Choosing glue

To find the right dry mix from Eunice, carefully read the comparison table, which presents the entire range of products of this company:

- Glue for tiles Yunis XXI has two production options - exclusively internal work (place of production in Moscow), and internal / external work (place of production in Chelyabinsk and Ulyanovsk).

- Prices are as of 2015.

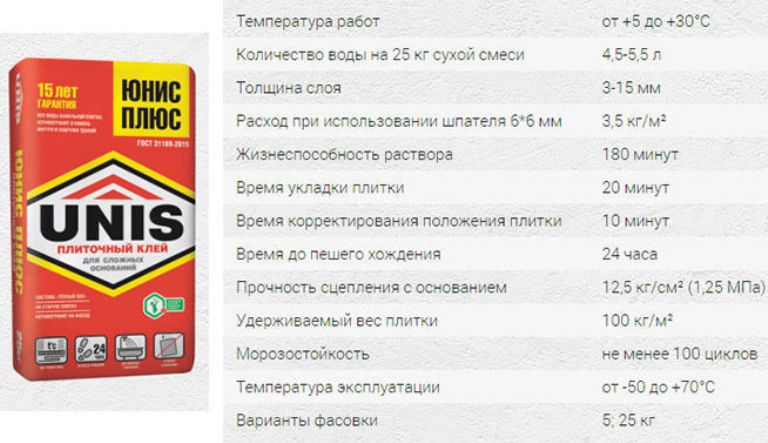

Eunice Plus

The main distinguishing feature of Unis Plus glue is its versatility. You can lay tiles, mosaics, stone, porcelain stoneware on it. Another significant plus of this material is strength. Adhesion of ceramic tiles and porcelain stoneware - 1.25MPa, withstands a maximum weight of 100kg / m2. It is possible to carry out both internal and external work, except for the cladding of the basement floors. Complex foundations are made from it under a warm floor and even over an old tile. Certified as a material safe for health, therefore it is approved for use in kindergartens, schools and other institutions. It is laid on a solid base - non-deformable concrete, cement, brick, gypsum.

