Linoleum adhesive brands

In hardware stores, funds from different manufacturers are sold. The most popular in practice are Ceresit, Thomsit, Homakoll, Titan and others. Below is a list of products that are suitable for gluing linoleum:

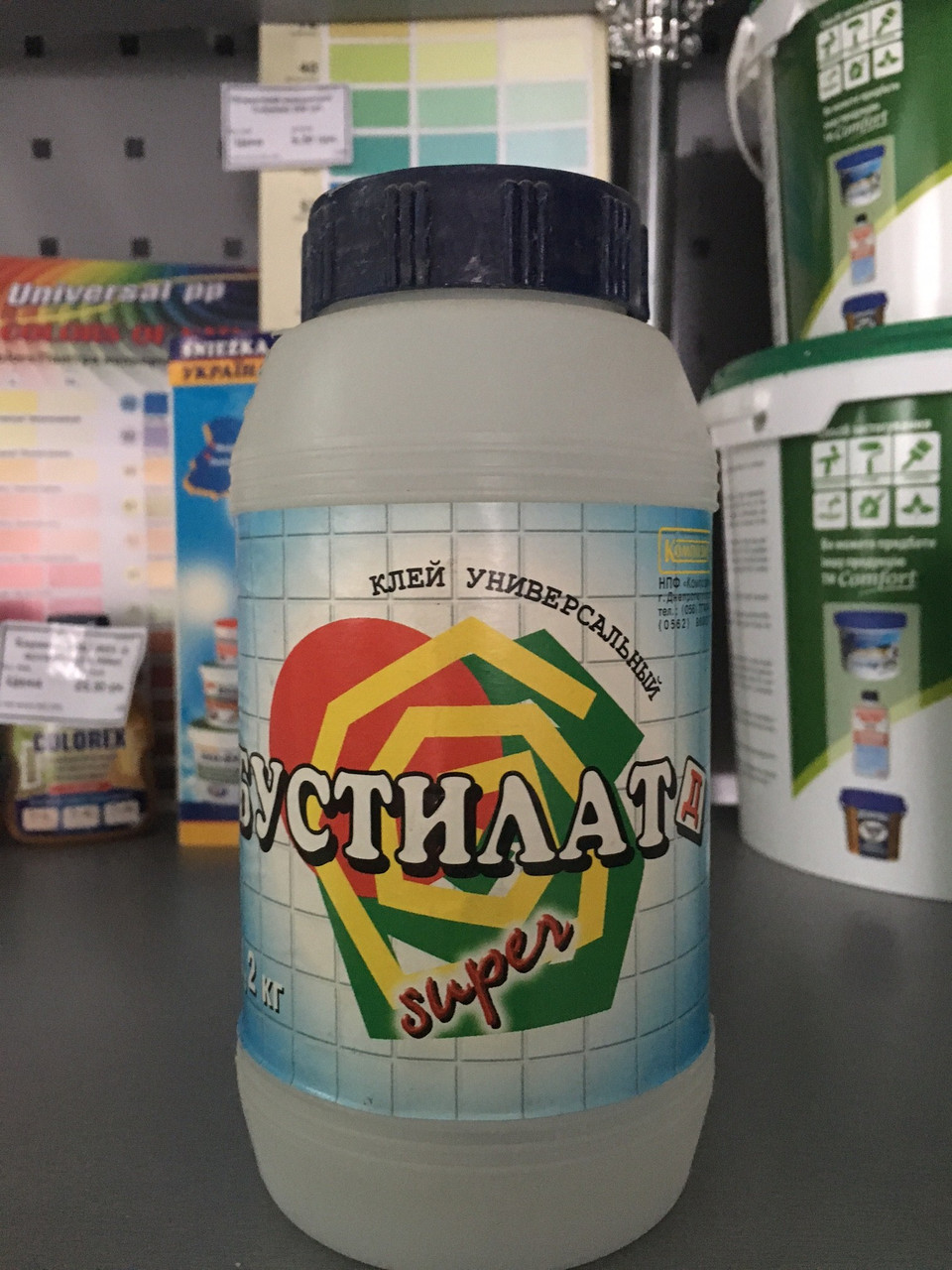

- "Expert Bustilat". Suitable for attaching linoleum to plywood, concrete, wood, it is better to use it on PVC coatings on a felt or jute basis. Drying time - 24 hours.

