Perlfix glue from Knauf: composition, advantages, application

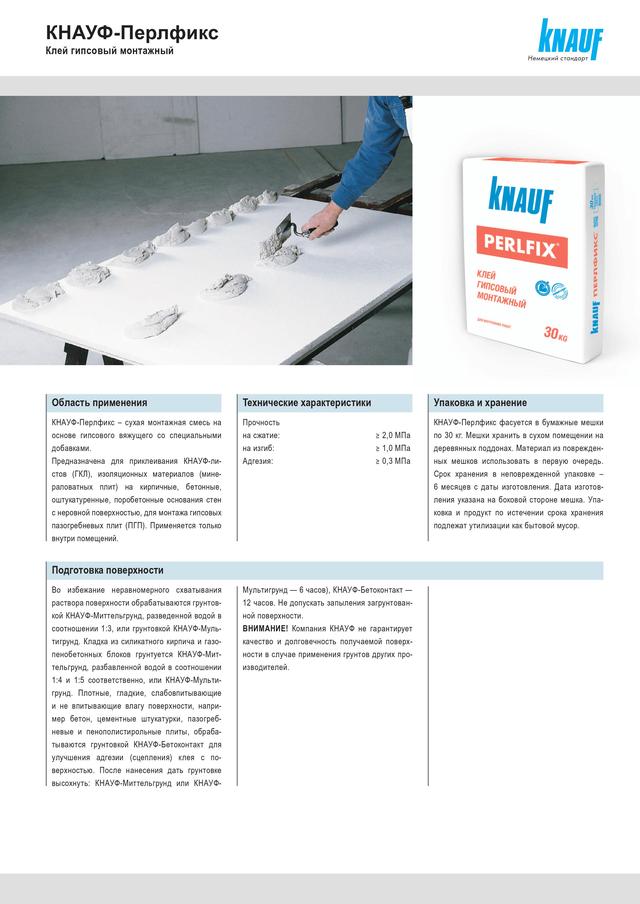

Among the variety of building adhesive mixtures, the Perlfix glue from the Knauf company stands out. The material meets the highest requirements. Its main purpose is the installation of drywall on various types of surfaces - concrete, brick, etc. Despite the long drying time, this glue is one of the best in terms of strength among analogues.

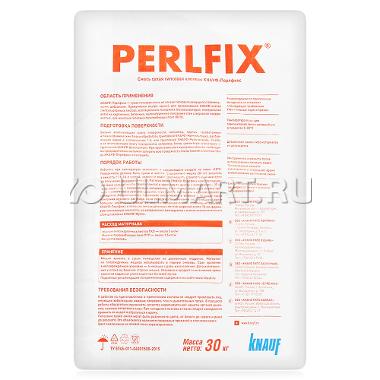

Knauf is a company known for the production of high quality construction products. "Perlfix" glue is a dry mix based on gypsum, improved with polymer additives. To prepare a solution, it is enough to dilute the powder with water. It is intended for gluing sheets of plasterboard, polystyrene, polystyrene and gypsum boards to various substrates, including uneven ones. On sale are bags with a mixture of 15 or 30 kg.

Technical characteristics of gypsum glue:

- Has increased adhesion.

- The composition is environmentally friendly and safe for humans.

- Designed for indoor use only.

- It is used at temperatures from +5 to +30 degrees.

- Can be used in unheated rooms.

- Resistant to moisture. Withstands high humidity, suitable for finishing kitchens, bathrooms.

- Suitable for small putty work.

- The long shelf life of the finish is several decades.

- Grips in 30 minutes, allows you to adjust the position of finishing materials. Complete drying occurs after 7 days.

- Resistant to mechanical stress.

- The shelf life of the composition is 6 months.

