Glass wallpaper gluing technology

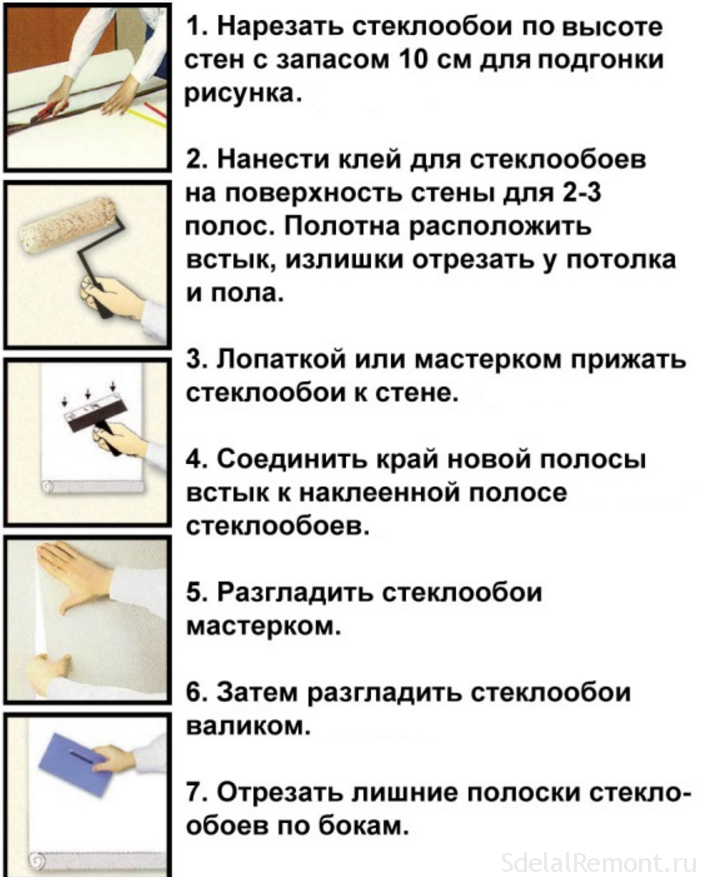

- We measure the height of the wall or the length of the ceiling and cut pieces of the desired size from the wallpaper roll.

- You need to start gluing glass wallpaper for painting from the corner.

- We measure from the corner the distance 2-3 cm less than the width of the roll.

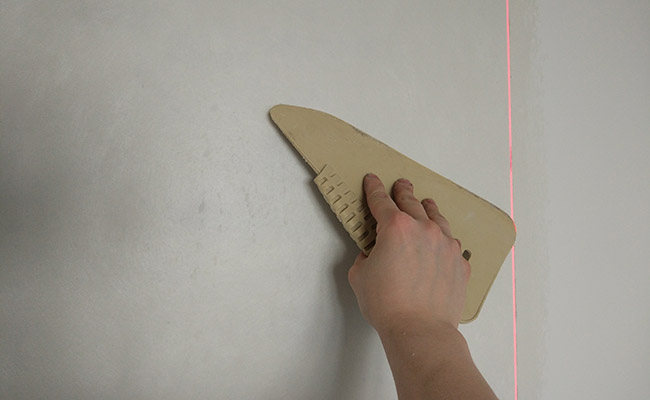

- We fix this distance for the first piece along the entire height of the wall using a slope or a laser level.

- Cover the wall surface and corners with glue abundantly.

- We take the first piece, glue it strictly vertically, going into the corner and pull the edge of the wallpaper along the plumb line from edge to corner (using a plastic spatula, we drive out the bubbles from right to left and from top to bottom).

- For reliability, you can walk over the glued piece with glue, but not abundantly.

- We glue the second sheet with an overlap. To do this, measure from the first piece the distance of the width of the second, smear the abundantly measured distance along the wall with glue and 5 cm of the first piece.

- We glue the second piece with the approach to the first.

- With a clerical knife, cut through a metal spatula or a long ruler overlap in 2 layers (first the second piece, then the first).

- We remove the remnants to get an invisible joint.

- We return to the first piece.

- Close up the corner. Using a metal spatula, cut off 2-3 cm in the corner.

