The choice of adhesive for extruded polystyrene foam

How to glue expanded polystyrene? For fixing the plates, you can use different means that have different components. But there is a specificity of the use of mixtures. So, for gluing to a concrete base it is better to use one, for fastening to a brick wall - others, for winter work - still others. There are adhesives that combine the properties of fastening material and insulation, and have low thermal conductivity.

Before buying, it is important to clarify that there are no substances that corrode polystyrene foam in the composition of the product. It:

- acetone,

- alcohol substitutes,

- toluene,

- ethers,

- other solvents.

The ideal option is to purchase specialized formulations, because their manufacturers have already taken into account all the important points. There are three main types of media that are suitable for bonding material. This is a plaster-adhesive mixture of different brands, polymer adhesives and bitumen glue (mastic).

People often use "liquid nails" in a bottle, silicone sealants, frost-resistant tile adhesives, drywall products, and tiles for gluing the material. Can I use them? Experts say that the use of such adhesives is possible, especially if additional fastening of the structure with dowels is planned. But the cost of work can turn out to be much higher, so it is better to buy funds intended for EPSS.

Features of material installation

For the insulation of facades and interior work, many different construction products are used. One of these products is polystyrene foam. The material is made up of slabs of various dimensions and thicknesses. For fixing the slabs to various substrates, including concrete and metal, specialized adhesives are purchased.

Both domestic and foreign companies are manufacturers of such products. Allocate funds for external and internal work.

According to experts, when choosing an adhesive for mounting a material, it is necessary to pay attention to several main points.

The main task of adhesives is to ensure reliable adhesion of the plates to the base, so the price of products in this case plays a secondary role.

Adhesive solutions or mixtures (especially products intended for outdoor use) must be resistant to temperature fluctuations, precipitation and other negative environmental influences.

The environmental friendliness of the compositions plays an important role.

If you do not pay attention to this nuance when buying a composition for interior decoration, the product can negatively affect the health of people in the room.

Ease of installation is also a significant nuance.

As practice shows, not all goods presented on supermarket shelves meet the above requirements. Because of this, the process of installing polystyrene foam is often complicated.

There is a certain specificity of working with glue for outdoor finishing work. As for the bituminous and cement mortar, the compositions should be applied in a permanent layer to the surface of the slab. The base of the wall, in turn, must be prepared so that the product can be glued as tightly as possible. To do this, it is cleaned of dirt and primed.

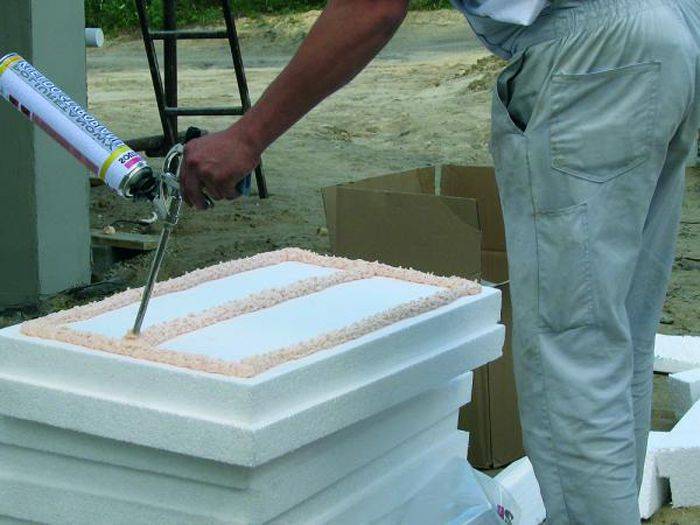

If it is planned to install polystyrene foam using glue-foam, the composition is applied along the perimeter of the product, as well as in the center in a zigzag. After that, the slab is fixed to the surface.

Features of installation of expanded polystyrene

Extruded PPS is a high density foam material.It is with this indicator that it differs from ordinary polystyrene - foam. The density increases during the production process when passing through the extruder, this seriously increases the thermal insulation characteristics of the material. The resulting slabs are composed of polymer and fine air bubbles.

Due to their smoothness, EPSP boards have very poor adhesion to the adhesive composition. This is the main problem with gluing. It is solved by the selection of special adhesives, which themselves have high adhesion to any surfaces. Also, some products can partially dissolve the foam top of the boards, soaking into them.