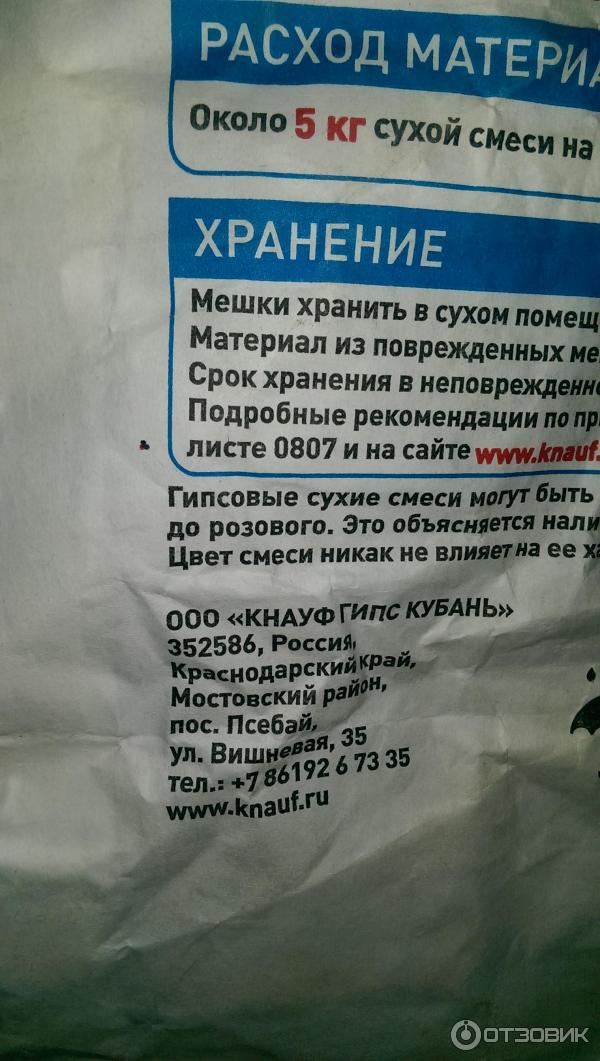

- The average consumption of glue per 1 m 2 is 5 kg. The exact amount depends on the type and evenness of the surface.

Perlfix assembly glue is a great opportunity to save money on repairs. Due to its strength, there is no need to use additional fasteners. The glue line retains its properties for many years.

To dissolve gypsum glue, an average of 15-16 liters of water is taken per bag (30 kg), that is, in a ratio of approximately 1: 2. Any plastic container is suitable for preparing the mixture. First, water is poured into it, and only then glue is poured in a thin continuous stream and stirred with a construction mixer until a homogeneous consistency, without lumps.

Wall preparation is required prior to glue application. They need to be cleaned of dirt and particles of the old finish and primed, regardless of the type. The best installation result will be when using Knauf primer products.

Advice! The powder is stored strictly in a dry and well-ventilated area, otherwise, due to the increased content of gypsum, the glue will damp. If the packaging has been broken, the mixture is poured into a whole bag and sealed.

Instructions for using the finished Perlfix:

- The glue is distributed on the wall with a rubber notched trowel pointwise with an interval of 3-4 cm.

- The glue is applied along the center line of the sheet in one row or staggered. The recommended layer thickness is 2 cm.

- For thick finishing materials, you will need two rows of glue, as well as additional processing around the perimeter.

- Ready-made drywall glue is usable within 30 minutes. The powder should be diluted in the required amount. It is not worth diluting the old glue with water, as its quality becomes several times worse.

- The gypsum plasterboard is firmly attached to the wall, leveled. Correction is best done in the first 10 minutes after gluing.

- The finish should be left alone for 7 days until it dries completely.

The use of Perlfix glue greatly facilitates installation work. This durable composition adheres well, but allows you to adjust the position of the finish for some time.Gypsum glue is a great alternative to self-tapping screws and metal fasteners that can damage the drywall structure.

Advantages

This excellent tool for mounting large and weighty slabs has many advantages:

- Gypsum glue is convenient and easy to prepare.

- It does not form lumps when mixed. Has a pasty consistency required for application.

- Installation does not require the installation of the frame.

