Concrete contact - characteristics of different grades of primer

The components of the concrete contact are Portland cement, sand, acrylic. Such a composition provides good adhesion to any surface, from traditional concrete to plastic or glass.

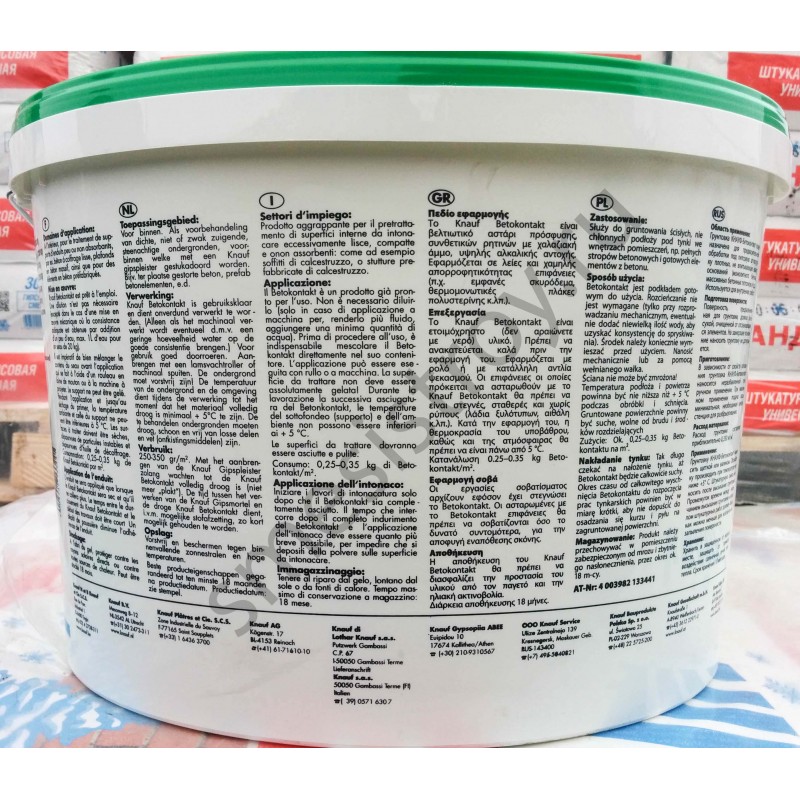

Knauf primer concretekontakt technical characteristics:

| Options | Meaning |

| PH level | 7,5 |

| Primer color | Pink or orange |

| Heat resistance of a dry surface | -20C / + 80C |

| Consumption, kg / m2 | 0,35 |

| Container | Plastic bucket 20 liters |

| Shelf life | 1 year |

| Store in a dry place at a temperature | ≤ + 1C |

»Alt =» »>

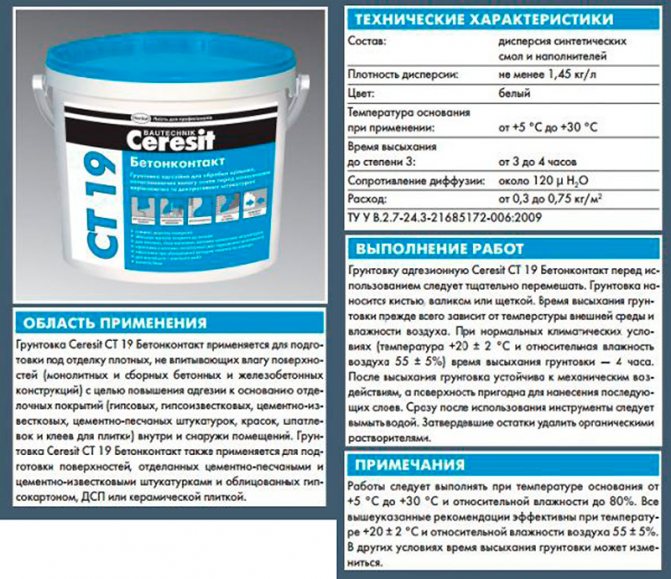

| Options | Meaning |

| Surface type | Concrete |

| Drying time | 180 minutes |

| Limiting temperatures | + 35C / + 5C |

| Appointment | Indoors |

| Container | 5 liter bucket |

| Shelf life | 12 months |

| Application technology | Brush or roller |

VD-AK-014 concrete contact primer:

| Options | Meaning |

| Density, g / cm3 | 1,37 |

| Consumption, g / m2 | 130-160 |

| pH | 7,5-9,0 |

| Drying time | 60 minutes |

| Limiting temperatures | + 35C / + 5C |

| Frost resistance 5 cycles feast temperature | -40C |

| Application | brush, roller |

- Fast drying: after 2-2.5 hours, you can continue to work with the surface;