The specifics of the installation of expanded polystyrene plates are as follows:

- if the material is purchased as insulation for the floor, it is laid on an expanded clay pillow or on a gasket made of other low-density material and poured with concrete,

- to insulate the foundation, the slab must be glued to the concrete of the base and secured with mounting fasteners,

- the material is laid on the roof, then a layer of bitumen is placed, or a PPP is laid between the ribs of the rafters inside the layers of the roof,

- when insulating the ceiling in an apartment on the top floor, lay expanded polystyrene from the attic on glue, then concreted or covered with crumbs, gravel, expanded clay.

What else can you glue?

- Among the variety of adhesives suitable for expanded polystyrene, styrofoam adhesive can be distinguished, which is also used for mounting polyurethane and foam. Among the positive features of the product, one can note the reliable fixation of the material to concrete, plaster and most wood-containing substrates. The products have a wide range of applications, therefore they are allowed to work both indoors and outdoors. In addition, after complete drying, the material can be additionally treated with dyes or varnish.

- A reliable adhesive provides a good fixation of raw materials, however, some craftsmen use improvised means in working with expanded polystyrene, for example, liquid nails or tile mastics. Often, silicone sealant is used for mounting the material. However, when choosing such compositions, people do not take into account the fact that such solutions most often corrode the material.

- Sometimes you can use double-sided tape to glue the raw material onto a small surface. But this method allows you to fix the material well only if the base is small. Otherwise, this installation option should not be considered.

For information on how to properly apply glue-foam using TechnoNICOL as an example, see the next video.

What is the best way to glue polystyrene to the ceiling and concrete?

In this case, it is better to choose quick-setting gypsum mixtures, liquid nails or polyurethane glue. When installing products on ceiling structures, two factors are taken into account: the plates will have to be held by hand and poor adhesion of polystyrene foam to any building materials. Mineral-polymer dry mixes and polyurethane liquid or foaming compositions are well suited for concrete facades and foundations.

Optimization of material consumption

Glue prices are high, excessive application negates the cheapness of this insulation. At the same time, it is not recommended to reduce the consumption specified by the manufacturer, this leads to the products falling off the surface or distortion of the joints. The only option for reducing the total cost of costs is the high-quality preparation of the base, the deviation in level should not exceed 5 mm, and the choice of the correct technique.

There is a clear rule - to ensure reliable adhesion, the adhesive must cover more than 40% of the panel area. The optimal pattern for uneven walls is a 3-6 cm wide strip around the perimeter (solid or long strokes) and finely applied inside.The minimum consumption is achieved when installing the foam on a surface with deviations in level of no more than 3-5 mm and spreading the solutions with notched trowels or using construction guns. Dry fast-setting mixtures are diluted in small portions, hardening compounds are unsuitable for fixing.

Advice for choosing an adhesive

The main criterion is the operating conditions: formulations with low moisture resistance are not used outside, and it is better not to use brands that emit harmful substances inside. Most of the varieties are universal, but nevertheless, checking the intended purpose is a mandatory initial stage.

Attention is drawn to the following parameters:

- consumption per 1 m2;

- date of release of products and shelf life of the material (relevant for dry mixes, the fresher they are, the better);

- temperature of installation and operation, most types do not allow gluing foam plastic in winter;

- moisture absorption and frost resistance (for outdoor brands);

- adhesion to work surfaces;

- vitality, time allotted for correction;

- ease of installation (in this regard, polyurethane adhesives definitely win);

- material prices.

The cost of adhesives for expanded polystyrene

| Brand name | Basis, recommended scope | Consumption for 1 m2 | Package volume or container capacity | Price, rubles |

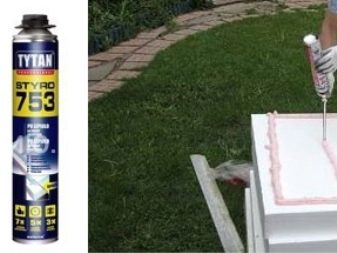

| Tytan Styro 753 | One-component polyurethane adhesive for thermal insulation of external structures | 80-100 ml | 750 ml | 390 |

| Titbond (red tube) | Synthetic rubber for outdoor and indoor use | 300 mm per 10 m strip | 296 ml | 190 |