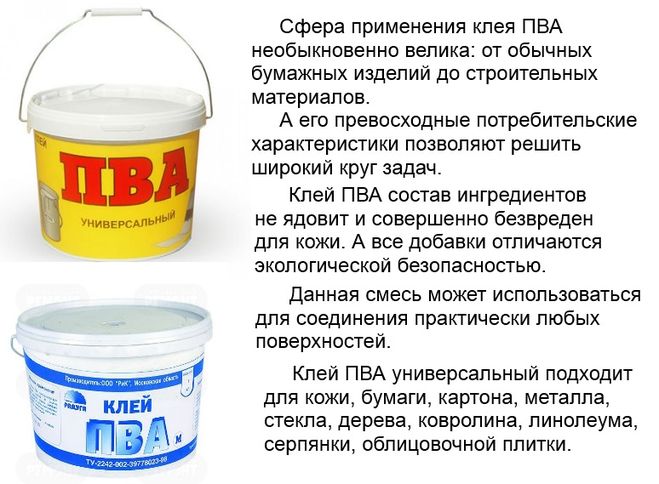

- PVA is universal. Includes latex, suitable for gluing various materials to floors and walls, suitable for felt linoleum. Low consumption - up to 250 g / square meter with continuous application.

- KS glue is universal. It is based on liquid sodium glass, therefore it is more often used when laying ceramic tiles. Suitable for linoleum on a fabric, felt, jute base.

- "Polynomial 105". Acrylic adhesive, can be applied to all types of materials and substrates, drying time is short - 12 hours.

- Homakoll 228. This is a water-dispersion adhesive for any household linoleum (homogeneous, heterogeneous). They can glue the material on a foam, pile, fabric base. The product does not contain solvents and contains little water. The analogs of Homakoll 228 are Homakoll 208, 202 and 248. Their properties are similar, but they are used only in rooms with low humidity.

- Thomsit L 240 D. Suitable for coatings less than 2.5 mm thick on water-absorbing substrates. It is used in hospitals, schools.

- Forbo Eurocol Super 599. Forbo universal glue, medium viscosity. Ideal for soft roll flooring. Its version - Forbo Erfurt 523 with antistatic properties prevents stray currents.

- Bostik KS 330. Dispersion adhesive, does not contain harmful components. Can be used for underfloor heating installation.

- Linocol - cold welding. It is mainly used for fastening floor joints. Easily holds seams up to 4 mm thick. Easy to use thanks to its thin spout.

- Mapei Ultrabond Eco Contact. For PVC coatings, solvent free. Adhesion at a very high level, will help to stick linoleum on steps, walls.