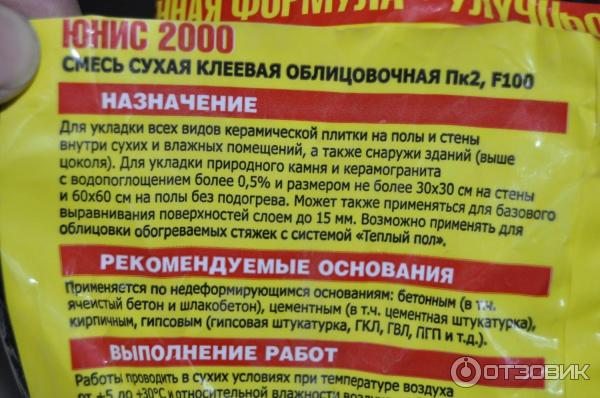

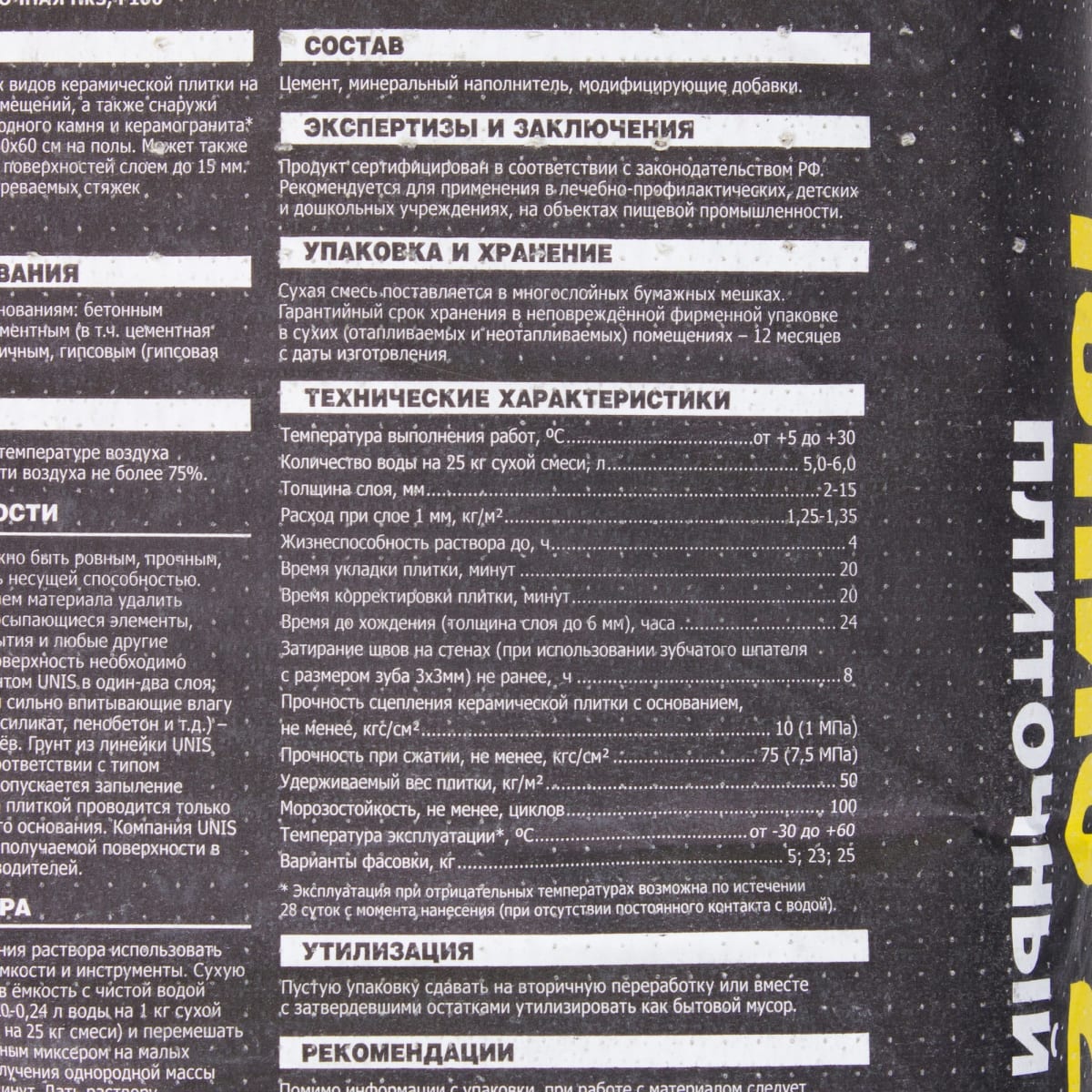

Eunice 2000

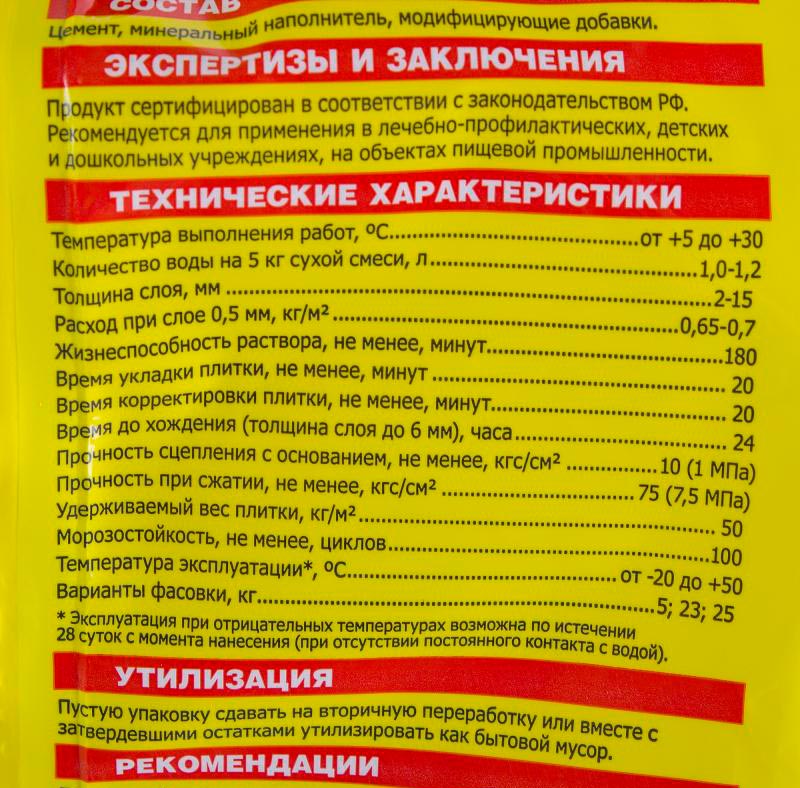

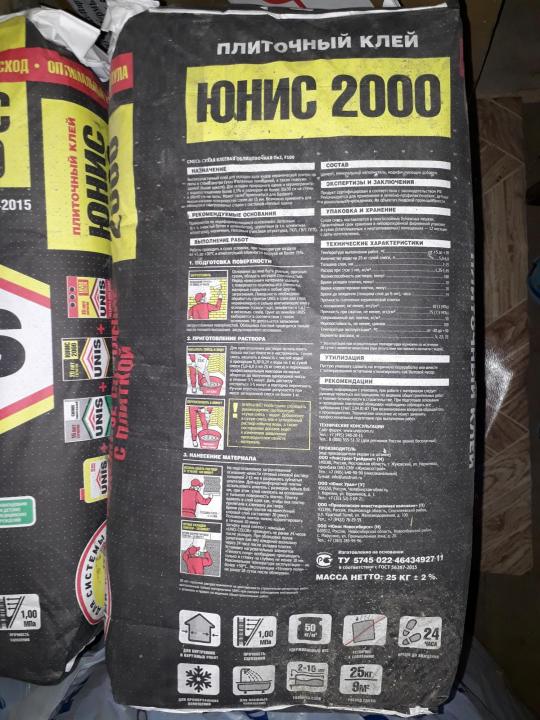

With the help of Eunice 2000 tile glue, wall and floor ceramic tiles and porcelain stoneware with a size of 60 * 60 are glued, and interior and exterior works are performed. It can be used as a leveling layer, perfectly filling irregularities in the substrate during installation. Suitable for strong concrete, plaster, cement and masonry substrates.