- Strength. The increased adhesion of Knauf allows the surface to be firmly bonded to the base, further strengthening the walls.

- Provides fairly quick drying.

- Economical consumption. Despite the fact that the cost of Perlfix is slightly higher than other adhesive mixtures, its costs are much lower.

- Saving the area of the room. The adhesive is applied in a very thin layer, which provides not only a lower consumption of the mixture, but also minimization of the "stolen" free area when facing surfaces.

- Durability. Thanks to water-retaining additives, Perlfix retains its adhesive properties for a long time.

- Unlike cement mixtures, the glue allows you to work with its composition for several hours longer.

- Allows to create a seam between slabs and blocks of minimum thickness, since Knauf guarantees that the wall does not freeze through the masonry seam.

Judging by the reviews, the video and the description of the main advantages, Knauf's Perlfix glue is ideal. The only drawback in the characteristics of the product is the need for self-preparation of glue, which accompanies the presence of dust.

Mounting

The gluing work begins with the preparation of the walls. They need to be cleaned of dirt, old finishes, chipping pieces. If the surface is curved, then it must first be leveled with plaster. Or use beacons and then glue the gypsum board to the beacons.

The adhesive will hold better if the surface is primed. It is advisable to focus on those recommended by the glue manufacturer.

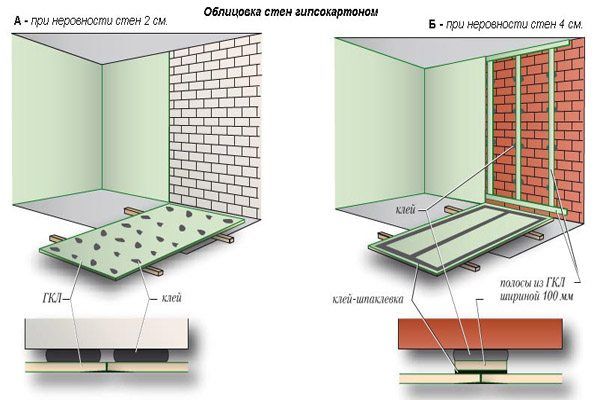

If the unevenness of the wall is more than 20 mm, then you will have to install point beacons. We take small fragments of gypsum board and put them on glue, aligning with the rule and other tools at the level we need minus the thickness of the sheet. When the beacons dry up and grab, you can start installing the sheets.

- Assembly glue is prepared in a clean bucket - water is poured, the mixture is poured and thoroughly mixed.

Cooking glue With a trowel or a spatula, glue is applied in small piles to the sheet - along the perimeter and somewhat in the middle.

We put glue on the sheet The sheet is set in place and pressed in such a way that it sits on the beacons.

Installing the sheet

- Apply glue liberally to the place where the joint of the sheets will be, so that the edge does not hang.

- We proceed to the next sheet.

If, on the contrary, the walls are even and the drops are within a few millimeters, then glue can be applied with a notched trowel. In this case, the consumption will be significantly lower and the work will be faster. It is convenient to use putty here, in particular, the same Knauf Fugenfüller.

Wall cladding with plasterboard

A few important points:

it is impossible that there is a lot of dust in the air during gluing. All dusty work must be done in a different place or at a different time;

it is impossible for drafts to walk in the room. For the entire time of drying and setting of the glue, windows and doors must be closed;

the mounted sheets must not be subjected to mechanical stress until completely dry.

After a short practice, you will see for yourself that drywall glue can significantly speed up the installation process and do without significant loss of usable space in the room.

The basic composition of glue for aerated concrete blocks, its varieties

The composition of special glue for aerated concrete can be discussed in general terms. The fact is that some polymer modifying additives and the characteristics of the cement used by manufacturers are not advertised and often refer to proprietary secrets. And the production technology of different companies can also have significant differences.

However, we can safely say that the mixture consists of:

- high quality Portland cement;

- quartz (sand) filler of a very fine fraction;

- a whole range of special mineral and synthetic additives that predetermine the special qualities of the adhesive mixture.