- A high coefficient of moisture resistance allows you to apply a screed;

- The service life of the substance is 80 years or more;

- Shades of different colors help to visually determine the uniformity of the layer on the walls.

Both the composition and characteristics of the primer fit the definition of a universal mortar, since the instructions for use show that even an unprepared person can work with the liquid. " alt = "">

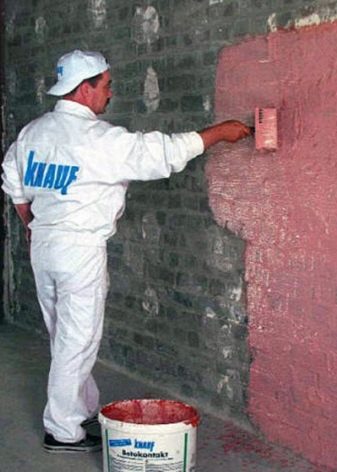

How to apply the primer correctly, and what are the subtleties?

The application process is quite simple and does not require special instructions. Manufacturers leave recommendations for use on the packaging, you should not ignore them. It is necessary to carefully read the recommendations for use, since some ready-made mixtures do not withstand low and very high temperatures, and if transportation is planned in the cold season, then you need to protect the packaging from freezing. With strong heating and cooling, the adhesion properties decrease significantly.

Almost all mixtures are sold ready-made, they can be immediately applied to the prepared surface. After opening the bucket, be sure to stir the solution in the container. The mixture should resemble paint with very fine grains. Before priming, it is necessary to ensure the air temperature in the room is at least 15 degrees. In no case should the emulsion be applied to frozen walls. At low temperatures, the composition may not adhere to the surface and, after lining, under the weight of the materials, it may lag behind the base.

A roller, wide brush or spatula is used to apply the emulsion. The lowest consumption of material - when applied with a wide brush (with a brush), since a large amount of mixture remains on the construction roller

If the surface is actively absorbing liquid, re-treat the area. The second layer is applied when the surface is uneven and with obvious defects.

For mechanical application of the primer, it can be diluted with a little water. To do this, we use the proportion: for 1 kilogram of the mixture, 50 ml of water at room temperature. After drying, proceed to the cladding. The sooner the finishing work on the wall is carried out, the more adhesion will be between the hard surface and the cladding material. Characteristics of the Concrete Contact primer allow you to process substrates in a residential area. This material is considered environmentally friendly, it does not emit chemical elements and harmful vapors into the air, therefore, even when priming, you do not need to use protective masks or suits.Ventilate the apartment after work.

The building materials market is expanding, new products appear - successful and not so - there are real bestsellers. One of these useful developments was the Knauf Concrete Contact primer. The purpose of this composition is to separate layers of different properties, but at the same time ensure their strong adhesion to each other. Thanks to the new formula, the cladding can now be used on difficult substrates, saving time and effort in preparing them.

Primer Betonokontakt of the Knauf brand is an adhesion dispersed mixture on an acrylic basis. It is intended for application on low-absorbent high-density surfaces like concrete monolith, on which the adhesive or leveling mortar simply has nothing to cling to. The primer itself easily adheres to such a base, turning into a continuous dark pink film. And the adhesion with the subsequent layer is provided by fine-grained alkali-resistant sand in its composition, which gives the coating the required roughness.

In addition, Betonokontakt Knauf allows you to apply lime and gypsum plaster to cement, although earlier this was simply impossible due to chemical reactions that occur between two dissimilar materials. However, experts found many other types of work, where the new primer came in handy:

- Strengthening before plastering of low-density products (expanded polystyrene, gypsum plasterboards).

- Laying ceramic tiles directly on the old one without preliminary dismantling.

