Varieties of adhesives

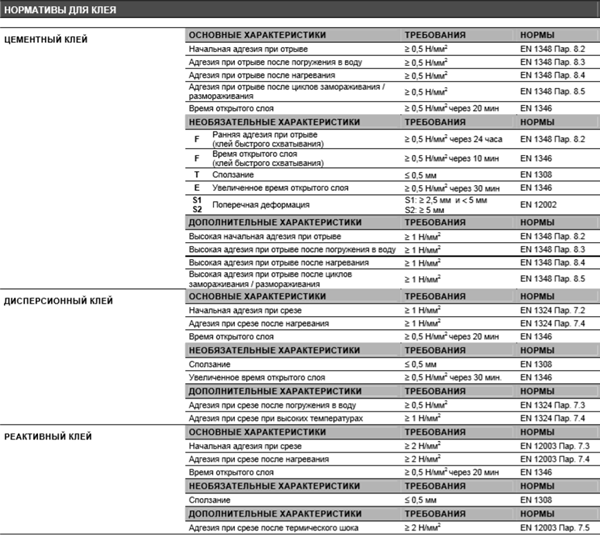

There are three types of tile adhesives with different bases, which are officially prescribed in the standard EN 12004 "Adhesives for ceramic tiles". So the basis is:

- Cement. Release form - dry mix for dilution with water. With its help, tiles, natural stone, mosaics, glass are laid.

- Dispersive. Produced ready-made. It is used for tiling finished surfaces, drywall.

- Reactive. It is a two-component mixture that is mixed in the appropriate proportion. At this stage, a reaction occurs between the components, contributing to the formation of a unique adhesive layer. This adhesive works well on non-standard substrates such as metal, wood, plastic and high stress surfaces.

In addition, all mixtures belong to 7 classes:

- main number 1 - basic formulations;

- main number 2 - improved adhesives with additional properties;

- additional F - adhesives with a fast setting period;

- additional T - do not slide off vertical surfaces;

- additional E - long term of the open layer;

- additional S1 - elastic adhesives;

- additional S2 - superelastic.

The mixture is produced in accordance with certain regulations, which depend on its type and class. More details in the table. One mixture can belong to several classes, take, for example, C2E - this is the decoding of an improved cement glue that has a long open layer time.

How to do the work

Before using "Litokol" you need to familiarize yourself with how to use it correctly.

Preparation of the base

First, it is necessary to carry out preliminary preparation of the bases. For this, the surface to be treated is pre-cleaned of dirt, washed and degreased. This is done so that the adhesive to be applied adheres better to the coating.

Glue application

When the base is prepared, you can start applying the product. It is evenly distributed over the coating in a thin layer. Then, 2-3 minutes after application, the adhesive material is applied to the treated surface.

Peculiarities

This type of dry glue mixture receives only positive reviews. No wonder. The characteristics of this product indicate that it is a high quality product in the construction and renovation industry, ideal for tiling.

- Litokol K55 glue is very flexible and has excellent adhesion.

- The mixture sets quickly and dries well, which contributes to faster trowelling. This product is an advanced glue. Due to this, it can be used not only when laying ordinary tiles, but also for installing a "warm floor".

- One of the features of the material is the fact that the mortar prevents the tiles from sliding at the time of laying. This is very convenient if the tiles are laid on the walls.

- In addition, the glue in question is non-toxic and recognized as environmentally friendly. It will not harm the master during the installation process, and also will not harm the health of the household. The consumption of this mixture is economical, which adds another significant plus to this product.

- Tile adhesive has a long life cycle. The already diluted mixture should be used within six hours. The applied layer and the laid tiles can be corrected within the next half hour. After that, the material begins to set and adjustment is unacceptable.

- To grout the joints, you need to wait exactly 24 hours. After a day, you can safely walk on the laid tiled floor."Warm floor" can be used only after a month (25-28 days). More details can be found in the instructions that come with this type of glue. The manufacturer gives clear recommendations for the use of the adhesive.

- Litokol K55 is perfect for any kind of ceramic, mosaic tiles, analogs made from natural stone, for example, marble or granite. You can choose tiles of any color and from any material, including glass.

- This adhesive does not appear after installation and does not change the color of the laid tiles.

- The material is considered frost-resistant. Due to this, it can be used for cladding outside buildings.

- This product can be used while laying pool tiles.

- This mixture is widely used for cement screeds, gypsum plasters, precast concrete, drywall.

Properties

The Italian company Litokol specializes in the development and production of adhesives for mosaics, tiles, porcelain stoneware, and natural stone tiles. In production, only the highest quality raw materials are used, which makes it possible to obtain glue with excellent technical characteristics. Under the Litokol brand there are several modifications of adhesive mixtures, each of which has its own qualities.

