Application area

Due to its strength, the clinker is used in the construction of terraces, entrances, as well as in the design of courtyards. With the help of clinker facade bricks, door and window openings are made out, porches, columns, and basements of buildings are decorated. Clinker tiles are laid out on winter terraces, in pools, on stairs. All this testifies to the fact that the material is able to withstand the most severe tests.

At the same time, clinker facade panels weigh less than tiles or bricks. Therefore, they are used not only for cladding newly built houses and buildings, but also for the repair and reconstruction of facade systems.

Plates without insulation are most relevant in three cases:

| For frame houses that were previously insulated. | For the installation of a ventilated facade system. | For hangars, warehouses, garages, which do not need to be insulated. |

Popular manufacturers

There are products from several manufacturers on the market. The best quality is demonstrated by the facing of German manufacturers. The most prominent representatives in this niche are Feldhaus Klinker and Stroeher.

Germany is also represented on the Russian market by the brands ABC, Rehaus and Korzilius.

Among domestic manufacturers, the Regent-Stroy brand should be noted.

Advantages and disadvantages

High consumer demand and a large number of positive reviews are due to a number of indisputable advantages of this material.

The design of the panels allows for a seamless facade cladding. This has a beneficial effect on increasing heat conservation and makes it possible to significantly save on heating of housing. The thermal conductivity index of a clinker slab with an 8 cm thick insulation layer is equal to the thermal conductivity of a 70 cm wide brickwork or a 40 cm thick aerated concrete wall.

- Simple installation and easy maintenance. Thanks to the universal “tongue-and-groove” fastening system, the facade cladding does not require the use of expensive tools and the involvement of specialists.

- The panels are highly resistant to ultraviolet rays, and therefore do not lose their original appearance for a long time, and do not require measures for their restoration and repair.

- The materials are not of interest to insects and rodents, and are not susceptible to mold and mildew.

- The presence of special gaps on the reverse side of the double-layer panels provides the necessary ventilation of the facade, which makes it possible to do without the installation of additional ventilation equipment.

- The tight connection of the panels to each other guarantees the absence of cold bridges, the presence of which can lead to the accumulation of condensate and waterlogging of the facade.

- The high soundproofing properties of the material will reliably protect the home from extraneous noise.

- Increased resistance to aggressive external environmental influences allows the panels to be used in any climatic zone. The material tolerates temperature extremes well, is not afraid of excess moisture and can last more than 50 years.

- The panels are lightweight, so that clinker cladding does not significantly affect the foundation and load-bearing walls.

- Possibility of installation in any season. The only limitation is the application of inter-grouting. Its installation can only be carried out at positive temperatures.

- The presence of additional elements for the decoration of external and internal corners, windows and openings greatly facilitates installation and gives the building a finished look.

The disadvantages of the material include its high cost, which is especially noticeable when facing buildings with two floors and above. The downside is the fragility of the clinker layer

Ceramic coating does not withstand mechanical stress and strong impacts, has low fracture strength and requires particularly careful storage, installation and transportation. There is also a poor vapor permeability of the panels, which, if the installation rules are not followed, can lead to excessive moisture in the facade due to the formation of condensation

Installation of facade panels with clinker tiles

Master of the house

can handle the cladding on its own. The main thing is to prepare everything

necessary materials with tools. And carefully monitor the implementation of all

installation requirements.

Preparation

Base surface

requires preparation before starting basic work.

Only when this part of the work is done will the walls last long enough.

Preliminary work for the exterior finishes of the house is performed in the following order:

- At first

carefully inspect the surface. If necessary - align everything

problem areas. The bulges must be removed. - Air conditioners,

shutters and other window, door structures are removed completely. - Take off

an old coating that used to serve as a decorative layer. - Priming

antiseptic mixture is excellent for pretreatment. Can

walk it over the surface several times.

Wireframes

Let's admit

an option when the sheathing is connected directly to the wall surface. But

installation will be difficult if there are the slightest depressions and bulges. The frame will provide

an even level of elements, will simplify the work. The base is made of wood, or

metal.

Construction

lathing takes place in several stages:

Identify

differences in the current plane.

The thread is pulled

on frame racks protruding extreme. After that it will be easier to determine

at what level the bar is attached. The lighthouses are mounted in the next step.

Lower

fastening also requires correct leveling.

Optimal

the direction of attachment is parallel to the ground. At the required height

make markings to obtain the most accurate results. By using

level, this markup will easily be transferred to the rest of the walls.