- Application on surfaces coated with oil or alkyd enamels for subsequent finishing.

- Reliable fastening of decorative stucco molding to any smooth surfaces after processing Knauf Betonokontakt.

- Preparation of metal structures, as well as concrete products with removed embedded elements for subsequent puttying.

- Strengthening dusty old concrete before finishing work.

General information about Knauf Betokontakt primer

Knauf Betokontakt primer is a ready-to-use mixture of pink shade. Produced in containers of 5 kg and a bucket weighing 20 kg. The shelf life is 18 months from the date of production; an opened product can be stored for about 6 months in a tightly closed container.

The product has pronounced adhesion properties, it is used on surfaces of a complex nature - poorly absorbent, smooth, dense. It is used to strengthen concrete foundations, gypsum plasterboards, in the preparation of metal structures for further work (putty), while laying ceramic tiles, fastening stucco moldings made of polystyrene, gypsum, polyurethane. Concrete contact simplifies construction work and reduces the amount of additional consumables due to its strengthening properties. Knauf Betokontakt primer smoothes surfaces, removes small defects in the base, microcracks.

Working with Knauf Betokontakt soil requires adherence to a certain temperature regime. It cannot be used at temperatures of –5 degrees Celsius and below, in frost, as well as when the thermometer is above + 26-27 degrees Celsius.

Knauf Betokontakt primer is available in two types - with mineral particles of 0.6 mm and 0.3 mm. The first type is used in rough finishing and coating of external surfaces, the second is used for more delicate work and before puttying.

When calculating the consumption of the required material, several factors should be taken into account:

- the degree of moisture absorption of the base;

- surface type;

- number of layers;

- method of application.

On a smooth surface such as paint and varnish and ceramic, the consumption of primer will be significantly lower than when applied to a concrete slab. The minimum consumption is approximately 200 g. per 1m², maximum - 350 gr.

Manufacturers release the mixture in a state that is completely ready for use.Experts allow the Knauf Betokontakt primer to be diluted with a little water for better mechanical application.

When applied by hand, the maximum amount of water to dilute is 50 ml per liter of primer. The mechanical spraying method uses a 2: 1 dilution - two parts of soil, one part of water.

Before starting work, the mixture must be thoroughly stirred so that all microparticles are distributed evenly over the entire area. When processing the surface, you can use any tool - brush, roller, mechanical spray. The pink color will help you see the blurry areas.

Advantages

Concrete contact "Prospectors" has many advantages. The main ones include the following:

- Ecological cleanliness. The building material does not contain impurities harmful to human health, so that they can safely handle surfaces in bedrooms and children's rooms.

- Resistant to fire. The advantages also include the absence of harmful emissions when heated.

- No smell.

- Resistant to mold and mildew growth. The composition contains antiseptic additives that effectively protect the treated bases and finishes from biological damage. Due to this feature, the building material can be used for repair work in rooms with high humidity.

- Provides excellent adhesion. When the solution is applied, a rough layer forms on the surface, due to which there is a reliable adhesion of the working surface with the used finishing materials.

- Convenience in work. The building compound does not need to be diluted.

- Fast drying time due to the increased viscosity of the primer. On average, it will take 2-3 hours to completely dry (at a temperature of 15-20 ° C).

- Economical consumption.

- The ability to withstand up to 5 cycles of freezing and defrosting without loss of consumer properties and deterioration of technical parameters.

Due to the latex included in the composition, the soil mass of the concrete contact does not delaminate, and the sand particles do not settle. Thanks to this feature, the composition is evenly distributed along the entire perimeter of the base. Betonokontakt "Prospectors" is one of the best primer samples on the construction market.

How to apply the primer correctly, and what are the subtleties?

The application process is quite simple and does not require special instructions. Manufacturers leave recommendations for use on the packaging, you should not ignore them. It is necessary to carefully read the recommendations for use, since some ready-made mixtures do not withstand low and very high temperatures, and if transportation is planned in the cold season, then you need to protect the packaging from freezing. With strong heating and cooling, the adhesion properties decrease significantly.

