Scope of application

Glue II Premium is used for joining wooden joints, gluing paper material, laminate, plywood, chipboard, veneer. The substance is used to repair outdoor wooden furniture. It can be used to glue cutting boards for cooking.

Original Wood Glue is used to construct and repair wooden musical instruments.

Titebond 3 is used for joining veneer, plywood, wood, plastics, chipboard. The tool is used for both internal and external construction work. Due to the harmlessness of the composition, the substance can be used in the food industry. The glue is not used for joining surfaces that are under water.

Composition and properties

Titebond glue is a professional carpentry product that has found wide application not only in production, but also in everyday life. The composition of the adhesive is represented by aliphatic resins, polymers, polyurethanes, protein, synthetic rubber and water. The material is not abrasive, which guarantees the safety of the cutting tool when cutting products.

After drying, the composition becomes quite resistant to the effects of negative temperatures, which makes it possible to use the product for the repair and manufacture of items, the operation of which will be carried out in outdoor conditions. Despite the heat resistance of the composition and its ability to tolerate temperature exposure well up to 40 degrees, it should be remembered that when the temperature rises to +100 degrees, the glue can ignite and sustain combustion. Titebond is well tolerated by solvents and can be easily removed from the surface before it dries. The initial setting time of the adhesive is 10 minutes, the viscosity of the composition is 4000 mPa / s. The pH value corresponds to 3 units.

The dry residue of the product after drying is equal to half the original volume. Subject to the storage conditions, the composition is suitable for use within two years after opening the bottle. The optimum temperature for gluing is + 10-12 degrees. The glue consumption varies from 170 to 190 g / sq. m. It depends on the environmental conditions and the degree of porosity of the wooden surface.

Usage Tips

It is recommended to use Titebond only at positive temperatures. Bonding surfaces must be dry, thoroughly cleaned of dirt, grease, foreign particles.

Before applying the substance to the surface, it must be stirred. It should be remembered that the composition completely hardens after 10-20 minutes. Therefore, it must be prepared before starting work. For a tighter adhesion of the surface, you can hold it under pressure for some time.

The adhesive mixture is not recommended for joining painted surfaces, as well as on damp surfaces.

All work with glue must be carried out in protective equipment. For this, special gloves and glasses are used. If the product gets on the skin or mucous membranes, it should be washed off with plenty of water, and if necessary, you should consult a specialist. The room must be well ventilated. The air humidity should not exceed the established standards.

The waterproof adhesive has a shelf life of 2 years from the date of opening the package. It should be stored at room temperature. Expired glue is not recommended.

Scope of use

The area of application of Titebond glue is quite extensive. The product can be applied to wood of any age and species. It is perfect for bonding laminate, plywood, cardboard and paper in any combination. In the woodworking industry, the composition is indispensable in the manufacture of furniture, decorative flooring and doors.In the field of design, glue is often used for artistic decoration of interior items with wooden elements, and during repairs it often acts as a sealant for sealing joints. One of the modifications of the glue is specially designed for the manufacture and repair of musical instruments. Due to its high moisture-resistant qualities, the absence of an abrasive effect and good resistance to mechanical stress, the composition is widely used for veneering MDF and chipboards, repairing school and home furniture, as well as as a means for restoring antiques, wooden souvenirs and household utensils.

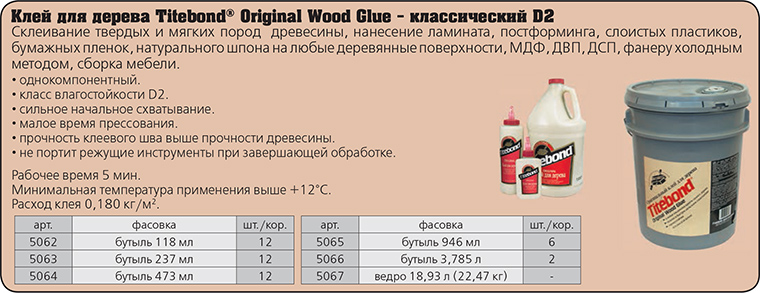

Titebond Original Wood Glue Industrial glue for wood

Titebond original Wood Glue Glue industrial for wood

Water resistance class D2

Titebond Dark Wood Glue Adhesive for dark woods

Water resistance class D2

Titebond II Premium Wood Glue Adhesive industrial moisture resistant one-component

Water resistance class D3

Titebond II Transparent Premium Wood Glue Adhesive moisture resistant transparent for wood

Water resistance class D3

Titebond III Ultimate Wood Glue The ultimate wood glue (Breakthrough in adhesive technology!)