- By thread

upholstery in a straight line, along the entire perimeter. Further, on this basis, they attach

bars or metal profiles. - After

the attachments of the lower part go to the upper part. Separate framing - for

openings of windows, doors. They separately remember the necessary installation of slopes. 2 cm

the lumen is left along the window perimeter. - Planks

fixed in parallel with the rails, the mounting level is one. A plumb bob will simplify

work, control of parameters. - TO

the panels are often transferred after the installation of the frame part is completed.

Panel mounting

Assembly

clinker panels for exterior decoration - one of the technologies that do not require

additional efforts. The process is similar to putting together a jigsaw puzzle for children.

It is necessary to combine all the elements with each other so that one ready-made

surface.

Subsequence

the action in this case is as follows:

- A place

the beginning of the installation - the corner at the bottom of the first row.

Tightness

to other parts, they increase when the structure is cut by 45 degrees.

On

the panels are mounted on the lower rail.

The work is carried out

and using self-tapping screws. You can drill holes in the wall and insert dowels,

if the crate does not suit initially. The same technology is used to attach

the main material for cladding.

When

installation of the first panel is complete - proceed to the next.

The main thing -

make sure that the parts are tightly connected to each other. Fastening involves

the same technology as described earlier.

Further

installation goes round.

Only

completing the previous row will allow you to move on to the next. Panels

follow each other, go from below and from the right to the top and to the left.

- After

the end of the main work goes to the sealing of joints, polyurethane foam. - On

at each stage of installation, check whether the structure is aligned.

If there is

necessity - the clinker is moved until it takes its normal position. Otherwise

the structure will come out skewed, and the seams will lose their original strength.

- Sometimes

in the course of work, it becomes necessary to cut the finishing material.

The necessary marks are made by applying the material to the walls. - Next

stage includes processing of door, window openings. When facing, usually

use plaster. All edges are aligned with a plastic corner. - On

in the final stage, the seams are rubbed with a frost-resistant mixture.

Advantages and disadvantages

Clinker tiles are often the choice for the exterior of a home. This is due to its technical characteristics. But clinker itself does not have thermal insulation properties, while products from it, in combination with insulation, have conquered the market as an effective material for exterior and interior decoration of buildings.

Before using panels for exterior decoration of a wooden house and other types of buildings, you need to familiarize yourself with the positive aspects of the products:

- Possess

high strength indicators. - The service life is 25-30 years.

- Provide protection against ingress

cold inside the room. - They have improved performance

soundproofing. - They retain their color for many years, as in

raw materials are free from dyes. Different shades are achieved with the help of certain

varieties of clay and changes in baking technology. - Withstand extreme temperature fluctuations

environment. - They are not covered with mold and mildew, do not

attractive to rodents and insects. - Safe for the environment and health

person. - Allows you to reduce costs by 40%

payment for heating due to the low coefficient of thermal conductivity and the absence of joints. - Easy to install. You can insulate the house

faster due to the fact that the panel contains both insulation and cladding,

therefore, it is not necessary to first install the thermal insulation layer, and then

decorative layer. - Versatile, as it is suitable for

different buildings. - If you choose a hinged facade, then you can

hide any wall defects. - They are attractive and respectable.

appearance, ennoble the facade. - Waterproof and impact resistant

pair. - In case of mechanical damage

area, the panel can be easily replaced. - Suitable for all types of substrates.

- Have high rates

fire safety. - Do not freeze.

- Favorable price when compared with others

systems for building thermal insulation. - Resistant to atmospheric precipitation.

Due to such impressive characteristics, the cost of the material is higher than that of other types of facade finishes, as is the cost of work per m2.

Clinker thermal panels also have several disadvantages. Professionals and users say that the weight of the products is heavy, therefore, to install them, you need to additionally strengthen the facade and foundation, and during transportation, the panels can be easily damaged. If dropped from a small height, they will crack or burst. Therefore, the manufacturer's instructions contain information on how to handle them with care.

The main criteria for choosing panels for the facade

Since cladding panels not only give the house an attractive appearance, but also perform a number of protective functions, special attention should be paid to the choice of facade panels. Any homeowner expects the maximum service life of the cladding, long-term preservation of operational properties and an acceptable price of the material.

The appearance of the facade is certainly of great importance for the owner of the house, but one should not forget about the protective functions of the panels.The use of cladding allows you to protect the house from the negative effects of moisture, low temperatures, the spread of fungus and other harmful influences, including mechanical damage. In addition, some types of cladding materials can be used as outdoor insulation.

