Weight of 1 meter of galvanized wire, dimensions and weight of a coil of steel wire

The table shows theoretical data. Due to the fact that, according to GOSTs, small deviations (+ or -) in the diameter of the wire are allowed, then the weight of 1 r.m. may also vary slightly.

| f, mm. | Coil weight, kg. | Outer coil, mm. | Inner coil, mm. | 1m / linear kg, not sc. | Weight 1m / rm. kg, gal. | Bay weight, kg. |

| 0,5 | 15 — 20 | 350-400 | 150-200 | 0,0015 | ||

| 0,6 | 20 — 25 | 400 | 200 | 0,0021 | 15-20 | |

| 0,7 | 25 — 30 | 400 | 150-200 | |||

| 0,8 | 30 — 70 | 350-500 | 150-200 | 0,004 | 22-30 | |

| 0,9 | 80 — 100 | 350-500 | 200 | 0,005 | 23-30 | |

| 1,0 | 80 — 130 | 500 | 250-450 | 0,006 | 0,0058 | 57-100 |

| 1,2 | 80 — 130 | 450-800 | 400-450 | 0,009 | 0,0094 | 50-120 |

| 1,25 | 120-160 | 750-800 | 400-450 | 0,0099 | 70-90 | |

| 1,4 | 120-160 | 750-800 | 400-450 | 0,012 | 0,0125 | 150-180 |

| 1,6 | 120-180 | 750-800 | 400-450 | 0,015 | 100-170 | |

| 1,8 | 120-180 | 800 | 400 | 0,019 | 0,0198 | 89-160 |

| 2,0 | 150-180 | 800 | 400 | 0,024 | 0,025 | 100-150 |

| 2,1 | 150-180 | 800 | 400 | 0,028 | ||

| 2,4 | 150-180 | 800 | 400 | 0,0312 | ||

| 2,5 | 150-180 | 800 | 400 | 0,039 | 0,405 | 100-150 |

| 2,8 | 150-180 | 800 | 400 | 0,0447 | ||

| 3,0 | 150-180 | 800 | 400 | 0,055 | 0,0572 | 130-180 |

| 3,25 | 150-180 | 800 | 400 | 0,0574 | ||

| 3,5 | 150-180 | 800 | 400 | 0,075 | 0,078 | |

| 4,0 | 150-180 | 800 | 400 | 0,099 | 0,1029 | 150-200 |

| 4,5 | 150-180 | 800 | 400 | 0,135 | ||

| 5,0 | 150-180 | 800 | 400 | 0,148 | 0,1601 | 150-220 |

| 6,0 | 150-200 | 750-900 | 450-500 | 0,220 | 0,2308 | 160-250 |

| 8,0 | 900-1200 | 1000 | 500 |

Standard values for the mass of galvanized wire:

Grid of weight values of one running meter of OP made of round profile carbon steel, issued in accordance with GOST 1526-81:

0.3 (mm) - 0.003 (kg), 0.5 (mm) - 0.005 (kg), 0.8 (mm) - 0.008 (kg), 1 (mm) - 0.01 (kg), 2 (mm) - 0.02 (kg).

Grid of weight values of one meter of galvanized steel wire of a round profile, produced according to TU 14-4-1457-87:

0.25 (mm) - 0.0025 (kg), 0.3 (mm) - 0.003 (kg), 0.4 (mm) - 0.004 (kg), 0.5 (mm) - 0.005 (kg).

The material should be stored and transported in spools and coils weighing 10 (kg) and 25 (kg), additionally packed in waxed paper, half roll or box.

How thick can it be?

The thickness of the galvanized coating varies. The thicker the coating, the more expensive it will cost and the better its performance will be.

All commercially available diameters:

- OP with a diameter of 2 mm. The thinnest and softest. This material can be easily knitted by hand, but it is not suitable for serious electrical work.

- The 2.2 mm diameter is not much different from the previous version.

- Diameter 3 mm. If this galvanized wire is used, higher strength and durability results can be obtained than if using a wire with a diameter of 2 mm.