In terms of safety, it is a complete analogue of the previous composition.

Eunice XXI

Eunice XXI tile glue is used for typical internal and external work - cladding floors and walls with ordinary tiles. It is used in rooms with high humidity and the likelihood of freezing in winter. Suitable for installing small porcelain stoneware - within 30cm and only on floors.

- Maximum loads in subzero temperatures are possible only after 28 days, and then only if there was no systematic contact with water during this period.

- Tile adhesive UNIS XXI has two production options - exclusively internal work (place of production in Moscow), and internal / external work (place of production in Chelyabinsk and Ulyanovsk). If internal work is carried out, then the layer should be a maximum of 10mm, if external - 15mm. The adhesion level is 0.5 and 0.7 MPa, respectively.

Eunice HiTech

The main purpose of the HiTech mixture is to work with complex substrates: ceilings, walls, floors. Installation can be carried out not only from the floor, but also from the ceiling. Differs in a rather long lifetime of the solution. Can be used in children's and medical institutions. One 25 kg bag is used for 7m2 of cladding.

Eunice Granite

Large and heavy natural stone and porcelain stoneware floor slabs are installed using Eunice Granite tile adhesive. They cover floors, walls, facades, plinths. Can be placed over old tiles and underfloor heating systems. The glue is thick enough, so it does not slip during the hardening period. Can be used in childcare facilities.

Eunice Granite is distinguished by increased adhesion strength - 1.5 MPa. If we compare it with a similar indicator from other manufacturers, we see that Hercules Elastic GM-195 has it exactly the same, and Ceresit CM 17 has only 1.3 MPa.

Eunice Belfix

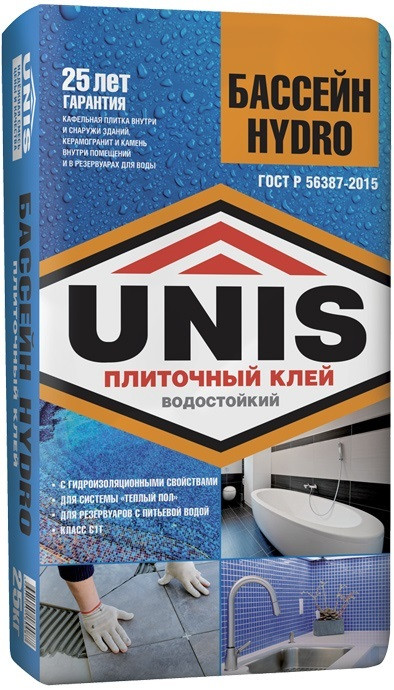

Eunice Belfix mix is produced in a non-standard white color, because it is used for laying marble, glass mosaic, natural stone, for which ordinary cement mix is categorically contraindicated. Differs in increased elasticity and frost resistance. Place of application - walls, floors, liquid tanks, rooms with high humidity, outdoors, heated floors. Can be used as a grout.The cost is higher than that of other types of adhesives - you need to pay 418 rubles for a 25 kg bag.

Unis Fix

Relatively inexpensive, but not the most reliable glue. Has a fairly high consumption, it does not appear on sale often. It is used for tiling on walls and floors in bathrooms, kitchens, terraces, balconies. Works with regular tiles.

Adhesive consumption per 1 m2

To calculate the adhesive consumption, you need to read the manufacturer's instructions on the packaging. The average is 3.6 kilograms per square meter, it is taken into account that the layer thickness will be 3 mm. If you plan to make a thicker layer for the size of the tile, then you need to make a calculation based on these data.

When working, you need to ensure that the composition does not get into the eyes, you can resort to putting on glasses, or do the work carefully.

Unis 2000 tile adhesive is a domestic solution that allows you to get an excellent result. It stands out for its high indicators of the strength of the tile connection to different bases. Among the analogues, it occupies a leading position, being a strong competitor, to the products of Hercules and Ceresit. It is easy to work with glue, it is safe for health, and can be used in children's rooms, for cladding work, withstanding environmental influences for many years.

Advantages and disadvantages

Unis Plus tile adhesive has a lot of advantages, due to which it is in demand among professional craftsmen in the field of construction and ordinary buyers. For example, it is an ecological raw material for construction and finishing works. It does not emit toxic substances, therefore it is harmless during installation, as well as during the entire operation of the finished coating. It is produced using modern technology, which allows to achieve high quality dry mix and a high degree of adhesion. Due to the sufficient life cycle that the adhesive possesses, the master tiler has enough time to lay each element and adjust it.