Any homeowner expects the maximum service life of the cladding, long-term preservation of operational properties and an acceptable price of the material. The appearance of the facade is certainly of great importance for the owner of the house, but one should not forget about the protective functions of the panels. The use of cladding allows you to protect the house from the negative effects of moisture, low temperatures, the spread of fungus and other harmful influences, including mechanical damage. In addition, some types of cladding materials can be used as outdoor insulation.

When choosing facade panels, special attention should be paid to the following main criteria:

- Operating conditions. The panels should be selected taking into account the minimum and maximum temperatures, the intensity of mechanical stress and other features;

- Possibility of self-assembly of the cladding. Installing panels on your own will significantly reduce material costs;

- The cost of the lathing and fixing accessories;

- Mounting method. Facade panels can be attached either to a special frame or directly to the walls;

- The presence of a heat insulator on the inner surface of the panel;

- Operational characteristics of panels, among which the most significant are:

- Environmental safety of the material;

- Antiseptic properties;

- Resistance to mechanical stress;

- Fire safety;

- Moisture resistance parameters;

- Warranty period of operation;

- The complexity of installation and the number of required auxiliary elements.

- The cost per m2 of cladding, taking into account the lathing, fasteners and other elements necessary for installation.

In addition to these criteria, it should be remembered that the low cost of panels is most often due to the use of short-lived materials and components, however, the high price of cladding is not always a guarantee of quality.

The nuances of choosing outdoor finishes

When deciding how to sheathe external walls, one should take into account the climatic features of the region, the type of insulation used and the purpose of the facade

Experts recommend adhering to the following rules:

- For rainy, damp terrain, it is better not to use block house and wood counterparts. Residents of cold regions should abandon metal siding, preferring thermal panels or DSP.

- Walls insulated with mineral wool can be revetted with siding, block house or clapboard. The least suitable option is plaster. The wet facade is applicable for polystyrene and its derivatives.

- If the main purpose of the cladding is decor, then the choice of material depends on the personal preferences of the owners of the house. If with the help of cladding it is necessary to additionally insulate the building, then it is better to use thermal panels and curtain facades (siding, fiber cement slabs).

The exterior decoration of the frame house is carried out with various materials. From the point of view of the ratio of price and quality, the most optimal options are: thermal panels and DSP sheets. Expensive cladding from a block house will be adequately replaced by composite planken, and it is better to refuse facade bricks and time-consuming plastering of walls.

How to calculate facade panels for a house

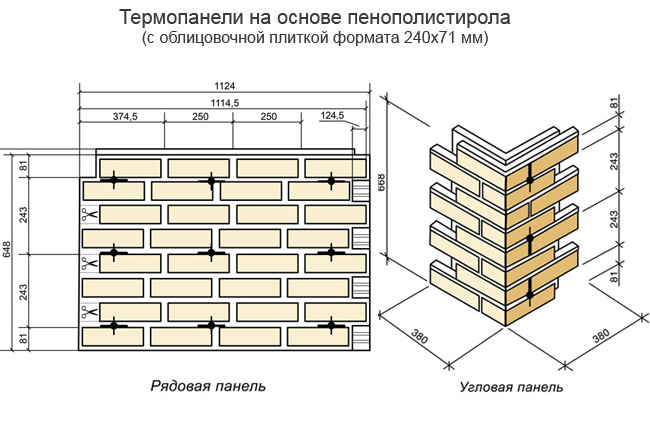

The calculation of front panels for the house is carried out according to the following instructions:

- First, we find out the area of the cladding. To do this, we multiply the perimeter of the house by its height. Then we subtract the area of the openings.

- Then we find out the area of one panel. To do this, multiply the height of the panel by its width.

- Finally, you need to divide the first value by the second. Those. the area of the house is divided by the area of one panel. We get the number of panels in pieces. Add a small margin of 5%. We can go buy.

Now let's look at an example.Let's say we have a house 6 * 8m, 3m high, there are 2 windows 1.2 * 1.8m and one door 0.9 * 2m.

- We consider the area of the cladding. The perimeter of a house is the sum of the lengths of its sides. Add 6 + 6 + 8 + 8 = 28m. Multiply by a height of 28 * 3 = 84m. Now we consider the area of the openings: windows 2pcs * (1.2 * 1.8) + 1 door (0.9 * 2) = 4.32 (window area) + 1.8 (door area) = 6.12m is the area openings. Now we subtract the area of the openings 84m - 6.12m = 77.88m from the cladding area.

- We find out the area of one panel. Height 0.648m, length 1.124m. So 0.648 * 1.124 = 0.73m.

- We calculate the number of panels in pieces. We divide the area of the cladding by the area of the panel 77.88m / 0.73m = 107 pcs. We add a stock of 5%, we get 112 pieces.