- Diameter 4 mm, which has average characteristics in all respects. It is still quite soft, but at the same time it is already very strong and, in terms of its cross section, is quite suitable for use as grounding or for other electrical work.

- Much less common with a 6 mm diameter. It is quite suitable for use in the mesh for finishing work.

- 8mm, the thickest one you can find in a general store. It is ideal for masonry work, concrete floor mesh, etc. But galvanized 8 mm wire rod also costs and weighs much more than its younger counterparts. Therefore, it should be purchased only if you are sure that you need it. In other cases, it will only be a waste of money, because the more millimeters, the more expensive it is.

Any galvanized soft material can be useful to you both in professional activities and in household needs. For home storage and use, galvanized wire rope with a diameter of 1 mm is best suited.

Installation of barbed wire

Barbed wire is the simplest and most effective way to protect a territory from intruders. Installation of barbed wire can be carried out on any type of fence, from a chain-link mesh to beautiful brick fences enclosing an elite cottage

Having decided to use barbed wire as a fence, you should pay attention to the fencing of the Egoza variety. It is a barbed reinforced tape, often twisted into a volumetric spiral

An example of mounted barbed wire on a corrugated fence

Pros and cons of barbed wire

Barbed wire has its merits and demerits. Of the positive qualities, it can be noted:

- Reliability and durability. Made in accordance with GOST, the reinforced tape has high strength and resistance to corrosion. The service life of the Egoza fence is up to 20 years,

Option for installing a thorn on a stone fence

The pluses of barbed wire on another consideration can be attributed to the disadvantages:

- The transparency of such a fence will not protect from prying eyes (of course, if Egoza is not installed on top of a high concrete fence),

- When choosing a wire fence, you need to understand that it is unlikely that it will serve as a decoration for the site and talk about the good taste of the owner.

Varieties of Egoza barbed tape

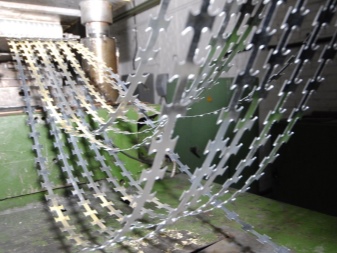

- AKL (reinforced barbed tape) is a wire made of galvanized steel, around which a tape with cutting blades is crimped. AKL - an improved type of "thorn" of the old model: instead of sharpened turns, a cutting tape stamped from sheet steel is used. Its razor-sharp edges can cause serious damage to a border trespasser.

- ASKL (Reinforced Twisted Barbed Tape) - A stamped cutting tape is twisted around a rigid galvanized wire. The blades have different directions - the effectiveness and the intimidating appearance of the fence are increased.

- SBB (spiral safety barrier) is a volumetric structure made in the form of a spiral. To create it, tapes from AKL or ASKL are used. The barbed spiral fence is difficult to overcome. Even after a few bites, the SBB continues to be a serious obstacle for violators.

- PBB (flat security barrier) is a flat structure in the form of spirals, similar to SBB, only PBB does not protrude beyond the fence and looks neat enough and not so formidable. Although this does not in the least reduce the protective function of the hedge.

Installation of barbed wire

The fence can be made entirely of barbed wire or complement the finished fence. The first method is well suited for limiting areas for pastures for livestock or temporary fences, the second option is more often used for reliable protection of private territory, as well as industrial buildings, warehouses and other specially protected facilities.

Types of brackets for fastening Egoza wire

Depending on the type of fence and the type of Egoza, various fasteners and brackets made of steel are used. With their help, the installation of a barbed fence is greatly simplified. Fastening to the support posts is carried out using welding or self-tapping screws.

- Straight bracket. Designed for fastening wires in several rows and installing spiral barriers. The straight bracket can be replaced by using the top of the support post, which should rise above the fence,

Types of barbed wire and features of its installation

Barbed wire (in everyday life "thorn") - a wire with sharp spikes located along the perimeter. It is used in the construction of the simplest and cheapest fences and helps to improve existing ones. To erect a fence, you only need supports and the wire itself, and even an inexperienced worker will be able to install it.