The mixture solution is economical and in most cases eliminates overruns. It is easy to work with as it can compensate for minor irregularities in the subfloor during tiling. The size of the tiles can be any - from small 10x10 cm to large 60x60 cm. The glue is resistant to various temperature fluctuations. Unlike many other compounds, it can be used for cladding walls and floors in rooms with a high degree of humidity. For example, it perfectly copes with the cladding of the bathroom and kitchen, it is appropriate for laying the floor in the hallway, on the balcony or loggia. If you use it over the "warm floor" system, you can use the coating after 28 days from the end of the work.

The mixture is characterized by an acceptable cost, which allows you to expand the circle of buyers, and will not hit the budget when facing with glue of large areas is planned. It is a fortified balanced formula. The composition stands out from the general line of the domestic manufacturer not only for its plasticity, but also for its ease of preparation. It is classified as a professional team. He is included in the rating of the best plaster mixes.

One of the disadvantages of Unis Plus glue is its color: the gray tint does not allow using the composition for transparent and translucent veneering materials, since the base color of the veneer will be disturbed

It is important to consider the size of the large cladding. For example, it is impossible to glue stone with this glue, the weight of which exceeds 100 kg / m²

In this case, the area of the slab should not exceed 0.35 m². In addition, for a flawless and durable finish, you need to carefully prepare the base, which will take not only time, but also additional spending on primer and plastering material. The material is not designed for global leveling of the base, the maximum defect should not exceed 5 mm in depth. Another disadvantage is the fact that the composition does not provide for cladding at sub-zero temperatures, despite the fact that operation in the cold is possible.

Nuances of use

Eunice 2000 tile adhesive can be used in bathrooms, terraces and balconies.

Its constituent components do not emit toxic elements, because only cement and natural fillers are used in the composition, to maintain safety, additional elements were selected separately. When working on laying tiles on the wall, it is necessary to carry out the work, starting from the top, moving smoothly to the bottom. The mixture is distinguished by its plastic quality, the presence of water in the finished mixture does not affect the base, while maintaining the strength properties when fixing the finish. To preserve the properties of the mixture during storage, packaging in the form of bags is used, with additional protection from moisture. Can be stored in a closed bag for up to 12 months. The products have a quality certificate.

When working on laying tiles on the wall, it is necessary to carry out the work, starting from the top, moving smoothly to the bottom.

How to apply correctly

To get the desired result, you must do the styling correctly. They begin work with surface preparation; the final result will largely depend on the quality of the base. Preparatory work consists of the following stages:

Eliminate the old finishing material.

Achieve evenness of the surface, you can use glue for drops of up to 1 millimeter per square meter, in other cases it is advisable to use plaster, the best choice would be to use a plaster mixture of the same manufacturer.

If gluing is done on an old tile, then notches are made on the surface of the material. They need to be done in a checkerboard pattern.

This action will improve adhesion.

The surface must be clean, remove all types of dirt, also degrease the wall or floor.

In rooms with high humidity, it is advised to use waterproofing of the same brand.

The surface is primed with 1-2 layers, if the work is carried out on a foam concrete or gas silicate base, then this point is given special attention.

In rooms with high humidity, it is advised to use waterproofing of the same brand.

In rooms with high humidity, it is advised to use waterproofing of the same brand.

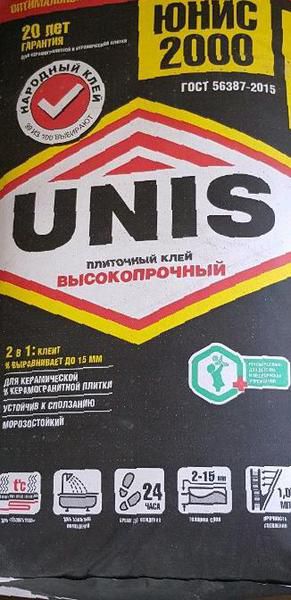

Eunice 2000, according to the instructions, should be bred in this way:

- A clean container is selected where the mixture will be stirred; the stirring tool must also be clean.

- The mixture is added to the water collected in the container in the required amount, mixed with a construction mixer, or with a drill with a nozzle, mix for about 3-5 minutes until a homogeneous mass without lumps is obtained.

- Then leave the solution for 5 minutes.

- After this time, the composition is again interfered with.

- It will be possible to use the ready-made glue within 3 hours, if the composition solidifies during this period, then you can mix it again, you cannot add water.

The ready-made glue can be used within 3 hours.

The ready-made glue can be used within 3 hours.