Now we calculate the corner panels in the same way. And subtract the corner panels from the ordinary panels.

For 100% accuracy in the number of panels, it is necessary to lay out the cladding on the drawing.

The simplest thing is to contact the manufacturer, as an accompaniment to the sale, they are free of charge and will probably count everything for you with high quality.

Features of clinker panels

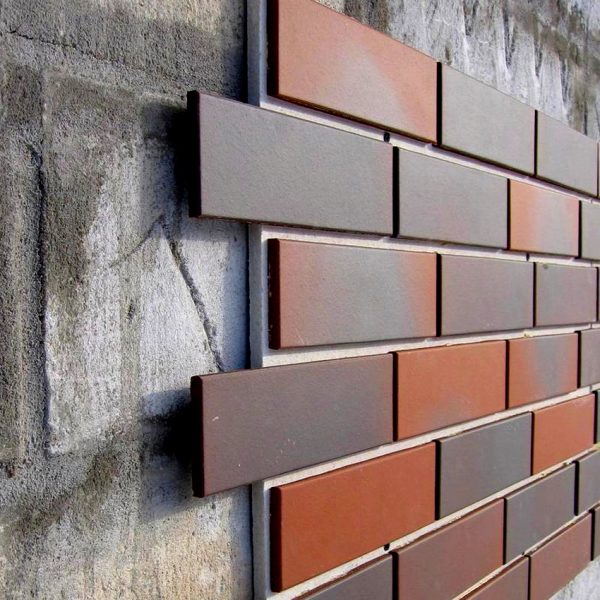

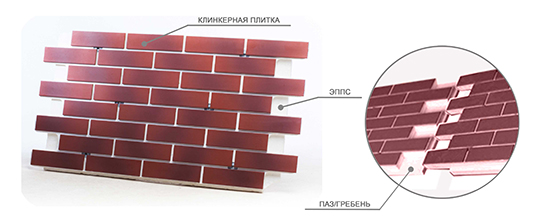

Clinker panels are so named because their outer layer is nothing more than a thin clinker tile. Most often, it imitates the texture of bricks of different colors. The edges of the panels resemble a comb, and therefore, at the junction, the joints of the separate fragments remain invisible to the eye even upon close examination.

The clinker has a very dense structure and almost no pores. In this regard, moisture does not penetrate inside, but slides over the surface.

Slabs with decorative clinker coating are two-layer and three-layer. In the first case, the clinker layer is supplemented with a layer of DSP or OSB. In the second, there is also a middle layer in the form of foam or more durable and high-quality extruded polystyrene foam. Such products are called clinker thermal panels.

Review of some Russian manufacturers of facade thermal panels

-

Russian company that has been producing thermal panels based on polyurethane foam since 2004. A distinctive feature of the product is the presence of special paper on the back wall, which acts as a waterproofing, and also allows the house to "breathe" due to a small gap.

Panel characteristics table

Tile Area, m2 Thickness, mm Insulation Price from Ceramika paradyz 0,63 30/60/80 PPU 1250 RUB Cerrad 0,63 30/60/80 PPU 1180 RUB Falcon 0,58 30/60/80 PPU 1105 RUB ABC 0,65 30/60/80 PPU RUB 1615 Feldhaus 0,65 30/60/80 PPU 1830 RUB Strohers 0,65 30/60/80 PPU 1830 RUB Ammonit 0,65 30/60/80 PPU 1970 RUB WesterWalder 0,65 30/60/80 PPU 1840 RUB -

Warm facade

A Russian company that has been producing thermal panels based on extruded polystyrene foam (penoplex) plates since 2012. The decorative element is clinker tiles of Russian, Polish and German manufacturers.

Panel characteristics table

Tile Area, m2 Thickness, mm Insulation Price from Cerrad 0,61 50/80 EPPS RUB 980 Paradyz 0,61 50/80 EPPS RUB 945 ABC 0,65 60/80 PPP 1555 RUB Falcon 0,48 50/80 EPPS 800 RUB Kamrock 0,48 50/80 EPPS 1250 RUB -

E-Klinker

The company produces panels with Polish and German EPS clinker tiles. Has been working since 2010. Also offers decoration and visualization services.

Panel characteristics table

Tile Area, m2 Thickness, mm Insulation Price from Cerrad 0,55 40+ EPS RUB 880 Feldhaus 0,58 40+ EPS — Roben 0,58 40+ EPS — The company provides turnkey installation services. There are no instructions for independent work.

-

Plitker

The company produces thermal panels based on German and Polish clinker tiles. PPU is used as a heater. Has all the necessary certificates, free shipping. And also provides installation services.

