Range

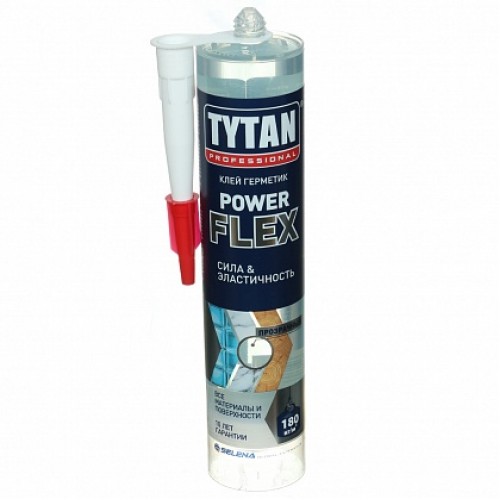

The catalog of Tytan products is varied. Let's dwell on three types of product in more detail.

Installation product Classic Fix

Glue Classic Fix ("Classic Fix") has versatility. Due to what the composition can be used indoors and outdoors. For the manufacture of a transparent composition, the manufacturer used synthetic rubber.

Specifications:

- full curing process - two days;

- product consumption is from 150 to 300 grams per square meter;

- resistance to temperatures from - 30 to +60 degrees Celsius;

- shelf life - 1 year.

Peculiarities:

- increased strength;

- excellent adhesion to most materials;

- resistance to moisture and frost.

Usage:

- work with materials such as wood, metal, PVC, polycarbonate, ABS, glass;

- installation of decorative elements and various items (mirrors, shelves, hooks and much more);

- connection of structures made of light and heavy metals.

Super strong compound No. 901

A rubber compound with excellent durability is used for indoor and outdoor work. In the process of work, a moisture-resistant, durable and elastic seam is formed.

Technical specifications:

- the glue dries completely in 24 hours;

- composition color - beige;

- material consumption from 200 to 400 grams per m²;

- glue can withstand temperatures from 30 degrees below zero to 60 degrees Celsius;

- the shelf life of the glue is a year.

Peculiarities:

- the composition does not contain toluene;

- durable and reliable seams;

- resistance to weathering.

Usage:

- installation of structures made of materials such as plaster, plastic, stone, ceramics, glass, wood, plywood;

- connection of elements and panels.

Special glue No. 915

The water-based composition is specially designed for use in rooms with high humidity. Liquid nails are ideal for bonding various building materials to porous surfaces.

Performance characteristics:

- glue color - white;

- the minimum temperature indicator maintained by the composition is 20 degrees below zero, the maximum is 60 degrees Celsius;

- the material hardens in two days;

- product shelf life - 12 months;

- the consumption volume ranges from 200 to 400 grams per square meter.

Peculiarities:

- excellent resistance to steam, moisture and dampness;

- the glue is not susceptible to the formation of mold and mildew;

- fast adhesion.

Usage: joining elements made of plastic, stone, natural wood, polystyrene and gypsum.

See below for more details.

Scope of application

Sealants are used in almost any type of repair and finishing work. Due to their numerous advantages, such as resistance to temperature extremes, exposure to aggressive chemical elements, water and ultraviolet light, such compositions are used both for outdoor work and in harsh industrial conditions.

As for domestic use, most often sealants are indispensable when installing plumbing, as well as other equipment and decor items in the bathroom. Any other glue will be of little use here, since constant humidity and the formation of mold fungi do not allow non-sealing compounds to serve for a long time in such conditions and to fix all items reliably. It is good to seal the joints between the sink, bathtub, toilet bowl and walls with a white silicone sealant. A silicone or polyurethane compound is also perfect for gluing the gaskets at the drum of the washing machine. On especially durable types of sealant, you can completely plant a mirror in the bathroom like on liquid nails and not be afraid that it will move away from the wall from the high humidity in the room.