An excursion into history

For the first time, a new method of fencing territories, in which a thin and flat hot-rolled steel wire should be used, was invented in France back in 1860. Just five years later, the diamond-toothed barb became a patented product. But then it was used extremely rarely.

The change came in 1872 with the introduction by the American Henry Rose of a wire fence made of small planks to which pieces of sharp wire were screwed. The fence was shown to Illinois farmers. Many have tried to improve on the design shown, but Joseph Glidden and Isaac Elwood succeeded best. Their product gained popularity, and the company, founded by partners, produced approximately 270 tons of finished products in 1875.

By 1900, there were no farms in the United States where animal enclosures were not protected by such fences - the "thorn" reliably guarded the cattle. In addition, the fence was cheap, which also provided a huge boost to American livestock development.

Rope cargo slings

Application:

movement and transportation of goods

When performing loading and unloading operations, most of the goods (rolled steel, timber, construction products and structures, equipment, containers, etc.) are moved using hook cranes.

To ensure reliable gripping of the load, for its stable orientation in space and for the uniform distribution of dynamic loads between its elements, removable load-gripping devices are used.

The simplest SCS are general purpose cargo slings. Currently, hook cranes are most often used with steel rope slings.

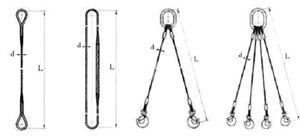

USK-1 USK-2 2SK 4SK

In the production workshops of LLC Ormetiz, multi-branch slings ("spiders" - 2SK, 4SK) and universal rope slings (USK-1, USK-2) are manufactured, which are one of the versions of circular and looped slings.

The ends of the rope of these slings are sealed by braiding, followed by wrapping the braided sections with annealed steel wire or electrical tape. The slings and their elements withstand a static load that exceeds their nominal value by 25%.

Ropes for slings comply with the requirements of GOST 3071, GOST 3079 and GOST 7668. For slings of type 2SK and 4SK, it is allowed to use ropes in accordance with GOST 2688, GOST 3070, GOST 3077 and GOST 7665.

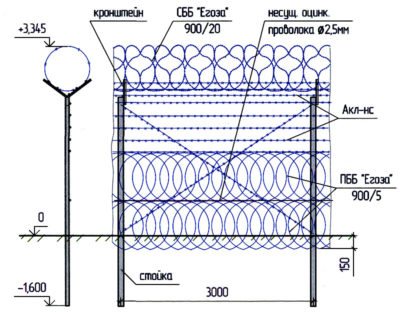

SBB "Egoza" spiral security barrier

SBB Egoza is a spiral wound from AKL or ASKL. Adjacent turns of the spiral are stapled at five (or more) equidistant points around the circumference, thus increasing the protective properties of the spiral. SBB Egoza cannot be eaten, pressed, overcome.

Standard version SBB "Egoza

The figure shows SBB Egoza-900 in the working (stretched) position. The SBB turns are fastened with brackets at five equidistant points around the circumference, the distance between adjacent brackets is 400 mm, one running meter of the SBB contains 5 turns. This installation scheme is the most optimal from the point of view of reasonable consumption of materials.

The warranty period is 16 years.

Binding SBB business cards with staples

We draw your attention to the fact that fastening the turns with a wire less than 3 mm significantly reduces the protective properties of Egoza, because the fine wire staple is easier to bite or straighten with bare hands

Staple of 1.5 mm tape Staple of 3 mm wire

Applicable materials

Base wire: Spring wire with a diameter of 2.5 mm GOST 9389 (grade 65g) or galvanized GOST 7372-79.

Spiked blades: Galvanized strip GOST 3559-75 or GOST 14918-80. Thickness 0.5-0.55 mm.

Staples: Wire with a diameter of 3.0 mm, galvanized or tape 1.5 mm thick, 10 mm wide, galvanized.

Example of designation SBB when ordering

………………………………………………………………………………………………………………………………………………………………………..