Adhesives are sold on sale in the form of a ready-made dry mix in the usual packaging for any builder or finisher: multi-layer paper bags, most often - 25 kilograms each. The composition is diluted with plain water according to the attached instructions. The glue is brought into working readiness immediately before the start of laying, since it has a rather limited period before the start of setting.

Despite the identity in purpose and basic composition, adhesive mixtures still have a certain classification.

So, they are divided into thick-layer and thin-layer

Thin-layer ones are intended for masonry with seams not exceeding 3 ÷ 5 mm. Such a composition is usually used with high-quality aerated concrete blocks that have almost perfect geometry. That is, the correction of the block positions with the help of a solution, if where required, is minimal.

On the packaging of this glue it is marked as “thin layer”. The thickness of the layer can be simply indicated, for example, from 2 to 5 mm.

Thick-layer compounds are more versatile, since they allow work with gas silicate blocks that have errors in shape and size. Their characteristics indicate that the layer thickness can reach 10 (sometimes more) millimeters.

It is unlikely that you will come across the wording “thick layer” on the packaging. The maximum seam thickness of 10 millimeters or even more is simply indicated.

It is clear that a possible thickness is indicated, but not at all obligatory. That is, at every opportunity, you should still strive to maintain the minimum - the reasons have already been discussed above.

* * * * * * *

The next classification criterion concerns the conditions for performing masonry work. Namely - adhesives are summer and universal.

Summer mixes - they are allowed to be used for outdoor work only at positive temperatures, usually above + 5 ℃.

The advantage of summer options is that they are usually made of white cement. That is, after the masonry dries up with thin-layer application, the seams become almost invisible against the background of the blocks. In some cases, this somewhat simplifies the finishing work.

Almost identical packaging, but with the indication of the "winter" and "summer" mixture. So you have to be more careful.

Winter adhesives allow construction work even at negative temperatures, of the order of -10 ÷ 15 ℃. And this lower limit must be either indicated on the package, or spelled out in the instructions for use of the composition.

By the way, such a gradation can be rather arbitrary. Some manufacturers offer universal mixtures in their assortment without dividing them into "winter - summer". It's just that when choosing a composition, if you already plan to carry out masonry, you should purchase one that meets the weather conditions and suits other selection criteria: seam thickness, color, cost.

Selection and application

A conscious choice of glue for a specific task can be made after preliminary verification of its characteristics and conditions for further use of the glued products. The assessment is made according to the following criteria:

- The parameters of humidity and temperature in the room where work will be carried out using Moment glue.

- What materials will be connected, their structure and homogeneity.

- Is the Moment supposed to come into contact with food?

- Required tensile strength, elasticity of the seam.

- What products will be connected, the size of the required seam (thick compositions of Moment glue are better for a thick seam).

- The ability of the resulting compound to withstand certain operational loads and influences: shock, vibration, deformation, other mechanical loads, frost, heating, contact with water, aggressive substances.

- No aggressive action of the glue. Momentum on the material of the surfaces to be joined.

- Which method is chosen for gluing - hot, cold.

- The ability of the working composition to completely fill the voids of porous materials.

For each type of Moment rubber glue, the packaging contains instructions for its correct and effective use. In a simplified version, the gluing technology consists of the following stages:

- Thorough cleaning of dirt on work surfaces, sanding (if necessary), degreasing.

- Application of the composition to the glued surfaces. If hot gluing is performed, the composition can be heated with a technical hairdryer. With the cold method of gluing rubber to plastic, the composition is first applied to the surface of the rubber product and kept for 15-20 minutes, after which both surfaces to be joined are treated with glue.

- Tight compression of parts for a few minutes and, if possible, further installation under the press.

An interesting way to compress workpieces from a specialist:

Minimum layer of glue application Moment - 2 mm. For joining thin and elastic materials (for example, when repairing a rubber boat), a seam of 1 mm is allowed. In this case, the use of gauze for reinforcement is recommended. The hardened seam will gain its maximum strength in 1-2 days.

