Peculiarities

Mapei is a company that has been operating in the construction market for over 70 years. It is constantly expanding the range of its products, including adhesives, while maintaining the high quality of all manufactured materials. In addition to the excellent quality of the products, confirmed by the ISO 9001 standard, several factors are attributed to the undoubted advantages of Italian adhesives.

- Environmental friendliness. All components used in production are safe for humans and the environment.

- Versatility. Branded glue is equally well suited for large objects and private low-rise housing.

- Ease of use. You don't need to have extensive construction experience to use Mapei. They can be used with equal efficiency by professionals and those who do self-repair for the first time.

- Profitability. It is enough to apply a small amount of the composition for high-quality adhesion of two surfaces, which significantly reduces the cost of repair and finishing work.

- UV resistance and increased durability. The material does not lose its properties over time.

- Sufficiently fast hardening (within 4 days) and the ability to withstand maximum load. This allows even heavy materials to be glued with it.

- Water repellent properties. An additional advantage of Italian adhesives is the simple and quick removal of their excess from various surfaces. At the same time, the finishing materials are not damaged or scratched.

There are no drawbacks, according to the experts in the construction industry. However, when buying, you need to be vigilant so as not to buy a fake product from a sought-after manufacturer.

Scope of Mapei Keraflex Maxi glue:

- Laying with an application thickness of up to 15 mm inside and outside the premises of ceramic tiles of any type (single and double firing, porcelain stoneware, clinker and clinker tiles, terracotta, as well as slabs of natural stone and heavy models of concrete artificial stone, etc.) and size on uneven substrates without prior leveling.

- Natural stone laying indoor and outdoor (provided that the stone is not sensitive to moisture).

- Spot bonding of insulating materials such as polystyrene, polyurethane foam, mineral wool and glass wool, hardboard, sound-absorbing panels, etc.

TECHNICAL CHARACTERISTICS OF MAPEI KERAFLEX MAXI ADHESIVE:

| Composition | powder of gray or white color, consisting of cement, sand of a selected granulometric composition, a large amount of synthetic resins and special additives |

| Bulk density of dry mix: | 1.40 g / cm 3 |

| Density of the mortar mixture: | 1.50 g / cm 3 |

| Mixing ratio: |

100 parts Keraflex Maxi (gray) for 32-34 parts water by weight 100 parts Keraflex Maxi (white) to 28-30 parts water by weight |

| Mixing water quantity: | 8.25 l of water per 25 kg bag of gray Keraflex Maxi |

| Pot life of the solution: | 8 hours (480 minutes) |

| Application temperature: | from +5 to +35 C |

| Open time: | 30 minutes |

| Adjustment time: | 60 minutes |

| Walking is allowed: | after 24 hours on a dry surface |

| Full cure time: | after 14 days |

| Grouting the floor: | in 24 hours |

| Grouting the walls: | after 4-8 hours depending on the absorbency of the substrate |

| Resistance to alkalis: | excellent |

| Oil resistance: | excellent (low to vegetable oils) |

| Resistance to solvents: | excellent |

| Heat resistance: | from -30oC to + 90oC |

|

Adhesion strength - after 28 days - after heat exposure: - after immersion in water: - after cycles of freezing and defrosting: |

2.6 N / mm2 |

Types of adhesives

Each Mapei adhesive is divided into two categories - synthetic and natural. Synthetic, in turn, are made using inorganic or polymeric compounds that are obtained by a chemical method. Natural products include products of plant, mineral and animal types. To increase the level of strength, the cement-based adhesive includes a number of special additives to strengthen the structure.

The high-quality, ready-to-use two-component mapei adhesive is divided into several categories depending on the application:

- cement - for laying porcelain stoneware, tiles or mosaics;

- products on a water dispersion basis - for laying cork, carpet or linoleum;

- for vinyl, cork or textile wall coverings;

- for bathroom or swimming pool - no slipping for laying ceramic tiles;

- for thermal insulation.

There are also cement products for laying on vertical surfaces with extended open times.

Laying tiles

If you have never installed tiles before, it is recommended that you complete a short tutorial beforehand. Tile glue, although it is able to forgive a number of mistakes made by the owner of the house, the final quality of work performance largely depends on the human factor.

Preparation of the base

If the surface has cracks, chips or other imperfections, it is necessary to purchase the Mapegrout Thixotropic repair compound in advance, and to repair all small cracks with it. If there are too large irregularities, plastering of the walls will be required. We recommend using Planicrete plaster additives 10 kg canister. Further, after leveling the base for gluing, a primer is applied. With its help, you can increase the level of adhesion.

Preparation of the solution

The open time mortar is intended for finishing both inside and outside the building. This means that it can retain its original consistency longer when fully cooked. Nevertheless, in the process of preparing the solution, it is necessary to prepare in advance for its quick application to the treated area. The preparation consists in mixing the active ingredients using a special construction mixer.