SBB / 600/15/5/3 AKL OTs

Spiral Diameter Length Quantity No. of wires

Barrier turn-600 mm coil-15 m turns in staples-points -base

Security single mount reinforced

running long turns on barbed

meter circumference tape

products-3 pcs. galvanized

GOST 7372-79

………………………………………………………………………………………………………………………………………………………………………..

Thus, SBB Egoza-600/15/5/3 AKL OTs - means: spiral safety barrier (SBB) Egoza with a coil diameter of 600 mm; one bay contains 15 running meters of SBB; one running meter of SBB contains 5 turns; number of attachment points of adjacent turns - 3 pcs; SBB is made of AKL tape; all materials are galvanized.

Product range

Egoza LLC produces barbed wire of various diameters.

The most demanded positions are:

SBB Egoza-500/15/5/3 AKL OTs

SBB Egoza-600/15/5/3 AKL OTs

SBB Egoza-900/15/5/5 AKL OTs

SBB Bars-1700 / 12.5 / 5/11 ASKL OTs

At the request of the Customer, our company will manufacture SBB of any diameter, density (number of turns in 1 r / m) and coil length.

General nomenclature of spiral safety barriers

|

Conditional |

Coil winding diameter, |

Coil length in working order, |

The number of turns in one r.m. |

Number of connections around the circumference of the turns, |

Base wire diameter, |

Number of turns in the coil, pcs |

Product height in working |

|

SBB Egoza-400/15/5/3 |

400 |

15 |

5 |

3 |

2,5 |

75 |

390 |

|

SBB Egoza-400/15/6/3 |

400 |

15 |

6 |

3 |

2,5 |

90 |

390 |

|

SBB Egoza-400/15/7/5 |

400 |

15 |

7 |

5 |

2,5 |

105 |

395 |

|

SBB Egoza-450/15/5/3 |

450 |

15 |

5 |

3 |

2,5 |

75 |

440 |

|

SBB Egoza-450/15/6/3 |

450 |

15 |

6 |

3 |

2,5 |

90 |

444 |

|

SBB Egoza-400/15/7/5 |

450 |

15 |

7 |

5 |

2,5 |

105 |

448 |

|

SBB Egoza-500/15/5/3 |

500 |

15 |

5 |

3 |

2,5 |

75 |

480 |

|

SBB Egoza-500/15/6/3 |

500 |

15 |

6 |

3 |

2,5 |

90 |

485 |

|

SBB Egoza-500/15/7/5 |

500 |

15 |

7 |

5 |

2,5 |

105 |

490 |

|

SBB Egoza-550/15/5/3 |

550 |

15 |

5 |

3 |

2,5 |

75 |

520 |

|

SBB Egoza-550/15/6/3 |

550 |

15 |

6 |

3 |

2,5 |

90 |

525 |

|

SBB Egoza-400/15/7/5 |

550 |

15 |

7 |

5 |

2,5 |

105 |

530 |

|

SBB Egoza-600/15/4/3 |

600 |

15 |

4 |

3 |

2,5 |

60 |

540 |

|

SBB Egoza-600/15/5/3 |

600 |

15 |

5 |

3 |

2,5 |

75 |

550 |

|

SBB Egoza-600/15/6/5 |

600 |

15 |

6 |

5 |

2,5 |

90 |

556 |

|

SBB Egoza-600/15/7/5 |

600 |

15 |

7 |

5 |

2,5 |

105 |

562 |

|

SBB Egoza-600/25/5/3 |

600 |

25 |

5 |

3 |

2,5 |

126 |

550 |

|

SBB Egoza-650/15/4/3 |

650 |

15 |

4 |

3 |

2,5 |

60 |

600 |

|

SBB Egoza-650/15/5/3 |

650 |

15 |

5 |

3 |

2,5 |

75 |

605 |

|

SBB Egoza-650/15/6/5 |

650 |

15 |

6 |

5 |

2,5 |

90 |

612 |

|

SBB Egoza-650/15/7/5 |

650 |

15 |

7 |

5 |

2,5 |

105 |

618 |