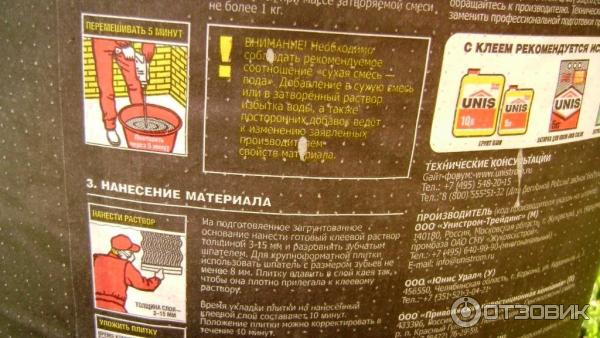

It is important to strictly observe the proportions indicated by the manufacturer in order not to lose the properties of the glue. The application process itself is done as follows:

- On the prepared surface, using a trowel, or a standard spatula, apply the composition (thickness 5-15 mm), then carry it over it with a notched trowel.

- For large tiles and porcelain stoneware, choose an 8 mm notched trowel.

- After that, the tile is pressed onto the applied layer, while the glue should be evenly distributed over the surface of the tile, for this, tapping is carried out with a rubber hammer.

- You should not immediately cover a large area with glue, the possibility of adjusting the position of the tile remains only 10 minutes, so the amount is calculated for this time.

- If the work is carried out outside the building and the tiles are large, then glue must be applied to the tiles as well.

- The evenness of laying the tiles is checked using a building level; to maintain this parameter, special crosses are used.

- The allowable time for starting walking on the floor is 24 hours, at the same time trowelling work can be carried out.

- The warm floor can be turned on only after 28 days.

The evenness of laying the tiles is checked using a building level; to maintain this parameter, special crosses are used.

Consumption rates of tile adhesive by brand

We have already said that the brand of glue affects its consumption during facing work. The manufacturer provides this information, but warns that this figure is approximate, so you should not rely only on it.

Consumption rate

Consider the most popular construction brands that produce these products. To begin with, we give general figures for a specific brand:

Eunice brand - from 1 to 1.16 kg per 1 mm of layer.