Speaking about the general properties of materials, the following points can be highlighted.

- Health safety. In the manufacture of Litokol adhesive mixtures, no harmful components are used, therefore the finished product is absolutely environmentally friendly.

- High level of adhesion to almost all types of substrates. The adhesive composition allows tiling even complex substrates such as wood and plastic surfaces.

- Excellent resistance to moisture and water. The Litokol range of materials also includes a separate type of mixture for tiling swimming pools.

- Resistant to high and low temperatures, as well as to its sharp drops.

- The mixture has good elasticity characteristics.

Varieties of Litokol glue, description and scope

Mosaic glue Litokol has several varieties, the compositions are divided into three groups: cement, reaction, dispersion. You can use glue for tile material for outdoor work. Applicable for many types of bases. It is possible to use it when gluing the material to the old tile finish.

Designed to work with the following materials:

- Brick, concrete and aerated concrete surfaces;

- Plastered bases and screeds;

- Plasterboard and gypsum fiber sheets;

- Gypsum surface, gypsum panels;

- Base with waterproofing.

You can use glue for tile material for outdoor work.

You can use glue for tile material for outdoor work.

Application features

Each type of Litokol adhesive mixtures can have its own application characteristics. For this reason, before starting work, it is recommended that you familiarize yourself with the instructions that are indicated on the packaging of the material.

Surface preparation

To work with any composition, it is necessary to prepare the surface. It should be flat and clean. If tiles are to be laid on the floor, it is necessary to wait until the cement-sand screed is completely dry (about 28 days from the moment of formation). The presence of small irregularities on the surface (no more than 0.3 cm) is allowed.

Application

The adhesive composition is not applied to the entire area of the treated surface at once, but only to a small part of it. The layer of glue should be uniform, for this, the mixture is distributed with a metal spatula, after which it is exposed to it with a notched trowel. The tile material is laid on the treated surface and pressed down well.

Features of use

To get the desired beautiful and durable result, it is important not only to choose the right product, but also to carry out the styling correctly. Litokol white glue is easy to use, the main thing is to follow the instructions

To get the desired beautiful and durable result, it is important not only to choose the right product, but also to carry out the styling correctly.

How to prepare the base

Without preparation of the base, a reliable fixation cannot be carried out, the adhesion will be poor. Work stages include:

- The cement screed must be completely dry.

- You can smooth the base using a self-leveling mixture.

- Work should be done with a clean surface, so all dirt and greasy stains are removed, including.

- Priming is carried out, this improves adhesion.

Without preparation of the base, a reliable fixation cannot be carried out, the adhesion will be poor.

Without preparation of the base, a reliable fixation cannot be carried out, the adhesion will be poor.

Glue application

On a dry surface, the diluted solution is applied to small zones so that solidification does not occur. How long the layer will dry will depend on humidity, temperature, moisture-absorbing properties of the base. The glue is applied to the surface with a notched trowel, after which the tile is applied to the surface with the reverse side. When laying, do not forget about expansion and tile joints.

On a dry surface, the diluted solution is applied to small zones so that solidification does not occur.

On a dry surface, the diluted solution is applied to small zones so that solidification does not occur.

Consumption for 1 m2

Average consumption of glue for laying tiles is 2.6 kg. per square meter, but for each type it can be different, the consumption on the package is prescribed. In this case, when calculating, the following factors must be taken into account:

- Surface type;

- Type of facing tiles.

When working with a well-prepared flat surface, the consumption will be lower, the size of the tile also has an impact on the amount of adhesive used. It should also be noted that the type of base is also important, if the material is porous, then some of the glue will be absorbed and a thicker layer will be required. The calculation is made taking into account all these features of the work.

Consumption will be lower when working on a well prepared flat surface.

Consumption will be lower when working on a well prepared flat surface.

Litikol glue is a reliable means for fixing various types of tile material, which can be used for both indoor and outdoor work. It is not difficult to work with the product, it is possible to do it yourself.

Glue application

The ready-made adhesive solution must be applied to small areas so that it does not have time to harden. The exact pot life of the finished product is usually indicated on the packaging.

The rate of drying of the glue is influenced by: temperature and humidity of the air, moisture absorption of the surface, etc.

The mixture is applied with a notched trowel so that small ridges are formed. They increase the adhesion to the tiles, which are laid on the back of the glue and pressed well.

When applying glue, it is worth remembering the need for expansion and tile joints.

On the first day after laying, it is important to protect the tiles from mechanical stress, water ingress and other factors that can ruin the work

During the week, styling needs protection from frost and direct sunlight.

