Brands and specifications

There is a wide variety of options for glue brand 88 on the building materials market. Different types have their own parameters and distinctive features. To choose the appropriate option, taking into account your own preferences and tasks, you should familiarize yourself with the description of each variety.

Depending on the brand, the glue is produced in a special container (tube, drum, barrel). The largest containers hold up to 50 liters of solution. The properties of the material remain unchanged for 6-12 months, subject to the basic storage rules. The container with the product must always be tightly closed. The optimum ambient temperature for storage is 10-25 degrees.

88-CA

Grade 88-CA has a tensile strength level of 11 kgf per 1 sq.... see. Consumption of funds does not exceed 300 g per m2. This composition is used for reliable adhesion of building materials such as foam rubber, metal surfaces, rubber, rubber, leather and a number of other products. Glue 88-CA holds surfaces for a long time even when they are in liquid and air environments. The properties of the solution are not weakened when exposed to ambient temperatures from -40 to +50 degrees. The 88-CA variety is used for construction purposes, the creation of upholstered furniture products, finishing works, and shoe repairs.

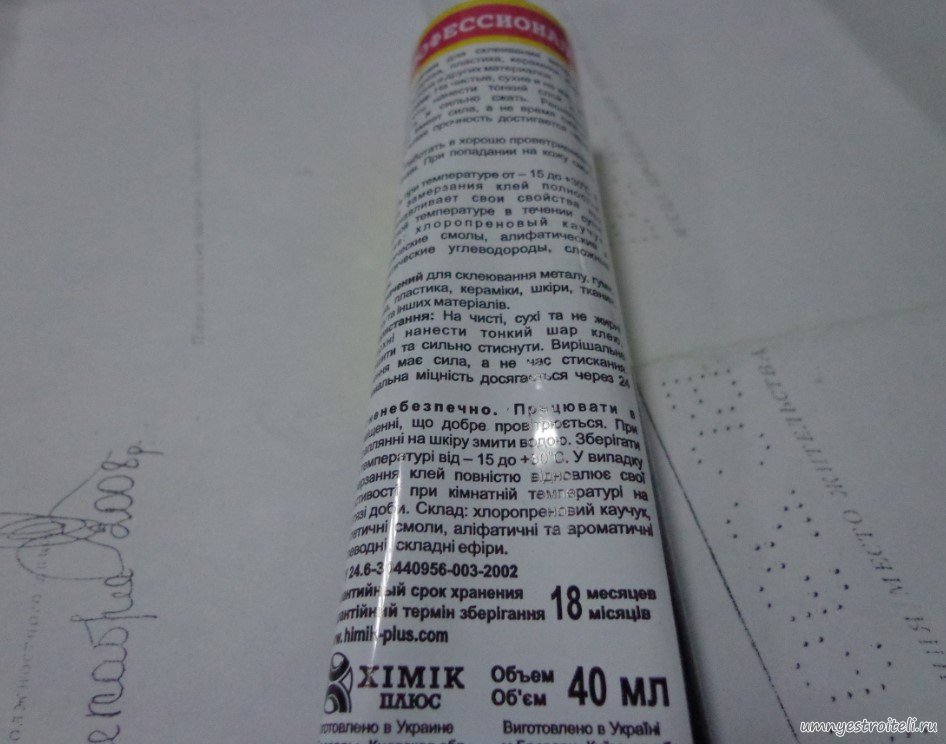

88-NP

The ultimate level of tensile strength of brand 88-NP reaches 13 kgf per 1 sq. see The substance undergoes temperatures from -50 to +70 degrees. For the treated surface, the solution is absolutely harmless and does not cause corrosion. The scope of use includes finishing work, automotive, footwear, furniture production.

88-Suite

Waterproof glue 88-Lux is designed for adhesion of plastic, rubber, leather, tarpaulin, fabrics, foam rubber, cellulose, ceramics and others. The Luxe variety is consumed in the amount of 100-500 g per sq. m depending on the absorbency and porosity of the processed product.

88-H

Glue 88-N is often used to bond rubber and metal products. The substance does not cause rust and forms a film on the surface that retains elasticity. During storage of products, slight sediment is allowed, therefore thorough mixing is required before use.

88-NT

Special glue 88-NT is a reliable means for fastening products made of ceramics, concrete, steel, wood. The solution retains a sticky consistency for a long time and exhibits adhesion properties immediately after compression.