- Do not forget to grease each glued piece on top with a light layer of glue.

It is better to glue fiberglass wallpaper to the ceiling using the joint method. For the convenience and quality of the ceiling finish, it is better to work together.

You can glue the fiberglass on the walls butt-joint, but the material from the glue breaks and is difficult to combine. It is easier to "overlap", that is, on the previous piece we put a new canvas going 2–3 cm, cut the overlap with a spatula or a ruler with a clerical knife, but do not press hard, cut it off carefully so as not to damage the wall, we get a perfect joint.

We smooth it and apply the glue without regret. Be sure to watch that there are no dry areas.

The stages of gluing fiberglass are similar to gluing fiberglass:

- Prepare the walls: process the seams, apply the joints with an even layer of putty (KHAUF, KHAUF Rotland Pasta, Ceresit, Monolith, Kron, etc.).

- After drying, sand and sand the unevenness.

- Remove dust from the walls with a vacuum cleaner.

- Cut pieces of fiberglass to the desired length.

- Glue the wall.

- Glue the fiberglass.

- Apply glue liberally to the glued piece with a roller and then rub it in with a spatula to clog all the pores of the fiberglass.

- Wait for complete drying (1 day).

- Fill with finishing filler.

- Apply a primer.

If your walls are crooked and cracking, then the fiberglass is applied twice, and it is imperative to putty the last layer, if the walls are for painting, then less paint will go away, and if under the wallpaper, then the fibers will not show through, and less glue will go under the wallpaper.

What is fiberglass and where is it used

The painting canvas consists of the finest glass threads, it is light, and very thin, for which it is often called "cobweb". If you unfold the canvas, you can get a perfectly flat surface, but due to its structure, it is rather prickly.

This material is created not by weaving, but by pressing glass fibers. The result is a very strong web that is lightweight.

Painting cobwebs are used in the process of leveling the walls of premises, in combination with plaster. And if the starting layer of putty is reinforced with fiberglass mesh, then this material acts as an intermediate layer between it and the finish.

The use of leveling compounds with fiberglass makes it easier to obtain an even base, which can then be painted. But, in addition to this application, non-woven glass fabric strengthens (reinforces) the finishing layer of plaster.

Particularly relevant is the use of fiberglass finishing for walls in newly built houses and apartments. Construction during the first 1-3 years, as the builders say, "shrinks". And as a result, along with the deformation of the walls, the finish cracks.

But, after all, you can use, for example, fiberglass wallpaper as a durable finishing material, or, as is most often done, simply apply mesh reinforcement, at no extra cost. Yes, it is, but canvas based on strong fibers has significant advantages over analogues.