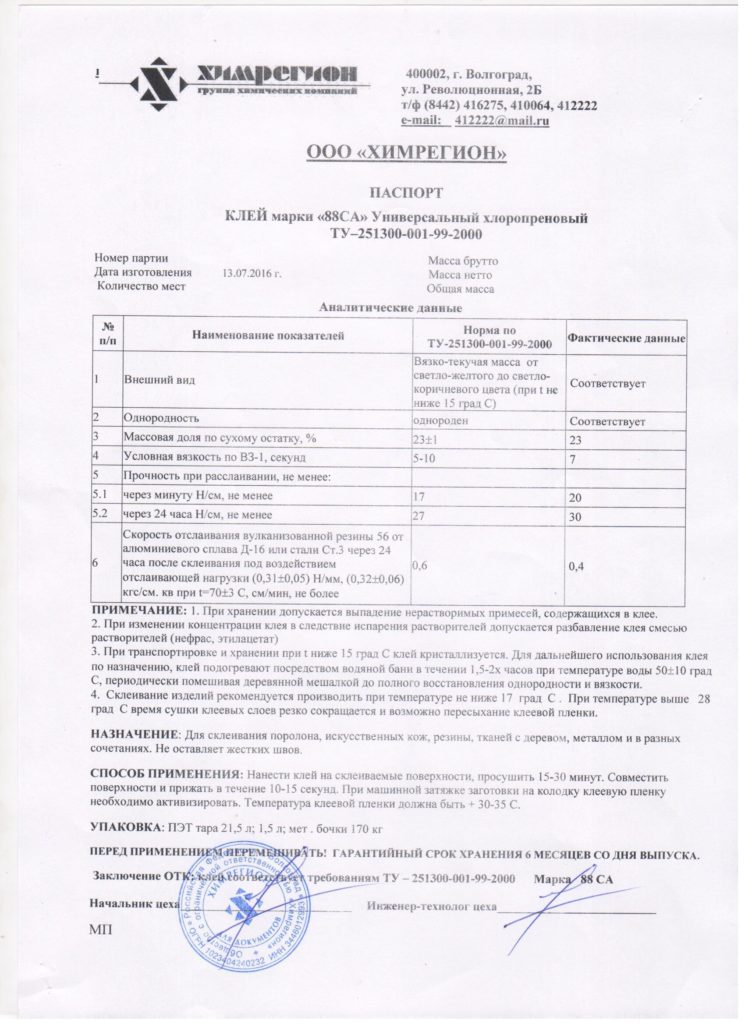

- Rubber glue 88. A well-known composition, considered universal in everyday life. It is best used for gluing joints. Slightly melts the base, but does not corrode it, which ensures good adhesion. It is sold in the form of "liquid nails" in cans and tubes.

- Sintex H44. Cold welding for commercial, semi-commercial, household linoleum. Prevents shrinkage, creates a durable seam. If the surface is damp during work, the seam will turn out white.

- Axton is versatile. Suitable for linoleum, carpet. It is sold in cans of 14 kg, applied with a spatula, has high frost resistance.

- Kiilto Uki. High-strength composition, at the same time environmentally friendly, odorless. It can be used to glue PVC coverings and boards, carpets, materials with a cellular-checkered backing.

- Forbo 522. Plasticizer migration resistant dispersion adhesive, best suited for foamed vinyl.

- Titan Wild. Widely used in renovation work, it can be applied to any floor covering. When thickened, it can be easily diluted with alcohol.

- VGT floor "Economy". Suitable for household linoleum, carpet, waterproof, elastic, freeze-resistant.

- Werner Müller adhesives. Various types of cold welding products are available for new and old coatings, synthetics and natural-based flooring. It is used only in dry rooms.

Tarkett adhesives should be noted separately. The manufacturer also produces floor coverings, so he knows a lot about the means for their installation. Compositions for natural cloths with antistatic properties and for a single-layer (homogeneous) material are being realized. Adhesives for commercial and semi-commercial coatings are sold separately.

Features of the glue

Bustilat exhibits high adhesive qualities in relation to many building materials, in particular: to fabrics, wood, concrete, polymers. After polymerization, it forms a strong thin film without a definite color.

The product is economical in consumption. Each square meter takes 100-180 grams. The duration of complete drying is 28-36 hours, depending on the humidity level of the room in which the repair was carried out. The long-term polymerization process makes it possible to eliminate installation flaws, to correct the canvases, and to correct the joints.

For 1 year, the glue in an uncorked container retains its properties, so the remaining product can be used for its intended purpose.

Advantages and disadvantages

The advantages of Bustilat include the following:

- Composition safety. The substance does not harm the human body.

- Ease of use. The tool can be combined with different types of materials. This is very convenient, since only one composition is enough for the repair. In such a situation, there is no need to buy several special tools.

- Excellent elasticity and high adhesive properties. Thanks to this, it is possible to achieve high strength of the fixing of materials over a long period of time.

- Low shrinkage and excellent adhesion. These parameters provide high reliability of the coupling with natural and artificial materials. As a result, it is possible to obtain a strong and even seam.

- Multifunctionality. The composition can be used as an adhesive or a primer. It can also act as a waterproofing mixture.

- Affordable price. This is due to cheap raw materials and optimization of the production process.

The product has no major flaws. The only drawback is considered to be low durability. In this case, it is worth giving preference to modern multicomponent formulations.

How to calculate the approximate consumption of reaction adhesive for 1m2

The principle of operation of the reaction variant is based on chemical reactions between its components. The process itself resembles cold welding. It is resistant to high humidity and water influence and does not require a specific indoor microclimate. The reaction variant is distinguished by its reliability and ductility. Consumption is 300-400 grams per m2, but some of its options may require more consumption per m2

Types of reaction adhesives:

Types of reaction adhesives:

- Cold welding (type A). It is usually used for gluing floor coverings, when docking them together;

- Cold welding (type C). Quite a thick option. Often used for gluing seams and old linoleum;

- Cold welding (type T). The product is a professional product. Used when joining polyester based coatings;

Today, installation work with linoleum is almost complete without glue. There are many types and variations, suitable for different purposes, with different properties and consumption.

When choosing a natural product, it is better to pay attention to the dispersive type, and when working in a humid room, a reactionary one is better suited

How to use?