88-M

This type has similar characteristics with 88-CA and NP, but significantly surpasses them in terms of reliability and water resistance. The tensile strength level exceeds 15 kgf per 1 sq. see Resistance to ambient temperature varies from -40 to +70 degrees. Most often, the substance is used in the manufacture of vehicles and for repair purposes.

88-Metal

The variety, created for fixing various products based on rubbers and rubber to metal, is used in production, for household and construction purposes. The main characteristics of the product are: high strength, resistance to liquids, elasticity and instant setting.

88-CR

Glue 88-KR is one of the most modern products. The substance reliably connects surfaces and is resistant to many external factors. The strength indicator reaches 25-26 kgf per 1 sq. see The material is actively used in the automotive field for the following purposes:

- finishing of passenger and cargo transport interiors;

- production of body elements;

- fixing sound insulation and door seals.

Moment

Extra strong type of glue Moment has a gel-like consistency and quickly bonds various materials. The moment is versatile, waterproof and resistant to extreme temperatures. The adhesive is easy to apply, does not run or drip from vertical surfaces.

Methods for using adhesives grade 88

How to glue 88 with glue to get the best result. First, mix it well until a homogeneous consistency is obtained. You can choose ethyl acetate as a solvent for glue 88, but you need to check the instructions to find the right thinner and find out the ratio.

Surface preparation consists of cleaning them from all types of contamination, degreasing and sanding to obtain better adhesion. 88 glue instructions for use include the following options for working:

- Hot method. The glue solution is applied to the product, waiting 30 minutes for it to dry. The surfaces are folded and heated up to +90 degrees for ten minutes. 3-5 hours should pass before using items;

- Cold method. Application of glue in a thin layer, then drying is carried out for 15 minutes, and the surface is again coated with glue solution. The parts are pressed, and will be ready for use in 24 hours, leave at room temperature.

First, mix it well until a homogeneous consistency is obtained.

First, mix it well until a homogeneous consistency is obtained.

Specifications

The glue is a thick, viscous mass of gray-green or beige in color, the tones of which can vary. The composition includes rubber, phenol-formaldehyde resin, ethyl acetate, nefras solution. Sediment is allowed. In this case, you will need to mix the substance well. It should be noted that the glue does not absorb various toxic components for human life and health. It will be safe to work with it under different conditions. It is water-resistant, heat-resistant, plastic, and quickly sets. Let's consider the main product options.

88-CA

This option is usually used in order to glue difficult-to-join building materials. These include, for example, metal, foam rubber and many others. That is why this brand is quite popular. The glue can withstand temperatures from minus forty to plus fifty degrees. The substance is resistant to mold and has excellent anti-corrosion properties. This option is actively used in the automotive industry, in the construction of aircraft, in the creation of furniture. It can be used as assembly glue.

88-H

This model will allow bonding vulcanized rubber to concrete / plastic / metal. Gasoline is included in the substance. The heat resistance of the glue is low. Strength -11.5 kgf / cm sq.

88-NP

This special substance is suitable for a wide range of applications. The option is quite durable, waterproof, regardless of whether it is fresh or salt water. Good adhesion of rubber to concrete, leather, glass, metal. The model can withstand significant temperature changes (from minus fifty to plus seventy). This product can be successfully used in the creation of upholstered furniture, in construction, and the automotive industry. At the same time, there are no volatile elements in the substance that would evaporate during solidification.

88-NT

This option has synthetic resins, gasoline, and various additives. Perfect for gluing leather, rubber, metal, wood, fabric. The substance is resistant to cold and heat

The impressive elasticity of the model also attracts attention. Can be used in industry or daily life

Complies with all GOST standards.

88-Luxe

This option is universal. It glues rubber, textiles, wood, foam rubber, paper, glass and much more. The model is used to create cars, furniture, radio equipment. Long-term stickiness is another advantage of the product.Thanks to this property, the substance can be used on impressive surfaces.

88-Metal

This versatile glue will help you bond metal to other non-metal products. Strong, durable, waterproof - this is how you can describe the model. The Rogneda company created this glue. The substance will provide a strong and reliable connection of surfaces. It should be noted that the material must not be diluted with toxic substances, with the exception of gasoline. The product contains polychloroprene rubber of increased elasticity. Users also note the quick drying of the product, low consumption, and, consequently, savings.