Tile Area, m2 Thickness, mm Insulation Price from Cerrad 0,63 20/40/60 PPU RUB 865 Paradyz 0,63 20/40/60 PPU RUB 935 ADW Klinker 0,69 45/65 PPU 1070 RUB ABC 0,69 45/65 PPU 1520 Stroeher 0,65 45/65 PPU 1725 -

Fraid

One of the first companies in this area. Has been working since 1994. Participant of many construction exhibitions and awards.

Tile Area, m2 Thickness, mm Insulation Price from Feldhaus 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 RUB 2500 Estima 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 1350 RUB Cerrad 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 1680 RUB Falcon 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 1390 RUB Kerama Marazzi 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 1635 RUB Opoczno 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 RUB 1,750 Paradyz 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 1650 RUB Roben 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 RUB 2740 Keramin 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 1350 RUB Stroeher 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 2520 RUB A.D.W. Klinker 0.5 or 1 50/100/150 or 30/60/80/100 Expanded polystyrene PSB-S35 RUB 2140

Technical Advantages

- Thermal panels make it possible to combine exterior design, heat and sound insulation. You don't have to schedule and spend work separately, which ultimately saves time and money.

- High strength of clinker material and its resistance to negative temperatures, moisture and acids. In fact, a set of these properties guarantees the insulation of the main wall from destructive atmospheric influences.

- The surface does not require additional maintenance and retains its original appearance for decades. Clinker tiles have been known in Europe since the 15th century, and they were used not only for decorating buildings like brick or stone, but also for arranging road surfaces. In fact, this material is not inferior in durability to natural stone.

- The materials used in the panel are not susceptible to mold growth. This quality is unlikely to be superfluous for any residential buildings, in addition, it guarantees no additional costs for cleaning in the future.

- Fire resistance. If for buildings made of brick and concrete this parameter is secondary, then for wooden structures it can significantly increase the protection from the elements and, as a result, your safety.

- A wide selection of colors and textures and an excellent appearance. Currently, more than three hundred solutions can be counted, and with the growing popularity of clinker, this number continues to grow.

Mounting advantages

- Light weight (20-25 kg per 1 m2) allows for installation alone and does not require reinforcement of the foundation.

- Installation of panels is less time-consuming in comparison with clinker or ceramic tiles.

- Facade panels allow you to install both the insulating and the decorative layer at the same time. In this case, the fastening is carried out with dowels and screws along the already mounted guides.

- Seamless installation ensures the integrity of the heat-insulating layer.

- Can be attached to all types of building surfaces (concrete, brick, wood, gas silicate blocks).

- No special preparation of the wall and construction equipment is required.

- The ability to perform installation work at low temperatures, in contrast to the installation of thermal curtains described in the material.

- Lack of visible joints.

- Does not require wall alignment.

Construction of facade thermal panels

Ready-made blocks of thermal panels are designed for

external decoration of buildings. But sometimes designers use them internally.

premises. Finished panels do not weigh down the walls, do not create excessive pressure

on the foundation.

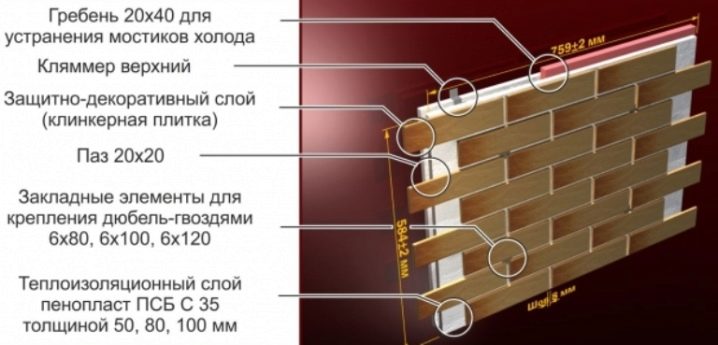

Thermopanels are structurally layered

pirogue.

- The top layer is decorative. Layer drawing repeats brick or

masonry. It also performs the protective functions of the main layer from

actions of nature. - The main layer serves as thermal insulation. For its manufacture

polystyrene foam and polyurethane foam are used.

The panels are manufactured at the plant according to the latest

technology using special matrices. High precision connection

panels masks possible installation defects. Panels are never created

cold bridges. The mount is reliable and can withstand even the force of slanting rain.

