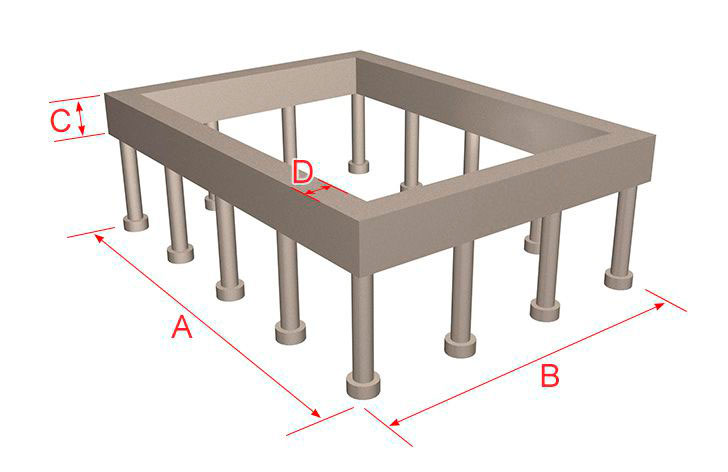

Calculation of the pile foundation

Select the type of grillage:

Grillage parameters:

Grillage width A (mm)

Grillage length B (mm)

Grillage height C (mm)

Grillage thickness D (mm)

Concrete grade

M100 (B7.5) M150 (B10) M200 (B15) M250 (B20) M300 (B22.5) M350 (B25) M400 (B30) M450 (B35) M500 (B40) M550 (B45) M600 (B50) M700 ( B55) M800 (B60)

Poles and piles parameters:

Number of poles and piles (pcs)

Column diameter D1 (mm)

Post height H1 (mm)

Post base diameter D2 (mm)

Post base height H2 (mm)

Reinforcement calculation:

Rebar length (m)

Calculation of the grillage formwork:

Board width (mm)

Board length (mm)

Board thickness (mm)

Calculate

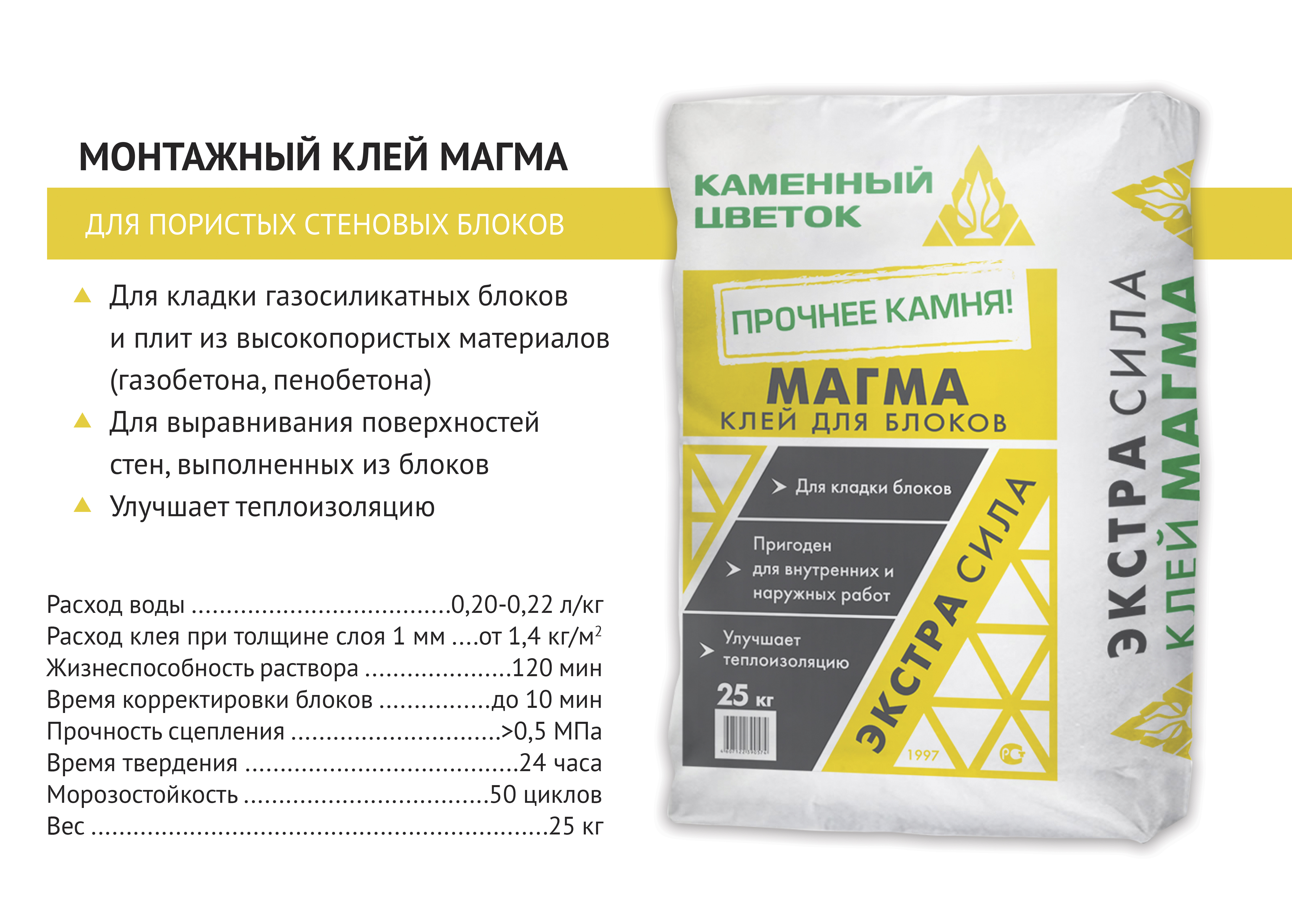

Adhesive for foam blocks: varieties, temperature of use and consumption

Each building material has specific features, taking into account which they are used in certain works on the construction of buildings and structures. In addition, taking into account the available characteristics, a composition is selected for each product that can provide reliable fixation. Among the assortment of materials, it is worth highlighting foam blocks, which also need high-quality adhesive composition.