88-M

This variant shows a high level of tensile strength. The glue can be used at temperatures ranging from minus forty to plus seventy degrees. As for the scope of application, it is similar to the above models.

We have considered the main options for glue modifications. It should be noted that the cost of each model is acceptable and affordable. This is another advantage of the product.

Glue 88-CA

Attention! Rubber glue 88-CA is not toxic, but it belongs to fire and explosive substances! It is forbidden to carry out work near open flames, near electric heaters, in the area of high temperatures and in places where sparking is possible (for example, next to welding)!

Advantages of 88-CA glue:

- high elasticity of the glue line;

- a wide range of glued materials;

- long-term stickiness, the adhesive layer retains residual stickiness for a long time, which is especially convenient when working with large areas of glued surfaces;

- non-toxic, does not emit harmful or hazardous substances into the atmosphere when dried and under the influence of high temperatures;

- the adhesive mixture does not contain toluene and other solvents that have a narcotic effect;

- the adhesive bond remains functional in air, in fresh and sea water at temperatures from -50 to + 60 ° C;

- the adhesive mixture is produced completely ready for use.

Directions for using 88-CA glue:

- Stir the glue 88-CA thoroughly before use.

- Thoroughly clean the surface of the product from dirt, degrease with gasoline or acetone and dry.

- Grease the surfaces to be glued with a thin layer of 88-CA glue, air dry for 10-15 minutes, apply a second layer - dry for 3 minutes.

- Roll the lubricated surfaces with a roller or press them together under light load for 2-3 hours.

- Operate the product after 24-48 hours.

The adhesive film (formed after the solvents evaporate) retains some elasticity.

Mode of application

- Rough the surfaces to be glued with a sandpaper, wipe with a solvent, dry for 10-15 minutes, coat with glue, dry for 8-12 minutes, smear a second time and dry for 2-3 minutes.

- Glue the surfaces, press firmly and let cure for 24 hours.

- Stir the glue thoroughly before use.

- The temperature of the glue before use should not be lower than + 18 ° C.

Composition and application

Rubber is a fairly common material, the use of which covers many industries. This is especially true for the production of footwear, the automotive industry and the manufacture of clothing.

Rubber glue 88 NP is used in all of the above areas and is one of the main joining materials. It is also often used to repair rubber boats, fishing suits, wheel tubes, shoes, belts. At a relatively affordable price, the glue has very good performance parameters and enviable durability.

The use of glue in light industry completely excludes the possibility of the presence of toxic and harmful chemical elements in its composition. It is made on the basis of phenol-formaldehyde resin neoprene with the addition of chloroprene rubber and a rubber compound solution.

According to GOST, glue 88 NP cannot contain volatile fractions, which will evaporate during solidification. Its components do not enter into chemical reactions with surrounding compounds under normal conditions. This allows you to use the adhesive without any problems for repairing shoes and clothes, as well as for installing decorative panels when finishing furniture or carrying out repairs in residential premises.

Application methods

Before processing, both surfaces are cleaned of accumulated dust, degreased and cleaned with sandpaper. The solution can then be applied using one of the following methods:

- The hot method, during which the product is applied in a thin layer and dried for half an hour. After that, a second surface is applied and heated for 10 minutes at a temperature of 90 degrees. For final adhesion, it remains to wait 3-5 hours.

- Cold method, which involves gluing the surface, drying for 15 minutes and then joining the surfaces. Before using the product, you need to tightly squeeze the parts and dry them at room temperature for 24 hours.

It is important to consider that when bonding porous surfaces, a pre-treatment primer must be used. Priming is necessary to reduce the absorption rate

This is interesting: How to sheathe a wooden house with clapboard from the inside?

Manufacturers

Glue 88 can be from different manufacturers.

The Rogneda company is the manufacturer of the 88-Luxe model, which is optimal for gluing rubber, leather, paper, metal and other items. This glue is used in the manufacture of furniture, in shoe repair, in industry and in everyday life. The substance helps to glue materials with high quality and reliably. You will be able to use the product easily and conveniently. When storing, it is worth considering the basic recommendations so that the substance will serve you for a long time. You can profitably buy 20 liters to save your money and buy a universal glue.