For laying linoleum or carpet, the adhesive solution is applied to the floor with a spatula.

Immediately after that, the finishing material is laid on the base.The cladding must be firmly pressed against the base. Upon completion, it is necessary to leave the finish for three days, until the glue is completely dry. The optimal consumption of the composition in this case is from 0.5 to 0.7 kilograms per m2.

Expert advice: You can add cement mortar to the glue. This will help speed up the hardening process of the layer if it is necessary to carry out the work as soon as possible. Proportions - 1: 1. To prepare the mixture, it is necessary to mix one part of cement and three parts of sand.

When using an adhesive for laying ceramic tiles, the composition must be carefully applied to the back of the finishing material. The optimum layer size is about 203 millimeters. After that, the tiles must be firmly pressed against the wall and fixed in this position until the glue sets. Full hardening of the glue occurs after three days.At this time, in no case should the finish be influenced. One square meter consumes from 0.4 to one kilogram of glue.

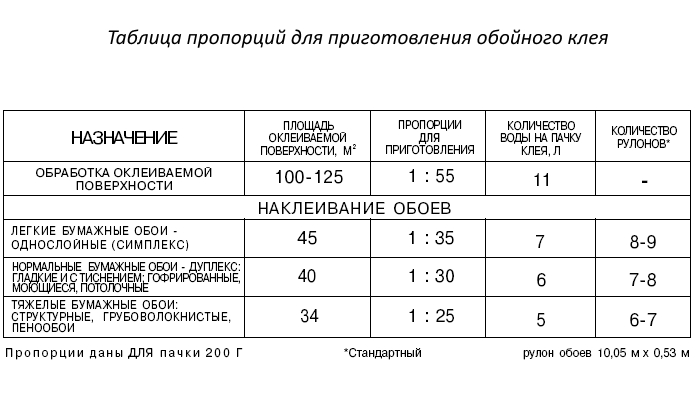

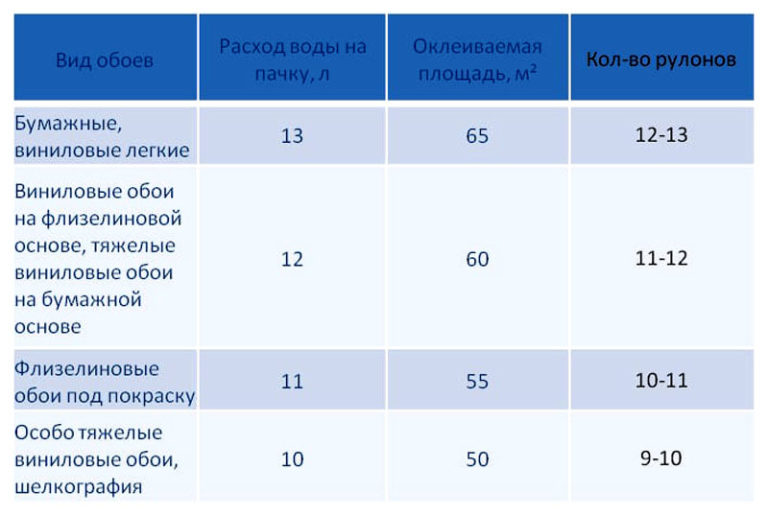

"Bustilat" is actively used for the installation of wallpaper from various materials. If the glue thickens over time, thin it slightly. Add a seventh part of pure water to the composition, this is the maximum allowable volume. If the product is fresh, then you do not have to dilute it.

It should be noted that the frozen layer of "Bustilat" cannot be removed with hot water, therefore it makes no sense to remove old wallpaper and treat the base in this way.

The most popular, affordable and effective method is mechanical cleaning, which is carried out with a metal spatula or sharp scraper. You can also use a grinder with a special attachment in the form of a metal brush. This method will help to get rid of the glue residues, however, a lot of dust and noise appears during operation. Protect the respiratory tract with a respirator while working.

The second way is to dampen a rag with water and heat the fabric with a hair dryer or iron. Under the influence of temperature, the crust of the layer acquires elasticity. It is an efficient and quiet process, but time consuming.

- Ventilate the area thoroughly before starting work.

- The work surface should also be prepared by removing dirt, traces of grease and various compounds. If necessary, a priming procedure is carried out (if the base has a porous structure).

- Be sure to read the instructions for use of the product. All necessary information is indicated on the packaging.