Advantages and disadvantages

When choosing an easy-to-install and high-quality building material for the construction of walls, experts increasingly prefer foam concrete blocks. However, the positive features of the products can be appreciated only when they are laid not on ordinary cement mortar, but when using a special glue. This composition is distinguished by its viscosity, it sets more efficiently, it is not characterized by shrinkage after solidification, in addition, the blocks, which are distinguished by their porous structure, do not absorb moisture from it, due to which it is considered better than a cement solution. The products are in demand in the construction of new buildings, as well as in the reconstruction and modernization of old buildings. Residential buildings, as well as country houses, baths and saunas are erected from the blocks. The material can be used not only for the laying of load-bearing walls, but also as a product for the installation of partitions, and also as a raw material for performing work to ensure heat and sound insulation of buildings.

As for the glue for foam blocks, it is necessary to highlight such main advantages of its use as:

- since the seam formed by the adhesive is thinner than the layer of cement mortar, the appearance of "cold bridges" between the structural elements is practically excluded;

- the consumption of the composition also depends on the small thickness of the layer, which will be less in comparison with other compositions;

- due to the need for a smaller amount of substance for work, you can significantly reduce the time for preparing the mixture, which also reduces labor costs;

- to dilute the composition, the use of special devices for mixing the material is not required; an ordinary drill is suitable for preparatory work with glue;

- the specific properties of the products have a positive effect on the soundproof and heat-insulating properties of the building material;

- good plasticity of the mixture makes it possible to adjust the stacking of blocks;

- the adhesive composition is moisture resistant, so the likelihood of the formation of microorganisms on the base is excluded;

- due to the minimum thickness of the connecting seam, there is no need for additional processing of the bases for leveling, which makes it possible to reduce the costs associated with finishing works of walls and partitions;

- the mixture is sold in small bags, due to which the products can be transported in ordinary light vehicles without using trucks;

- all components of the glue are completely safe for humans and the environment.

In addition to positive qualities, such compositions have the following disadvantages:

- the products are of high cost, due to which they are mainly used for the construction of small buildings, however, adhering to the recommendations for the dilution of the composition, it is possible to achieve rational use of the products, which will not significantly affect the costs;

- it is not possible to visually determine the quality of the mixture.

To reduce the risk of purchasing goods that will have low quality characteristics, it is necessary to focus on the following nuances:

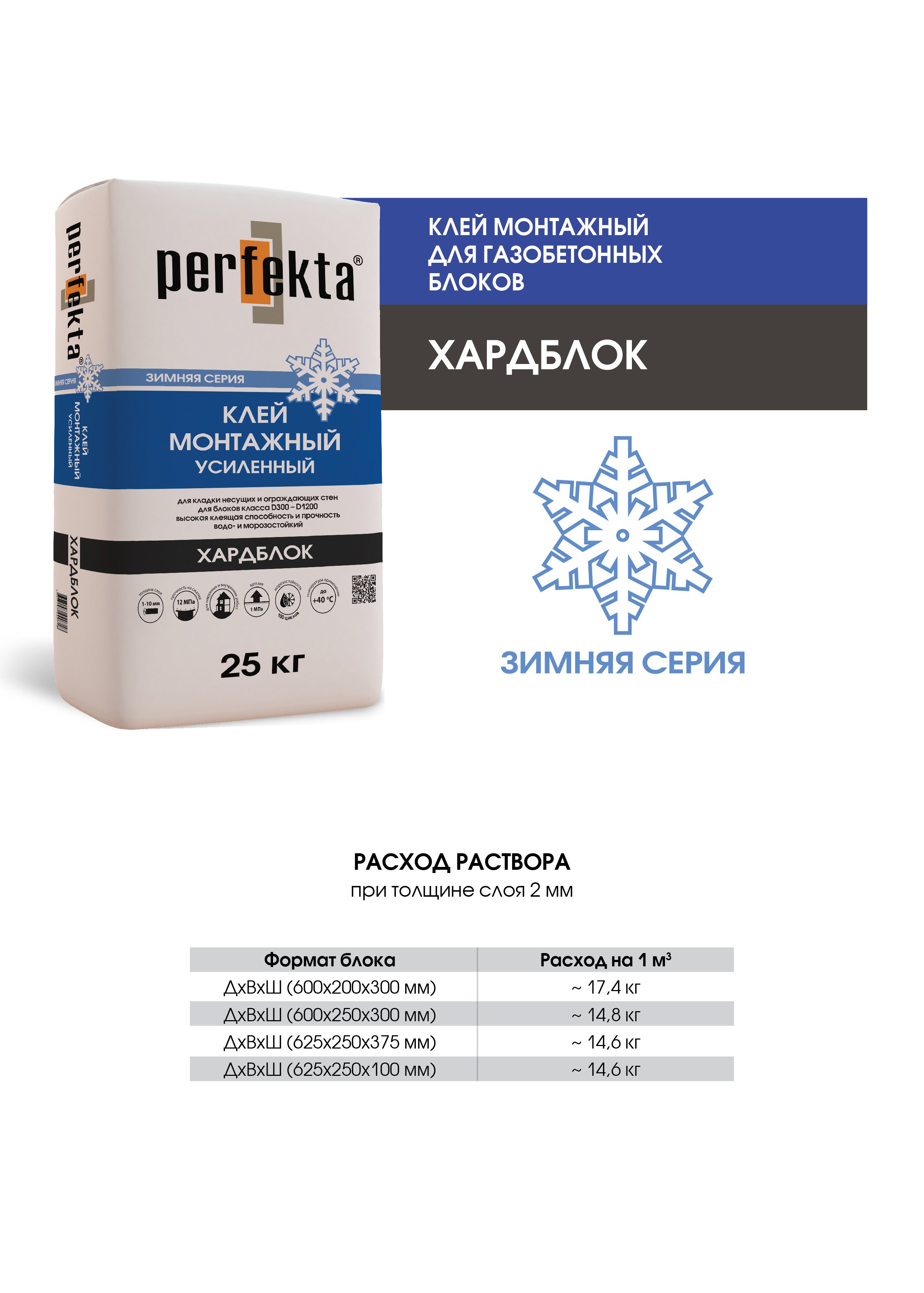

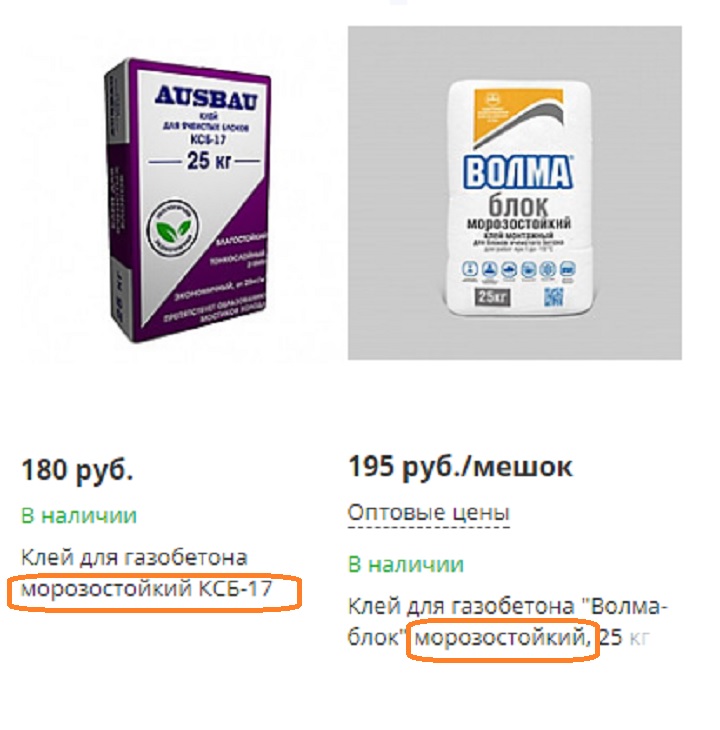

- for installation work in winter at negative temperatures, you should buy glue, which includes special frost-resistant additives that affect the properties of the entire mixture;

- experts recommend not to rush to purchase recently released material, it is better to opt for a composition with a later date of manufacture;

- products from little-known brands should not be considered for work, since there is a risk that this product is of poor quality; products of popular and well-known brands rarely have low performance characteristics, with the exception of counterfeits under this trademark;

- in the course of calculating the required amount of the mixture required for operation, some errors should be taken into account, which in any case may arise during the laying of foam blocks, therefore it is better to have at least one extra bag of glue in stock.

Assistance in choosing an adhesive

The question arises: what kind of glue is better to choose, and what should you pay attention to? This is what we are going to understand now.

Review of the most popular brands

The narrowly targeted adhesive for polystyrene concrete cannot boast of such a wide range as, for example, a composition for aerated concrete. However, there is still a choice. Moreover, there are universal compositions intended for lightweight concrete products in general, which can be easily applied in the case of laying a polystyrene concrete block.

As already mentioned, dry mixes of different brands differ from each other. Manufacturers strive to stand out from competitors, and for this purpose they focus on certain properties. In one solution there will be increased plasticity, in the other - its viability, and so on.

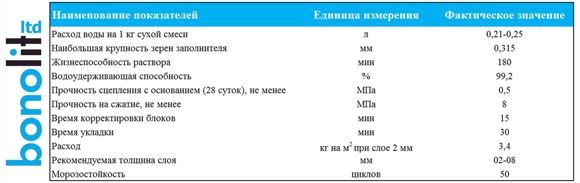

We will use the table and consider some options for adhesive and masonry compositions in the form of dry mixes intended for laying polystyrene concrete.

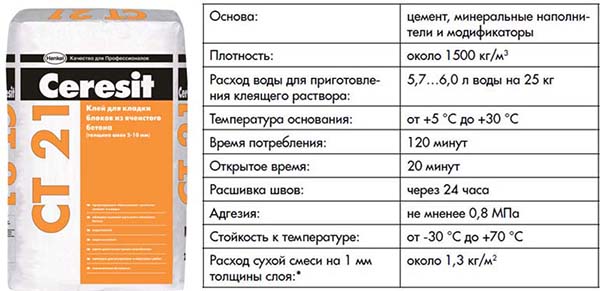

Adhesives and masonry compounds from popular manufacturers:

|

Composition for laying polystyrene concrete block "Polystyrene" |

It is a cement-sand mixture. However, this is not at all the solution that is obtained with self-preparation. This option contains special additives that regulate water permeability, atmospheric and biological stability.

The mixture is versatile, suitable for both outdoor and indoor use. Frost resistance grade - 200 cycles, correction time 10 minutes. The layer thickness can be from 2 to 8 mm. |

|

Betonkol adhesive for aerated concrete and polystyrene concrete masonry |

This composition is intended for laying most of lightweight concrete products and this should not surprise you. After all, all representatives of lightweight concrete are very similar to each other in terms of properties.