Water resistance class D4

Titebond Liquid Hide Wood Glue Protein Wood Glue

Titebond Molding & Trim Wood Glue Molding Adhesive

Titebond Polyurethane Liquid Glue Polyurethane adhesive

Professional wood glue (standard for woodworking).

Strong initial tack and short pressing times.

Provides a higher bond strength than the wood itself.

Not abrasive. Does not damage cutting tools during finishing.

Bonding of hard and soft woods in the joinery industry (butt and surface joints such as tongue / groove, tongue, etc.).

Application of laminate, postforming, laminated plastics, paper films, natural veneer on any wooden surfaces, MDF, fiberboard, chipboard, plywood by the cold method.

Furniture assembly.

It is cleaned with water until it dries.

Physical properties

Base: emulsion of aliphatic resin

State: viscous liquid

Color: cream, translucent cream after drying

Dry residue: 46%

Viscosity: 3200 mPa * s

Acidity ph: 4.6

Freeze resistance: stable

Shelf life: 24 months in original packaging at 20 ° С

Moisture resistance class: D2

Directions for use

Application temperature: + 10 ° C

Consumption: 180 g / m2

Working time: 5-10 minutes depending on conditions Working surfaces must be dry, free of oil, grease, dirt, peeling old paint and any other materials that reduce adhesion

Cleaning: cleaned with water until dry

After drying, the excess is removed mechanically

Peculiarities

Freezing does not change the structure of the glue, but causes it to thicken.

After long-term storage, it is sufficient to stir it thoroughly before use to restore its properties. Meets the requirements of ASTM C557 (USA) and AFG-01 D3498 of the American Plywood Association.

Not recommended

Use outdoors, as well as in rooms with high humidity, where open water is possible.

Precautionary measures

Use only in well ventilated areas. May cause skin irritation

If dizziness or other unpleasant effects appear, you need to go out into the fresh air, consult a doctor. If any glue gets in your eyes, rinse them with running water for 15 minutes. If the glue comes in contact with your skin, wipe it off and wash the skin with soapy water. Keep the glue out of the reach of children!

Use only for its intended purpose.

Packaging

vendor code

package

box weight, kg

pcs / box

box / pallet

5063

237 ml

3,63

12

160

5064

473 ml

7,25

12

100

5066

3,785 l

9,07

2

63

5067

18.9 l

22,68

1

24

Store and transport at t> 5 ° C.

Characteristic

Depending on the type of composition, the Titebond adhesive (to a greater or lesser extent) has the following characteristics:

- possesses water resistance;

- provides high bond strength;

- has resistance to high temperatures (up to 50 degrees above zero);

- does not collapse under the influence of chemicals;

- does not perceive acoustic vibrations;

- does not contain abrasive components, and, therefore, does not spoil tools;

- the substance contains toxic components;

- does not collapse when frozen;

- flammable at a temperature of 100 degrees.

Among other things, Titebond 3 universal adhesive has the following properties:

- environmental friendliness;

- suitable for work at low temperatures.

Knowing the main characteristics of the composition allows you to get the best quality at no extra cost.

Advantages and disadvantages

High consumer demand and a large number of positive reviews about Titebond wood glue are due to such undeniable advantages of this composition:

- the presence of a world-class certificate indicates the high quality of the material and implies its use as a professional tool;

- the mechanical strength of the seam being formed is several times higher than the strength of wood;

- the glue is environmentally friendly and non-toxic, which allows the glued products to be used in residential and public spaces without restrictions;

- durability of the connection makes it possible to use glue in furniture production and construction;

- the composition does not stick to metal surfaces, which greatly facilitates the choice of the tool and its care.