Decorative panels with imitation stone or

bricks are in demand by consumers due to their decorative qualities. Imitation

natural stone is difficult to distinguish from masonry. And take care of him

easy - it is enough to clean it from dust once a year with a damp sponge. Panels

beveled hidden edges that provide a seamless finish. Finishing type

under the stone is resistant to fading in the bright sun. No scratches appear on it.

Thermal panels for brick are popular and are considered traditional. They are suitable for many structures, buildings. There are many proposals for choosing the color and texture of bricks.Brick color can be white, yellow, gray, red, terracotta. Aged or burnt in appearance, with a rough or smooth surface.

Glass products

Not quite ordinary products, original and high quality. Most often they can be seen on administrative buildings, supermarkets, sports facilities and the like. This is a representative class that not everyone can afford. However, there are homeowners who decide to sheathe their home with fragments of glass panels.

There are three classes of products:

- Impact resistant materials are identified with the “A” mark.

- Vandal-proof are marked with a "B" marker.

- Protected from bullets are designated by the letter "B".

For finishing the exterior walls of the house, special glasses are used: reinforced type, tempered and laminated (also called triplex).

- Reinforced glass panels are produced with a thickness of at least 6 mm. At the same time, glass for facing can be painted in a certain color, be transparent or decorated with decoration: matting, mirror surface, translucent and transparent.

- Panels made of glass granulate. On the back and front side, they are reinforced with a reinforcing mesh. Thickness is large, about 26 mm. The outer part is additionally equipped with glass. It can be painted, decorated with stone chips or metal plates. Thanks to this, the cladding can imitate precious metals.

- Crystallized cladding panels. Their feature is their increased strength due to their composition. They are made from inorganic constituents under conditions of creation similar to the natural formation of granite. Surprisingly, in terms of their characteristics, materials are superior to products made from artificial stone. And due to the low coefficient of heat conductivity, the cladding protects the room from the cold and does not allow street noise to pass through so much.

The disadvantage of all glass panels for walls is high cost and complexity of installation. Only professionals can correctly perform all calculations and draw up a project.

As for the installation process, there are 3 options:

- Classic, another name is crossbar. The whole process is reduced to the installation of the selected glass panels in an aluminum frame and subsequent fixation using special clamps.

- Frameless method. In this case, the facade looks very original and modern. In this case, special cassettes are used for finishing. They are made of aluminum profiles and glass. Fixing the cassettes to each other is possible thanks to the holes that are pre-drilled in the aluminum frames. So that the joints are not a weak point of the facade cladding, they are sheathed with a sealant. This creates a monolithic protected structure, in which the frames are practically invisible.

- Spider method. This option applies only to public buildings. There is no way to do it yourself. Only trained specialists will be able to fully and efficiently cope with the task. The system has no frames, it is made exclusively of glass panels. In turn, they are connected to each other by means of clamps, which are called spiders.

Styrofoam or polyurethane foam?

Evaluation of a particular material is based on its technical characteristics, operating conditions and consumer opinions. The use of expanded polystyrene and polyurethane foam in panels under the same conditions allows us to compare and obtain data for an objective conclusion.

Environmental Safety

| Expanded polystyrene | Polyurethane foam |

|---|---|

| The material is biologically neutral and environmentally friendly.

That is why it is used not only in the insulation of various structures, but also in light industry as a filler for upholstered furniture, pillows, etc. |

The material is capable of self-oxidation in air, which leads to the release of peroxide. At temperatures above +80 ° C, mechanical destruction begins and phenol is released. |

Properties

| Expanded polystyrene | Polyurethane foam |

|---|---|

| Water vapor permeability - 0.05 mg / (m h Pa)

Water absorption - 0.4% by volume Thermal conductivity - 0.038-0.041 W / (m · K) |

Water vapor permeability - 0.05 mg / (m h Pa)

Water absorption - 1-3% by volume Thermal conductivity - 0.019-0.035 W / (m · K) |

Performance characteristics

| Expanded polystyrene | Polyurethane foam |

|---|---|

| It is not destroyed under the influence of fungi and microorganisms, but it can become the basis for the development of their colonies.

Due to the presence of voids and a high coefficient of moisture absorption, it is possible for moisture to enter the material and its subsequent destruction at low temperatures. Service life - about 15 years |

Mold and moss colonies are not formed on the surface of this material.

Provides reliable waterproofing, accordingly, there are no structural changes in the material, even in conditions of significant temperature changes. Service life - about 60 years |

Conclusion: all things being equal, polyurethane foam is the most acceptable option.

Decorative coating. Which is better?