The composition differs in increased viability - up to 4 hours. But the adjustment time is only 5 minutes. Frost resistance reaches 200 cycles, peel strength is increased. The recommended layer thickness is 2-5 mm. |

|

Glue "Keraflex" |

Again, the adhesive is suitable for aerated concrete and polystyrene concrete block. He is universal. Frost resistance and durability are very competitive.

The pot life is about 3 hours, the time allotted for adjustment is 5-7 minutes. The manufacturer recommends using the glue at a temperature not lower than +5 degrees. The seam thickness should be between 2 mm and 1 cm. |

|

Bolars lightweight concrete block adhesive |

This is a variant of the winter composition, which we will discuss in more detail later.

The air temperature during work can be down to -10 degrees. The compressive strength is about 7.5 MPa, which is slightly higher than that of the above-described compositions. In most cases, the indicator for adhesive mixtures is 5 MPa. Frost resistance - about 50 cycles. Adjustment time 10 minutes. The layer thickness can be from 2 to 8 mm. |

|

Glue "block" |

This composition is suitable for laying almost any lightweight concrete product. He is also versatile.

Differs in moisture resistance, high peel strength. Compressive strength reaches 20 MPa. Pot life - 3 hours, product adjustment time - 7 minutes. |

Types of mixtures and their purpose

In total, there are two types of adhesive mixture: conventional compounds, the use of which is allowed at temperatures not lower than +5 degrees, and winter compounds, the use of which is permissible even at negative air temperatures.

Features of using glue with antifreeze additive are as follows:

- If the weather is warm outside, and you only have winter glue available, then it is quite possible to use it, and this will not entail any negative consequences. But the opposite is not worth doing.

- The presence of an antifreeze additive does not mean at all that styling can be done at absolutely any temperature. In severe frosts, work should be suspended. As a rule, manufacturers indicate a limit of minus 10-12 degrees. That is, these are the minimum temperatures.

- When using glue, the mixture is kneaded in small portions with the expectation that it will work out for about 20-30 minutes.

- It is recommended to use warm water.

- Block products should not be covered with snow or ice.

A house from a polystyrene concrete block can be built in winter

By using these tips, you will be able to avoid unpleasant consequences.

What should be the glue?

Why exactly glue for aerated concrete, and not the usual cement mixture? It's all about the special properties of aerated concrete. For masonry, standard solutions can be used, but not recommended, since the thickness of the joints will be too large, the likelihood of serious heat loss increases. The physical properties of the glue are as close as possible to those of the building material, but the cement mortar cannot boast of this.

When using a compound specially designed for work, the thickness of the seams is only 2-4 mm. At the same time, the mixture turns out to be moisture resistant, durable, economical, remarkably enduring even severe frosts. Adhesive for aerated concrete is equally successfully used for external masonry of walls and internal work, but in the first case it is better to use special winter varieties, especially when construction is carried out in the northern regions. For the correct use of the composition, the surface must be cleaned, dried, removed from oil and other stains, dust. In this case, the adhesion will be excellent, no further problems will arise.

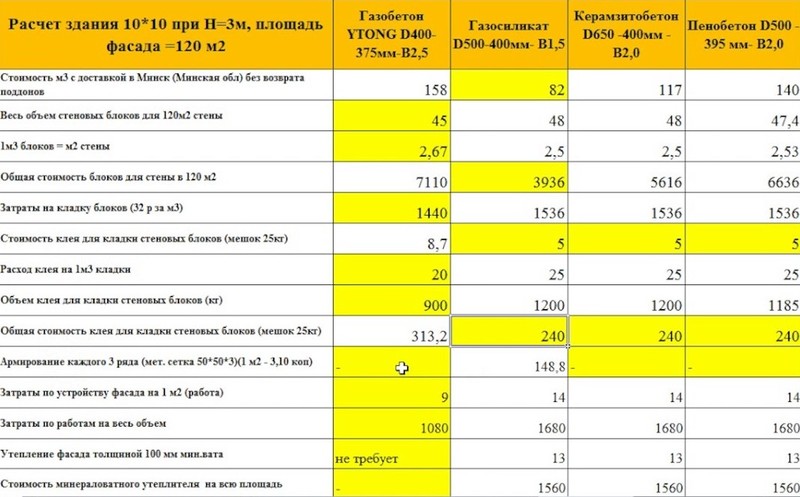

Table for laying blocks on glue.

The mixture includes components such as:

- high quality cement;

- mineral natural fillers;

- special polymer additives.

Since there is cement, all work is carried out only with protective gloves. For the face, you must use a gauze bandage or respirator, which will protect the respiratory system. Today, 2 types of glue are used for work:

- A white solution that can be used to perform work in the warm, summer season.

- Gray mortar, which is used for masonry at any time of the year, including in winter.

The white glue contains a special Portland cement.In appearance, this mixture is similar to, and this property makes it possible to save on interior decorative finishing. The wall turns out to be light and uniform, there is no need to hide the seams. Gray (universal, winter) glue contains special additives, which makes it possible to use the solution at low temperatures. The lowest threshold is -10 ° C. There are other restrictions, you must take them into account when choosing.

Selection of adhesives and additives

For the installation of masonry, a thin layer of adhesive should be applied. The usual consumption data for this composition at a thickness of 2 millimeters is significantly reduced when compared with a solution of sand and cement, which allows you to achieve an optimal thermal conductivity.

A high-quality adhesive composition for winter work is distinguished by a high adhesion rate and resistance to moisture and low temperature conditions. These features allow it to be used for filling and leveling surfaces. The adhesive composition is based on a mixture of Portland cement and fine-grained sand.

A special feature is made up of polymer components that increase the adhesive capabilities and improve plasticity. Used when mixing glue and modifiers, with which the appearance of cracks is minimized.