| Knauf Perlfix | Gypsum-based dry mix for indoor use | 1.5KG | 30 Kg | 280 |

| Glue-foam TechnoNIKOL | Universal polyurethane foam | 75 mm | 750 ml | 300 |

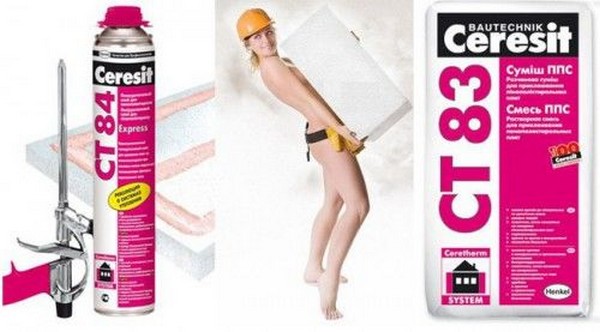

| Ceresite CT 83 | Dry mixture of minerals and polymers for external foam insulation | 3-8 kg (depends on the evenness of the base) | 25 Kg | 400 |

| BERGhome MK 35 | Cement-based adhesive with fine sand and modifying additives for outdoor use, suitable for installation in winter | 2.2-6.5 kg | 300 | |

| Ceresite CT 84 | Polyurethane adhesive, exterior insulation of buildings | 70-100 | 850 | 600 |

| Eskaro Styropor | Polyvinyl acetate, fillers and additives. For bonding material to internal surfaces | 0.6-1 l | 3 l | 520 |

Overview of adhesives

Adhesives for indoor and outdoor use differ in composition and characteristics. They can also have a different consistency, be sold as a dry or ready-to-use mixture. The only property that all types of glue have in common is the prohibition on the inclusion of any solvents. Contact of gasoline or acetone with the insulation is unacceptable, because these substances can burn through it.

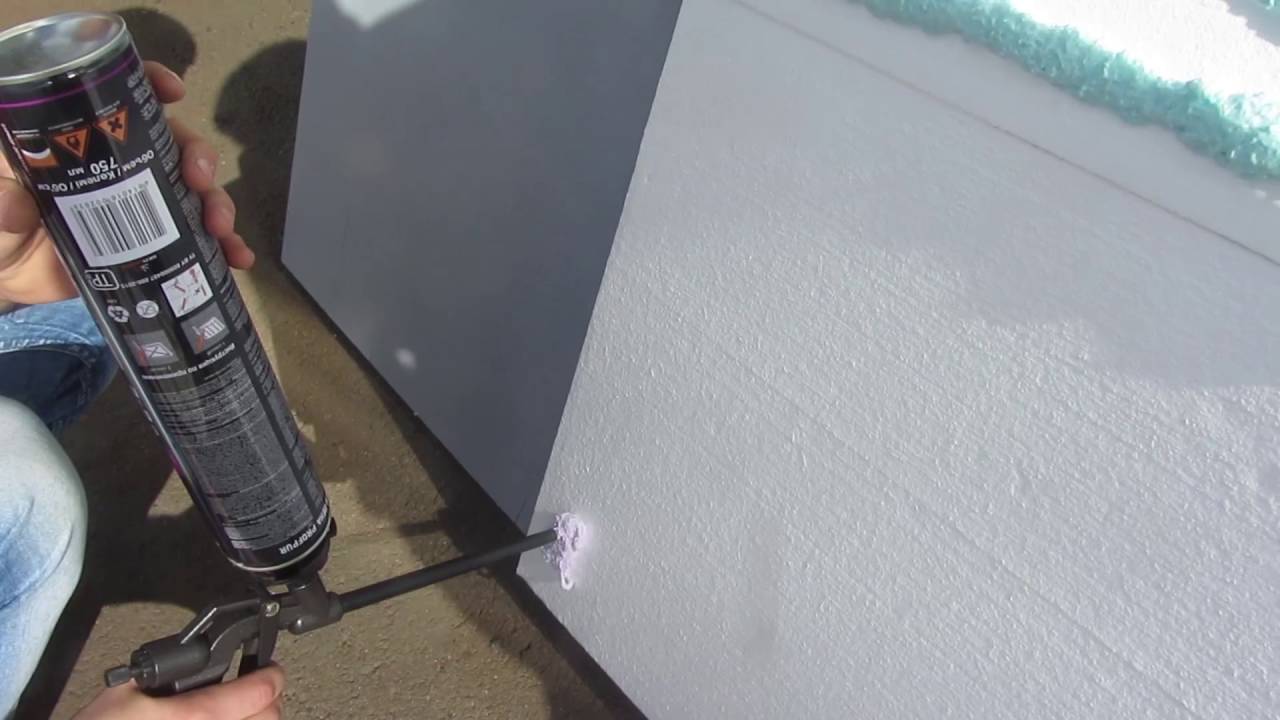

As for glue-foam, this type of product is very convenient for use due to its ease of application. The finished composition includes all the necessary components that allow you to quickly and efficiently glue the products. However, it should be borne in mind that this glue dries very quickly. It is used most often as a single-use product.