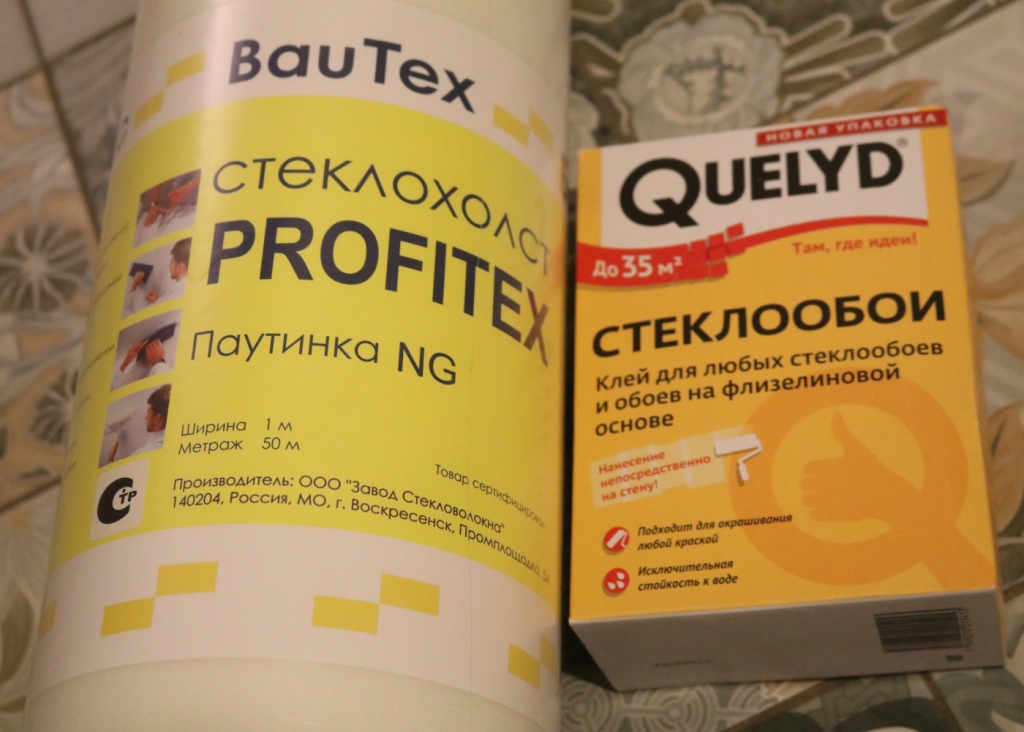

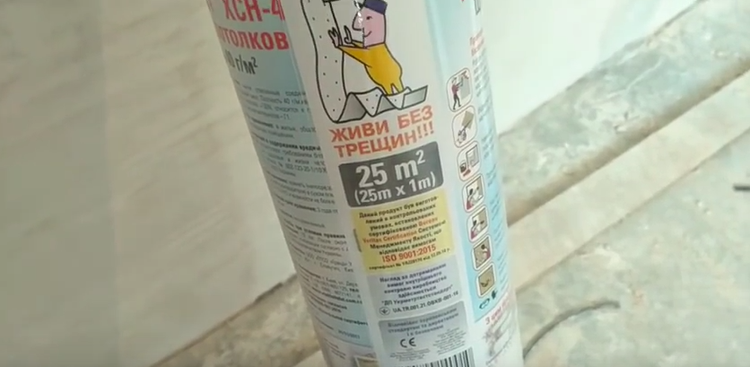

Adhesive for fiberglass

There is a special glue for fiberglass, it says to us "for fiberglass". Yes, because canvas is a special case of fiberglass wallpaper. Every normal manufacturer has this type of glue, it differs from the usual wallpaper with special additives - methylcellulose, sometimes PVA, so it is more powerful than standard starch. It is sold both in the usual cardboard boxes and in ready-made buckets. Among dry adhesives, our masters like Quelyd, Krass, Pufas the most. Among the ready-made ones is Oscar. You probably all know how to make glue - pour it very slowly into a bucket of cold water with constant stirring. Lumps and dirt should not be allowed. As for the consumption, it will be much higher than the figures that are written on the pack. On average, one pack per pound is enough for 20-25 squares, due to the peculiarities of the technology. We will talk about them.

Adhesives for fiberglass

Before studying the topic of how to glue fiberglass, it is better to get acquainted with the features of adhesive mixtures for it.

Types of adhesive

Building materials stores sell 2 types of such compounds: ready-made, packaged in plastic buckets, and dry powders in paper bags.

- Ready-made glue (5, 10 l or larger). When buying it, you must check the date of manufacture on the container. Otherwise, you can purchase expired goods, and the result of the work will be the appearance of bubbles. Another potential nuisance is web flaking due to poorer adhesion. It is recommended to use open containers in the near future, since there is no guarantee that the composition will not lose its characteristics.

- Dry powder. This is a more practical option, since this type of glue costs less, but it allows dosed use - only in the right amount. Prepare the glue in strict accordance with the instructions on the package. Unless otherwise indicated, the powder is poured into warm water, stirring constantly. The prepared composition is kept for about 10-15 minutes, because it should swell. Then the glue is stirred again.

The third possible option is PVA, but with only one condition. The fiberglass has a rather low density, so the glue will soon turn yellow in the light. This color change will definitely affect the light finish. If the choice fell on PVA, it is better to choose paint in dark tones. However, special mixtures are better: they contain additional additives that give the material maximum strength.

Glass-breaking adhesives

Since fiberglass can be glued with the same compositions as fiberglass, the assortment for choice is wide enough. The most popular brands are mixtures of several manufacturers.

