designed to create holes for Euro screws. The one-piece screed came into use in the 70s of the XX century, today it is used as a unified fastening by the largest manufacturers of household items. The confirmation drill is not uniform in its thickness, since the metal products that you have to work with have a thickened head and cap.

It will not work to do this with ordinary devices. Under the Euro screw for wood or chipboard, you need to drill a hole, in some areas of which the diameter will change. The design of the tool itself has a fastening part that is fixed in the drill chuck, and a blind hole for a removable part. It matches the screw and has a slip fit to avoid bending or breakage.

The cutting element for drills for confirmation is multistage, with a countersink that allows the head to be sunk in and change the width of the passage. There are also non-collapsible options. In addition, these drills have a number of characteristic features that distinguish them from other counterparts.

- Angled front side. This allows the drill to enter the material more easily and ensures correct centering when creating the hole.

- The angle of the screw groove, repeating the thread of the confirmation. It is needed to facilitate the entry of the fastener and better hold it in place.

- Adjustable stop position. It eliminates the need to additionally control the depth of entry.

- Thorough polishing of the nib. It facilitates chip evacuation, provides ease of sliding.

- The minimum dimensions of the thrust platform. This design eliminates creasing of the sidewalls of the hole. In this case, the strength of the drill does not suffer.

- The presence of a countersink in the drill design. The hole immediately has the desired stepping, you can screw the Euro screw without creating additional deepening.

Hardness values in the range 61-64 according to Rockwell, bending resistance, impact strength 150-165 kc are considered normal. Heat resistance should be at +120 degrees Celsius. A drill with such indicators allows you to quickly form holes in different types of surfaces, does not chip, and retains its characteristics for a long time.

Features of drills for confirms

When working with a confirmation mount, it is important to correctly determine which holes to drill for the Euro screw. Having looked at the appearance of a standard Euro screw, and given that it completely goes deep into the body of the part, we can conclude that it is necessary to drill a hole with two different diameters and tapered sections.

Of course, you can use a constant section drill under the Euro screw. Rather, you will need two twist drills of different diameters and two countersinks. It is quite difficult to select such a diverse set of tools for each standard size of the confirmat, therefore it is better to use a special drill for a Euro screw.

With a confirmation drill, a hole of the required configuration is obtained in one operation. Such a tool consists of two detachable parts. It includes a conventional twist drill for wood of a certain diameter. With this drill, a hole is obtained in a wooden part into which the threaded part of the fastener will be screwed.

The second part of the cutting tool is a milling cutter, which cuts a hole in the wood for a smooth cylindrical part with a transition, as well as a conical recess for a countersunk head. The twist drill fits into the center hole of the cutter and is fixed in it with a special fixing bolt. The bolt is screwed in with a hex wrench.

The compound drill for furniture joints is convenient in that when the central twist drill for wood is worn out, it can be replaced. You can take a regular drill from a set of suitable diameter, insert it into the cutter and secure with a fixing screw.When using a suitable confirmation drill, the Euro screw is screwed into such a hole without unnecessary effort and does not destroy the structure of the part.

A quality drill for the euro screw is made of high-speed steel and has the letters HSS in its marking. Also, the marking on the shank of the drill or cutter must indicate its diameter and working length. The kit should preferably include a hex wrench to tighten the fixing bolt. The shank of the cutter is usually cylindrical in shape and can be installed in the chuck of a conventional drill or screwdriver. Drills for laminated chipboard should have increased strength, reliability and good sharpening of the cutting edges.

Features and Benefits

The confirmat is a countersunk screw with slots of two types - for a six- and four-sided tool.

Its shaft has a blunt end, is equipped with a massive, widely protruding thread, the lower turns of which are tapered with notches, designed for threading in the material.

The shank has a smooth, unthreaded section under the screw head.

Euro screws are made of high quality carbon steel, equipped with a nickel, zinc or brass coating.

The steel used for the production of Euro screws is plastic, so they bend, but do not break if installed incorrectly, which makes it easy to remove them from the material.

One-piece screed is designed for joining parts made of wood and materials created on the basis of woodworking products - chipboard and MDF panels.

The size range of this fastener is presented in the following ratios of the outer thread diameter and screw length (mm): 5x40, 5x50, 6.3x40, 6.3x50, 7x40, 7x50, 7x60, 7x70.

The most popular are confirmations with a length of 50 and 70 mm with a thread diameter of 7 mm.

Euro screws with a regular head require additional countersinking of the hole to place the head flush, but they are also available with a small tooth under the head, which provides the hole with a chamfer of the desired size simply during installation.