Dry formulations allow you to use them several times, mixing the mixture in portions, as needed.

Adhesive foam for outdoor use has a polyurethane base and is sold in cans, which simplifies the application of the composition to the sheets of material. Unlike bituminous products, it dries quickly, so there is no need for material supports. The tool is gaining strength after a couple of hours.

Adhesives designed for working with polystyrene foam plates can be divided into two types:

- dry products;

- polyurethane solutions.

The differences between these groups lie in the method of breeding, packaging, appearance, and also the technique of processing the material.

In addition, Styrofoam products can be categorized into split formulations and general purpose products. The latter type has a wider range of applications.Such compositions can not only perform basic functions, but also serve as a means for reinforcing slabs with a mesh. Their disadvantages include average quality characteristics. However, this disadvantage justifies the affordable cost of the product. For a more reliable installation, it is worth giving preference to adhesive solutions or mixtures of a narrow spectrum of action.

For outdoor work

The most suitable composition for external work with expanded polystyrene plates can be considered bituminous glue, despite the fact that it contains a solvent. This component does not pose any danger to the insulation. The products are sold ready-to-use. To glue the surfaces together, bituminous glue must be applied to the wall.

Another popular type is cement glue, which is excellent for working with brick substrates, concrete and cinder block walls, as well as for fixing ceiling tiles. Usually such a mixture is sold dry, and for preparation, the powder is diluted with water. The disadvantages of dry products include the fact that it takes some time to dilute the glue to the desired consistency. However, the cement-polymer composition and low cost make the product very popular. It is suitable for those cases when extruded polystyrene foam is used as insulation.

In room

When installing polystyrene foam boards indoors, it is necessary to use compounds that meet the following requirements:

- high level of adhesion;

- lack of toxic substances in the composition;

- resistance to temperature fluctuations;

- quick installation and minimal smudges.

In apartments and houses with a constant positive air temperature and minimum humidity, the boards can be glued to the surface using PVA glue. In rooms where the humidity is high enough, it is better to use rubber-based glue. Such products are excellent for working with metal, plastic, concrete, wood and ceramics.

Dry gypsum mix can be used for surfaces with base defects. This group includes Knauf Perflix glue. This is a completely natural product that is intended for indoor use only.

When working with decorative elements and ceiling surfaces, it is worth stopping the choice on water-soluble compounds. Such products are white, therefore, they allow you to hide as much as possible all existing seams and joints between sheets of material.

Installation of insulation using foam glue

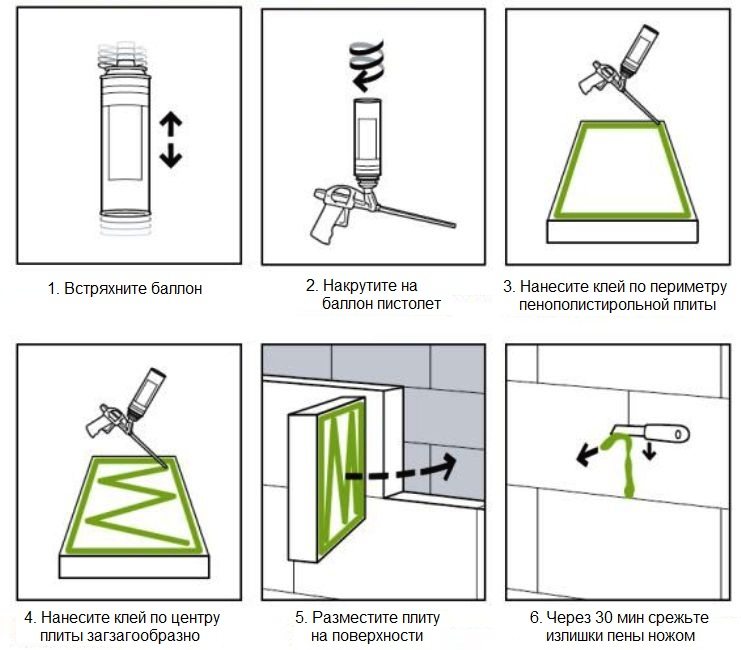

If you decide to stick the insulation with glue foam, then you can install it yourself. To do this, just do the following:

- Make sure that the air temperature does not exceed +35 degrees and not below 0. Some formulations indicate a more accurate range at which the adhesive solution is recommended to be applied.