The Expert company also produces a quality product. It is suitable for bonding materials in industry and in everyday life. The model has good hold, forms a strong, elastic, moisture resistant seam.

There are other manufacturers as well. All imported products will be of high quality characteristics. Moreover, their cost will be much higher than that of domestic companies.

General information

Chloroprene glue (nairite) 88 is made on the basis of nairite (chloroprene rubber) and a number of other components - nefras, ethyl acetate, phenol-formaldehyde resin. The mixture contains stickiness enhancers, a number of other synthetic resins.

The product is manufactured in accordance with GOST 12172-74. In appearance, the mass has a beige, brownish, greenish color. Sediment is allowed, which does not reduce the basic properties.

Manufacturing plants produce glue in different packages - in small containers, in cans and sprays, in drums and barrels of 25 - 50 liters each. Shelf life - 1 year, storage is carried out at temperatures of -40 ... + 30 degrees.

Glue 88 and all its varieties are of consistently high quality. Easy to apply to surfaces, easy to use. The complex composition provides excellent adhesive properties, makes the glue waterproof, elastic, some compounds are considered to be a particularly strong material. Each species has its own characteristics and common features. For example, 88-NP glue can withstand low and high temperatures, 88-M glue is very tear-resistant.

What it is?

Glue 88 is a versatile water resistant compound that is commonly used to bond a variety of coatings, from glass to wood. This glue sticks together everything that other universal adhesives can hold together - leather, metal, glass, rubber, they even glue the hair of toys with it. Many people ask the question - why exactly 88, why not 39 or 74, 51 or 62. The answer to this question can be found in the technical literature, which was released back in the 80s of the last century.As it turned out, after its creation, any adhesive composition undergoes mandatory test procedures that check its strength and elasticity.

As a rule, the hardened composition is subjected to cooking, exposure to chemicals, increased tensile and compressive stress, and even lower or higher temperatures. All these tests last for 7 days, but as the story goes, with this glue, by chance, tests were carried out for 8 days. Noticing this at the last moment, they gave an increased burst pressure with a force of 8 joules - and the glue withstood all this. This is where its name came from, which testifies to its unconditional quality, since not all types of glue are capable of withstanding such experiments. Glue 88 is produced in accordance with the current GOST 12172-74.

Application area

Such an adhesive composition can be used for all kinds of substances, for example, for imitation leather, leather, metal, fabric, wood, glass, cardboard, polymeric materials and others. The substance is also suitable for both linoleum and rubber. And glue for the shoe industry is also actively used, and it is precisely such substances that will be easily applied to products at different temperatures, and everything sets quickly. The product will be ready for use after a day if you glued everything in a cold way, and if it was hot, then after 3 hours you can use the product.

As for the methods of using the adhesive composition, or rather, gluing, there can be two options:

Hot glue should be spread in a thin layer over the required surface, and after half an hour, it is important to expose the object that was glued to high temperatures (about +90 degrees Celsius). Next, we leave the subject under pressure for a while.

The cold method can also ensure a reliable connection of products.

Distribute the substance evenly on the required item. After 20 minutes, you can apply another layer of adhesive, and under the press, the object that was glued should spend a day.

If we talk about an industrial scale, then such glue as No. 88 can be seen on sale even in cans of 25 kg. As for the warranty period, it will be one year, and if the substance was stored correctly, it may be longer (the storage temperature should be from +10 to +25 degrees. Such glue is actively used for the construction industry. They can glue materials on rubber base or rubber products to reinforced concrete or wooden bases.Glue is also used in everyday life, which allows you to glue not only leather products, but also stick foam rubber on different surfaces

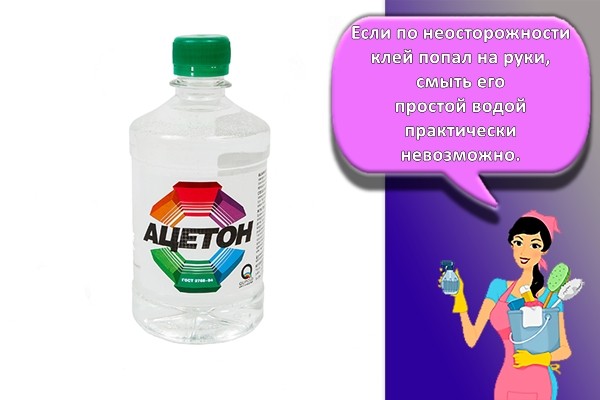

How to wash the glue off your hands

If, through carelessness, the glue gets on your hands, it is almost impossible to wash it off with plain water. This will require the use of special tools.