Manufacturers offer several options for finishing panels: porcelain stoneware, concrete, ceramics, clinker tiles, etc.

| Decorative coating | Peculiarities |

|---|---|

| Porcelain stoneware | Neutral to chemicals, wear-resistant, not exposed to dirt, does not absorb moisture |

| Ceramics | Has similar characteristics to porcelain stoneware, but has less strength |

| Concrete tiles | Not suitable for climates with sudden temperature changes, as it has a high moisture absorption coefficient. More expensive options for concrete tiles have an additional protective layer against moisture penetration |

| Clinker | The most common and optimal decorative coating |

The Russian companies listed above can be divided into two categories. The first is a complete production with the manufacture of both an insulating layer and a decorative coating, the second is the purchase of foreign-made finishing materials with the subsequent manufacture of finished products. The cost of the panels depends on the choice of finishing material and the thickness of the insulation.

Types and characteristics of thermal panels for facades

At the factory, in the manufacture of panels, clinker tiles with polymer insulation are connected with glue or simply pressed into it. When using the second version of this facing material, the facades of the houses last longer. It is more reliable and durable. However, the price of pressed panels is higher than that of glued products.

The cost also depends on the place of production. Front thermal panels from German manufacturers will cost more than those made in Russia. This is affected by the payment for the brand and the transport shoulder to the house being built. However, their quality and the resulting facade will definitely be at their best.

for finishing country houses depends on primary raw materials. If the heat insulator and facing tiles are taken on their own, then the product is cheaper. And if everything is German, then the cost will be quite high.

However, you should not save too much on your own house, it is being built for yourself. In addition, the technology at such enterprises is often controlled by representatives of a German or other European company that developed the manufactured facade cladding. And this significantly reduces the risk of purchasing low-quality panels.

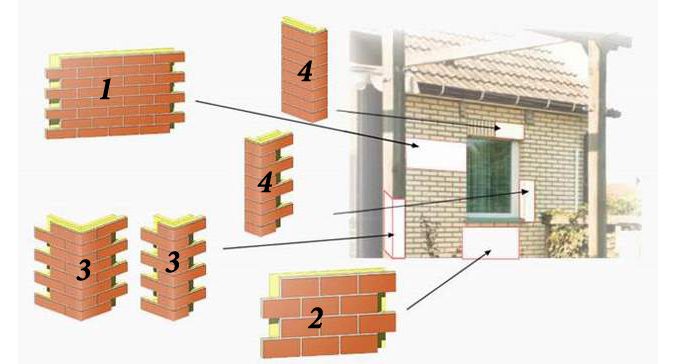

According to the purpose and place of installation on the facade of the house, clinker panels are divided into:

-

Privates (front and basement);

-

Corner L-shaped for corners of houses;

-

Corner add-ons for framing window slopes.