- Remove the protective cap from the cylinder and insert it into the gun with the valve at the top.

- Shake the pistol with the balloon vigorously (about 20 times).

- Step back about 20 mm from the edge of the polystyrene foam board and apply glue around the perimeter of the product. After that, you need to hold the pistol diagonally.

- Place the board to the surface with the side where the adhesive is applied. You need to press the product (without effort) for 5 minutes, this time is enough for the foam to expand as much as possible.

- Make sure the plate is locked in place. If the insulation is crooked, then you need to align it. The glue sets in 20 minutes, so you have plenty of time to make adjustments.

- The distance between the boards should be about 2 mm. In order for the gaps to be even, it is necessary to use special plastic crosses for the seams.

- If in some areas it was not possible to maintain the required distance and cold bridges formed, then the space can be filled either with a piece of expanded polystyrene or with glue, the excess of which can be easily removed after the foam dries.

Some experts increase the strength of adhesion of the foam to the treated surface using expansion dowels. If you decide to use them, then installation can be performed only 2 hours after applying the foam.

GLUE-FOAM TECHNONICOL

One-component polyurethane adhesive for bonding expanded polystyrene and extruded polystyrene (XPS) boards. Consists of isocyanate oligomers, displacing propane / isobutane gas.

Advantages

- convenient and easy to use;

- reduces the time to complete the work;

- high adhesion to concrete, cement plasters and other mineral substrates, as well as to wood, chipboards, OSB boards, mosaic cladding, bituminous materials, etc .;

- good resistance to moisture, mold, aging;

- low thermal conductivity;

- minimal secondary expansion.

Application

TECHNONICOL GLUE-FOAM is intended for fixing panels of expanded polystyrene and extruded polystyrene foam (EPS) to the base when insulating external and internal walls of a building, roofs, basements, foundations, floors in both new and reconstructed buildings. Specifications

| Indicators | Unit measurements | GLUE-FOAM TECHNONICOL |

| Adhesion strength (adhesion) to a concrete surface, not less | MPa | 0,4 |

| Adhesion strength (adhesion) with expanded polystyrene, not less | MPa | 0,09 |

| Thermal conductivity | W / mK | 0,035 |

| The degree of evacuation of the contents from the package, not less | % | 85 |

| Polymerization start time, no more | min | 15 |

| Curing time at 20 ° С and relative humidity more than 50%, no more | h | 2 |

| Full curing time, no more | h | 24 |

| Density after curing | g / cm3 | 25 |

Fastening of expanded polystyrene

It is used at temperatures from 0 ° C to + 35 ° C.

- Install the TECHNONICOL Glue-Foam cylinder for expanded polystyrene with the valve upwards on a flat surface, remove the protective cap from the valve and carefully align the cylinder valve with the landing bridge of the assembly gun. After placing the can on the gun, shake the can vigorously 20 times.

- TECHNONICOL GLUE-FOAM for expanded polystyrene is applied with an assembly gun in the position of the balloon upward, keeping the distance between the gun and the plate for the correct application of the glue.

- TECHNONICOL GLUE-FOAM for expanded polystyrene should be applied along the perimeter with an indent of about 2 cm from the edge of the board in strips about 3 cm wide and in one strip through the center of the board at an equal distance from its long sides. After applying TECHNONICOL FOAM ADHESIVE for expanded polystyrene to the board, wait at least 5 minutes for the foam to fully expand, and then fix the insulation board on a vertical surface.

- Place the panel with TECHNONICOL FOAM ADHESIVE for expanded polystyrene to the wall and press lightly. Fix the board until the glue sets. Insulation plates should be fastened close to each other with a gap in the seams. The gap between the plates should not exceed 2 mm. The panels can be adjusted within 5-20 minutes. after installation depending on the environmental conditions.

- To prevent the formation of cold bridges, larger gaps between the insulation plates must be tightly filled with styrofoam scraps and TECHNONICOL FOAM GLUE for expanded polystyrene. Cut off excess foam after drying with a knife and sand with a float.

Storage

Store and transport containers with glue in an upright position, in dry conditions at temperatures from + 5 ° C to + 35 ° C. A short-term (no more than 1 week) decrease in temperature to -20 degrees is allowed.