- Quelyd is a French brand. A large number of various adhesives for wallpaper, liquids for their removal, sealants and mastics are produced under it. The most popular product for glass fiber wallpapers is Optima.

- Oscar is a Swedish brand, the compositions are produced in Russia. The adhesive, ready-made or dry, is characterized by minimal consumption and high strength. Additionally contains fungicides that prevent the formation of mold.

- Kleo is another Frenchman. This company specializes in the production of dry adhesives for glass fiber wallpaper and fiberglass. The products are distinguished by high quality, but reasonable price, quick preparation of the mixture, the same drying.

- Pufas is a German candidate for surface repair. The manufacturer produces paints and varnishes, adhesives, primers. The product for glass wallpaper is famous for its excellent adhesion properties.

- Bostik is another brand from France. The company produces various adhesives, but the best known is the parquet mix. Despite the low price, the adhesive mixtures for the canvas guarantee the reliability of the coating, easy joining of the canvases.

Other worthy contenders include products from Spektrum (Sweden), Nortex, Wellton, Bolars (Russia).

Popular alternative

There is a recipe for making a decent adhesive with your own hand. To do this, mix:

- 1 pack of regular (cheap) dry wallpaper glue;

- 1 kg PVA;

- 5 liters of warm water.

First, dry glue is mixed with water to obtain a homogeneous, lump-free composition. After that, PVA is poured in. This sequence avoids lumps of PVA and dry undiluted powder.

Glass fiber gluing technology

Before gluing the fiberglass, you need to determine the side that should be adjacent to the wall. This is done easily, all materials in rolls are twisted inward with the wrong side. To get a high-quality result, they work according to a certain gluing technology.

Before gluing the fiberglass, you need to determine the side that should be adjacent to the wall.

Before gluing the fiberglass, you need to determine the side that should be adjacent to the wall.

Preparation and tools

First, the preparation of the tools necessary for the work begins. The list includes the following tools:

- Powder dilution capacity;

- Roller with a long handle;

- Brushes of different sizes;

- Plastic spatula;

- Roulette;

- Level;

- Painting knife.

First of all, before gluing the fiberglass, the surface is prepared, it is cleaned of dirt. Large flaws need to be leveled, putty and plaster are used. In the presence of plaster, it is wiped several times with a rag.

A mixture is prepared if a ready-made solution is not used. The rules are specified in the instructions. The surface is marked according to the size of the material. After that, the canvases are cut to the required size.

Large flaws need to be leveled, putty and plaster are used.

Large flaws need to be leveled, putty and plaster are used.

Pasting corners

Fiberglass can be glued to the outer and inner corners. If, when gluing, an extra part of the material appears in the corner part, then it is cut off. Both canvases are glued so that they go 4-5 centimeters around the corner. To obtain a neat joint, an incision is made in the center, the excess parts are removed.

If, when gluing, an extra part of the material appears in the corner part, then it is cut off.

If, when gluing, an extra part of the material appears in the corner part, then it is cut off.

Trimming excess

You can remove excess parts with a construction knife. They work using a ruler, a vertical incision is made in the middle of the overlap. As a result, the canvases are connected along the butt part, and the excess material is simply cut off.

You can remove excess parts with a construction knife.

You can remove excess parts with a construction knife.

How to glue on drywall

When working with gypsum plasterboards, priming is required. To make the surface even, putty is applied to the joints and caps of the screws. These areas are sanded and then primed. Next, the fiberglass is glued to the dry surface, the glue is applied to the wall.

To make the surface even, putty is applied to the joints and caps of the screws.

To make the surface even, putty is applied to the joints and caps of the screws.

Bonding technology

Painting fiberglass is glued to glass wallpaper glue

Good glue is important, but it doesn't have to be expensive. The gluing technology is very similar to wallpapering:

- With a roller or brush, the glue is applied to the wall or ceiling. The glue layer is thick, but you need to distribute it evenly.

- A cobweb is rolled out on the oiled wall, it is well impregnated with glue, it lays down easily. The canvas must be straightened evenly, without folds and "accordions".

- We expel air bubbles with a plastic spatula or a large stainless steel construction spatula. It's easier to do this by moving it from the middle to the edges.