Professional advice

Experts advise to dilute the glue only in small portions. Given the time the solution is ready for work, it is difficult to completely use up all the packaging diluted with water. Therefore, it is better to divide it into 2-3 parts, carefully apply it to the sheet and stick it on the wall, and then proceed to the next stage. Here are other expert tips for working with Perlfix glue:

- You can not ignore the priming of walls and sheets of gypsum board. Without this, it will not be possible to reduce the porosity of the material, as well as enhance the adhesion to the surface. The choice of primer depends on the specific type of finish and substrate material. After applying the primer, you need to wait until it is completely dry, and also make sure that no particles of dust or dirt stick to the wet wall.

- If you use a thicker solution, it will dry faster, and there will be little time to adjust. But such glue will not crawl out at the seams of the gypsum board, which will reduce the time for finishing.

- The use of cold water to dilute the mortar will slightly increase the pot life of the mortar. Do not use hot water for gypsum adhesives!

- When applying spot glue, start from the center, continuing towards the periphery. Be sure to walk around the perimeter in order to securely fasten the sheets and prevent them from moving away from the wall.

- Do not add the unused solution, which begins to harden, to the freshly diluted mixture. It will thicken much faster or may deteriorate altogether. It is also forbidden to add water to the hardening solution - this will seriously reduce its adhesive properties.

Some specialists do not apply glue pointwise, but with a notched trowel over the entire sheet with a smaller layer thickness (1 cm). In this case, the alignment of the gypsum board on the wall is easier. Usually, this technique is used in the presence of serious irregularities, cracks, pits in the base. If all the recommendations are followed, you can get an excellent quality of wall finishing, an excellent level of adhesion, which will prolong the life of the finished coating.

How to use

Before starting work with Knauf Perlfix glue, you should determine its consumption on the desired surface. According to the instructions, the consumption of the assembly composition for drywall is 5 kg per 1 m² when processing the surfaces of gypsum plasterboard and gypsum plasterboard, in the case of working with GWP, the consumption will be 1.5 kg per 1 m². However, in practice, the consumption of funds may be slightly different, it all depends on the experience of the master. Professionals, who have already pretty much got their hands on the installation of tongue-and-groove tiles (PGP), apply a little diluted glue to the surface so that after the sheet is applied, a little means comes out of the joint.Newbies in the construction industry do not like to save the mixture, thinking that this is bad, and they apply a lot of glue, which leaves a large amount of excess composition.

Here you should take into account the fact that the work takes place with gypsum, and not with ordinary glue or cement. If in the second case it is possible to remove all the excess with a spatula and put them back into the container, then in the first one - this cannot be done, because the mixture collected from the gypsum will greatly reduce the life of the glue. It will simply dry right in the bucket in about fifteen minutes, which will result in overruns. But thanks to its ease of use, you can quickly and easily learn how much to mix and apply to the substrate to be treated.

One of the main conditions when working with Perlfix glue is the temperature level, which should not be lower than +5 degrees. When working with a product weighing 30 kg, you will need 16 liters of water.

Working with Knauf Perlfix glue is done in the following order:

- first you need to clean the wall from dirt, dust and detachment;

- in the case of working with gypsum plasterboard, the wall should be primed, preferably with a primer of the same brand as the drywall glue itself;

- perform the process of mixing the mixture, usually this is done in a plastic container;

- a dry mixture is added to the water in a ratio of 1: 2;

- stirring is recommended with a construction mixer, as a result, you should get a mixture without lumps, similar in density to sour cream;

- in the case of a strong density or liquid state of the glue, add water or dry product, respectively. Professional craftsmen, so as not to be mistaken, add the mixture gradually, while stirring. This allows you to control the consistency of the glue;

- you need to use the resulting mass within thirty minutes, so it is advisable to make small portions that will be used during this time;

- it is recommended to apply Perlfix pointwise, making distances of 30–35 centimeters;

- if drywall is less than one centimeter thick, glue is applied along the center line in a row, when working with a thickened sheet, it is applied in two rows over the entire plane;

- the sheet is carefully applied to the wall from bottom to top, and then leveled.