Almost all mixtures are sold ready-made, they can be immediately applied to the prepared surface. After opening the bucket, be sure to stir the solution in the container. The mixture should resemble paint with very fine grains. Before priming, it is necessary to ensure the air temperature in the room is at least 15 degrees. In no case should the emulsion be applied to frozen walls. At low temperatures, the composition may not adhere to the surface and, after lining, under the weight of the materials, it may lag behind the base.

A roller, wide brush or spatula is used to apply the emulsion. The lowest consumption of material - when applied with a wide brush (with a brush), since a large amount of mixture remains on the construction roller

If the surface is actively absorbing liquid, re-treat the area. The second layer is applied when the surface is uneven and with obvious defects.

For mechanical application of the primer, it can be diluted with a little water. To do this, we use the proportion: for 1 kilogram of the mixture, 50 ml of water at room temperature. After drying, proceed to the cladding.The sooner the finishing work on the wall is carried out, the more adhesion will be between the hard surface and the cladding material. Characteristics of the Concrete Contact primer allow you to process substrates in a residential area. This material is considered environmentally friendly, it does not emit chemical elements and harmful vapors into the air, therefore, even when priming, you do not need to use protective masks or suits. Ventilate the apartment after work.

For most people, the word "repair" is unlikely to cause at least some positive emotions. Usually this process is associated with huge expenses: effort, money and time.

Container and storage

Standard containers for concrete contact are plastic buckets with a capacity of 2.5, 5, 10, 20, 30 and 40 liters. Some manufacturers pour the primer into plastic drums with a capacity of 20, 30 and 40 liters. A tightly closed container ensures that the composition is completely ready for use - you just need to stir it. If the container has been open for some time, then it is advisable to dilute the primer with water.

The guaranteed storage time of the mixture is a year, see the date of manufacture on the package. The concrete contact should be stored at a positive temperature in the range of + 50C / + 300C. If you allow even a short-term freezing, then the primer will become unusable. Storage should take place in a closed room, since the ingress of UV radiation on the composition destroys it. If the area of the impregnated surface is small, then it will be more economical to work with dry powder, the required amount of which is diluted to the required volume.

Performance parameters of the primer

Recommendations for working with concrete contact

- Purchase concrete contact stores that guarantee its originality. To do this, require product quality certificates and other accompanying documents. If you have trusted the seller in the market, then you must understand that such an attitude can result in the purchase of fake products and loss of product quality;

- Check the homogeneity of the solution before use. If you see lumps, then this speaks only of one thing - the quality of the product is negligible, or it is expired;

- Independent work with the composition is accompanied by the use of personal protective equipment;

- All treated surfaces of a large area undergo a step-by-step coating, since it is difficult for one to paint over a wall with an area of more than 20-30 m2 at once - the primer will dry unevenly, which will lead to a violation of the technology.

Properties and applications of concrete contact

Concrete contact: composition and properties

This polymer blend is not a deep penetration primer

The exact composition of the concrete contact is a secret behind seven seals, since manufacturers are not inclined to share important information with competitors. However, its main components are well known: they are acrylic or latex, glue, gypsum, quartz sand, talc, cement mixture or marble chips.

Modifiers must be added to any primer. Their task is to impart a certain property to the surface: they must impart increased strength, frost resistance, etc.

Polymer materials guarantee reliable adhesion, cement is responsible for the hardness and strength of the primer layer. Quartz sand provides it with a roughness. The diameter of its grains of sand depends only on the purpose of the composition: small ones are added to the mixture for finishing, larger fractions - under plaster, putty. This primer is usually pink in color, so untreated areas are easy to spot.

The ratio and composition of the components differs depending on the type of concrete contact: some of them are intended only for work inside buildings, others “specialize” in outdoor operations, and still others belong to universal primers. The task of the material is to ensure excellent adhesion of dissimilar materials. Applied to the surface, the concrete contact creates a rough layer, thanks to which it easily holds any finishing material.Another feature of the primer is the ability to absorb excess moisture that appears on concrete structures.

The universal type of concrete contact gives the chance to get perfect adhesion to any surface. They are treated with:

- concrete;

- drywall;

- wood;

- ceramic tiles;

- brick;

- metal;

- painted surfaces;

- glass.

