Views

To date, the company produces a line of varieties of mounting glue-foam for the mounting gun, while offering a cleaner that helps to remove the composition.

The composition in question is a professional tool, although everyone can use it.

- Professional composition for aerated concrete and masonry - glue-foam of a dark gray shade, replacing cement laying mixtures. Suitable for load-bearing walls and blocks. Has high adhesion characteristics. It features high tensile strength, suitable for fixing ceramic blocks.

- TechnoNICOL universal 500 is an adhesive material, among other bases, capable of attaching decorative panels made of solid wood, plastic and tin. Suitable for dry building technology. Has a blue tint. The weight of the bottle is 750 ml.

- "TechnoNICOL" Logicpir is a type of blue shade, designed for working with fiberglass, bitumen, concrete, PIR F boards. Provides for the correction of the treated surfaces within 15 minutes. Suitable for indoor and outdoor insulation.

A separate line is dedicated to household polyurethane foams, which include 70 Professional (winter), 65 Maximum (all-season), 240 Professional (fire-resistant), 650 Master (all-season), fire-resistant 455. The products are intended for joint use, each of them has a certificate of compliance with safety standards and quality with an indication of the test report. The purifier's documentation is a certificate of state registration.

Peculiarities

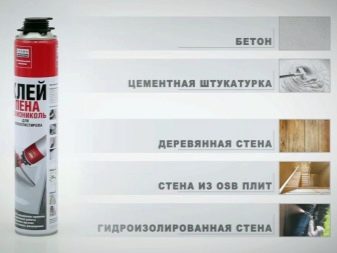

Glue-foam "TechnoNICOL" is a fixing compound consisting of polyurethane, used for fixing foam sheets and panels made in the process of extrusion and used for insulation. High adhesion rates make it possible to use it on brick, stone and wooden surfaces, fix slabs made of gypsum, gypsum plasterboard, aerated concrete. The addition of special solutions to the composition of the foam increases its resistance to fire.

Modern and convenient packaging (metal cylinder with a volume of 0.4, 0.520, 0.750 and 1 l) makes it possible to significantly reduce the time of work.

Advantages:

- resistance to the appearance of dangerous organic organisms and fungi;

- lack of condensing liquid;

- profitability;

- low level of thermal conductivity;

- resistance to sudden changes in temperature and the negative impact of atmospheric precipitation;

- water resistance;

- minimum expansion percentage;

- short setting period;

- high level of adhesion;

- environmental Safety;

- lack of freons;

- affordable price range;

- high technical performance;

- ease of use;

- availability in all hardware stores;

- long period of operation;

- wide range of applications.

Disadvantages:

- inability to use mineral wool for fixing;

- the need for a special assembly gun.

This type of adhesive is used on objects of various types and purposes:

- civil;

- social;

- industrial;

- defense.

Instructions for use

Since each composition is different in the method of application, it is necessary to know several nuances of use indicated by the trademark, which provided a separate technology for the glue-foam.

To simplify the task, and at the same time the consumption of the composition, experts provide a detailed description of the work.

- In order not to complicate the work with foam glue, it is initially necessary to fix the starting profile-fixer on the base to be treated.

- The container with the composition should be installed on a flat surface so that the valve is located at the top.

- Then it is inserted into a special assembly gun, the protective cap is removed, aligning the valve with the bridge of the tool used.

- After the balloon is inserted and fixed, it must be shaken well.

- In the process of applying the glue-foam to the base with a gun, it is necessary to ensure that the balloon is constantly in an upright position, heading up.

In order for the application of the composition to be uniform, it is necessary to maintain the same distance between the panel and the assembly gun.

The glue used for expanded polystyrene is usually applied along the perimeter of the plate, while retreating from the edge about 2-2.5 cm.

The foam strips should be approximately 2.5-3 cm wide

In this case, it is especially important that one of the applied adhesive strips runs strictly in the center of the board.