Eunice

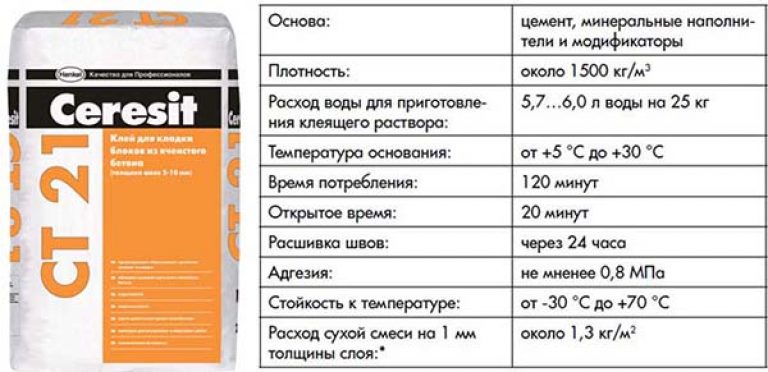

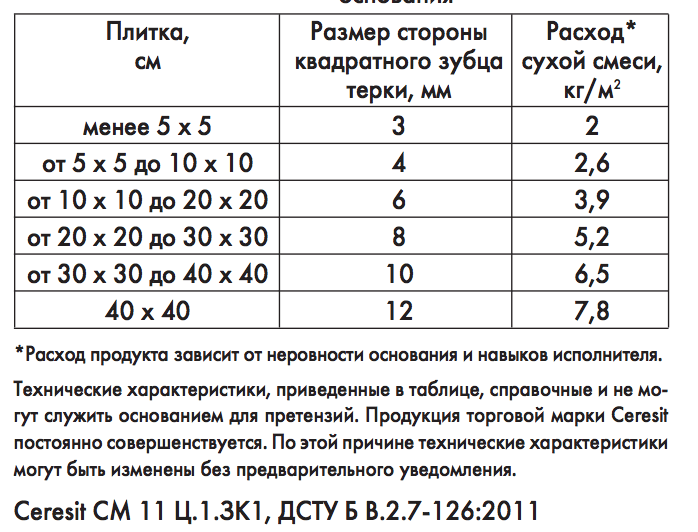

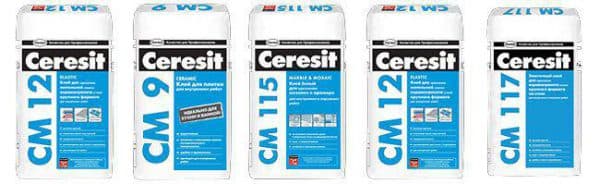

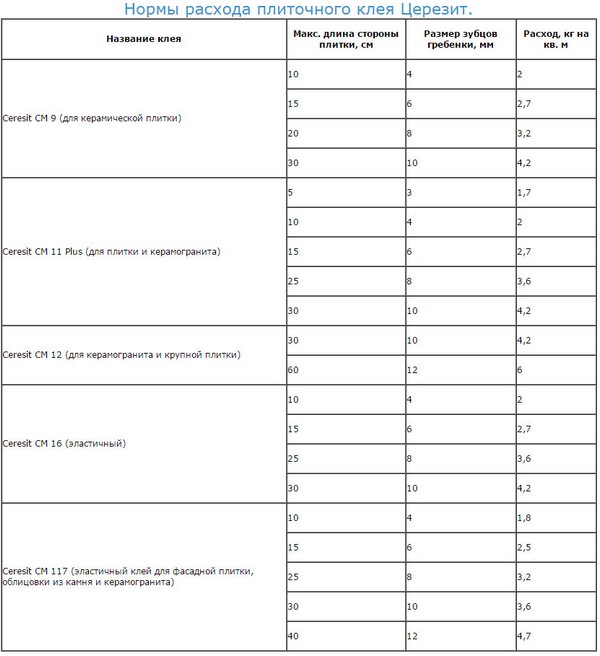

Ceresit brand - from 1.4 to 1.6 kg per 1 mm layer. If the layer is from 2 to 8 mm, then the consumption will be from 1.5 to 6 kg.

Ceresit

Litokol brand - from 1.3 to 1.5 kg per 1 mm layer. With a layer of 2 to 8 mm, the consumption of glue will be from 2.5 to 6 kg.

Litokol

Hercules brand - 1.5 kg per 1 mm layer.

Hercules

Mapei brand - from 1.2 to 1.6 kg per 1 mm layer. With a layer of 2 to 8 mm, the consumption will be from 2 to 8 kg.

Mapei

Let us consider in more detail the consumption of glue, depending not only on the manufacturer, but also on the specific type of its products. To begin with, consider the consumption per 1 m2 of Eunice tile adhesive.

Here are the varieties of her glue and their consumption per square meter:

Clay Eunice XXI - consumption is almost 1.2 kg with a layer of 2 mm. If the tile is large, i.e. you have to make the layer thicker, then the consumption increases. For example, a 6 mm layer will require 3.5 kg of adhesive per square meter.

Eunice XXI

Eunice 2000 - consumption will be the same as in the previous version.

Eunice 2000

Eunice Pool - consumption will be 1 kg per 1 square measure with a layer thickness of 1 mm. With a layer of 6 mm, 3.1 kg will be required.

Eunice Pool

Eunice Granite - the consumption of tile adhesive Eunice Granite per 1 m2 will be the same 1 and 3.1 kg with a layer thickness of 1 and 6 mm, respectively.

Eunice Granite

Yunis Plus - the consumption of tile adhesive Yunis Plus per 1m2 will be 1.16 kg at 1 mm layer, and 3.5 kg at a layer of 6 mm.

Eunice Plus

Below are the different types of this glue that can be freely purchased in our country:

- Ceresite CM 9 - consumption is 1.6 kg at 1 mm layer. If the layer is 2 mm, then 4.2 kg will be required for facing one square meter.

- Ceresit CM 11 Plus - consumption is 1.5 kg at 1 mm layer.

- Ceresite CM 12 - consumption is 1.6 kg per 1 mm layer.

- Ceresite CM 117 - glue consumption is 1.4 kg per 1 mm of layer.

- Ceresit CM 16 - glue consumption is 1.5 kg at 1 mm layer of applied glue.

For products from the Litokol brand, the following consumption of adhesive will be characteristic:

- Litoflex K 81 - consumption of tile adhesive per 1 sq. M is 1.35 kg (hereinafter we mean 1 mm of adhesive layer).

- Litoflex K 80 - the consumption of adhesive for ceramic tiles is 1.35 kg.

- Litoflex K80 eco - the consumption of glue for porcelain stoneware tiles will be about 3 kg.

- Litokol X 11 - consumption is 1.35 kg.

- Litofloor K66 - consumption will be equal to 1.5 kg.

- Litokol K 77 - the composition of this adhesive is perfect for laying tiles on the floor. Consumption will be about 1.3 kg with a layer of 1 mm. It is worth noting that the glue is applied not only to the surface, but also to the tile itself, so the total amount of glue spent will be higher.

- Litokol K 47 - the consumption of this glue will be the same as in the previous case.

- Litoacril Fix - it contains synthetic resins, and the consumption of glue will be about 1.5 kg. This indicator is typical for tiles whose size does not exceed 15 by 15 cm, but for large tiles (45 by 45 cm), at least 4 kilograms of glue will be required.

Excellent mixtures are considered to be Kreps. This is an ideal value for money. There is a ruler for both outdoor and indoor use.

Kreps

So, the glue "Basic", which is used for laying tiles and ceramic tiles, will be consumed by 4.5 kg per square meter with a thickness of the applied glue equal to 3 mm.

Base

Series "Aqua.Stop" - consumption will be from 5 to 8 kg at 1 mm layer. This composition is used for laying tiles in swimming pools, saunas, etc.