The choice of glue for the intended purpose

Depending on where the coating is laid, the facing material and the mixture that will fix this material are chosen.

Despite the fact that many compositions are universal, it is worth paying attention first of all to a special glue because of its improved, in one direction or another, parameters.

On the floor in the hallway, corridor or kitchen

You should not save on the quality and quantity of consumables by laying tiles in these areas of the apartment.

Considering that the cladding is constantly exposed to various negative factors (for example, humidity or high loads), it is possible to use adhesives such as LITOFLEX K80, LITOFLOOR K66 or LITOELASTIC as a fixer for tiles.

For bathroom or pool

The cladding of rooms with high humidity must meet the main requirement - good moisture resistance.

The liquid should not be absorbed and compliance with this rule directly depends on the solution on which the tiles are laid.

For a bathroom or a pool, such articles as: LITOFLEX K80, LITOPLUS K55, LITOACRIL PLUS are perfect.

We also recommend to look - How to choose glue for bathroom tiles

Indoor wall cladding

Vertical cladding is more difficult than horizontal cladding. If the floor tiles can be fixed with special crosses, then with the walls things are a little different.

The advantage of the adhesive mixture for vertical coatings lies in its main quality - thixotropy, that is, the tile during operation, until the moment of hardening, should not slip.

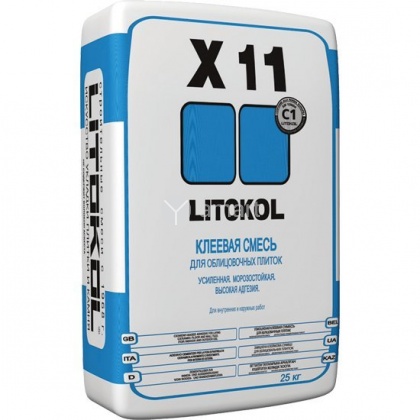

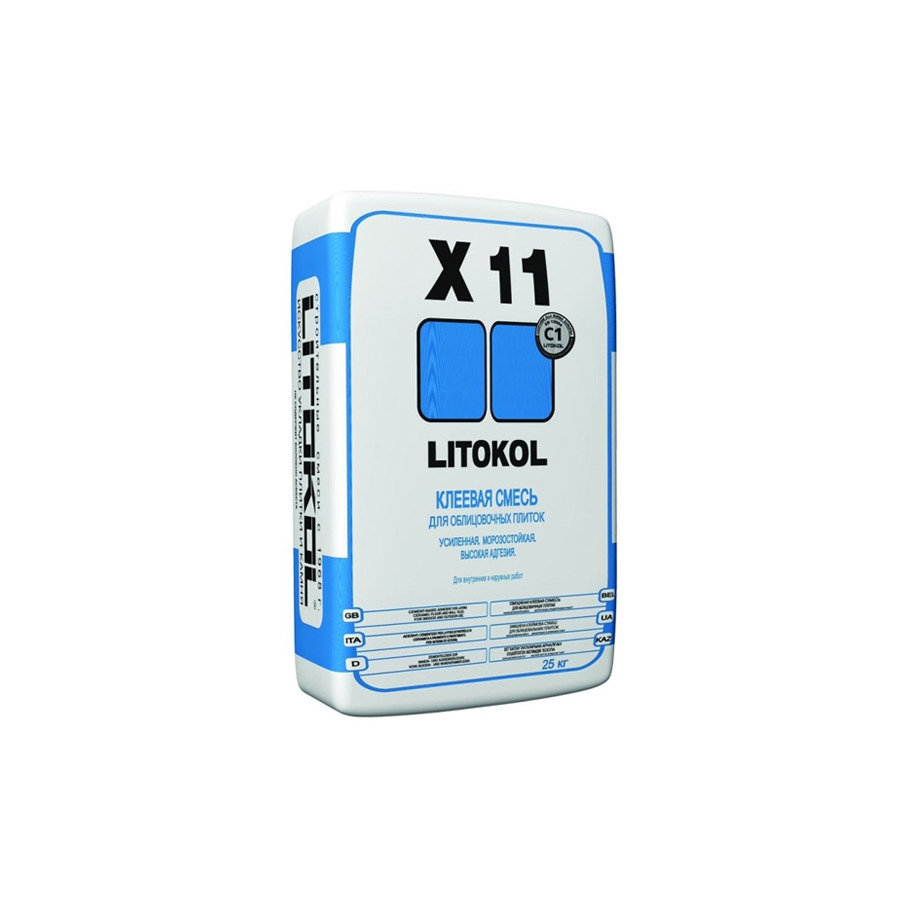

Items LITOKOL X11, LITOKOL K17, LITOKOL K17, LITOFLEX K80 and LITOFLOOR K66 are able to ensure compliance with this point.