After the adhesive foam has been applied to the base, it is necessary to give it time to expand, leaving the board for a few minutes. It is strictly forbidden to glue the thermal insulation plate immediately.

After 5-7 minutes, the panel is glued to the base, slightly pressing in this position until the glue sets.

- After gluing the first board, others are glued to it, trying to avoid the formation of cracks.

- If, during fixation, a seam of more than 2 mm is obtained, an adjustment should be made, for which the master has no more than 5-10 minutes.

- Sometimes the cracks are sealed with scraps of foam, but it is better to do the job with high quality initially, as this can affect the formation of cold bridges.

- After the final drying of the composition, the foam in the places of protrusion should be cut off with a construction knife. If necessary, grind the seams.

Advantages and disadvantages

Specially developed products are always superior in properties to conventional tile adhesives. In the case of Technonikol brand glue-foam, this rule is also observed. Its use has a lot of advantages:

- ease of use - the finished composition does not need to be diluted, it is easily squeezed out of the container;

- shortening the time of installation work - achieved due to the convenience and quick setting;

- the presence of a short, but sufficient time to clarify the location of the slab;

- the possibility of sealing joints and cracks without buying another means;

- lack of "cold bridges" due to the same thermal conductivity as the material to be glued;

- 100% reliability of fastening, high quality of adhesion to any bases;

- resistance to moisture, mold - no additional antifungal treatment is required;

- suitability for indoor and outdoor use.

The only disadvantages are a higher price than that of a cheap tile adhesive, although in comparison with analogues, TechnoNIKOL often wins. Also, you can not use foam at negative temperatures, you will have to wait for the warm season.

Types and description

On the shelves of hardware stores, you can purchase several types of TekhnoNIKOL polyurethane foam:

- 500 Professional;

- 70 Professional;

- synthetic polymer adhesive for expanded polystyrene boards.

Glue-foam 500 Professional is a modern universal fixing solution for installation of heat-insulating sheets made of expanded polystyrene. Scope - thermal insulation of walls, floors, roofs, foundations and plinths. This adhesive can be used to fix aerated concrete (aerated concrete blocks), sheets of plastic, drywall, iron and wood.

Technical features:

- adhesion period - 16 minutes;

- curing time - 1 day;

- colors - light blue;

- high fire level;

- temperature regime for installation - from 0 degrees to +40 degrees.

Polyurethane foam 70 Professional is a fixing composition consisting of one component in an aerosol can, which has an improved formula to increase the volume of foam output.

Advantages:

- high percentage of primary expansion;

- large volume of composition output;

- fire resistant;

- high adhesion rates.

The TechnoNIKOL trademark produces two types of these products:

- all-season;

- winter.

Technical parameters of all-season foam:

- density - 30 kg per 1m3;

- adhesion period - 11 minutes;

- curing time - 1 day;

- temperature regime during work - from -10 degrees to +35 degrees.

Features of winter foam:

- density - 30 kg per 1m3;

- the beginning of hardening - 10 minutes;

- full adhesion period - 24 hours;

- temperature regime during work - from -18 degrees to +35 degrees.

Polyurethane adhesive is a special type of mortar for fixing expanded polystyrene sheets, XPS boards, ceramic tiles, polystyrene foam. The base component is polyurethane, which releases isobutane after reaction with air.

Specifications:

- setting period - 20 minutes;

- color - gray.

Before applying the foam, a surface degreasing cleaner must be used.

Instructions for use

For high-quality performance of work and reduce the level of foam consumption, experts advise you to follow several rules:

- install the cylinder on a flat working base strictly vertically;

- remove the safety cap from the valve and connect the cylinder to the tool seat;

- shake up the aerosol can with polyurethane foam;

- during all stages of work, the cylinder must not be placed horizontally;

- when applying the composition, it is necessary to maintain the same distance between the working surface and the gun;

- the width of the mortar stripes should not be more than 30 mm;

- for reliable fixation of heat-insulating materials, it is necessary to withstand the expansion time of the foam;

- 5 minutes after applying the composition to the work surface, it is necessary to apply the panel and hold it until it is completely fixed;

- there should be no gaps and cracks between the plates to be fixed;

- correction of panels can be carried out within 10 minutes;

- after complete drying, it is necessary to remove the remaining foam and polish the working surface.