One common option is acetone, which tends to soften the adhesive, making it easy to remove. Acetone is part of nail polish removers and can be purchased in a large number of stores.

It is enough to apply the product on a cotton swab or towel and treat the skin surface. When the dried glue softens, it will gradually flake off and it will remain to gently scrape off the remnants. After using acetone, it is recommended to thoroughly wash your hands with disinfectant soap.

The most affordable and simplest way is to use hand cream. To remove the dried adhesive solution, it is necessary to grind the cream until the substance begins to exfoliate from the skin. An additional advantage is that the cream simultaneously serves as a moisturizing function, which helps to reduce possible damage from exposure to the skin. It is useful to use a cream to eliminate material residues with dry skin of the hands.

Glue 88 - what is it

Glue 88, due to its unique composition, makes the adhesion particularly strong.In consistency, it is a homogeneous substance with a viscosity consisting of phenol-formaldehyde resin, nefras, ethyl acetate, chloroprene rubber. The color can be from gray-green to light beige.

If a precipitate is visible in the solution, then stir it before use. Adhesion promoters and resins can be added depending on the type. Due to the peculiarity of the production, the glue allows you to create a reliable fixation with concrete surfaces. It can also be used to repair moving objects that also vibrate.

Glue 88, due to its unique composition, makes the adhesion particularly strong.

Glue 88, due to its unique composition, makes the adhesion particularly strong.

General information and scope

The substance is manufactured in accordance with GOST... The release is made in different types of containers, there are options for aerosols, cans, barrels. The composition is poured in different volumes. The adhesive is of good quality and is easy to work with. The constituent elements help to obtain excellent adhesion rates, as the mortar has a waterproof, elastic property. Glue 88 technical characteristics may vary depending on the type of product, the variety of types makes it possible to choose the right option for different purposes.

You can glue vulcanized rubber, glass, plastic, ceramic and faience surfaces with glue. Products are used for bonding metals and alloy to concrete and other materials. Glue 88 is a universal solution, therefore it is also used for gluing leather, textile, and wood items.

It is used in the following variants:

- When building ships;

- In aviation production;

- In the manufacture of automotive parts;

- In construction work;

- When woodworking;

- During repair work;

- For household needs.

So the solution can be used for the connections of the upholstery in the car, headliner, doors and other interior items. For the production of furniture, a composition is also chosen; it is suitable for connecting individual parts, fabric parts. In the shoe industry, glue 88 is also used, the soles of the insoles are glued together with it, and more. During construction, floor coverings, tiles, moldings are glued to them.

The adhesive is of good quality and is easy to work with.

The adhesive is of good quality and is easy to work with.

How to use glue 88: detailed instructions

Adhesive 88 is water resistant, versatile and has an immediate set. It is intended for joining surfaces made of metal, wood, polymer-synthetic materials, plastic, glass, ceramic and porcelain products. This article contains helpful tips on how to use 88 glue.

Glue 88 glues the skin

Views

- Glue 88-CA has the following characteristics:

- tensile strength indicator above 11 kgf / cm kV;

- the expense of the product is 300 g / m2.

This type has established itself as a quality tool that can provide durable connections for building materials such as metal surfaces, foam rubber and many other materials.

- Glue 88-NP has the following characteristics:

- tensile strength indicator above 13 kgf / cm2;

- increased level of resistance to fresh and salt water.

This type has a fairly wide range of applications. For example, it is used when gluing plastic coatings in the construction of cars, and the same in industrial and private construction, when it is required to glue rubber to a surface made of metal, glass, concrete, genuine leather, etc.

- Glue 88-M has the following characteristics:

- tensile strength indicator above 15 kgf / cm2;

- resistance to temperature fluctuations in the range from -40 to + 70 ° С.

This type is analogous to 88-CA and 88-NP, but significantly surpassed them in terms of strength and water resistance. It is mainly used in construction for bonding rubber to metal, glass, concrete, natural leather, wood, etc. It is also actively used in the process of repairing cars and motorcycles, as shown in the photo.