If the confirmation is mounted on the side of the front surface of the furniture case, then today a wide selection of decorative plugs and stickers is offered for masking the screw heads, which can be selected in accordance with the decor of the furniture material.

The nuances of fasteners

With all the versatility of this fastener and the simplicity of working with them, a certain skill is required, mainly associated with knowledge of the characteristics of a particular material to be installed.

You can make holes for confirms using drills with a diameter of 4.5-5 mm for the screw shaft, and under the head, the hole is made with a special stepped cutter attached to the drill.

The last option is the most convenient, as it allows you to prepare holes in one pass.

To make a quality hole, it is best to use a high speed tool. At low RPM, the drill can pull on the wood and become clogged with chips that will not be completely removed from the hole.

The cutter makes perfect holes, the drill leaves small chips along the edge of the holes when removed, which is not critical in this case, since the screw head will cover them.

Euro screws provide more reliable connections in comparison with other types of fasteners due to the wide protruding thread, which firmly cuts into the material.

Confirmations are installed using a screwdriver or drill with the appropriate bits or hand keys.

For beginners, it is better to install manually in order to control the process, and in case of excessive resistance of the screw during installation, remove the fasteners in time, avoiding mechanical damage to the material.

Conclusion

For those who just want to learn how to assemble furniture with their own hands, the ideal way to master this business is to apply a confirmation. The dimensions here must be kept as accurate as possible.In order for the ends of the parts to be connected to be even, it is necessary to have an exclusively right angle with respect to the plane. Then the assembly of furniture with Euro screws will simply delight and enthrall.

Confirmation he is Euroscrew he is Euro screw he is screw tie Is, simply put, a furniture screw. Loved by furniture makers for ease of installation and does not require special precision when adding - you only need a drill and a hex key for confirmation.

To install this tie, two holes are needed: one is drilled at the end the main part, and the other is in the face part that joins the main one. The confirmation is so simple in the additive that you can drill holes for it even in place during the assembly of the product. A beginner furniture maker will also cope with this.

In order to simplify the drilling of holes for the Euro screw, a special drill is produced. consists of a cutter and a conventional drill. The cutter is designed for drilling a hole with a diameter of 7 mm (under the neck of the confirmation) and countersinking (under the head of the confirmation). The drill is inserted into the cutter skirt and clamped with a screw.

It is often not so easy to find such a drill on sale, especially in small towns. But even if you don't buy it, don't be discouraged, it has some drawbacks. This is my personal opinion.

The first thing I encountered when working with a drill for a confirmation is that with a large amount of work, sawdust gets clogged between the drill and the cutter skirt over time. This quickly leads to the failure of the drill. The clamping screw is loosened by vibration. We have to clamp it more often, so the edges on the key and, as a result, on the screw itself lick off.

I don't use a confirmation drill. I use two conventional drills (different sizes for thread and screw neck) and countersink.

When drilling a blind hole into the end of the plate, it is important to maintain perpendicularity so that the drill does not pierce the wall of the part! I speak my own

But, I digress a little. An article about the confirmation.

The most popular confirmation is 7x50. The screw tie is twisted with a special wrench by hand or with a hex bat using a drill or screwdriver.

Do not buy confirmations made for a Phillips screwdriver under any circumstances! With such a Euro screw, you will not be able to tighten the parts as tightly as possible. This can lead to loosening of the product.

- this is not a hidden fixture. The hat is visible. It is usually closed with either a plastic plug or a sticker, matching the chipboard color.

- furniture that is assembled at confirmations does not withstand repeated assembly and disassembly (no more than three times). This is due to the fact that the confirmat cuts threads in chipboard - a relatively soft material. And with frequent disassembly, the threads can break.

- Confirmate is easy to install and does not require special equipment and precision when adding (as is the case with minifix). But you shouldn't relax. To make high-quality furniture, you need to accurately drill for any fastener.

- the confirmat tightens the parts tightly and reliably enough. It "sits" well in the material.

- withstands heavy loads. But in the case of fixing the shelf, which is expected to be well "loaded", the confirmat + dowel fasteners are used.

- can be corrected with a mallet. For example, align parts to ends. But in this case, it is better not to twist the confirmation from there.

In my opinion, the confirmation is convenient, reliable, and quick to use. But if there is an opportunity to use hardware or a device for more complex fasteners, I would choose an eccentric coupler.

A popular type of fastening - furniture Euro screw is known in various variations: confirmat, Euro screw, “Euro screw”. It got its name from the Confirmat trademark, under which the German company produced fasteners. The main sphere of using euro screws is the assembly of furniture structures.