|

SBB Egoza-750/25/4/3 |

750 |

25 |

4 |

3 |

2,5 |

100 |

690 |

|

SBB Egoza-750/15/5/5 |

750 |

15 |

5 |

5 |

2,5 |

75 |

700 |

|

SBB Egoza-750/25/5/5 |

750 |

25 |

5 |

5 |

2,5 |

126 |

700 |

|

SBB Egoza-900/25/3/3 |

900 |

25 |

3 |

3 |

2,5 |

75 |

820 |

|

SBB Egoza-900/15/4/3 |

900 |

15 |

4 |

3 |

2,5 |

60 |

835 |

|

SBB Egoza-900/15/5/5 |

900 |

15 |

5 |

5 |

2,5 |

75 |

850 |

|

SBB Egoza-900/25/5/5 |

900 |

25 |

5 |

5 |

2,5 |

126 |

850 |

|

SBB Egoza-950/25/3/3 |

950 |

25 |

3 |

3 |

2,5 |

75 |

890 |

|

SBB Egoza-950/15/4/3 |

950 |

15 |

4 |

3 |

2,5 |

60 |

900 |

|

SBB Egoza-950/15/5/5 |

950 |

15 |

5 |

5 |

2,5 |

75 |

900 |

|

SBB Egoza-950/25/5/5 |

950 |

25 |

5 |

5 |

2,5 |

126 |

900 |

Construction nails

Application:

for wooden structures and parts

Construction nails are made of round section with flat or conical head. The end surface of the flat head is smooth, the conical head is corrugated. The assortment of the produced nails and their geometrical dimensions are indicated in the table.

| Rod diameter, mm | Nail length, mm | Head diameter, mm, not less | Theoretical weight 1000 pcs. nails, kg. |

| 1,2 | 16 | 2,4 | 0,147 |

| 1,2 | 20 | 2,4 | 0,183 |

| 1,2 | 25 | 2,4 | 0,219 |

| 1,4 | 25 | 2,8 | 0,302 |

| 1,4 | 32 | 2,8 | 0,385 |

| 1,4 | 40 | 2,8 | 0,482 |

| 1,6 | 25 | 3,2 | 0,397 |

| 1,6 | 40 | 3,2 | 0,633 |

| 1,6 | 50 | 3,2 | 0,791 |

| 1,8 | 32 | 3,5 | 0,640 |

| 1,8 | 40 | 3,5 | 0,787 |

| 1,8 | 50 | 3,5 | 0,967 |

| 1,8 | 60 | 3,5 | 1,160 |

| 2,0 | 40 | 4,0 | 0,949 |

| 2,0 | 50 | 4,0 | 1,190 |

| 2,5 | 50 | 5,0 | 1,870 |

| 2,5 | 60 | 5,0 | 2,230 |

| 3,0 | 70 | 6,0 | 3,770 |

| 3,0 | 80 | 6,0 | 4,330 |

| 3,5 | 90 | 7,0 | 6,600 |

| 4,0 | 100 | 7,5 | 9,500 |

| 4,0 | 120 | 7,5 | 11,500 |

| 5,0 | 120 | 9,0 | 17,800 |

| 5,0 | 150 | 9,0 | 21,900 |

| 6,0 | 150 | 11,0 | 32,400 |

| 6,0 | 200 | 11,0 | 43,100 |

What is Spiked Wire?

If you still do not understand why barbed thread fence is called the most effective type of fence, study the features of this material.

An interesting video about how the studded wire was invented:

Firstly, strong reinforced threads are almost impossible to cut, even with nippers. No random thief will carry with him a bunch of special devices to overcome such a fence.

Secondly, in different sections of the tape or spiral, the location and frequency of the spikes can change, which additionally protects the most vulnerable spots in the fence.

Well, and finally, pay attention to the fences of various state institutions, prisons, closed objects - you will see a "thorn" almost everywhere, which means that the effectiveness of such a fence has been tested more than once. Fences like these are usually pretty intimidating.