- Again we take a roller or brush and apply glue on top of the fiberglass.

- Rub the glue with a spatula, filling the pores. If there is not enough glue, we add, the excess remains on the spatula.

-

The second sheet is glued with an overlap with the first. The canvas extends by about 2 cm. The sequence is the same: we apply glue to the wall, roll the canvas, expel the bubbles. Then we take a ruler or a large spatula, a stationery knife with a sharp blade. We apply a ruler / spatula to the junction of two canvases, cut through both canvases.

Do not press hard - you can scratch the putty and a groove will remain, which will be visible. The task is to cut through both canvases, but not to cut the putty. It's easier to do this with a sharp knife. We remove the excess strips, coat the wall under the joint with glue (brush), connect and press with a spatula.

- Apply glue on top of the second sheet and fill the pores with a spatula.

- We glue the next strip.

As you can see, nothing complicated. Only all operations must be carried out carefully, achieving the best result that you are capable of.

There are several nuances in terms of working conditions. The room should be free of drafts, the temperature should not be lower than + 15 ° C, the humidity should be within normal limits. Doors and windows are kept closed until the glue dries. If the sun is hot, it is better to curtain the windows. That's all, actually.

Painting fiberglass - what is it and why

When the building shrinks or the plaster / putty dries out, small cracks form on the walls and ceiling. They spoil the appearance of painted surfaces very much. To prevent their formation when plastering, use a paint net. It reinforces the finishing materials preventing the formation of large cracks. Microcracks are fought with glass fiber painting. It is a thin nonwoven fabric made from many glass fibers of varying thickness. The fibers are interconnected chaotically, which prevents the appearance of cracks. There may be microcracks, but they are not visible. This determines the area of application of the glass-fiber painting - to improve the quality of the finishing of walls and ceilings.

To keep the painted surfaces even and smooth, use a "gossamer"

The thickness of this material is small - it is translucent. Due to its appearance, it received the name "spider web". Sold in rolls 1 meter wide, has a different density - from 20 g / m2 to 55 g / m2. The density is selected depending on the area of application. For interior work, 30-40 g / m2 is more often used.

Fiberglass is glued with glass fiber glue on more or less even walls. It successfully masks small cracks (up to 0.5 mm wide) and irregularities, creating an even surface. Therefore, this technology is becoming more widespread - it simplifies the preparation of walls for painting (putty), and the result is no worse. The same material can be glued to drywall. It successfully masks the joints and prevents the formation of cracks in these places. The main thing when gluing the seams of the fiberglass should be located away from the joints of the gypsum board.

It looks like a fiberglass cobweb

Painting fiberglass is inconvenient to work - fiberglass is pricked, its smallest particles can get into the lungs. Therefore, it is necessary to work in protective clothing and, preferably, in a respirator. After it is glued on and hidden with several layers of finishing materials, there is no question of any migration of fiberglass. In this state, it is absolutely harmless.

Glass cloth application technology

Answering the question of how to properly glue the fiberglass, we can say that the technology of gluing the fiberglass is quite simple. It is necessary to apply the mixture to the wall (the wall is prepared in advance), then a strip of material is applied, while lightly pressing along the edges. Then the mixture is evenly applied to the wall to attach the next canvas.

The spatula smoothes the junction of the canvases. Immediately, an incision is made between two strips at the place of their overlap. This is done with a wallpaper knife.The cut strips are removed. Next, another layer of glue is applied to the "web" and is also smoothed with a spatula. This completes the pasting of the fiberglass, and it is ready for painting or decorative plastering.

How to choose glue for fiberglass on drywall

To glue the glass wallpaper onto drywall, even ordinary wallpaper glue will do. But still, the best way out is to use special formulations.

Why reinvent the wheel and buy special mixes if wallpaper glue works? Everything is simple enough. The fact is that some dry mixtures may contain starch. If it is present, the prepared solution will not bond the material to the wall surface very well. As a result, if a plasterboard ceiling was covered with such material, then the wallpaper may simply peel off after a while.

In order to reliably cover even the ceiling with fiberglass, you need to use mixtures without starch.