Glue application

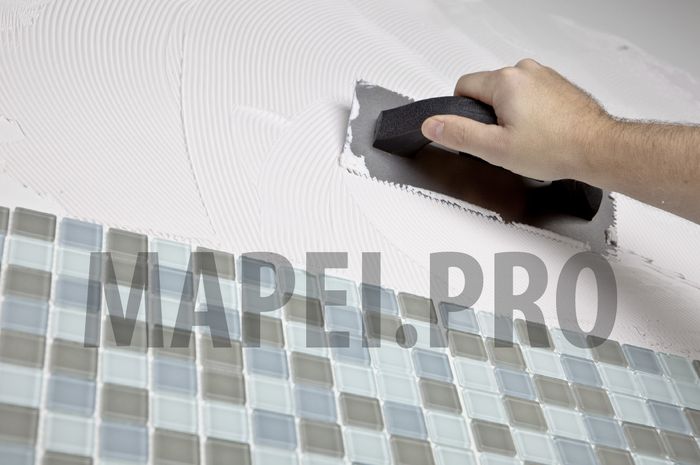

Synthetic adhesive with extended open time must be applied in an even layer. To do this, use a roller or corrugated trowel (depending on the consistency).

Laying coverings

The adhesive is intended for further use on surfaces with extended open drying times. Stacking requirements are standard. It is recommended that you familiarize yourself with them in advance.

Filling and sealing tile joints

It is recommended to use the following materials for filling the joints:

- Kerapoxy grout;

- Ultracolor Plus grout;

- epoxy grout Kerapoxy Design.

Grinding

After the first application, you can grind the adhesive as soon as it starts to harden. This requirement is optional. It is only required when it is necessary to achieve increased adhesion strength of the coating.

PACKAGE

Elastorapid is available in white or gray and is always available in stock.

- White Elastorapid: 28.75 kg kit

-

- Part A: bag 22.5 kg

- Part B: Canister 6.25 kg

- Gray Elastorapid: 31.25 kg set

-

- Component A: 25 kg bag

- Part B: Canister 6.25 kg

STORAGE

Elastorapid - component A: Shelf life in a dry place in original packaging is 12 months.

Elastorapid - component B: Shelf life is 24 months. Afraid of freezing.

ADHESIVE CONSUMPTION Elastorapide MAPEI ELASTORAPID.

- Mosaic and small-format tiles (trowel No. 4) 2.5-3 kg / m2

- Regular sizes (trowel no. 5) 3.5-4 kg / m2

- Large sizes, external floors (trowel no. 6) 5-6 kg / m2

- Uneven back surfaces and bases, natural stone (trowel no. 10) 8 kg / m2 or more.

Range

In total, Mapei offers consumers several dozen different adhesives, which allows you to choose the best option for each specific case. All Mapei adhesive products are divided into several groups. The first group is in composition. It includes adhesives:

- cement-based;

- based on synthetic resins;

- reactive polymer compositions.

By design, the compositions are intended for ceramic tiles and flooring. In this case, options for the floor may differ depending on the material used for decoration. Each adhesive composition of the Italian brand has its own "fans", but the most popular are several.

Keralastic T

Universal adhesive for mounting ceramic tiles and stone on screeds, plastered walls, concrete, asphalt, wood, metal and plastic panels, reinforced polyester, gypsum, gypsum plasterboard and other surfaces. The composition can be used when decorating internal and external walls.

In terms of composition, Keralastic T is a two-component polyurethane adhesive that is free from water and solvents. The components of the glue are mixed immediately before use and form a thick elastic paste, the life of which is 30-40 minutes, after which it begins to set and dry.

Regardless of the base material and the weight of the tile, the trims do not slide down. The glue itself hardens without shrinkage, reliably bonding two different surfaces. You can use a two-component adhesive at an ambient temperature of +10 to + 30C. Keralastic T is sold in metal cans. Each kit without fail includes a polymer (component A) and a hardener (component B). The weight of the kit can be 5 or 10 kg.

Keraflex Maxi

Refers to cement-based adhesives. It is used for gluing tiles (most often large-format) or stone on a wide variety of surfaces. In this case, gluing with this composition is allowed on uneven walls without prior leveling. Keraflex Maxi is a gray or white powder containing cement, sand, particle size distribution, synthetic resins and special additives.

A number of substances added to the mixture were developed at the company's research center. The dry powder is diluted with water before use. The instruction prescribes that the prepared solution must be used within 8 hours. This type of composition can be applied on any surfaces at temperatures from + 5 to + 35.

Granirapid

Fast-setting two-component adhesive. The basis of the first component is quartz sand, the second is synthetic latex. Thoroughly mixed before use, these components give the adhesive high adhesive properties and elasticity, which simplifies the application and installation of finishing materials.