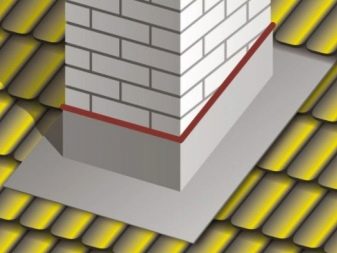

The sealing properties of bitumen glue are actively used in the processing of threaded connections in various mechanisms, as well as seams in drainpipes, even from the inside. It is also popular during renovation work on facades and roofs of buildings, during the renovation of PVC products and even vinyl siding.Reliable adhesion of parts that are outdoors and exposed to temperature fluctuations - all this is a bitumen sealant on the shoulder. And the elements of the tiles, through which water flows from the roof, and the steps peeling off at the threshold of the house, and tiles made of natural stone - everything is easily fixed with the above-mentioned composition.

The most famous area of application for both silicone and acrylic sealants is the installation of plastic windows, as well as the gluing of gaskets on the closing mechanisms adjacent directly to the glass. The second most popular room after the bathroom when working with sealants is the kitchen. There are seams on tables and window sills, they lend themselves well to gluing, regardless of whether they are created from artificial material on a composite basis or from natural stone. This also includes work on adhesion to each other of parquet or laminate bars, which require a moisture-resistant composition that well reflects mechanical shock.

Description

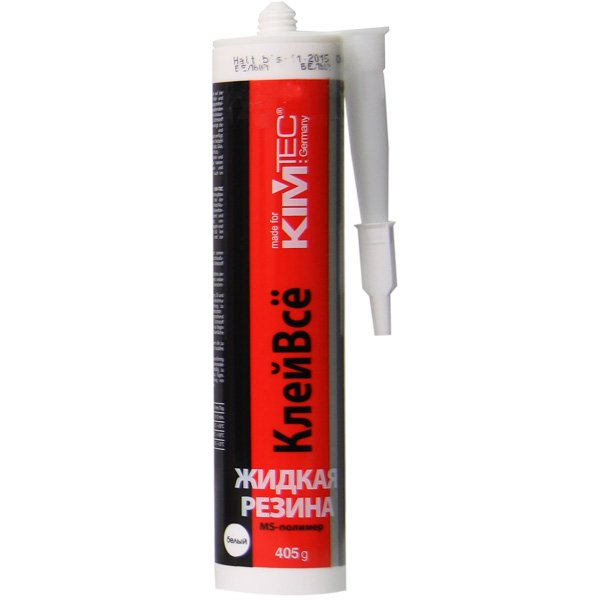

BISON LIQUID RUBBER CARD 50 ML

1000 and 1 application for repair, protection and waterproofing.

APPLICATION AREA

Ideal for bonding, filling voids in leather, rubber, textiles, neoprene, synthetic materials, wood, metal or ceramic. It is also great for repairing (sports) footwear (heels, soles), sneakers, gloves, slippers, inflatable rubber or vinyl products (boats, mattresses), bags, raincoats, diving suits, saddles, decorative materials, headlights; as well as for strengthening the seams. Not suitable for polyethylene (PE) and polypropylene (PP).

PROPERTIES

- Lasting

- Waterproof

- Permanently elastic

- Universal

- Filling the voids

- Chemically resistant

- Heat-resistant within -40 ° С to + 120 ° С

- Transparent

PREPARATION Working conditions: do not apply at temperatures below + 5 ° C or at too low relative humidity. Requirements for surfaces: materials must be completely dry throughout the entire thickness. Surface pretreatment: bonded surfaces must be dry and free from grease and dust. Sand with the supplied abrasive paper Tools: abrasive paper and trowel (included).

APPLICATION Instructions for use

Using a spatula, spread the paste evenly over the surface to be repaired, protruding at least 2 mm beyond the contour of the damage. Smooth with a spatula. Outsole and rubber boats: surfaces must be absolutely clean and dry on all sides. Sand it. Apply in a thin layer (less than 1mm). Place the supplied polyester mesh (min. Width 2.5 cm) and press it into the paste with a spatula. Apply another layer of paste on top, completely covering the mesh. Smooth with a trowel and leave for 48 hours Removing stains / residues: Remove fresh stains with acetone

Dried adhesive can only be removed mechanically.Note: if the cap cannot be unscrewed, hold it under running hot water and unscrew. Use a sharp knife to remove dried glue residues from the cap and around the spout

The adhesive hardens when exposed to ambient humidity. Therefore, slight foaming is possible. Low air humidity greatly slows down the curing process.