Therefore, when choosing an adhesive mixture, pay special attention to its composition, as well as to the purpose of the adhesive. It's easier to buy more expensive glue once than to re-glue the ceiling and walls later.

Sometimes experts recommend certain types of putty as an adhesive. But the use of putty can lead to the formation of a "cobweb" when pulling the material as a result of "air".

At the same time, even liquid types of putty will not be able to sufficiently saturate the material. As a result, after a while, it may begin to peel off. And the first such place will, of course, be the ceiling.

Some people recommend additionally moistening the fiberglass with water when using putty. But this will not give a result, but will rather lead to damage to both drywall and the wallpaper itself.

Textures and patterns

Glass fiber can have a different texture. The most common are the following.

- "Herringbone" - a classic pattern, suitable for the decoration of any premises, can be of different sizes. A large herringbone will be an excellent option for a spacious room.

- "Rhombus". Suitable for connoisseurs of geometric shapes and straight lines. Such a pattern will organically fit into the interior of the kitchen, dining room, corridor.

- "Rogozhka". Wallpaper has the same relief on both sides, can be glued on horizontal and vertical surfaces. There are small, medium and large "matting". This texture, in addition to decorative, also performs reinforcing functions. This option is very popular in office spaces.

- "Spider Web" is a classic, chaotic, abstract drawing. When paint is applied, the texture becomes almost invisible, but not smooth, which makes it ideal for ceiling decoration. Wallpaper with this pattern does not need to be adjusted.

There are also exclusive models with an unusual texture.

- Crepe pattern. The drawing resembles a jacquard weave with a chaotically located fine texture. If a layer of paint is applied to the wallpaper, they visually resemble embossed plaster, which creates a play of light and shade on the surface.

- "Papyrus". Outwardly it resembles ancient paper with ornaments, creates a unique atmosphere of comfort.

- Stripes. These include the patterns "Empire", "Modern" and "Stripe". They all represent a beautiful intersection of stripes. "Stripe" is suitable for original people who love a unique interior. The pattern is an alternation of small and large stripes.

- "Vertical". The texture is unobtrusive, restrained. Such wallpapers can be chosen for rooms of any size and purpose.

- "Deruzhka". Such a pattern will organically fit into the country style, chalet, suitable for a house at a summer cottage. The large relief resembles natural bamboo or linen weaving, like mats. This creates a comfortable and cozy atmosphere in the room.

In addition to the above patterns, there are many more options offered by manufacturers: "chess" and "quadro", which are a combination of squares, "polka dots", suitable for rooms with children, "diagonal" used in rooms where you want to visually correct the geometry of the space.

With the help of various techniques for painting fiberglass wallpaper, you can diversify the interior, make it original.

The use of borders. With the help of them, you can divide the surface into several parts. The texture can be the same, or it can be different on different sides of the border. After gluing fiberglass wallpaper to the wall, without waiting for them to dry, you can proceed to the next step. A strip is cut out on the canvas, which will correspond to the future border. The remaining canvas on both sides of this strip is painted in two layers. An interesting solution is the use of contrasting colors. After the paint has dried, a border is glued to the designated place.

Azure staining. To do this, first, a base coat of paint is applied in the form of a varnish from a mixture of contrasting colors with decorative splashes of white. After this layer has dried, glaze is applied. A special brush is used for this. Movements during paint application should be short, crosswise. After 20 minutes, use a rubber spatula to spread the flakes evenly on the canvas. A brighter effect can be achieved by applying another layer of azure.

How to glue fiberglass?

The technology is simple enough to be straightforward. Who knows how the wallpapering process takes place can easily figure out this operation. In order for the work to take place without delay, first prepare everything you need. This list includes:

- fiberglass in rolls;

- ready-made adhesive composition;

- a small container (cuvette) for it;

- brushes of different sizes;

- long-handled roller;

- stepladder (table);

- regular wide and plastic wallpaper spatula;

- painting knife, ruler;

- pencil (marker);

- cutter.

To prepare glue from a dry mixture, you will need a bucket, a drill with a mixer attachment, or a small wooden stick (narrow rail). In addition, they purchase in advance means for reliable protection against glass - glasses, gloves, a respirator. It is best to work with long sleeves.