Experts assure that you can use the fast-hardening adhesive until late autumn, while stable positive temperatures remain during the day. The wall installed during the day receives the specified properties until frost, which comes at night. And the weak thermal conductivity of aerated concrete will play a positive role here. It turns out that there is enough time for the glue to fully set.

As a second option, you can consider the use of special additives or frost-resistant adhesives. There are not very many of them, but you will succeed in solving the problem of winter construction.

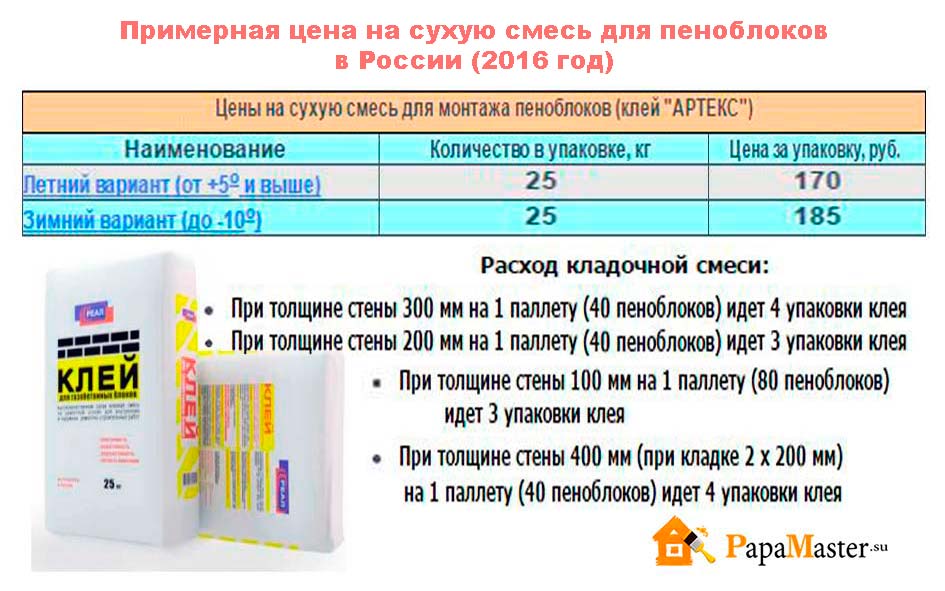

Consumption per 1 m3 of aerated concrete

If the packaging indicates that the consumption is more than 30 kg, then the glue is designed to fill cracks, chips. Overruns must not be allowed.

Average consumption

The data with the calculation of consumption should be on the packaging of the product itself, for example, 1.5-1.7 kg of dry composition per square meter, while observing the thickness of the seams not more than 1 mm. These figures are relevant only when working with flat horizontal surfaces.

Manufacturers, as a rule, produce packages of adhesive mixture of 20-30 kg, which is just enough for a cubic meter. masonry. Glue should be purchased with a margin of at least 25% of the result of the calculations performed.

What determines the expense

The list of factors affecting the consumption of finished glue for blocks per 1 m3 of masonry includes:

- the presence of defects, irregularities on the surface of the blocks;

- the degree of concentration of the mixture;

- solution temperature;

- the application tool used;

- available weather conditions.

The setting process can take from 5 to 30 minutes, and the full drying of the seams at the same time lasts at least a day.

For the most accurate calculation, it is also important to consider: features of the composition of the mixture (the greater the concentration of sand or other components, the higher the consumption);

features of the composition of the mixture (the greater the concentration of sand or other components, the higher the consumption);

the chosen method of laying (for beginners, the consumption always turns out to be higher);

the presence of reinforcing layers, which proportionally increases the required thickness of the adhesive solution.

Calculation formula

Calculation of the amount of dry matter for 1 cube of masonry aerated concrete blocks are carried out taking into account the length (l), height (h) of the surface, as well as the thickness of the seam of the intended adhesive composition (b). The first two indicators are measured in meters, and the thickness in millimeters. The calculation of the quantity (S) also uses the conventional value of the volume of dry concentrate and is 1.4.

Standard packaging of dry composition according to 25 kg remains convenient for 1m3 of masonry.In a practical example, it looks like this: after measuring the parameters of the future wall, 64 m3 of aerated concrete were calculated. If the thickness of the adhesive solution is 3 mm, then the product itself will need 64 bags. If the adhesion seam is reduced by 1 mm, then the glue itself will need 5-5.5 kg less.

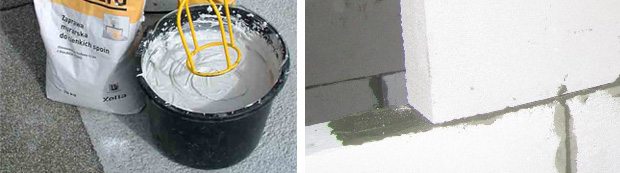

Glue mixture solution preparation technology

The preparation of the working solution is carried out according to the instructions of the manufacturer of the dry concentrate. The general steps and principles for preparing an adhesive mixture include the following points:

- to prepare the solution, use a container of the appropriate volume and a drill with a mixer;

- measure out the required amount of dry mix and water, as indicated in the manufacturer's instructions. As a rule, the proportions are on average 1: 0.22, that is, 220 g of water is taken for 1 kg of dry concentrate;

- the range of water temperature for the solution is from +15 to + 60 ° C;

- knead the mass until smooth, then let the solution settle for 10-15 minutes and mix thoroughly again.

The solution is mixed in portions in accordance with the intensity of work on laying aerated concrete. The service life of the working mixture is about 3-4 hours, but this figure may vary depending on the brand, working conditions and other design factors. It is not allowed to add water to the finished solution, while the glue should be periodically stirred during operation.