The rough layer of this primer guarantees a strong connection of materials that are completely different in structure: tiles and metal, wood and glass. The concrete contact holds firmly, does not crumble, does not crack. The biggest advantage of this primer is that the work does not require the tedious step of getting rid of the old, but still reliable coating: treated with this compound, it is able to stick almost tightly to the new type of finish.

Prospectors - materials for repair and construction

The well-known domestic manufacturer of building materials offers a wide range of its products, presented in our online store OptoStroy. Today the company offers more than eighty items of products required for finishing work. You can order Prospectors from us in Moscow and other regions of the country, while not worrying about the quality and originality of the purchased products.

Assortment of building materials

The company has three main areas:

- dry mixes;

- ready-made putties;

- paint and varnish products.

You can buy putties at OptoStroy, the finished finishing material will allow you to quickly and efficiently carry out finishing work and prepare the walls for further repair. The further finishing of the walls and their appearance depends on the quality of the putty, therefore, buying the Prospector putty means being confident in the quality of the further front covering of the walls.

Together with the putty, you can buy gypsum plaster miners 30 kg price, which will allow you to insulate and level the walls. Also, the production of the company is not limited only to these materials, along with them the assortment is presented:

- primer;

- ;

- grouting;

- waterproofing materials;

- worms for the production of vermicompost, etc.

If you purchase a self-leveling floor Prospector, it will help you easily level the surface in the room and prepare it for further laying of laminate, tile or other floor covering.

The primer will provide you with high-quality wallpapering. You can also buy the Prospector primer in our online catalog with fast delivery to the desired region of the country.

General information

Concrete contact is an adhesive mixture, however, the agent is considered a primer, since it does not on its own contribute to the adhesion of surfaces, but only creates the conditions necessary for further work. Betonokontakt Knauf helps to glue the metal to the tile and prepare it for the application of a special adhesive, but itself is not used as a glue. How did the specialists manage to achieve this effect? The fact is that the primer contains glue, as well as crushed quartz. Sand allows you to make the surface rough, due to which other materials will be well fixed on it. Also, the composition of the concrete contact is influenced by the technical characteristics and its purpose. So, mixtures with the addition of cement or other components are presented on the market. In addition, when choosing a product, you need to know about other features of the product.

Dense, poorly absorbent substrates Drywall

Surface

Ceilings Walls

Specifications

Consumption 0.2-0.3 kg per 1 sq. m Surface readiness for subsequent coating 2-3 hours (at temperatures from +15 to + 25 ° C) Mass fraction of latex by dry residue, not less than 60% Shelf life from the date of manufacture 12 months

Appointment

It is used for interior finishing work in all types of buildings and structures (A-B), including rooms where a wet disinfection mode is provided, except for surfaces that have direct contact with drinking water and food. It is intended for preliminary treatment of dense, poorly absorbing substrates (monolithic concrete, concrete blocks, concrete ceilings) before applying gypsum, gypsum-lime, plasters. As an adhesion primer before laying new ceramic tiles on old ones using tile adhesive ("Prospectors" tile adhesives). As a primer before plastering old tiles with gypsum plaster. For pretreatment of gypsum board before facing with ceramic tiles.

Attention

The primer has a high viscosity, so it completely fills the pores of the base, almost without penetrating the very structure of the surface

Therefore, it is very important to thoroughly dust the surface before priming.

Safety precautions for use Surface preparation The substrate must be dry, solid, free of substances such as dust, dirt, organic contamination (formwork separating agents), loose elements.

The purpose of the primer is to prepare a surface for further finishing, such as painting. The primer allows you to level the surface, eliminate microcracks, and also improve the adhesion of the base to the decorative material.

Betonkontakt is no exception. This primer is suitable for concrete surfaces, but can also be used for brick or drywall. The use of concrete contact allows you to simplify the work with decorative finishing materials, reduce their consumption and increase the durability of the coating.

Consumption of concrete contact per 1 m2 depends on the characteristics of the surface on which the primer is used. At the same time, the main role is played not so much by its type (various grades of concrete, brick), but by its porosity. It is this factor that affects the rate of absorption of the primer, and, accordingly, its consumption.

Traditionally, the following surface options are distinguished

- No pores or low porosity. These include: ceramic tiles, painted walls, rubbed concrete. On such surfaces, the consumption of Concrete Contact per 1 m2 will be minimal: 0.15 - 0.25 kg. The primer is easy to apply in an even layer, and, as a rule, does not require additional leveling.