DRYING TIME Skin formation: ~ 10-30 minutes Final strength: 48 hours.

* Drying time will vary depending on surface type, amount of adhesive applied, humidity and ambient temperature.

TECHNICAL DATA Moisture resistance: Very good Water resistance: Good Heat resistance: -40 ° C to + 120 ° C UV resistance: Good Chemical resistance: Good Elasticity: Very good Filling ability: Very good

TECHNICAL DATA Base: MS polymer Viscosity: approx. 125 mPa Color: transparent

Peculiarities

Silicone adhesive sealant first appeared on store shelves in the 1970s and has become one of the multi-functional, versatile construction products that is still used today in joint sealing and many other construction jobs. He is preferred by professionals and ordinary home craftsmen who have started repairs. After all, there has always been a need for grinding joints, sealing holes or seams, and therefore invented a glue-sealant to help.

The adhesive sealant is used on numerous surfaces and has the following properties:

- resistance to temperature drops (atmospheric pressure is not scary when applied from the outside of the room);

- heat resistance in conditions from -50 to +300 degrees;

- plastic;

- adhesion to various parts;

- up to 100% elasticity;

- holds its shape and does not flow down when applied with a thickness of less than 1 centimeter from vertical surfaces;

- polymerization shrinkage is zero;

- filling gaps and cracks;

- solid and durable structure;

- different temperature range;

- after application does not emit harmful and toxic substances - this building material provides complete environmental safety, and the presence of a slight odor does not indicate the harmfulness of the product.

The substances that are used in the manufacture of the adhesive sealant are as follows:

- rubber;

- plasticizer;

- an element for imparting plasticity and the necessary strength;

- vulcanizer (there are several types of vulcanizers to impart viscosity to the agent);

- material that allows the silicone to adhere to the surface.

The quality of the adhesive sealant is influenced by the additives that are used at the production stage. To reduce viscosity, a number of specific constituents are included.

These include the following:

- components with natural bases;

- chemicals to kill mold and mildew;

- viscosity additives;

- fungicides - antifungal antiseptics;

- mechanical adhesion additives and chalk;

- quartz dust and glass;

- fungicides that prevent the development of all types of microorganisms;

- dyes - silicone in the course of work is not subjected to further painting, color creation occurs at the production stage.

Heat resistance and adhesion have an important effect on the quality of the adhesive sealant. It should be easily applied to coatings made of wood, ceramics, iron, concrete and plastic, and its aging after drying serves as a guarantee of longevity.

Sealant adhesives remain resistant and durable to the external environment, as well as destructive factors. All of these listed options are versatile in their own way and help to achieve high results in various areas of adaptation.

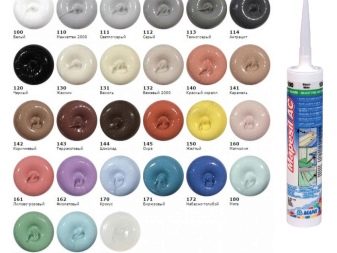

Colors

During the repair, it is very important for the master that the joints and seams are not visually striking, do not draw attention to themselves. The ability to glue the surfaces at eye level with a sealant to match the base product is a very important thing. A transparent sealant is considered the most versatile, so it is most often used when repairing plumbing at joints.

The colorless composition retains the same degree of water resistance as the painted versions, therefore it is applied even where water leaks and excessive mold formation are possible. A sealant is also very popular when grouting joints during the assembly of kitchen sets, because the color of natural wood or stone is extremely difficult to imitate with a monochromatic composition

The most versatile is considered to be a transparent sealant, so it is most often used when repairing plumbing at joints. The colorless composition retains the same degree of water resistance as the painted versions, so it is applied even where water leaks and excessive mold formation are possible. A sealant is also very popular when grouting joints during the assembly of kitchen sets, because the color of natural wood or stone is extremely difficult to imitate with a monochromatic composition.

White sealant is the most common in any hardware store. Most often, white is the natural color of the composition, therefore, coloring additives are not mixed into it, which increase the final cost of the product. It is convenient for gluing seams of mostly white plumbing, between tiles in the bathroom, as well as the slopes of plastic windows.