Fences like these are usually pretty intimidating.

pros

Among the advantages of this material are not only good protective properties. Besides:

- Galvanized options have a long service life (plus or minus 20 years);

- Do-it-yourself installation of barbed wire on a fence;

- This material can be installed on a concrete fence, and on a wooden or plastic;

- A big plus is the relatively low cost;

- It is possible to install a tape with spikes on an existing boom;

- Such a fence will be as light and air permeable as possible.

Of course, when installing the barbed tape, you will have to use protective gloves and a fairly sturdy overalls. The risk of injuring hands or other parts of the body with such a thread is very high, the wounds remain very unpleasant and "sore".

What signs can warn of the danger of high voltage The only drawback of the barbed tape is its unsightly appearance. For many people, it is associated with the prison fence. But if there is a need to ensure maximum safety on the site, decorative characteristics may fade into the background.

Brackets for fasteners

To firmly fix the “thorn” on the fence, special brackets are used. They have a different shape, which is used depending on the type of fence and the type of wire.

There are such options:

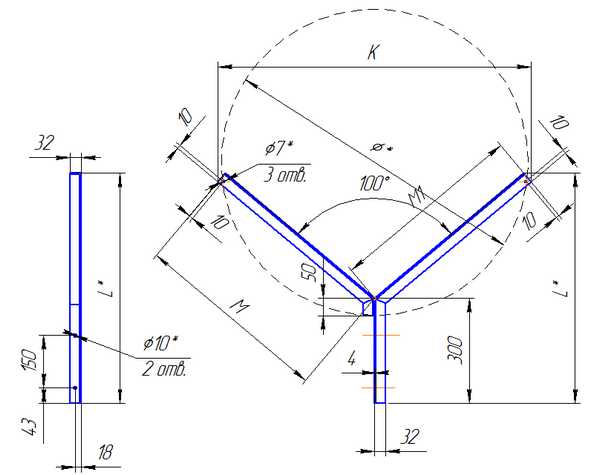

- straight brackets (vertical or inclined) with brackets, between which a wire is stretched in several rows of different density;

- inclined brackets in the form of the letter L - the principle of installing the barbed tape is the same, but thanks to the configuration of the fasteners, the fence becomes even more reliable;

- Y-shaped brackets serve the same purposes, it is especially convenient to mount the fighter on them;

- Semicircular brackets are great for securing voluminous spiral tapes both on fences and on the ground.

If you are installing a thorn in a residential area, straight brackets will suffice. They can be tilted at an angle to make it impossible to hit the fence.

Fence scheme option

Installation of barbed wire on a fence

To install the barbed tape on a ready-made fence, you will need not only brackets, but also a set of certain tools. Namely:

- welding machine;

- metal staples;

- pliers;

- protective gloves and overalls.

In addition to the barbed wire, you can purchase a steel string that will hold the structure in position and prevent it from sagging over time.

The scheme of using threads to hold the "thorn"

The order of work is as follows:

- Brackets are attached to the top of the fence;

- At a height of about half a meter from the edge of the fence, a steel thread is pulled between the brackets;

- A spiked fidget is wound along this thread in the desired position and with sufficient frequency;

- The thorn is attached to the brackets with metal staples.

Wire Bracket Options

They are divided into the following types:

- Straight - such a bracket is needed to fix the spiral, which must be installed in several rows, or the spiral fence is being installed. If there is not enough material, then it is possible to use it only for the upper part of the pillars, which are used as a support.

- L-shaped - this type is used when installing a protective wire in 2-3 rows. The bracket has stretched lines and must be placed on the inside or outside of the fence. A spiral tape is also attached to it.

- Y-shaped view, it is needed to install a volumetric spiral or mount a sharp spiral in 2-3 rows.

- Semicircular - this type is chosen if the tape is installed on a slope or directly on the ground. It is convenient to use for fastening a spiral barrier.