Knauf Perlfix glue has optimal plasticity and adhesion to materials. It perfectly demonstrates its properties when working with tongue-and-groove plates and frameless base cladding. The democratic price of the product and the large volume allow you to spend less money on repair work.

How to properly glue drywall on Knauf Perlfix glue, see below.

General information about the Knauf company

It is a world-renowned manufacturer of construction products. Its materials are used for interior and exterior decoration, as well as for machine application.

The organization was created in 1932 in Germany by two brothers - Alfons and Karl Knauf. Their company has proven itself as a manufacturer of high quality finishing materials. Now she has reached the world leadership in the construction industry.

The first factory was opened in Bavaria in 1949. Initially, the company produced only gypsum mixes, and from the beginning of 1958 it began to produce gypsum plasterboards as well. In order to finally gain a foothold in the market and expand the range of products, Knauf in 1970 acquires a stake in Deutsche Perlite GmbH (the company produced dry cement mixtures), and soon a plant for the production of fiberglass thermal insulation in Shelbyville (USA). This diversified risks and brought the organization to a new level.

In 1993 the Knauf company opens factories in the CIS countries. Today it is a successful company with a worldwide reputation for the production of high-quality and durable materials.

Features and Description

Perlfix is a plaster-based assembly adhesive. It is a product of the international industrial company Knauf. The company was founded in Germany in 1932.The brothers Alfons and Kard Knauf, who lived in northern Bavaria, were fascinated by its qualities when they became acquainted with gypsum. They dreamed of creating ideal building materials using it.

Today Knauf Gips KG is an international company with production facilities all over the world. The production processes are still based on gypsum. The company's technologists are developing unique building materials using it.

Perlfix securely fixes finishing materials. He does not need additional fasteners. The guaranteed service life of the coating glued to it is several decades. Perlfix ready-to-use mortar is used over a wide temperature range. The adhesive is used in houses with medium humidity. The fixation period is one week. The seams must be rubbed. Do this after the glue has completely risen. In sealed packaging, Perlfix retains its qualities for 6 months.

The adhesive mass is non-toxic and hypoallergenic. There are no harmful impurities in the composition. The glue is not harmful to human health. To fix the finishing material well, the adhesive solution is applied in a layer 2 cm thick. The glue is sold as a ready-made dry mixture. He does not need hardeners. It is simply stirred with cold water. A significant plus of using assembly glue from Knauf is simplicity. It is stirred with water, bringing to a pasty state. The finished batch must be used within half an hour.

Perlfix cannot be used in rooms with high humidity. Direct contact with water is not allowed. A coating applied to Perlfix glue will last for many years, provided the work surface is properly prepared. Perlfix has good adhesion to concrete substrates. The increased gypsum content guarantees the strength of the adhesive in compression and bending.

How to calculate consumption per 1 m2

The consumer always wants to know exactly how many bags of the mixture should be bought so that they are enough to complete the renovation in the room. Buying more is wasted money. Therefore, the issue of expense is dealt with before the start of work and purchase.

As stated earlier, Perlfix is sold in 30kg bags. Therefore, glue for gypsum board Perlfix is 30 kg. Knauf consumption is easy to calculate. The manufacturer on the packaging of the products indicated the consumption per square meter of five kilograms. Based on these data, calculations are carried out. They consist in the following actions:

- The first step is to calculate the area of the room by multiplying the width by the length of the walls.

- The resulting figure is multiplied by 5, the product will indicate the required amount of glue in kilograms.

- This result is divided by 30, this is the number of kilograms of the mixture in one bag.

The final figure indicates how many Perlfix bags to buy. With a fractional answer, rounding up is performed.