Ultramastic III

This is a tile adhesive that is sold ready-to-use. It is used for the installation of any kind of tiles or mosaics on walls, floors or ceilings indoors, as well as for exterior decoration of building facades. It can be used to fix thermal and sound insulation materials, decorative ceiling panels, foam concrete blocks.

The basis of the adhesive composition includes special acrylic resins, fractionated mineral filler and other components.

Eporip

An adhesive composition for gluing reinforced concrete products and concrete elements to each other or to metal surfaces. Also used to fill cracks in concrete. It is an epoxy adhesive made up of two components, one of which is used to cure the adhesive mixture. Due to its consistency (if the proportions are correctly observed), it can be applied to horizontal and vertical surfaces. The glue is applied at a temperature not lower than + 5C.

For information on how to apply Mapei glue by airless, see the following video.

Application of polyurethane glue:

Prepared polyurethane adhesive Mapei KERALASTIC T is applied to the substrate evenly with a notched trowel. A trowel should be chosen that allows at least 65-70% of the surface to be wetted on the back of the tile.

When laying the flooring outdoors, ensure that the back of the tiles is completely wetted.

If it is necessary to achieve both the waterproofing of the base and the gluing of the tiles, for example, in the case of laying wooden kitchen surfaces, you can proceed in one of the following ways:

Apply KERALASTIC T to the substrate with the flat side of the trowel to a thickness of at least 2 mm; then pass over this surface with a notched trowel, giving it a ribbing, taking into account, however, that the minimum thickness should be at least 1 mm. This thickness must be maintained even after the tiles have been laid, and in particular with a pronounced relief of the back surface.

Apply KERALATIC T adhesive to the substrate with the flat side of the trowel evenly (1 mm) to ensure waterproofing, and then apply a new layer of Mapei KERALASTIC T polyurethane adhesive with a notched trowel after the first layer has hardened (but in any case no later than 24 hours)

In this method, pay attention to the viability of the mixture: with small volumes, this method will not work, because while waiting for the drying time of the first layer, the remaining mixture will have to be thrown away

Grouting tiles:

The joints between the tiles can be filled after 12 hours with MAPEI's special cement or epoxy fillers, available in various colors.

Expansion joints must be filled with special MAPEI sealants.

Pedestrian Readiness:

The floors are ready for foot traffic in 12 hours.

Ready for operation

The coatings applied with KERALASTIC T glue can be put into operation after 7 days.

CLEANING HANDS AND TOOLS AFTER WORK

Tools, containers and clothing contaminated with KERALASTIC T can be easily cleaned with alcohol before hardening occurs.

Cured KERALASTIC T can be cleaned mechanically or with Pulicol.

SAFETY

KERALASTIC T component A is irritating in direct contact with the eyes and has an allergenic effect on the skin. Component B is corrosive and irritating if it comes into direct contact with the skin or stomach, causing allergic reactions.

Avoid contact of glue on the skin in every possible way, always use gloves when laying.

Always wear gloves and goggles when adding component B and when mixing.

If the component comes into contact with the skin, wash thoroughly with plenty of soap and water and in case of an allergic reaction, consult a doctor.

If the mixture comes into contact with the eyes, rinse with copious amounts of water and consult a doctor IMMEDIATELY.

KERALASTIC T is hazardous to the aquatic environment. Avoid release of this material to the environment.

Universal two-component polyurethane adhesive for ceramic tiles and stones

Two-component polyurethane tile adhesive MAPEI KERALASTIC T is an elastic and waterproofing polyurethane adhesive, which does not contain water or solvents... Consists of two components: Component A - polyurethane base and Component B - special hardener.

When these two components are mixed together, a paste is obtained that has the following characteristics:

- Excellent workability properties;

- High durability and aging resistance

- Excellent adhesion to all materials commonly used in construction

- Cures chemically without shrinkage, acquiring significant strength

- Increased elasticity

- High thixotropy: KERALASTIC T adhesive can be applied to vertical surfaces and is able to hold heavy large tiles. Slip resistance complies with the European standard EN 1308.

Area of application of the Mapei Keralastic T two-component polyurethane adhesive for tiles:

- Indoor and outdoor laying of ceramic tiles, clinker steps and terrace slabs of any format, stone slabs and artificial stone tiles, as well as mosaics of any type on the following bases:

-

- screeds,

- plaster,

- concrete, asphalt,

- wood,

- metal,

- PVC,

- reinforced polyester,

- asbestos cement,

- gypsum,

- drywall,

- prefabricated block gypsum panels, etc.