Instructions for use

When insulating walls, it is necessary to exclude air movement in the gap between the base and the insulation panel. To fill these gaps, an insulating mass is spread into the gaps. The admissible temperature for working with foam is from 0 to + 30˚С. If the balloon with glue was in the cold, it should be kept in a warm room for 12 hours.

For quality work, follow the following guidelines:

Clean the surfaces of the wall and foam panels from dirt and dust accumulations. Dry well. Apply notches to the plane of the panel for better adhesion.

The incisions are made at random to a depth of 5 mm using a tool with hard, fine teeth, such as a file or a notched trowel.

- The mass is applied directly from the balloon, or using a mounting gun.

- In a vertical position, remove the protective cap, and, if there is a mounting gun, insert the cylinder into the gun body. Shake for 15-25 sec.

- If there is no gun before opening, shake the tube with glue several times.

Spread the foam adhesive around the perimeter and diagonally of the expanded polystyrene panels.

- The volume of the foam seam should be 2.5–3 cm.

- Leave the composition to swell for 5 minutes. At this time, moisten the base from the sprayer to remove the dust layer.

- Press the panel to the base, wait for the insulation sheet to hold upright on its own.

After finishing work, clean the assembly gun with a special cleaner.

We recommend a video on the topic:

Instructions for use

How to apply foam adhesive correctly? The instructions are the same for the entire line of products. As a preparation, you need to make the surface absolutely dry, clean, free of dirt and debris - this will increase adhesion. The base is wiped or washed, dried. To apply glue, use a mounting gun or directly a balloon. The second option is much more convenient, it reduces foam consumption.

How to glue expanded polystyrene boards? The correct order of work is as follows:

- put the cylinder on a flat surface with the valve up;

- remove the protection cap, connect the cylinder to the appropriate place in the assembly gun;

- shake the can;

- apply glue to the board around the perimeter, slightly stepping back from the edge (the glue strips should be no thicker than 3 cm);

- apply glue in the center of the board with a strip from top to bottom;

- wait 5 minutes, attach the stove to the base (do not tear it off the wall when moving);

- press the expanded polystyrene, fix in the desired position, leave until the glue sets;

- repeat the work, leaving 3 mm gaps between the tiles;

- after drying, apply glue foam to fill the gaps;

- after a day, cut off the crawled foam with a knife, glue spots can be removed with a special cleaner of the same brand.

Advantages and disadvantages of the material ↑

The most popular material for fixing insulation boards is outdoor tile adhesive. Its main advantage is its low cost. Otherwise, special adhesive foams, including TechnoNIKOL, are significantly superior to tile adhesive. In comparison with it, TechnoNIKOL products have the following advantages:

- ease of use, unlike tile glue, the foam is simply squeezed out of the can, it does not need to be diluted;

- reduces the time for thermal insulation work;

- the setting time is 10-15 minutes, during which you can move the insulation plate, giving it the correct position;

- effectively seals joints and gaps;

- prevents the appearance of "cold bridges", has the same thermal conductivity as expanded polystyrene;

- high adhesion to concrete and other materials;

- resistance to moisture, mold;

- practically does not expand after setting.

The disadvantages of the material include the inability to use at temperatures below 0 degrees and a rather high cost in comparison with tiled facade glue.

Attaching the cylinder to the assembly gun

Attaching the cylinder to the assembly gun

Distinctive features and purpose

This substance is a one-component polyurethane-based adhesive. It is used for fixing boards - polystyrene and extrusion. The substance is characterized by high adhesion parameters. This makes it suitable for concrete or wood substrates.