- Surfaces with medium porosity These are high-grade concrete, monolithic structures, self-leveling cement floors, facing bricks or concrete tiles. Here the consumption will be higher, and will amount to 0.2 - 0.35 kg per square meter.

- Porous surfaces. This type includes sand concrete, wall bricks and similar materials. Consumption of Concrete contact per 1 m2 is 0.3 - 0.5 kg, which is explained by the need to fill the pores. It should also be borne in mind that if the surface is characterized by strong porosity, then it must be treated with special impregnations, otherwise the coating with a primer will not lead to the desired results. In addition, the absorption of the primer into the pores leads to unevenness of the layer, which requires regular trimming.

The best practical way to determine the consumption of a concrete contact is to test a surface area. To do this, you can stick masking tape on the wall, forming a square meter by meter. You will need a strictly defined amount of primer, approximately 0.5 - 1 kg (cooked). It is necessary to apply a primer until a smooth, uniform surface is obtained, without streaks and gaps.

When the square is finished, weigh the remainder of the primer and subtract it from the starting weight. The result is the consumption of Betonkontakt per 1 m2.

Is it possible to reduce material consumption?

In theory, yes, but you shouldn't. The cost of Concrete Contact is not so high to save a lot.But the lack of a primer can lead to a number of negative consequences: cracking of the decorative coating, delamination and deterioration of waterproofing properties.

Thus, the first priority is to ensure a high-quality application of the primer, not to save it.

.

Material composition, properties and specifications

As follows from the certificate of conformity, the primer is a mixture of certain components:

- cellulose ether;

- vinyl acetate copolymer;

- limestone flour;

- quartz fine sand:

- additives of the fungicidal group.

p> The primer has the property of imparting roughness to smooth surfaces. It contains quartz sand, which helps to connect almost any building materials. The technical characteristics of the composition are as follows:

- the material has a high drying rate. Repair work is allowed to be resumed a couple of hours after its application;

- the primer has good moisture resistance. Primer Betonokontakt Knauf is considered a waterproofing finishing option, since after drying a water-repellent film appears;

- the primer is neutral in acidity, meets the requirements of GOST 28196 89;

- primer for concrete Knauf Betonokontakt is packed in buckets of 5 and 20 kg;

- shelf life of the material - up to one and a half years, if the container is hermetically closed;

- the pink tint of the material allows you to control the quality and uniformity of the application.

Possessing good protection from external damage, the primer layer will last long enough - up to eight decades.

The main property of the soil is the preservation of the moisture content of the leveling mixture, which creates uniform drying. Because of this, the plaster solution will not be covered with cracks, the mixture will improve adhesion, and reduce the consumption of liquid materials.

Knauf Betokontakt primer: characteristics and advantages of use

The main tasks of the Knauf Betokontakt primer are the adhesion of the plaster to smooth surfaces and the creation of a reliable, durable coating. It is functional, simplifies many stages of work associated with surface preparation and dismantling of the previous coating.

If earlier it was necessary to use several different compounds, now one Knauf Betokontakt primer is enough.

Typically, this soil is used in working with building materials that have the following characteristics:

- high density (concrete);

- moisture resistance;

- smoothness (glass, ceramics).

But experts note that concrete contact has the following properties:

- strengthening of weak loose bases (drywall);

- increased adhesive properties;

- resistance to alkaline compounds;

- leveling the surface;

- elimination of microcracks in the base;

- adhesion to any material.

These qualities of the Knauf Betokontakt primer extend the range of its application. It is perfect for preparatory and rough work before applying plaster on surfaces made of concrete, cement, drywall, various metal structures. The primer adheres tightly to the base and forms a rough-to-touch film that provides a high degree of fixation of the subsequent coating.

Manufacturers have created a universal composition, Knauf Betokontakt primer is used by specialists in working with wood, metal parts, decorative elements made of polystyrene. The resistance of the soil to alkaline compounds makes it possible to use plaster based on lime and gypsum.