For outdoor, veranda, exterior walls and plinths

Outdoor cladding is subject to strong temperature changes, and therefore possible deformation. Thanks to the high achievements in the production of adhesive mixtures, the influence of climatic conditions can be minimized.

For laying tiles for outdoor decoration, mixtures with the addition of latex are used, which increases the elasticity of the mortar. Suitable names from the LITOKOL manufacturer: LITOKOL X11, LITOFLEX K80 and LITOFLEX K81.

Don't forget to look also - Outdoor frost-resistant adhesive

Stairs and rooms with high loads

Laying tiles on stairs, in elevator cabins, etc. is carried out using the following compounds: SUPERFLEX K77, LITOSTONE K98 / K99. They are characterized by increased adhesion, strength and elasticity.

Often, they try to put the stairs into operation as soon as possible. The quick adhesion and drying of these solutions allows the load to be made within a day, after the veneer.

Preparation of the base

For high-quality installation, you need to prepare the base before starting work:

- The cement screed must be completely cured. The full setting time is 28 days.

- The plane is checked with a long level or rule. There should be no differences greater than 3 mm. To level the floor, you can use a self-leveling mixture.

- The surface must be free of dust, grease, oil or paint.

- The base primer reduces its water absorption, removes dust, increases adhesion, allows you to get rid of direct contact of gypsum with cement. The manufacturer recommends using a proprietary primer depending on the substrate: Primer-N, C, L, F.

- The primer must dry completely.

- The walls and bottom of pools, fountains and other water tanks are carefully leveled. To do this, you can use a cement-sand mortar, for example M300 with the addition of IDROKOL X20-m latex.

Substrate preparation before tiling: priming and application of Litoliv self-leveling floor.

Tips & Tricks

Certain types of substrates and adhesives can be difficult to handle. There are a few things to keep in mind when buying material and using it.

- It is not recommended to use cement compositions for gypsum surfaces, since these materials do not interact well with each other. An alternative solution might be to prevent direct contact between them. To do this, before applying the glue, gypsum bases are subject to mandatory priming.

- Before laying glass mosaics on the surface of the pool or fountains, the base must be treated with a mixture of cement and sand in order to perfect leveling.

- It is always necessary to take into account the curing speed of the used Litokol glue, since after the formation of a film on the applied composition, it will be possible to glue the tiles to this area only after applying a new layer. It is worth remembering that drying time may vary depending on temperature and humidity conditions. For example, in direct sunlight and under the influence of dry wind, the glue hardening process will be faster.

- When working with Litokol adhesive mixtures, tiles do not need to be soaked in water.

- If it is necessary to tile surfaces that will be subjected to high mechanical stress, it is recommended to apply the adhesive mixture both to the base and to the back of the tile.

For information on how to properly apply glue to tiles, see the video below.

LITOKOL brand information

The Litokol brand is an Italian company that appeared in 1968. The first factory specialized in the production of tile adhesives. The initial production of Litokol turned out to be of high quality. It provided a secure connection between tiles and work surfaces. Thanks to this, in the 70s, foreign branches of the Litokol company began to appear.

In the early 2000s, the manufacturer Litokol began to gain respect among the finishers in the post-Soviet space. A large sales office appeared in Kiev. A large plant for the production of dry mixes, assembly adhesives, and other finishing materials from the Litokol company was built in the Moscow region.

Now Litokol products are known in 90 countries of the world. Maximum automation of production allows to achieve high quality and productivity indicators.

Among the names of the company Litokol, the following positions stand out:

- Tile adhesives.

- Epoxy adhesives consisting of a base and a hardener.

- Compounds for leveling screeds.

- Primers for various surfaces.

- Self-leveling fillings for floor coverings.

- Dispersion mixtures that are applied before laying tiles on different surfaces.

- Litokol waterproofing, antiseptic primers.

- Compositions for waterproofing floors, walls, water tanks.

- Additional components for adhesives to improve their characteristics.

- Putty, plaster mixes.

- Special removers, degreasers for cleaning old decorative compounds.

Thus, the products from Litokol can be used, ranging from masonry walls and ending with finishing work when decorating premises.

Tile adhesive Litokol

Litokol k81, created for laying tiles, looks like a dry mix consisting of cement with the addition of other components that improve its quality. Among them are artificial resins, chemical elements that increase adhesion properties. Differs from similar products in elasticity, environmental friendliness, efficiency. Also, the composition dries quickly, reducing the duration of finishing work, can withstand thermal effects, therefore, it is permissible to use it for laying a warm floor.