Strong glue is suitable for large tiles with appropriate weight. The consumption of glue will be from 5 to 8 kg at 1 mm layer.

Instructions for use

Standard requirements for facing work are temperature +5 - +30 degrees, air humidity up to 75%.

Cooking the surface

Before starting the main work, you need to prepare the foundation:

- Completely get rid of old finishes - tiles, plaster, screeds.

- Make the base perfectly flat. The maximum acceptable height difference is 1mm per 1m.To seal cracks over 10mm in size, we use Eunice "Silin", Eunice "Teplon" or Eunice "Standard" plaster.

- If the installation will be carried out on top of an old tile, then for better adhesion it is necessary to make notches on it with an interval of 5 cm, adhering to a checkerboard pattern.

- The surface must be completely dry and free from grease.

- If the room is humid, then coating waterproofing is done over the entire surface using Eunice Hydroplast.

- To improve adhesion, you need a primer treatment with Eunice, which is done once, maximum twice. With particular care, you need to walk on surfaces made of gas silicate, foam concrete, because they are highly absorbent.

- No wetting of the tile or surface is necessary.

If the base is not leveled, then the layer of the applied solution will not be uniform, which means that shrinkage will occur in different ways. This threatens with delamination or cracks on the surface of the tile.

Mix the solution

- The solution is mixed with a clean instrument in a clean container.

- The dry mixture is gradually added to the water, adhering to the proportions indicated in the instructions. The solution is mixed until a homogeneous consistency is obtained. This usually takes 3 to 5 minutes.

- After that, the solution must be left alone for about 5 minutes, for ripening, and then stir again.

- Mix the solution manually or with a mixer, turning it on at low speed. It is recommended to manually knead no more than 1 kg of the mixture.

- The time of realization of the ready-made solution is 3 hours, if a HiTech mixture is used, then 5 hours. When the mixture thickens during the working period, it can be simply mixed without adding water.

- Ideally, keep all proportions so as not to degrade the quality of the finished mixture.

Apply glue

The finished surface is covered with a layer of glue, with a thickness of 3 to 15 mm, after which it is leveled with a comb along the entire length.

If large tiles or porcelain stoneware are used for laying, the length of the comb teeth is from 8 cm. It is also necessary to monitor the weight of the tiles, which should not be higher than the maximum permissible.

The tile must be pressed firmly against the adhesive layer in order to obtain an even distribution and to avoid the formation of voids. For better laying, the tiles are pressed in, performing back and forth movements or tapped with a mallet. After the tile has "sat down" in place, the layer of glue should not be more than the limit value.

Only as much area should be covered with glue as can be veneered during the activity of the solution - this is usually from 10 to 20 minutes. After this period, adhesion will become much worse.

Usually the mixture is applied only to the base, but if outdoor work is being done or marble slabs, large tiles or embossed tiles are laid, then the glue must be applied to the tile itself.

If you need to correct the tile, then within 10-20 minutes after laying it can be done safely. Check all planes with a level. The uniformity of the seams is obtained using plastic crosses.

After a day, you can move around the tiles and grout using UNIS COLOR color trowels.

Consumption rates for different types of glue and manufacturing companies

Different brands of glue differ in material consumption. Some manufacturers increase adhesion in the composition of the substance, others - resistance to creep, and still others create the composition so that its structure dries faster.

Different brands of glue differ in material consumption. Some manufacturers increase adhesion in the composition of the substance, others - resistance to creep, and still others create the composition so that its structure dries faster.

These factors affect the volume of adhesive material presented in a standard kilogram bag. Consumption of glue brands that produce glue vary.

The most popular brands that will be discussed in the article:

- Ceresite. For 1 sq.m. it will take 1, 4-1.6 kg of glue. The thickness of the glue will be 2-9 mm;

- Hercules. Its consumption will be 1.5 kg per 1 sq. M. with a thickness of 1 mm glue;

- Mapei. The consumption of such a sticky substance is 1.2-1.6 kg per 1 sq. m (1 mm glue). With abundant application of 2-8 kg per 1 sq.m. (2-8 mm);

- Litokol. 1.3-1.5 kg per 1 sq.m. (1mm of glue) will be spent by an experienced craftsman. A beginner builder may use 2.5-6 kg (with a thickness of 2-8 mm);

- Unix.For such glue, you need to proceed at the rate of 1-1.16 kg per 1 sq. M. by a thickness of 1 mm.

Comparative table for Hercules glue and its types:

Now let's move on to a more detailed analysis using the example of the popular Unis brand.

This brand continues to delight builders with quality products, which, by the way, are not limited to glue, but are presented on the markets and other goods for repair work.

The company "Yunis" has established itself in the market of building materials for a long time, since the first batch of materials for construction was supplied, more than twenty years have passed.