1-row front, 2-row basement, 3-corner, 4-additional

By weight and size

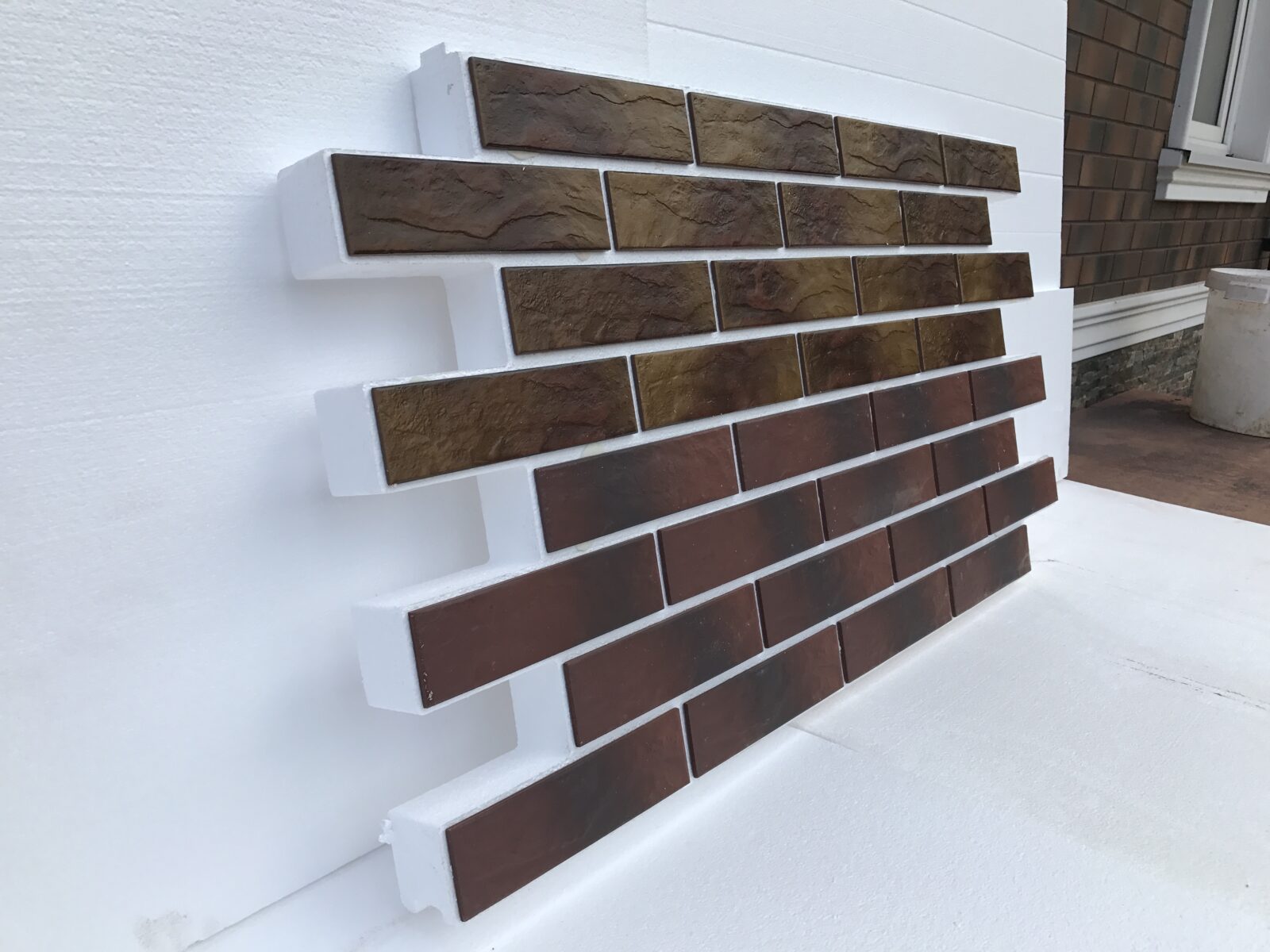

The weight and degree of thermal insulation of a thermal panel with clinker tiles is determined by the thickness of the insulation and the dimensions of the clinker. The insulator layer varies in the range of 30–100 mm. Thin panels are designed for outbuildings and private house facades that are already warm.Products with thicker insulation are used when not only a beautiful finish is required, but also high-quality thermal insulation.

The thinner the tile, the lighter the panel. It is the clinker that makes up the bulk of the considered cladding for the facade. The polymer heat insulator weighs an order of magnitude less. The thickness of the clinker tiles can be from 8 to 12 mm. The larger it is, the more beautiful is the design of the facades of houses. The total weight of the panel can be up to 16-17 kg.

In terms of dimensions, facade thermal panels differ greatly from different manufacturers. This is affected by the technology used at the factory, the dimensions of the tiles taken for the manufacture of the facade cladding and the presence of grooves at the end. Ordinary panels can have the following width and height in millimeters - 760x600, 1040x600, 1140x690, 1250x600, 1560x624, 1590x598, etc. Corner elements in most cases for the facades of private houses are produced with a width of one clinker tile - 240, 245 or 265 mm.

Varieties

Clinker panels are available in two- and three-layer versions. Three-layer models consist of a ceramic layer, expanded polystyrene and an additional heat-insulating base, with the help of which they are attached to the facade. An additional layer can be made of fiber cement, glass magnetic or oriented strand board. Fiber cement is characterized by environmental friendliness, good strength and durability. The glass-magnetic base attracts with flexibility and makes it possible to clad curved walls, and a slab on a wooden base has high noise and heat insulation properties, is lightweight and low in price.

Each slab, regardless of the number of layers, has special holes and fixing grooves. In the process of manufacturing three-layer models based on expanded polystyrene, a technology is used that provides closed perforation, which provides the finished product with a minimum vapor exchange. However, it should be borne in mind that the existing vapor permeability indicators are insufficient for full ventilation, therefore, clinker panels are not recommended for finishing the facades of wooden houses.

Two-layer models consist of a clinker decorative layer and a base made of OSB or DSP, and are intended for cladding facades that do not require insulation, or for those buildings where insulation has already been installed. Their main advantage relative to three-layer slabs is good vapor permeability, which is due to the absence of an insulating layer. Thanks to this quality, the walls of the facade have the ability to breathe, and excess moisture is easily drained outside. The service life of lightweight panels is 25 years. By location, the panels are divided into thinner wall and thick basement options. The height of the ceramic layer of the latter can reach 1.7 cm.