Specifications

This tool is a solution of a mixture:

- rubber;

- phenol formaldehyde resin;

- ethyl acetate;

- and nefras.

Glue 88, we drag the ceiling of the car

In consistency, the solution is viscous and homogeneous. Its color ranges from gray-green to beige. According to the instructions, precipitation is allowed.

Application

This adhesive is a high quality product for use on a production scale. The fast-setting property has made it widely used in the footwear industry. This product is also appreciated for its ease of application to a surface of any temperature:

- As mentioned earlier, glue 88 in construction is used to make joints by cold applying rubber based on general purpose rubber to surfaces made of metal, glass, concrete, wood, etc .;

- In everyday life, the tool has found its application for gluing leather and textile products in the process of manufacturing and repairing shoes, as well as for joining foam rubber products with metal, wood and reinforced concrete surfaces.

Glue 88 is produced on an industrial scale in containers of 25 kg, as shown in the photo, with a warranty period for the invariability of technical parameters for 1 year. However, the guarantee remains only if the conditions for proper storage of the product are met: the container with the substance must be tightly closed with a lid and be kept in a room with a temperature regime of +10 to + 25 ° C.

The product arrives on store shelves completely ready for use, and its high quality is guaranteed by the manufacturer.

Application methods

- Cold. According to the instructions, this adhesive is applied to the surface of the material in an even thin layer and dried for a third of an hour. Then the procedure is repeated one more time.

After this, the surfaces must be firmly connected to each other for a couple of minutes and left for another day in a resting position;

- Hot. According to the instructions, this adhesive is applied to the surface of the material in an even thin layer and dried for half an hour, as shown in the photo.

The surfaces need to be heated to 80-90 ° C, and then firmly connected to each other for a couple of minutes and left for 3 hours.

Let's sum up

Adhesive 88 is distinguished by its versatility and the ability to firmly bond difficult-to-bond surfaces. The most common brands are Lux, NP and CA, as seen in the photo.

All of them are characterized by a unique adhesive ability and are used in different temperature conditions.

Their constituent components are manufactured by the most experienced companies, which ensures high quality adhesive composition.

Glue 88

The modern chemical industry greatly simplifies technological processes, releasing relevant products intended for widespread use. Today glue 88 is also a unique development designed for joining seemingly incompatible materials.

Features of glue 88

- excellent heat resistance indicators;

- unique vibration resistance;

- waterproofness;

- the ability to provide a wide combinatoriality of the materials to be glued.

Properties and specifications

Glue 88 is made from polychloroprene materials. It is a light brown liquid in texture.

It is used where it is important to ensure instant setting speed while maintaining heat resistance. The glued seams do not diverge under the influence of temperatures from minus thirty to plus ninety degrees

Basic physical and chemical properties

- conditional viscosity not less than 120 s., according to VZ-246 (nozzle 4mm.);

- when peeling rubber from steel, the bond strength when using 88 glue is more than 2.0 kg / cm;

- the glue contains non-volatile compounds in the total mass of no more than 20%.

Scope of glue 88

Glue 88 is often used as a bonding agent for various types of leather products, metal, wood, imitation leather, fabric, cardboard, glass, polymer materials, rubber based on styrene, isoprene, natural rubbers.

Due to its unique ability to quickly set, this type of glue is widely used in the shoe industry. Surfaces are glued using cold or thermal methods, at choice. If glued in a cold way, then the product is ready for use only after twenty-four hours.

If glued in a hot way, then the product can be started to operate, already after three hours.

Glue 88 is a high quality product for use on a production scale. In the footwear industry, it quickly found application not only due to its fast adhesion, but also because it is easy to apply to the product in any temperature regime.

It is universal in nature, therefore, it is actively used where it is necessary to connect elements that are difficult to glue together.

Popular brands

Today you can order 88 different brands of glue:

- Lux;

- NP;

- CA;

- Glue 88 foam rubber;

- 88-H;

- 88-HT;

- 88-P1;

- Glue 88 metal;

All of them have unique adhesive properties and are used in various temperature conditions. They combine materials supplied by the best domestic and foreign manufacturers. At each stage of the production of each brand of glue, a multi-stage quality control is carried out.

In the video, an example of using 88 glue for gluing neoprene:

The glue is delivered to the customer completely ready for direct use. The high quality level is guaranteed by the manufacturer.