It should be borne in mind that the consumption of glue for gas silicate depends on a number of factors, including:

- block geometry and surface defects;

- the presence of reinforcing elements;

- characteristics of the tool for applying the bonding composition;

- temperature and concentration of the solution;

- weather conditions and qualifications of the master.

The formula for the consumption of the adhesive solution looks like this: S = [(l + h) / l * h] * b 1.4, where:

- S - consumption of 1 kg of the mixture per 1 m³ of the base;

- l, h - dimensions of length and height in m;

- b - seam thickness in mm;

- 1.4 - conventional value of the consumption of dry concentrate in kg / m² with a thickness of the bonding layer of 1 mm.

In order to carry out the construction of walls made of porous concrete with the highest quality, it is necessary to use adhesive mixtures taking into account their purpose: for indoor or outdoor work, for laying gas silicate at positive or negative ambient temperatures

It is also worth paying attention to the setting speed of the working solution, this parameter varies from 5 to 25 minutes, depending on the brand of product

In this case, the minimum period of solidification of the adhesive base in a block structure is 24 hours, and for the final result, a period of at least three days is required after installation.

Types and composition

When choosing an adhesive mixture, it is necessary to take into account the operating conditions. In accordance with this, the materials are divided into 2 groups:

- winter;

- summer.

In the first case, assembly adhesive for foam concrete can be used at temperatures within + 5 ... + 30 ° С. At the same time, the mixture retains its properties, will serve for a long period without loss of quality. It is not recommended to cook this type of glue in large quantities.

A high drying rate is noted - after 1-2 hours the composition begins to solidify. When the consistency of the mixture changes, it cannot be used, since this will not provide a sufficiently high-quality adhesion. When mixing summer glue, it is recommended to use.

Winter mixtures are intended for use in more severe conditions: the temperature at which the substance can be applied varies within the range of + 5 ... -10 ° C. This allows in winter, without fear of a decrease in the quality of adhesion of materials.

The disadvantage of such adhesives is the need for their rapid consumption after mixing. So, after half an hour, the mixture will begin to solidify, which will make it impossible to further use it for laying blocks. Hot water is used to prepare the glue. It also contains anti-freeze components.

When using summer or winter glue, the ratio of the components must be observed. A change in the amount of materials can lead to a deterioration in the properties of the finished mixture.

The glue contains the following components:

Fine-grained quartz sand creates thin seams.

- fine-grained quartz sand allows you to create thin seams - up to 3 mm thick;

- Portland cement allows you to get a strong connection, and the composition quickly hardens;

- plasticizers or polymer additives are used to increase the plasticity of the finished mass, as a result, it fills up leaks better, which contributes to an increase in the quality of the masonry, since the mixture covers the entire surface of the block, including small irregularities;

- special components that help to retain moisture, thereby increasing the service life of the finished structure, since the risk of cracking is reduced.

Varieties of mortar for laying foam blocks

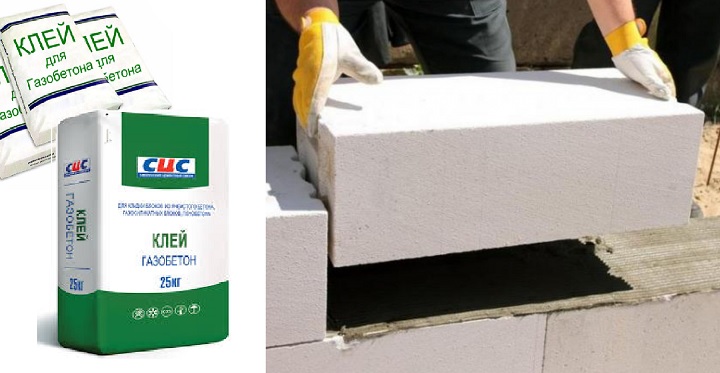

The construction of walls from foam blocks involves the use of one of two options for their coupling: with the help of special glue or with cement mortar. Disputes on this matter do not subside until now, there are many arguments in favor of both.

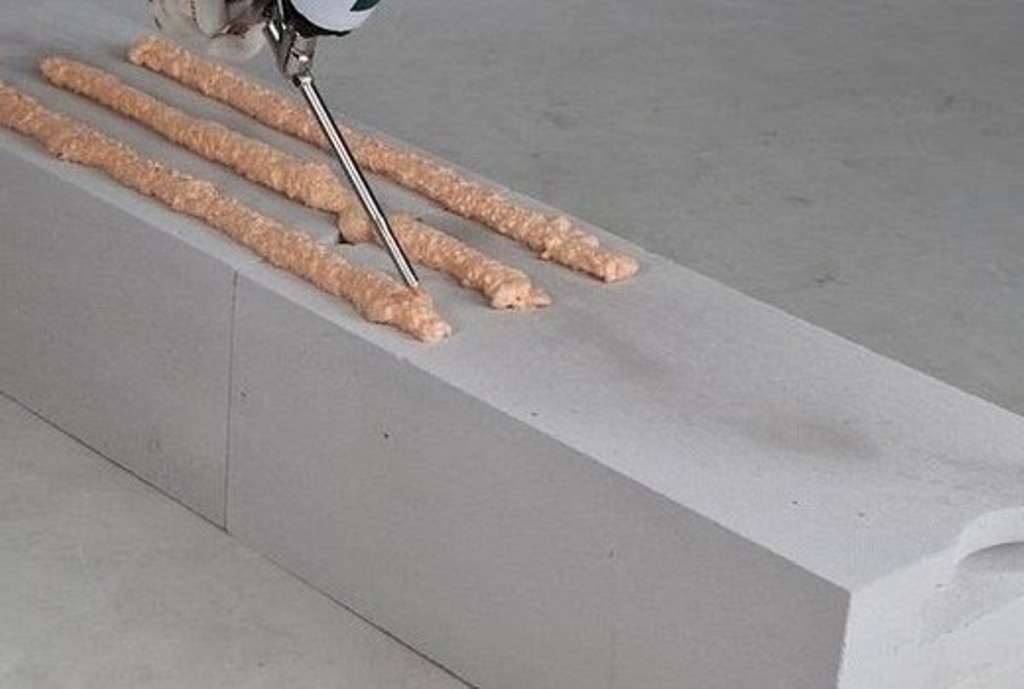

Features of using glue

Having appeared, the foam blocks were designed specifically for the use of adhesive mixtures for their installation. This method of coupling the structural elements of the wall is the most modern and has a number of advantages, among them:

- Low mixture consumption. The glue is applied in a layer of less than 5 millimeters, this avoids many manipulations associated with a thick layer of mortar and reduces the overall labor intensity of the process.

- The foam block has excellent thermal insulation performance, and the small thickness of the seams prevents heat loss at the joints of the blocks.

- When using glue, it is much easier to achieve an almost perfectly flat wall surface. This helps to simplify its subsequent processing, saving labor and materials.

- The adhesive provides a stronger bond between the blocks.

- High speed of drying of the adhesive mixture.

Adhesive for foam blocks

Adhesive for foam blocks

However, how the glue shows itself depends on the blocks themselves. Due to the thinness of the applied layer, strict requirements are imposed on their geometry. Therefore, it is preferable to use foam blocks obtained by cutting from a monolithic base. This manufacturing method will allow you to achieve the maximum correspondence of the size of the elements to each other. With a separate fill of each block, the difference in their sizes can be more than 5 millimeters.

Features of using cement mortar

The most common method of making foam concrete blocks is by pouring the substance into molds. Therefore, the building materials market is dominated by foam blocks with a geometry that is far from ideal. In this case, it is necessary to lay blocks of foam concrete without alternative on a sand-cement mortar.

Sand-cement mortar

Sand-cement mortar

In this case, the thickness of the seam will fluctuate at the level of approximately one centimeter. Due to this, you can easily smooth out the discrepancy between the sizes of the foam concrete blocks. However, the cement slurry has one significant drawback - high thermal conductivity. Thick seams create so-called cold bridges. Due to this, one of the main advantages of foam block walls is partially lost - high thermal insulation qualities.

It should be noted that regardless of the geometric characteristics, the first row of foam blocks is always placed on a cement mortar. This measure is used to level all the unevenness of the foundation, because the quality of the entire wall depends on how exactly the first row lies.

The main brands of adhesive mixtures for aerated concrete

The question of which is the best glue is difficult to decide. The credibility of manufacturers presenting their products on the construction market, the brand of glue, technical parameters are the main points that need to be considered before making a final decision.

To find out which glue to choose, you can test different brands yourself.But it's easier to find out the opinion of professionals.

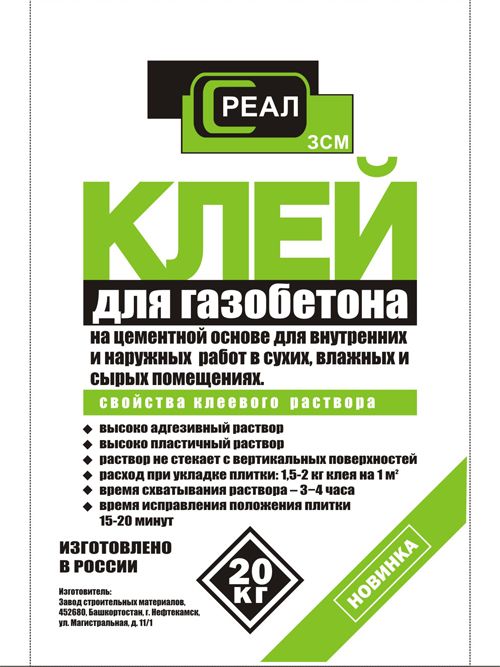

"Real"

Clay Real is used for indoor or outdoor use, with the use of antifreeze additives - up to -15 ° C.

Grades of the resulting glue: strength - M50, mobility - Pk 2, medium density - D1500 - D1700, frost resistance - F50. With a working time of 3 hours, adjustments can be made in about 10 minutes.

Consumption per 1m3 with a layer of glue of 1 mm - from 21 kg to 25 kg. Aerated concrete putty with a thickness of 4 mm - 5 mm is enough for finishing products laid on Real glue.

Solution of the brand "Real"

Solution of the brand "Real"

Volma

Ready-made solutions are required to be used in 2.5 hours, the adjustment time is 10 minutes. Consumption for a device of 1 m2 with a layer of 1 mm is 1.4 kg. A layer of 2 to 5 mm is recommended.

Volma

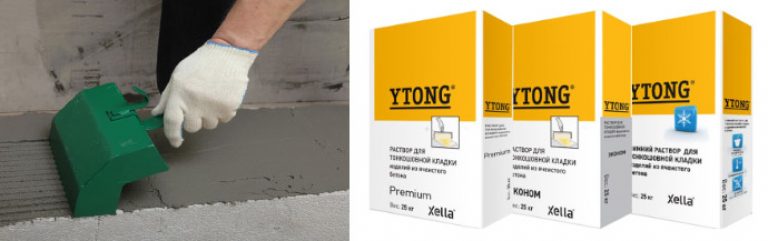

Ytong

The Ytong solution is available in summer and winter versions. They have an increased water-holding capacity and make it possible to perform thinly sutured masonry from 1 mm.

Adhesives of this brand are distinguished by good adhesion properties and high strength. Foam glue is also produced under this name.