The guaranteed shelf life is 12 months.

How to properly and how to glue foam

Ideal - branded glue, based on polyurethane.The composition of the glue is selected in such a way that the connection is strong, the seam is neat, the structure of the foam is not disturbed. Polyurethane glue is exactly what you can use to glue the foam together. The adhesive composition does not respond to changes in ambient temperature, is moisture resistant, and is not afraid of mechanical influences. Low consumption - 200-350 g / m2. Before buying, you should calculate the approximate amount of glue and lay 10% of the reserve, which will help to avoid problems during the repair.

For a quality repair, you need to think not only about how to glue the foam, but also about how to reduce the consumption of glue. It is better to use a fine-grained abrasive for surface treatment. Then gently apply the compound to the surfaces to be bonded and press them firmly together for a few minutes.

Depending on how you need to glue the materials (for centuries, if repairs are made at home or not, if you need to make a fake to school for a child), the method of applying glue and the requirements for the adhesive composition differ. Running a little ahead, we can say that in most cases ordinary PVA glue is suitable

Polyurethane glue is exactly what you can use to glue the foam together.

Polyurethane glue is exactly what you can use to glue the foam together.

Choosing the right adhesive

Before gluing the extruded polystyrene foam together, you need to understand two important points that affect the complexity and efficiency of the repair. Foam boards are smooth, construction glue does not allow creating adhesive bonds. As a result, the materials do not stick. Construction glue contains various solvents from organic substances that corrode foam when it gets in, products deteriorate, the final result cannot be achieved.

When buying a new adhesive, you need to test it for compatibility with polystyrene: a substance is applied to a small piece or crumb and left for half an hour, inspect the material for deformations and defects. If they are absent, you can use this type of glue.

When purchasing a new adhesive, it is required to test it for compatibility with polystyrene.

When purchasing a new adhesive, it is required to test it for compatibility with polystyrene.

When choosing an adhesive, pay attention to the following:

- The shape and structure of the foam, the surface;

- Conditions in the house where the renovation is being done;

- Composition price. An important point that will have a key influence on the choice;

- The conditions of the room in which the materials will be used.

The combination of the above factors determines the glue required for use. For fakes, ordinary PVA is suitable for school, it is available in every home, it costs a penny and is able to glue together any materials: from paper airplanes to cornices.

For fakes, a regular PVA is suitable for school.

What glue does not corrode

Not any glue is suitable for working with this material, most of the substances destroy it. The material dissolves and "burns through", which causes deformation. As a result, you have to look for new glue, buy additional sheets of foam, waste time and money. What kind of glue does not corrode foam? All those types that do not belong to those listed below:

- Acetone is used to make the glue. Such compositions are used to degrease surfaces;

- Oil derivatives are used for production: gasoline, kerosene, xylene, etc. Combustible substances destroy the foam;

- Alcohols.

Most suitable foam formulations are marked on the label. She informs that this glue is recommended to be used for working with expanded polystyrene and products made of this material.

Most suitable foam formulations are marked on the label.

Most suitable foam formulations are marked on the label.

The role of polyurethane foam in the installation of expanded polystyrene

Polyurethane foam is a one-component aerosol that is released in ordinary containers, the same as ordinary polyurethane foam.

First, the aerosol can is inserted into a special gun, which is used to adjust the release of the desired foam volume. Before direct use, you need to thoroughly shake the contents of the container in order to mix the particles detached during storage.

In modern construction, a wide range of aerosol adhesive mixtures are presented, which have the following advantages:

- Reduced time spent on installation operations.

- Absolute absence of any odors.

- High coefficient of adhesion to all building materials.

- Moisture and frost resistance.

- Compact dimensions of storage of polyurethane foam.

- The ability to carry out installation work at low temperatures.

- The ability to use both inside and outside buildings.

- The adhesive material does not emit any toxic fumes.

- Possibility of using dowels after 2 hours after installation.

As you can see, this method of installing expanded polystyrene has a large list of advantages, but also disadvantages. So, for example, it is necessary to have a particularly carefully leveled surface for the application of foam, a high harmful effect of ultraviolet rays, a high cost of the material, and it is also necessary to use a special flushing, which will extend the operating life of the gun.

So, mounting glue-foam is ideal for mounting polystyrene sheets on a relatively flat surface. Moreover, this material allows you to significantly save time for installation work, as well as the amount of energy consumed.