Black sealant, if it is of natural origin, is a rich color of oil with a glossy sheen. It is not suitable for many places, only for internal gluing of pipes or threaded mechanisms, as well as in places inaccessible to the daily gaze of a person.An exception is the deliberate use of black sealant as a decorative element inside art spaces and lofts, when they want to emphasize the texture of an uneven wall with a dark gasket.

Sealants with colored pigments such as red, yellow or beige are not uncommon these days. They are more expensive than a white shade, but for the correct aesthetic perception of the repair, it is worth slightly overpaying, given the fact that silicone sealants, unlike acrylic, are almost impossible to paint with ordinary paint after hardening.

Peculiarities

Adhesive sealant is a mixture consisting of a set of polymeric materials with various organic and artificial additives. The scope of its purpose depends on the main element that is part of the tool.

A sealant must have a number of beneficial properties.

- The ability to adhere, that is, good adhesion to other surfaces, so that the edges do not lag anywhere, the surface with glue does not swell and does not bump. The more surfaces that can be treated with the same type of sealant, the more versatile it is considered, and, accordingly, the more expensive it costs.

- Resisting the development of mold fungi, which is especially important for the joints between tiles in the bathroom, where, due to poor-quality sealant, sometimes all repairs have to be redone.

- Resistance to the formation of cracks in the seam and their destruction, because glue is not a consumable that needs to be changed every year. Ideally, the sealant should withstand both mechanical shock and internal tremors and vibrations for years. If even a small crack has formed in the hermetically sealed seam, it immediately begins to let through both heat and moisture.

The ability to easily tolerate changes in the environment, such as sudden changes in temperature, increased exposure to moisture, dust or ultraviolet radiation

Many types of sealants are used for outdoor objects, so it is important that they do not crumble after the first rain.

Resistance when interacting with aggressive chemical elements such as gasoline or alkali is also very important, even if we are not talking about industrial facilities. For example, you can only glue the door rubber bands on your car so that they last at least a year, you can only use very high-quality material.

- Plasticity and viscosity also play a big role in choosing the right adhesive sealant, because it should smoothly fit into the gap and seam of any shape and depth, evenly distributed over the surface.

- The speed of drying and hardening, because the faster these processes occur, the safer the repair algorithm. This characteristic of sealants is especially important when repairing in open areas, when the glue that hardens for a long time will simply creep out from bad weather. In some cases, the slow rate of hardening, on the contrary, can be salutary, especially when the seam is sealed inaccurately from sudden movement or carelessness. Otherwise, the quickly hardened material will have to be cut off in the places where the excess is formed with a knife or the result should be left as it is.

Advice

As you already know, the range of sealants with an adhesive effect is so extensive that sometimes it seems impossible to choose the one you need on your own. When buying, it is worth contacting consultants, because they will help you decide on the choice of a product depending on the surface to be processed. Do not be afraid to ask the seller for documentation about the presentation of the product brand. The shelf life is usually 18 months from the date of production. Storage should be tightly closed, while adhering to the temperature indicated on the bottle.

Before buying, you need to focus on the percentage of the components, which should be as follows:

- silicone - at least 25%;

- rubber mastic - from 3 to 5%;

- acrylic - 4-5%;

- polyurethane - 3-5%;

- the content of the cement mixture is not less than 0.4%;

- epoxy resin - 2%.

Attention should be paid to the timing of the manufacture of the adhesive sealant, its quality, and to avoid such products:

- with a damaged label;

- low cost, which raises suspicion;

- with a note that silicone is 100%, because absolutely all manufacturers use additives;

- with a light tube weight;

- with the lack of information on the cylinder and composition;

- the seller does not have copies of the quality certificate.

In the next video, you will find a detailed overview of the Soudal universal adhesive sealant.

Advantages and disadvantages

All sealants, regardless of their chemical composition, have the same set of advantages:

- adhesion or the ability to grow together with many materials;

- water resistance, heat resistance and resistance to aggressive environmental influences, including corrosive chemical elements;

- some types of sealants differ in their constituent substances - fungicides, which have an antifungal effect;

- high elasticity coupled with strength, which allows it to withstand vibrations, mechanical shocks and temperature drops, while not cracking.