Classic V-bracket schematic

Description

Any serially produced product is subject to a special GOST. There is a state standard for barbed wire. It was approved back in 1969 to replace the hopelessly outdated standards of the 1941 edition. Barbed wire is classified by coating use and manufacturing accuracy. The largest dimensions of individual elements and permissible deviations for these indicators are strictly normalized.

The list of technical requirements contains:

-

base material;

-

spike material;

-

the location of the thorns;

-

unacceptable metal defects;

-

features of various coatings;

-

surface density of coatings.

The state standard even says how long the barbed wire should be in one coil. According to GOST 285-69, one coil contains 380 running meters of clarified or galvanized barbed wire, and its weight is 35 kg (with a deviation of 2 kg up or down). But it's not that simple. Some sources indicate that more than 400 linear meters of wire can be in the bay.

Species overview

Today several types of products are produced under the name "Egoza". They all have different external data and characteristics. The simplest type is wire or thread-like and looks like a steel cord. It can be uniform, with an inextricable interweaving of elements in the bay and pointed spikes directed to the sides. Corrugated wire of this type is woven in the form of a "pigtail", which increases its strength characteristics, the number of spikes and strands is doubled.

By composition

Barbed wire is not only round - it can be made in the form of a ribbon. Such "Egoza" has a flat structure, spikes are located along its edge. Since the strip wire is made from a galvanized strip of metal, it is quite easy to cut with special tools. This greatly limits its independent use.

They are divided into 2 categories.

- ASKL. Reinforced tape twisted and wrapped around the wire reinforcement. This type is quite popular, but not very reliable - it is easy to dismantle it, freeing the passage. In this case, the number of thorns increases; externally, the fence looks quite impressive.

- ACL.The barbed reinforced tape in this design is wrapped and rolled in the longitudinal direction on a flexible core. The design is resistant to mechanical damage, strong and durable. The standard tape thickness is 0.55 mm, the profile is equipped with double-edged and symmetrical spikes.

It is worth considering that, according to the standard, the Egoza-type wire should be made exclusively from galvanized wire and tape of established samples. The core diameter is set at 2.5 mm. The thickness of the tape for combined products varies from 0.5 to 0.55 mm.

According to the degree of hardness

Considering this characteristic of barbed wire, 2 main categories can be distinguished.

- Elastic. It provides a high level of strength and rigidity to the material. This type is intended for creating long-span fences.

- Soft. Annealed wire is used for its manufacture. She is very flexible, easily takes the right direction. It is convenient to work with such material when installing short sections of the fence, complex in shape. Soft wire "Egoza" is easy to use in everyday life.

Volumetric and flat

Barbed wire "Egoza" AKL and ASKL has a tape design. But under this brand, volumetric and flat fences are also produced. They allow you to quickly deploy the structure on the ground, to cover large areas on any type of terrain. Here are the most popular options.

SBB (spiral security barrier). A three-dimensional structure is made of wire AKL or ASKL by winding with staple connection in a checkerboard pattern in 3-5 rows. The finished fence turns out to be springy, resilient, voluminous and difficult to overcome. It is almost impossible to push or bite it with tools.

Popular manufacturers

The "thorn" brand "Egoza" is in demand. This enterprise manufactures its products in the city of Miass in the immediate vicinity of the Ural federal highway. This location immediately creates an impressive logistical advantage. The main workshop was equipped with two automated lines, and the products are painted with a powder-polymer composition. Hot zinc coating is available upon customer's request; the thickness of its layer can vary from 70 to 120 microns.

It is worth paying attention to the production in the city of Lyudinovo, Kaluga region. From there you can order barbed wire in the versions SBB, AKL, PKLZ

"Mesh and Wire Plant" has been engaged in the production of ACL since 2006. The assortment also includes:

- Bruno's spiral;

- SCL;

- galvanized sharp wire with a diameter of 2.8 mm;

- flat "Gyurza";

- flattened barbed tape "Acacia" (and a number of other options).

You can also take a closer look at the products:

- PJSC TNMK;

- MMK-Metiz;

- Atlant-Media LLC;

- ROL-MET-BUD;

- Eurobarb Concertina;

- SE "Soyuz";

- Granza.