Differs from similar products in elasticity, environmental friendliness, efficiency.

Differs from similar products in elasticity, environmental friendliness, efficiency.

Material features and specifications

The popularity of the Litokol tile adhesive is due to its special technical characteristics, which are spelled out in the description for the product:

- The finished solution resembles a paste in consistency;

- Possible temperature indicators for work varies from +5 to +40 degrees;

- Permissible performance indicators range from -30 to +90 degrees;

- You can apply the ready-made mixture within 8 hours;

- Correction of the position of the tile can be carried out within 1 hour;

- Adhesion index - 1 N / sq.mm;

- The composition is frost-resistant, withstands at least 50 cycles;

- The mixture is waterproof;

- The recommended layer thickness is 2-5 millimeters;

- Average consumption is 2.5-6 kilograms per square meter.

When working, there is no vertical sliding of the material, therefore it is used for wall decoration. Trowelling is possible in 6-8 hours, it will be possible to walk on the flooring neatly, and grout in 24 hours.

When working, there is no vertical sliding of the material, therefore it is used for wall decoration.

When working, there is no vertical sliding of the material, therefore it is used for wall decoration.

Advantages and disadvantages

Experts note that the glue, unlike many analogues, dries quickly, and a long time to correct the position of the tile material also has a positive effect on the work. You can use the diluted mixture for 8 hours. Which is also a long time, it is especially convenient for beginners. In addition, the pluses include:

- Does not allow the finishing material to slip;

- Versatility, you can work with different tiles - porcelain stoneware, granite, mosaic, tiles;

- A composition that is safe for health, does not include toxic elements;

- High adhesion rate, applicable for use in conditions of high permeability;

- Low consumption due to low layer thickness;

- Withstands the negative impact of environmental factors;

- Water resistance;

- Frost resistance;

- Acceptable cost.

You can use the diluted mixture for 8 hours.

You can use the diluted mixture for 8 hours.

Glue application

Application of LITOKOL K17 glue.

- The glue should be applied to the area that you have time to veneer until a light crust forms. The exact time is determined in practice, it may vary depending on the water absorption of the substrate, temperature, humidity levels and other factors. For example, in hot weather or in strong winds, the pot life of the solution will be shorter than usual.

- The mixture must be evenly distributed over the surface of the base, first with an ordinary trowel, and then smoothed with a notched comb. The size of the prong is selected depending on the tile format.

- The tiles do not need to be soaked in water before laying, but it is recommended to wipe the back from dust.

- Place the tiles on the adhesive and press with a sliding motion.

- Within about 20 minutes (depending on the type of glue), the position of the tile can be adjusted.

- There should be seams between the tiles. A minimum clearance of 5 mm should be left along the partitions and at the joints with any protruding elements.

- During the first days after installation, you need to protect the cladding from water, and 5-7 days - from frost and sunlight.

- It is recommended to use Litokol grout to fill the joints.

Summing up, I would like to say that you should not use one mixture for all types of work. For each type of substrate and installation conditions, there is a specific brand of adhesive that takes into account their characteristics.

comments powered by HyperComments

Apply glue

- The glue does not need to be applied immediately to the entire surface, otherwise it will begin to set, and after a light crust has formed, nothing can be done with it. The curing time can be different and depend on the level of water absorption of the base, humidity, temperature, etc. If it is hot outside and a strong wind blows, the curing time of the solution increases significantly.

- So, we apply the glue on a small surface and evenly distribute it in an even layer, and then we go through it with a toothed comb. The dimensions of the trowel-comb teeth directly depend on the dimensions of the tile.

- Some craftsmen pre-soak the tiles in water. You do not need to do this, just clean the back of the dust.

- The tile is applied to the glue layer and adheres well.

- If the tile does not lay down as needed, then within 20 minutes you can make an adjustment. This time is different for different brands of glue.

- The tiles are laid with seams that are adjustable depending on the location. If the seams stretch in the area of the partition or are joined with some kind of protruding surfaces, then the gap should be minimal - 5mm.

- In the first 24 hours, the styling should not come into contact with water, and for the next 5-7 days, it needs complete isolation from the sun and frost.

- It is best to fill the joints with Litokol grout.

When laying porcelain stoneware or tiles in those places that will constantly experience heavy loads, the glue must be distributed both to the base and to the tile. This will increase adhesion and eliminate voids. The consumption of the glue mixture will be an order of magnitude higher.

In conclusion, we want to give some practical advice - no need to try to do all the work with one glue. For each surface, type of material and cladding conditions, you can choose a suitable brand of adhesive mixture, which is fully consistent with their characteristics.