Of the few disadvantages, the following can be distinguished:

- pungent odor and the presence of toxic substances in the composition of certain types of sealants;

- a sufficiently long period of drying of each layer.

Views

In addition to the silicone base, there is also an acrylic-based adhesive sealant. They differ in characteristic constituent components. The silicone base uses rubber, and the acrylic base uses acid. A universal variety is acrylic adhesive sealant, after application it can be easily sanded to create a completely smooth coating, which can be further prepared for painting, which is unacceptable with rubber.

Adhesive sealants are viscous in composition, and are divided into one-component and two-component types.

One-component, as a rule, are divided into two main groups:

- neutral - they release part of the compound solution, which does not oxidize when in contact with the material, this list includes materials such as PVC, copper, metal surfaces and wood;

- acidic - this group oxidizes the above surfaces and does not guarantee adhesion throughout the seam.

Two-component formulations are less common and are used more in industrial applications. These types of polymers form an elastic bond when cured. Since they have stable heat resistance and adhere well to many building surfaces, their range is quite wide among builders and ordinary users who have undertaken major or cosmetic repairs.

It is worth paying attention to the shelf life before the purchase itself, to the integrity of the packaging and for what areas of use it is intended. The final result of the work will depend only on how correctly and accurately the adhesive sealant will be selected

Advantages and disadvantages

It is the adhesive sealant that is one of the most commonly used building materials. Reviews, main differences, disadvantages and advantages will help you in your further choice.

Adhesive sealant has the following advantages:

- strength and durability;

- high level of elasticity;

- compatibility with different materials;

- resistance to chemicals and ultraviolet light;

- high level of heat resistance;

- freezes quickly;

- changes in air humidity do not affect adhesion;

- high temperature resistance;

- gluing to different surfaces (stone, ceramic tiles, concrete, metal and glass surfaces);

- excludes the development of microorganisms (mold, fungus);

- moisture insulation;

- resistance to environmental factors;

- ease of use;

- affordable price;

- retains its basic properties for decades.

Among the disadvantages are the following:

- there are a number of surfaces, the connection with which does not perform its function well, for example, polyethylene or fluoroplastic;

- the exterior must be washed and degreased with special means before application, it is thoroughly cleaned and dried at the end;

- there is a deterioration in the interaction of properties when applied to a wet plane, which concerns only non-waterproof types;

- in the absence of impurities, it is not subject to further painting;

- when solidified, it stains poorly;

- may fade when applied to external sources;

- poor adhesion to plastic coatings;

- there is a specific smell that disappears after a while;

- the hardening process depends on temperature changes, sometimes this process is too long;

- not the fastest recycling process.

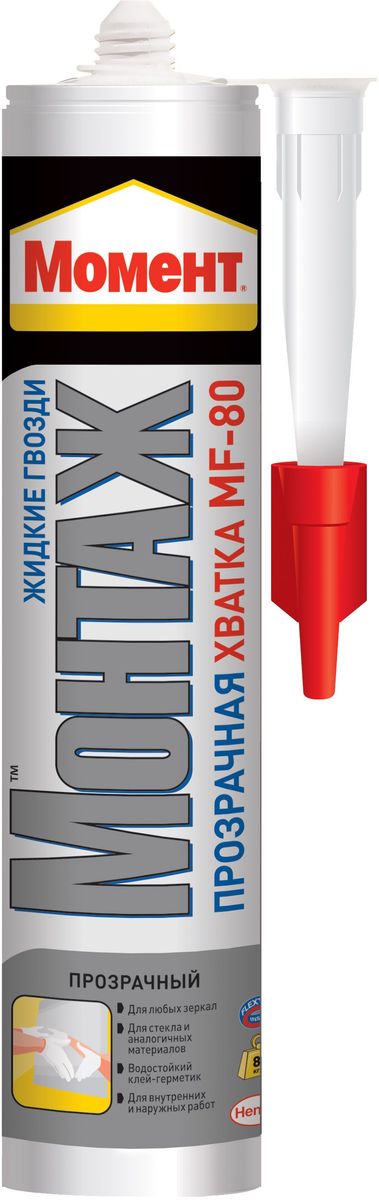

Instructions for use

First you need to find the right glue so that it perfectly matches the materials used. The easiest way is to use polyurethane glue, it dries faster, and it is easy to apply. When working with glue, it is necessary to provide good ventilation, but without drafts - the latter violate the quality of adhesion and change the drying rate of the composition.