The polyurethane foam contains special additives. They make the product fireproof. The product promotes insulation. For this, it is combined with insulating plates. The composition helps to seal the joints.

Mounting adhesive foam is very easy to apply. It reduces the time spent on insulation. It is used to work with plasterboard elements, aerated concrete, gypsum fiber. Also, the substance helps to glue the glass-magnesium sheets.

The material is produced in cylinders. They include from 400 to 1000 milliliters of the product. The composition is consumed depending on the amount of the binder component. Professional glue, which has a volume of 1000 milliliters, contains 750 milliliters of binder.

TechnoNIKOL glue is characterized by resistance to water and mold. It is used for interior work. It is also permissible to use it outside. The substance is used for walls, roofs, basements. It is also suitable for the foundation. Also, the composition is used for flooring. The composition is suitable for new buildings and structures that are planned to be restored.

The glue is characterized by special properties. It helps to temporarily fix XPS and EPS boards.

Types of glue-foam

This brand of foam adhesive is a one-component polyurethane adhesive. It allows you to mount products from extruded polystyrene foam and regular foam. The composition of the material is represented by various target additives, and isocyanate oligomers play the main role in it. They are able to actively displace propane and isobutane during the reaction with oxygen from the ambient air. Distinctive properties of glue-foam are as follows:

- providing good thermal insulation;

- reliable fixation with the base;

- resistance to mold, moisture;

- excellent wear resistance and long service life.

The insulating and adhesive qualities of the foam glue are at a high level. This allows you to use a tool for attaching expanded polystyrene to concrete, brick, wooden walls and other bases. It is widely used in works with plasterboard, aerated concrete, gypsum fiber, glass-magnesium sheet. There are two main types of "TechnoNIKOL" for expanded polystyrene, they are described below. Each product is sold in bottles of 400, 750, 1000 ml.

TechnoNIKOL 500 Professional - universal glue-foam

This product is the most popular in the series, it has excellent bond strength and high adhesion to any surface. It is widely used for XPS (Extruded Polystyrene Foam), including thermal insulation boards made of this material. Also, the foam can be used to seal the joints between the slabs during the arrangement of the insulation:

- roofs;

- foundation;

- basement;

- basement floor;

- outside the house;

- inside the house and apartment.

Foam glue is suitable for filling cracks in walls, fixing plastic, sheet metal, panels, drywall, mineral wool. The glue will fill any voids, cavities. It can also be used to glue tiles on the roof, decorative elements - plinths, cladding, stucco molding. The universal tool is suitable for all types of substrates listed above, as well as for plaster, chipboard, tiles, porcelain stoneware.

The technical parameters of TechnoNIKOL foam are as follows:

- thermal conductivity - 0.035 W / mk;

- setting time with the base - 10 minutes;

- final drying - 24 hours;

- density of the finished adhesive layer - 25 g / cu. cm;

- the shade of the foam after hardening is blue;

- temperature during work - from 0 to +35 degrees;

- recommended humidity when gluing boards - up to 55%;

- adhesion to extruded polystyrene foam - 0.13 MPa, concrete and wood - 0.15 MPa, metal - 0.07 MPa.

Within the first ten minutes, you can change the position of the glued board, which is ideal for beginners.

TechnoNIKOL for expanded polystyrene

This material is designed for gluing polystyrene foam boards, perfect for arranging thermal insulation. The composition contains polyurethane, which tends to increase in size by 10%. With the use of this glue-foam, you can attach expanded polystyrene to buildings from the outside and from the inside, insulate basements and the foundation. It seals the joints between slabs, removes holes and voids.

The technical parameters of the product are similar, the difference is in the initial setting period. It is slightly larger than all-purpose glue (15 minutes). It also differs in the color of the finished layer (gray). If necessary, you can use "TechnoNIKOL" for expanded polystyrene and for fixing other materials, but the manufacturer recommends using it for its intended purpose.