Primer properties

Knauf Betokontakt not only strengthens weak surfaces and increases the adhesion of smooth substrates before plastering. The ability of an acrylic mixture to clog pores and microcracks allows you to reduce the consumption of viscous (liquid) finishing materials and retain water in the leveling solutions, which is necessary for their normal setting. Thanks to this, the plaster does not exfoliate and does not crack from the rapid loss of moisture.

The performance characteristics of the Knauf mixture are also noteworthy. For example, fungicidal additives are already included in its formula, which means that additional antiseptic treatment is no longer required. Concrete contact itself does an excellent job of protecting walls from mold, reducing your repair costs. To this it is worth adding also the good vapor permeability of the created intermediate layer - it does not interfere with diffusion air exchange between the room and the street.

In some way, the disadvantage of the primer is the need to quickly start further work as soon as Betonokontakt Knauf is dry. It is impossible to postpone finishing, and even more so in parallel to carry out other activities in the room - a rough adhesive layer easily accumulates dust, deteriorating the properties of preparation.

Characteristics and consumption

Primer Betonokontakt from Knauf is produced with a mineral filler of two fractions, on which the scope of application of a particular composition depends:

- 0.6 mm - used before rough leveling;

- 0.3 mm - it is worth purchasing it to prepare plastered surfaces before puttingty.

The pink pigment introduced into the composition allows you to control the application and not miss a single area during processing.

Knauf specifications:

- Acidity - neutral (pH 7.5-8.5).

- Drying time of the layer - from 3 hours depending on the humidity and temperature in the room.

- Service life - up to 80 years. Although the material is still too "young" to confirm or deny the manufacturer's claims.

- Wide temperature range of application - according to its characteristics, Betonokontakt can be called a primer for indoor and outdoor use. After drying, it retains its properties at -40 .. + 60 ° C, withstanding at least 5 freeze-thaw cycles.

- Possibility to apply in any convenient way (brush, brush, roller, mechanical spraying method).

- Absolute environmental friendliness - the use of an adhesive primer is allowed even in poorly ventilated rooms and does not require respiratory protection. There are simply no toxic solvents in its formula that can harm a person.

The consumption of the primer depends on the characteristics of the substrate: smoothness and porosity (absorbency). She will show the minimum result on tiles - 200 g / m2, on monolithic concrete of different densities, this figure will increase to 250-350 g / m2.

Recommendations for use

Knauf primer is already completely ready for application. However, before starting, it is recommended to stir it with a drill with a mixer nozzle at low speeds so that the fine-grained sand is evenly distributed throughout the volume. Work is carried out only after cleaning and dust removal of the base. In this case, the temperature of the wall to be treated must be within the range of +5 .. + 30 ° С.

Unlike many similar mixtures, here the manufacturer allows the primer to be diluted with water in order to reduce the consumption of material by 1 m2 and to simplify the painting of the dispersion composition. However, for manual application, the amount of water should not exceed 50 ml / liter. Firstly, too liquid solution will not allow you to create a continuous "coat". Secondly, the sand will quickly settle at the bottom of the tank and will have to be constantly mixed.

For soft substrates, as well as for application by spraying, it is allowed to dilute the mixture with water in a ratio of 2: 1. Alternatively, experts recommend using a different technology. It allows you to reduce the consumption of Concrete Contact by 1 m2, but at the same time get a high-quality result. Processing is carried out in two layers:

Price

How to use a primer

The diluted Betonokontakt retains its technical characteristics for at least a year. Since it has a water base, the thick fraction often settles to the bottom, while the liquid fraction stays at the top. This stratification does not mean that the product is unusable. It is simply mixed to a uniform consistency so that the layer of primer (as well as the strength of adhesion to concrete) is uniform.But the dried traces of the mixture on the walls of the opened bucket indicate that the period of its use has expired.

Priming with Concrete Contact is performed following several rules.

- First, dirt and oil stains are removed from the surface, peels are removed, and deep cracks are closed.

- Prepare or mix the solution thoroughly.

- Apply Concrete Contact with a wide brush or foam roller. In this case, short vertical and horizontal strokes alternate.

- Most often, one coat of primer is sufficient, but if the walls are too uneven, the treatment can be done in two steps. The second pass is needed if, after the first layer dries, flaws are noticeable, or it can be easily removed by hand.