You need to work with glue like this:

- Perform high-quality preparation of the base. All dirt and dust must be removed from the wall, ceiling, and other surfaces. Remove the falling off pieces of the old coating, apply plaster, cover all holes and defects as well. Products made of metal, plastic should be sanded, degreased. Use a primer if possible. The substrate must be absolutely dry immediately before applying the adhesive.

- Apply Titan glue to one side (for complex or large surfaces, all surfaces to be glued must be processed, for tiles - apply glue with a snake). Firmly press the materials together, do not tear off your hands or the fixing device for at least a minute (if we are talking about a ceiling tile, you need to hold it with your hand for 60 seconds, then you can release it). Leave the products alone until the glue is completely dry.

Glue-mastic is applied with a spatula pointwise or by a continuous method, if the product has a significant weight. "Liquid nails" are applied with a glue gun in strips, waves in a thick layer, they can be used to finish surfaces with differences and defects.

Dried glue stains are noticeable in bright light, so it is recommended to remove them immediately. Expanded polystyrene, other soft substrates can be cleaned with a damp cloth if the glue has not yet hardened. After drying, the glue is removed from solid substrates by picking it up with a sharp spatula and tearing it off with your hands. You can also use organic solvents for cleaning surfaces - acetone, white spirit.

How to dilute the glue

It happens that the glue dries up and becomes more viscous. If it has thickened, you can dilute the composition by simple steps. It is necessary to take ordinary medical alcohol, add it to the glue in a small volume, shake well. The diluted product dries a little longer, but it penetrates better into the smallest cracks, pits. How to dilute the glue in tubes when thickening? It will not be possible to restore the normal consistency of such a product due to the tightness of the package, but it can become too viscous only after the expiration date.

Glue-mastic Abizol G

Titanium bitumen-rubber mastic is excellent for gluing polyurethane, expanded polystyrene, tiles, artificial stone, wood, drywall to various surfaces (concrete, plaster, cement, brick and other surfaces).

The mastic can be used for leveling surfaces, sealing metal structures, repairing roofing material, filling joints and cracks in roofing, as well as gluing ceiling tiles. Due to its heat resistance, the composition is actively used in the laying and facing of stoves and fireplaces.

Abizol G is renowned for its fast drying and the ability to apply it even on damp surfaces.

Mode of application: glue is a thick substance that is packaged in cans. Before use, the composition must be thoroughly mixed and, if necessary, diluted with water or medical alcohol (no more than 5%).

The material is applied with a spatula on one of the glued surfaces with a thin layer (no more than 4 mm). In the case of gluing a stone or tile, press the product to the surface for 5-10 seconds and only then release it. During the first seconds, the position of the object to be glued can be corrected, then the composition begins to solidify. It sets in 20 seconds, and it takes up to 12 hours to dry completely.

Usage

It is not difficult to use the sealant, it does not require special professional training.

It is enough to adhere to a certain algorithm for its application to any surface.

- Before opening the container, make the room ventilated, wear protective gloves and a mask.

- The surface on which the sealant will be applied must be wiped, cleaned from previous paint and varnish layers and degreased. If you cannot completely remove all unnecessary things, you can first prime the coating with a special compound. It is better to seal the neighboring elements with masking tape and oilcloth so that the sealant does not stain too much.

- For small work indoors, it is recommended to load the sealant into the assembly gun, and squeeze out the compound at an angle in thin strips to the place of the intended seam. If two moving elements are glued together, then you can mechanically flatten them against each other and hold for a minute or two in this position.

- Excess sealant can be removed with a spatula or white spirit until the compound is dry. After it has hardened, unnecessary residues are either cut off with a special knife, or they acquire a solvent for a specific type of sealant.