Preparatory activities

They, as always, consist in the preliminary preparation of the surfaces.

- They are completely cleaned of the previous coating, then large defects, for example, cracks, are necessarily putty. Determine the necessity of the operation by checking their size. Such a test is done with a spatula: if the crack is wider than its blade, then it is necessary to fix it.

- When the spatula refuses to fit into the hole, no putty is needed. The surfaces are cleaned of dust, then the walls (ceilings) are primed with a deep penetration compound, or with glue, not too diluted with water. Waiting for the surfaces to dry.

- The bases are marked for the dimensions of the sheets, leaving a small allowance for overlapping joints. Use a pencil or marker. Rolls are unrolled with the seamy (rough) side up.

Then the elements for the ceiling and floor are carefully cut out of the fiberglass in accordance with the measurements taken. The size of the canvases can be arbitrary: the one with which it is more convenient to work. For walls, they can be cut to the full height at once, for ceilings there is a limitation: it is extremely difficult to handle segments exceeding 2 meters in length even with two people. On a horizontal surface, the canvases are placed along the room.

What are the features of this work?

How to glue fiberglass? This operation differs little from working with wallpaper. In the same way as in the case of conventional wall materials, drafts should not be allowed in the room. But the process itself is somewhat simpler due to the fact that the adhesive is spread directly on the bases.

- Glue is applied to a section of a wall or ceiling with a roller. In corners and other hard-to-reach places, brushes are used. A piece of cobweb is glued. To avoid the formation of bubbles, the surface is carefully ("herringbone") smoothed with a wallpaper spatula.

- The excess is cut off from the glued canvas, if any, then it is impregnated with glue again. Again, they are passed over the surface with a spatula to ensure good impregnation with the composition. The finished sheet should darken slightly.

- The adjacent piece is glued with an overlap, the overlap is from 30 to 40 mm. Then, at the junction of two canvases, a ruler (or a wide spatula) is applied, along which an incision is made through both layers. Excess tapes are removed, and the seam is again coated with glue.

- Do the same in the corners. The first sheet is bent 40-50 mm, the next - in the opposite direction. In the middle (in the corner), the fiberglass is cut, and then the strips are removed.

- Each new canvas and joints must be treated with glue. Its excess is removed with a spatula located almost at right angles. The surfaces are freed from excess adhesive with a soft cloth.

An additional layer of glue in this case acts as a primer, but the application of the original primer before the next operation is still required in most cases. After the surfaces have dried (but not earlier), you can proceed to further work, which depends on the chosen topcoat.

Not all surfaces are pasted over in this way, with the exception of drywall. In this case, the sheets of fiberglass are placed only end-to-end. The reason is the upper paper layer of the gypsum board, it is easy to damage it, and the defect will inevitably lead to cracking of the gypsum "filling". There is a way to avoid an emergency - blunt the tip of the blade against brick or concrete. Such a knife will not touch the cardboard, but it will calmly cut the fiberglass.

Where is used

Fiberglass, which is discussed in our article, can be used in two areas, namely, in the production of building materials and finishing work. The total cost of glass fiber for painting largely depends on the scope of application. If we take the production sphere, then glass fiber is used in it for:

- production of roll-type roofing materials;

- linoleum coating production;

- production of water panels;

- manufacturing of waterproofing materials;

- the manufacture of foam glass;

- production of glass wool slabs;

- manufacture of molds;

- production of filter elements for drainage structures;

- manufacturing of printed circuit boards.

As for the scope of work, here fiberglass is used for:

- Performing waterproofing and anti-corrosion works in the field of pipelines. In combination with fiberglass, in this case, various bitumen and mastics are used.

- Carrying out finishing work inside the building, when glass fiber is used for painting, or in cases where the use of this material is necessary for better fixation of wallpaper or drywall on wall or ceiling surfaces. This dense material contributes to the creation of a reinforcing layer on the surface, and also prevents the appearance of cracks in the decorative finish.

The demand and popularity of fiberglass in the modern construction environment is due to many different factors, including the durability of the material, the stability of its dimensions, a high level of tensile strength, resistance to combustion, and a low level of susceptibility to chemical and atmospheric influences.