Ytong

"Kreps"

Kreps are used for the construction of internal and external structures. At an ambient temperature of + 20 ° C, the glue remains viable for 4 hours.

The addition of the anti-freeze composition "Kreps Antifreeze" makes it possible to carry out masonry work at temperatures up to minus 10 ° C. The maximum fraction is 0.63 mm. It is recommended to apply in a layer of 2 mm or more. Consumption for 1 m2 with a thickness of 1 mm is 1.6 kg.

Kreps kgb

"Polygran"

The polygon is made on the basis of Portland cement using fine-grained quartz sand and modifying additives that give plasticity and ease of use.

After hardening, a strong, frost and water resistant joint is formed, which has high adhesion to the base. Application thickness from 1.5 mm. Glue consumption per 1 m3 - 18 kg with a seam of 2 mm... The mixture retains its working qualities for 4 hours at a temperature of plus 5-30 degrees, 1 hour at a temperature of up to minus 10. Frost resistance class F50.

"Polygran"

"Polygran"

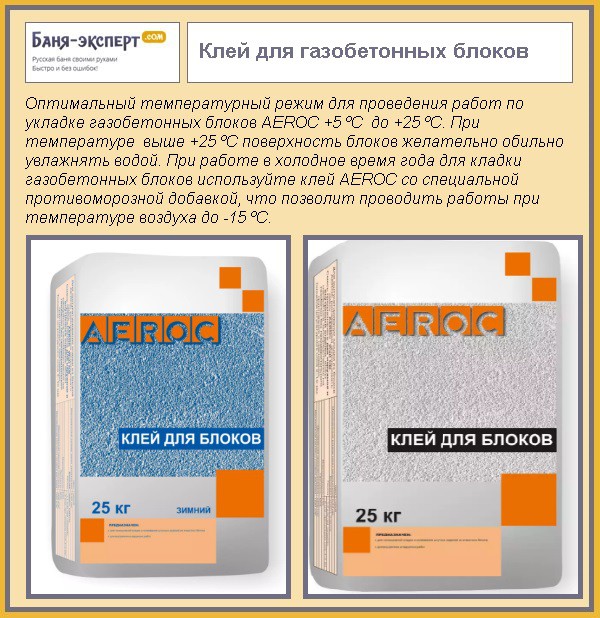

Aerok

Aerok special construction adhesive is used at substrate temperatures from 0 ° C to + 30 ° C. With the winter version, you can work up to -10 degrees, on packages with such glue, as a rule, there is an image *. After diluting the glue with water, the solution must be used within 3 hours. Consumption per 1 m3 of masonry - 25 kg.

Ae

Ae

"UDK"

The manufacturer of the UDK brand offers ready-made mortars with characteristics that are best adapted to aerated concrete and provide high-quality and durable adhesion with a minimum joint size. Consumption of glue for 1 m2 with a layer thickness of 3 mm is 2.5 kg.

Yudk

Yudk

"Warmit"

"Warmit" is produced in Russia. Its difference from others is that ash is included in the composition. This component increases the strength of the glue line. However, reviews on such "know-how" on construction forums are rather ambiguous. Consumption per 1 m3 ranges from 11 kg to 20 kg.

"Warmit"

- Practice shows that despite some difference in consumption, which is indicated by manufacturers of different brands of glue, an average of 25 kg bag of mortar is used for one cube of masonry. Store materials only in dry, well-heated rooms, preferably in closed containers.

- The video in this article will help you choose the right masonry material for construction.

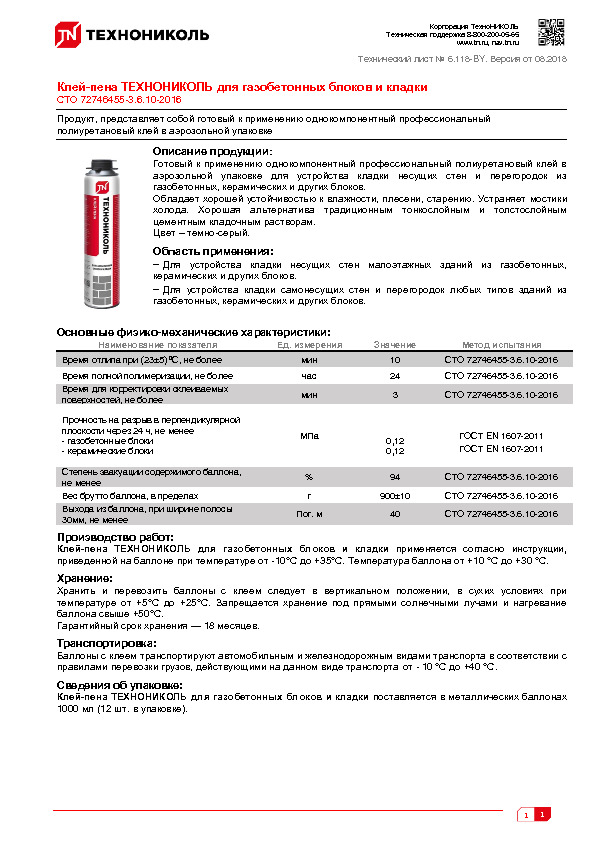

- A fairly new product on the construction market is polyurethane foam adhesive. It is produced in cylinders and is highly economical: one cylinder per 1 m3 of masonry.

- The price for them is much higher than the price of cement-sand mortars. If you use tile adhesive for masonry blocks, then the total cost of construction work will be even higher. However, using a calculator, you can see that the consumption of special adhesive solutions per 1m3 of masonry is at least three times less than that of a concrete solution.

It is better not to save on the price of construction glue, since its quality usually depends on it.Taking into account other advantages of glue mixtures, the question "what to glue the aerated concrete blocks on" is most often solved in favor of glue.