- The price of the glue depends on many factors: the manufacturer's margin, the percentage of the store, the type of composition. The minimum price for a kilogram is about 100 rubles.

During the repair, you cannot do without adhesives. This is justified by the fact that the use of elements such as nails or screws can make the material look unsightly. In order not to spoil the appearance of the room after renovation, Glue Bustilate is often used: we will find out the main properties and use cases below.

The glue is used for gluing wood and ceramic products, wallpaper, linoleum and other structures. It is worth noting that this substance has existed on the market for about 50 years, however, even today the use of bustilate glue has not lost its popularity. This proves that bustilate is a high quality material that is available for any category of builders, as well as for those people who make repairs with their own hands.

Recommendations for the selection and application of glue

So, the main criterion for choosing an adhesive is the type of subfloor. Different formulations are used for absorbent and non-absorbent substrates, and if you use inappropriate glue, strong attachment will not work. Absorbent surfaces include cement and concrete screed, solid wood, plywood flooring, chipboard, fiberboard, OSB.

Linoleum is glued to them with water-soluble compounds, but there are also some nuances here. Board materials, such as plywood, fiberboard and others, can deform from excess moisture, so thick adhesive mixtures with a minimum water content should be chosen for them. For a concrete floor, the consistency of the glue does not really matter.

Non-absorbent floors are considered to be tiled with natural stone, porcelain stoneware, tiles. Here, already water-soluble compounds will be ineffective, since there is nowhere for moisture to go out, and high-quality adhesion between surfaces will not work.

You need to buy glue with or after linoleum to make sure that the composition is suitable for this particular coating. On the packaging of the glue, it is always indicated for which types of linoleum it is suitable, what the base of the coating should be. Be sure to check the expiration date, because expired glue will not hold the canvas.It is best to buy adhesives in building supermarkets or large stores where there are conditions for the proper storage of such materials. This is especially true for water-soluble adhesives, which completely lose their adhesive properties after freezing. The exception is special dispersion agents with frost-resistant additives: they can withstand from 3 to 5 freezing and thawing cycles without losing their main characteristics.

In order not to overpay, before buying, you should calculate the required amount of glue. To do this, you first need to measure the room and calculate the total coverage area. As a rule, consumption varies between 200-500 g per m2 (this is influenced by the type of work surface and the base of the coating). For example, a fabric or felt base requires more glue than foam and rubber, and a plank floor requires more than a concrete screed.

To reduce the consumption of glue, it is recommended to prime the floor. Glue should be bought with a small margin so that you do not have to interrupt the installation and go back to the store.

Linoleum and glue must be in the room where the coating will be laid for at least a day. Work should be carried out at a temperature not lower than 15 ° C and an air humidity not higher than 75%. In this case, the moisture content of the floor base should not exceed 8% for wood and 2% for screed.

The advantages and disadvantages of bustilate

- No toxicity. Most of the busylate models do not contain harmful chemicals and do not release them into the air, regardless of external conditions;

- Reliability. Over the decades of use, the positive qualities of this glue have been well studied, as well as the technologies for its effective use. They trust the product and know how to work with it;

- Availability and low cost. It is not difficult to find a bustilate in the nearest hardware store, but its cost, due to the low price of the initial components and production optimization, is at a low level;

- High elasticity. Even if the surfaces to be glued are deformed, the glue, to some extent, will retain its bonding qualities.

- The composition is practical. High bonding capacity allows this adhesive to withstand both light wallpaper and heavy ceramic tiles equally effectively. In addition, the composition can be used as a primer and waterproofing.

This glue simply does not have any serious drawbacks, showing itself from the best side in a variety of uses. The only thing worth mentioning is his age. Indeed, over these decades, a large number of analogues have come out, many of which, according to one or another indicator, can surpass busylate and be more reliable in certain operating conditions.

Instructions for the use of glue "Bustilat-M"

The consumption of glue for linoleum per 1m2 was mentioned above. This composition is universal and is used for gluing linoleum and other coatings on any substrate. This mixture can be used to mount tiles to any surface. The mixture is highly elastic and capable of providing a strong bond of materials for a long time. The shrinkage here is insignificant, the glue is frost-resistant and waterproof. Among the surfaces for use should be highlighted:

- Fiberboard;

- Chipboard;

- concrete;

- wood.