- Laying ceramic tiles, stone slabs and mosaics in shower rooms, as well as on reinforced concrete products used in prefabricated block shower cabins

- Installing ceramic tiles and mosaics on any traditional surfaces and wooden kitchen bases and imparting waterproofing properties to them

- Laying of ceramic tiles, stone slabs and mosaics on balconies, terraces, flat roofs, open for walking of the dome.

- Laying of natural stone from composite materials (VERDE ALPI marble, roofing slate, etc.), including those subjected to shear and swelling under the influence of moisture (class C dimensional stability according to the MAPEI standard).

- Laying ceramic tiles and stone slabs on surfaces subject to strong vibrations and deformations.

Instructions for the use of two-component polyurethane tile adhesive

Working with polymer adhesive Mapei Keralastic has its own characteristics, and the more correctly the base and the mixture itself are prepared, the more effective its application will be.

Preparation of the base

It is necessary to level the surface with special care, the final result depends on it.

It is necessary to level the surface with special care, the final result depends on it.

First you need to prepare the base. It must be free of dust and dirt. Any fragile elements must also be removed, the surface must be cleaned of paint, grease, and oil stains (if any) removed.

It is also important that the surface is dry before starting work.

It is important that the cement base on which the tiles are installed has at least 28 days to solidify in the warm season. Otherwise, the adhesion to the surface will be severely impaired.

To shorten this time, you can use special binders for screeds, which are also available in the Mapei product line.

If Mapei Keralastic is applied to metal surfaces, they must also be cleaned of rust and old paint first. For this, the sandblasting method is used.

For installation of tiles on gypsum, anhydrite or plasterboard surfaces, it is necessary to apply a layer of primer in advance to strengthen the base before starting work.

Advantages and disadvantages

The use of Mapei adhesive for tile installation has the following advantages:

- the consumer can purchase a ready-to-use composition;

- glue for modern coatings is able to withstand operation for a long period of time;

- thanks to the readiness of the composition for work, the technician can quickly start finishing;

- the composition is resistant to the negative effects of ultraviolet radiation;

- even distribution and adhesion to the main and tiled surface;

- the presence of a water-repellent effect;

- easy rinsing of excess mix from tiles using a damp cloth.

The versatility of adhesive for ceramic tiles and stone

You need a notched trowel to apply the glue.

You need a notched trowel to apply the glue.

This adhesive is versatile in use. It is suitable for mounting tiles of any format on both vertical and horizontal surfaces.

In addition, Keralastic T is equally effective for interior and exterior decoration.

Most often it is used for the following works:

- laying mosaics, tiles and stone in the bathroom and shower cabins (even on reinforced concrete surfaces, and for facing prefabricated block shower cabins);

- used for cladding wooden bases in the kitchen, increases their waterproofing properties;

- used for mounting materials that swell when exposed to moisture;

- often used as an adhesive for ceramic tiles, stone, glass mosaics for balconies, flat roofs and terraces;

- suitable for finishing substrates that are regularly exposed to strong vibrations.

Recommendations for the use of two-component adhesive for stone tiles

Useful tips for using the Mapei Keralastic T adhesive will help you get the job done faster and more efficiently:

- The product must not be applied to a highly damp surface, and should not be used for cladding surfaces with a potential threat of capillary rise of internal moisture.

- The product is packaged in packages with an accurate calculation of the dosage of each component, therefore, when preparing a mixture, it is impossible to determine the amount of components by eye. If the proportions are violated during mixing, this will reduce the reliability of Mapei Keralastic T, and complicate its hardening.

- Any work using this tool should be carried out at a temperature of 10 to 30 degrees Celsius.

- If you plan to use the product on surfaces that are under water all the time, you should consult in advance with the technologist of the Mapi company, whether this is possible. Also, a consultation can help you choose the most suitable material from a wide range of Mapi products.

Some applications of MAPEI KERAFLEX MAXI glue:

- laying ceramic tiles (double and single fired, porcelain stoneware, facade clinker tiles) and stone slabs (provided they are moisture resistant) on the following substrates:

-

- Cement screeds and heated floors.

- Walls covered with cement or cement-lime plaster;

- Rigidly fixed plasterboard boards;

- Laying ceramic and marble tiles on floors over existing cladding (ceramic, marble, etc.);

- Floor cladding with ceramic clinker treads subject to heavy traffic;

- Wall and floor cladding on top of Mapelastic waterproofing coating;

- Fastening tiles or decor (ceramic, single-fired, clinker, terracotta) with a highly profiled back.

Never do not use Mapei KERAFLEX MAXI:

- When laying on wood or wood conglomerates.

- Over metal, rubber, PVC and linoleum surfaces.

- For laying slabs of natural stone or marble subject to efflorescence or staining.

- For laying slabs of natural stone or marble, highly sensitive to moisture.

- Over precast concrete or concrete subject to strong shear.

- Where fast foot traffic is required.