Clay Eunice XXI

This versatile product is suitable for various types of tiled surfaces: natural stone, tiles or ceramics. The material consumption is as follows: 1.16 kilograms per 1 sq. M. 1 millimeter of glue. For 6 mm, 3.5 kg of substance is required.

Eunice 2000

The adhesive has universal characteristics and is suitable for all known types of tile materials. Its consumption is 1.16 kg per 1 square meter per 1 mm glue / 3.5 kg per 6 mm glue.

The adhesive has universal characteristics and is suitable for all known types of tile materials. Its consumption is 1.16 kg per 1 square meter per 1 mm glue / 3.5 kg per 6 mm glue.

Eunice Granite

This compound is specially designed for gluing boards with large dimensions and heavy surfaces.

Tile adhesive will ideally adhere products made of natural stones and porcelain stoneware. Its consumption is considered to be from 3.1 kilograms per 1 sq. M. for 6 mm glue.

To visually assess the amount of tiles that can be glued on one 25 kg bag of Eunice glue, watch the video below:

Eunice Plus

Adhesive for repair work with various types of tile material. Both indoors and outdoors. The consumption of such a substance is 3 and a half kilograms of glue per 1 sq. M. for 6 mm.

Comparison table for Eunice glue and its types:

UNIS Hi Tech

The manufacturer took care of the quality of this glue and gave it a high-tech composition. On a surface that is not subject to abundant absorption, 1 kg 160 g of glue will be consumed per square meter.

When absorbed, 3.5 - to a thickness of 6 mm of adhesive.

Another manufacturer whose products are in high demand is Litokol. The company presents a cement-based adhesive.

Litoflex K 80

The glue has high adhesiveness and increased elasticity of the composition. They are laid with ceramic and porcelain stoneware tiles. Perfect for underfloor heating surfaces.

The glue has high adhesiveness and increased elasticity of the composition. They are laid with ceramic and porcelain stoneware tiles. Perfect for underfloor heating surfaces.

The consumption of such a product will be 1 kilogram 350 grams per 1 sq. meter per layer, made in 1 millimeter.

Litofloor K 66

The composition of the adhesive solution is intended for those boards that are of high weight. Suitable for gluing ceramics and porcelain stoneware. For one square. meter will require 1.5 kilograms of such a substance in a layer made with a thickness of 1 mm.

Prospectors standard

The main advantage is the long time to adjust the tiles. If on average up to seven minutes is given for other formulations, then this glue can be freely adjusted for almost fifteen minutes.

The consumption of this brand of glue is proportional to the layer thickness, but on average, this figure is four kilograms per square meter of surface.

Glue "Prospectors Standard" is usually referred to as universal, due to the property of gluing any of the types of tiles. Suitable for work not only indoors, but also outside.

Ceresite

The substance is intended for bonding various types of tiles. With a thin application of a layer of 1 mm, a composition suitable for use per 1 square meter will be equal to 1.5 kilograms.

The number indicating the consumption can be increased from one and a half kilograms to seven, depending on the quality of the spatula and the method of applying the composition.

Comparative table for Ceresit glue and its types:

What surfaces does tile adhesive work with?

The versatility of the glue lies in the ability to work with various types of substrates - concrete, plaster, cement screed, walls, floors. They do not even have to be further leveled before laying. Also, you do not need to spend additional efforts to create a notch, which is usually necessary before veneering.

The area to which the adhesive will be applied must be clean, dry and as even as possible.

Concrete

Eunice 2000 is compatible with concrete surfaces, providing a reliable adhesion of the cladding to the substrate. Before applying the glue, they are cleaned of dust, dirt, traces of oil. The destroyed layer of concrete is chipped. For even surfaces, in order to normalize the consumption of the mixture, the composition is applied with a comb spatula.

In all other cases, in the presence of cracks and potholes, differences in height, they are filled with glue, achieving an even plane. Correction of the tile cladding is possible within 10 minutes, then the process of hardening of the mixture begins.

Gypsum

Thanks to its balanced composition, Eunice 2000 guarantees a significant pull-off force of the tile from the substrate. Even plaster. Cleaning is carried out manually or mechanically. The finished mixture is applied to the surfaces to be faced, while it is allowed to create glue contact zones, both on the base and on the tile itself.

Brick

Cladding with tiled material will allow you to change the appearance of bare brick walls beyond recognition. There are enough options for this: torn stone, sandstone, clinker casting, glazed tiles. It remains to choose a reliable adhesive. Eunice 2000 will work in this case too. You just need to worry that the wall is cleaned of old plaster, mold, paint, traces of oil or oil products before installation.

Cement

Cement walls and floors are included in the list of materials with which the adhesive manufacturer guarantees acceptable adhesion. As in the previous cases, cleaning from dust and dirt will be required. When using Unis as a leveling layer (this is allowed by the manufacturer), the consumption of glue increases proportionally.

A square meter of the surface during cladding can withstand up to 50 kilograms of tiles. This means that heavy materials (granite, marble, cermets) can be used.