Concrete can be cellular. As soon as you know the consumption of glue for linoleum per 1m2, you can purchase the required amount of the mixture. Before applying it, make sure that the surface is solid and free from contamination. If it is crumbling and weak, it should be treated with a strengthening impregnation.

Before use, "Bustilat" must be mixed well in a container and applied with a brush or notched trowel. Application to the floor surface is carried out as evenly as possible, after which the linoleum is pressed over the entire area. There may be different consumption for different types of linoleum glue.Glue for linoleum, the consumption per 1 m2 of which was mentioned above, will dry for about 2 days. You can spend up to 0.8 kg per square meter.

Areas of application of "Bustilat"

The glue is used for arranging various coatings inside the house, if a strong fixation of finishing materials is required. Due to its elasticity, the glue seam will serve for a long time, because it is not subject to destruction by vibrations, vibration, mechanical stress. The tool is perfect for such bases:

- concrete;

- wood;

- bricks;

- Fiberboard, chipboard;

- stone;

- plaster.

"Bustilat" is glued wallpaper of different types, including the most difficult ones. It is suitable for fixing carpets, other pile coverings, linoleum with a fabric and felt base. The glue is suitable for fixing polymer and ceramic tiles, panels, stucco moldings, baguettes and other decor, wood finishes. Also, the glue is useful for working with asbestos-cement slabs. Another tool is added during various repairs to cement, which will increase the strength of the mortar or screed.

Criterias of choice

When choosing an adhesive for fixing a floor covering, there are a number of criteria to consider.

Sub floor type

First of all, you should focus on the type of subfloor. Depending on this, one or another composition is chosen.

Absorbent

This category includes a cement or concrete base. Also, the absorbent coatings include chipboard, fiberboard, OSB, plywood flooring or solid wood. For such substrates, it is recommended to choose a water-soluble composition.

In this case, it is worth considering some features. Board materials are capable of deforming from excess moisture. Therefore, thick compositions with a minimum of water are suitable for them. Any glue will work for concrete.

Non-absorbent

This category includes floors that are tiled with natural stone, tiles or porcelain stoneware. In this case, water-soluble formulations will have no effect, since there is no space for moisture to escape. In such a situation, reaction adhesives are suitable.

When using them, it is important to observe safety rules - to use protective gloves and a mask. Ventilation of the room is of no small importance.

Linoleum can be based on different components. There are homogeneous and heterogeneous compositions. Often the coating is made of PVC. The choice of glue is based on the manufacturer's recommendations. Gummilac is suitable for a foamed coating. It provides excellent adhesion and helps to avoid damage to the coating. For commercial linoleum with a complex composition, you will need a special substance.

Recommended brands of glue for different types of linoleum

Before gluing linoleum, we recommend that you familiarize yourself with the most common types of adhesives for different types of linoleum. From reaction adhesives it is recommended to use such as:

- Werner Müller. This type of glue is often used for welding commercial and domestic coatings, and the length of the seam does not matter. When gluing thin linoleum seams, a group A glue is recommended, the standard consumption is 1 tube per 9-10 meters of the joint. Group C glue is used for gluing wide joints at a rate of one tube per 6-7 meters of joint.

- Linocol is ideal for joining the seams of heterogeneous linoleum based on foamed PVC.

- "Thomsit K" - has a stronger degree of fixation than the aforementioned competitor and is usually used for joint joints of a homogeneous coating.

From dispersion adhesives, we recommend such as:

- "Homakol". This type of glue is water-based, and the degree of fixation is indicated in numbers. For example. Khomokol 208 is a universal glue based on PVA glue, used for laying a heterogeneous coating on a felt or jute base. Homokol 248 has a higher fixation rate and is used for homogeneous materials.

- Forbo Erfurt. This brand of glue, like Himakol, has numerical designations.For example, Forbo Erfurt 525 does not contain solvents and differs from others in its fast curing, which speeds up the installation speed. Forbo Erfurt 522 is considered universal and can be used on all types of surfaces.

From the Forbo Erfurt collection it is possible to distinguish such samples as 523, which is intended for conductive linoleums with copper mesh and 578, which is frost-resistant and can be used both for PVC coverings and for linoleum on a fabric or felt base.

Before gluing linoleum using any type of glue, it is recommended to study in detail the characteristics of the composition and the manufacturer's recommendations.

Based on the theoretical knowledge gained, you can independently decide whether you need to glue linoleum in your case and what type of glue to use. To consolidate the material, we recommend watching the video material at the end of the article.