The powder is stored in a dry place, the best way is to place it on wooden pallets, this storage will create ventilation. With an increase in humidity in the room, the composition will retain its properties. If the bag is damaged, the mixture is poured into a new container, which must be tightly closed. The glue can be stored in a well-closed package for 6 months without losing its characteristics.

The powder is stored in a dry place, the best way is to place it on wooden pallets, this storage will create ventilation.

The powder is stored in a dry place, the best way is to place it on wooden pallets, this storage will create ventilation.

Knauf Perlfix gypsum mounting glue is a quality product that will help to obtain a high-strength connection of various finishing materials to the surface. It is easy to work with it, independent application is possible. Due to its positive properties and acceptable cost, it is in demand by many specialists and ordinary buyers.

It is important when buying to check for a quality certificate in order to get an original product, and not a cheap fake that will not have the expected properties.

Adhesive for foam concrete BOLARS Mounting (frost-resistant)

General information:

- GOST, TU: TU 5745-030-56852407-09

- Manufacturers: AG Construction Market LLC

- OKP code: 5745111005

Specifications

Technical characteristics: Color: gray. Drying time - 24 hours. The density of the mortar mixture is 1.4-1.5 g / cm3. Bulk density of dry mix - 1650-1750 kg / m3. The thickness of the applied layer is 2-10 mm. Adhesion - not less than 5 kg / cm2. Compressive strength - not less than 75 kg / cm2. Frost resistance - at least 50 cycles. The service life of the solution to work at -10 ° C is 30 minutes, with an increase in temperature, the service time increases up to 3 hours. Thermal conductivity - 0.32 W / mK. The temperature of the work is from -10 ° С to + 30 ° С. Operating temperature from -40 ° С to + 60 ° С.

Description: Glue BOLARS Assembly frost-resistant - multifunctional construction glue, made on a cement-sand base with the use of high-performance imported polymer additives. Consumption: 3-3.5 kg / m2. Packing: 25 kg kraft bags.

Scope: For laying blocks and slabs made of aerated concrete, gas silicate, foam and aerated concrete. It is used when laying walls and leveling surfaces. The glue has heat and sound insulating qualities. Used for indoor and outdoor use.

Application method: Amount of water per 1 kg of dry mix: 0.20-0.24 l (for a 25 kg bag - 5.5-6 l). Stir manually or mechanically (with a drill with a nozzle), evenly pouring the dry mixture into water until a homogeneous pasty mass is obtained. Let the solution stand for 5-10 minutes, mix again. The surface must be clean. Dust, grease should be removed, the glossy surface should be sanded, significant irregularities should be leveled with the filler group of BOLARS materials. It is recommended to treat the surface with deep penetrating soil BOLARS Deep Penetration Soil. The adhesive should be applied with a smooth trowel and then leveled with a notched trowel.

Analogs of glue

There are similar products in stores, which practically do not differ in properties from Knauf Perlfix. The most popular ones are:

- ByProc - universal gypsum glue GKU-450. It is used for interior work at normal and low air humidity. It is used for fixing sheets of gypsum board, heat and sound insulation, mineral wool and expanded polystyrene, gypsum fiber. Also, the glue is ideal for gluing stucco moldings, a number of decorative materials and small tiles.

- Volma Montage. This dry mixture provides high adhesion and long service life, allows you to attach gypsum elements, gypsum boards, tongue-and-groove plates, sheets of thermal insulation to the walls. The mixture has a low consumption - up to 2 kg per 1 sq. m, as well as the viability of the solution up to 1 hour.

- Perel Gipsel - the glue is famous for its frost resistance, therefore it can be used in unheated rooms. The time for adjusting the position of the plates glued to this tool is only 5 minutes, so it will be quite difficult for a beginner to work with it.

- "Osnovit" - Gipsform MG assembly glue. It is used for fastening all types of gypsum plasterboard and gypsum fiber, as well as expanded polystyrene. Produced in medium-sized bags - 20 kg.