Types and characteristics of glue

How to glue linoleum to the floor? There are two main types of adhesives on the market - dispersion and reactive. The choice depends on the characteristics of the coating and the surface on which it is laid.

Dispersion adhesives

All products of this type are aqueous emulsions of polymer resins with the addition of various fillers, mineral particles. The benefits are clear. Funds:

- do not have an unpleasant odor;

- elastic;

- thanks to the water base, they are non-toxic, environmentally friendly;

- have excellent adhesion to the substrate.

The products are suitable for gluing linoleum to concrete floors. After hardening, they are not affected by moisture, they perfectly seal joints and seams. The price is low: for example, the popular Homakoll glue costs 200-250 rubles / kilogram. Consumption per 1 sq. m is minimal, while many adhesives are frost-resistant.

Dispersion funds are divided into several groups:

- acrylate with acrylic resins are suitable for fastening to wood, concrete, a base made of mineral materials of semi-commercial and commercial linoleum;

- polyvinyl acetate, bustilates with the addition of latex, chalk are suitable for gluing thick felt-based PVC coating to fiberboard, chipboard, concrete;

- compositions like "Gumilax" based on rubber and latex resins are suitable for homogeneous material or foamed household covering on a natural basis;

- electrically conductive adhesives with a dispersion of conductive powder are used when laying antistatic linoleum;

- rubber mastics with bitumen resin are used for flooring on the ground floors, in damp rooms. The rest are only suitable for rooms with humidity up to 55-60%.

Many dispersion adhesives cannot be operated at low temperatures, therefore, for a balcony, summer kitchen or other similar premises, it is better to purchase a composition marked with frost resistance. It will not crumble even when it freezes. When buying, it is imperative to clarify the indication of GOST, check the certificates of conformity and the date of issue. Expired adhesives partially lose their properties.

Reaction compositions

How to glue the coating securely in difficult areas? For this purpose, reaction adhesives are used, for example, universal and for carpet. They are called "cold welding" and are used for welding seams and joints.

The components of the composition react with the material. After polymerization, a tough, moisture-resistant layer is formed between the base and the floor covering, which is resistant to tearing and shearing. The adhesion strength is very high, the joint can withstand shock loads and vibration.

There are one-component and two-component adhesives, the latter must be mixed before use.

Scope of use of reaction adhesives:

- offices and other commercial premises;

- rooms with high traffic - living rooms, hallways, kitchens;

- bathrooms;

- balconies;

- stairs, common corridors.

All adhesives can be divided into two groups depending on the composition:

- Polyurethane. Suitable for any type of linoleum, for all known substrates.They are often used in residential premises, since the unpleasant odor is weak and quickly disappears. The cost is high - from 400-500 rubles per kilogram.

- Epoxy. Consist of epoxy resin and hardener (two-component). Their strength is even higher, but the composition contains toxic components (solvents). Typically, these adhesives are used for outdoor use. Price - from 600 rubles per kilogram.

Most reactive adhesives have a significant drop in adhesion when used on dirty floors. Therefore, it should be thoroughly washed before work. Substrates made of mineral materials need a layer of primer - this will reduce glue consumption and improve adhesion

The disadvantages of adhesives include their rapid flammability - installation must be done with great care

Linoleum adhesive

Not everyone believes that linoleum needs to be glued, many prefer to glue the coating with double-sided tape, using the "cold welding" method, or the method of partial gluing in the form of stripes along the edges of the surface and in places where there are seams, using the glue moment for linoleum. However, according to experts, the most reliable way to fix linoleum is to use an adhesive solution.

The most reliable way to fix linoleum is to use an adhesive solution.

The most reliable way to fix linoleum is to use an adhesive solution.

Pros and cons of laying the coating on glue

Of course, the technique of laying linoleum with glue has a lot of advantages. So, the pluses include:

- Reliable fixation of linoleum to the base, increasing the wear resistance of the surface;

- Eliminates the appearance of deformations and wave effect;

- Reduces the risk of mechanical damage to the surface in the process of moving large furniture;

- The integrity of the canvases is preserved at the joints;

- The period of operation is extended by 30-40%.

The disadvantages of this method include:

- Adhesive costs;

- Drying time of the adhesive;

- Difficulties in dismantling.

Reliable fixation of linoleum to the base, increasing the wear resistance of the surface.

Reliable fixation of linoleum to the base, increasing the wear resistance of the surface.