Masonry mesh 50x50; 50x75; 100x100 and other sizes, weight, price

Masonry mesh is one type of welded mesh.

Masonry mesh 50x50x3; 50x75x4; 100x100x5 and other sizes are used for reinforcing brickwork, for reinforcing reinforced concrete, road surfaces, for sheathing of pipelines, for reinforcement when pouring floors, ceilings, foundations.

Transportation is carried out in cards (sheets).

Masonry mesh is a welded mesh made of corrugated wire VR-1 GOST 6727-80 by resistance spot welding on special machines.

Mesh for masonry and reinforced concrete structures of concrete goods is characterized by the size of the side of the cell in the clear and the diameter of the rod. The design uses a smooth wire GOST 3282-76 or reinforcing, corrugated wire VR-1 GOST 6727-80.

The size of the side of the cell in the light is the distance between adjacent warp wires or adjacent weft wires.

The maximum width at the ends of the protruding wires is 2350mm.

Formed from wires located in two mutually perpendicular directions and welded at their intersection by spot welding.

This mesh is also used as a plaster mesh.

Scope of application:

- for plastering works, for the reinforcement of gypsum panels;

- for fencing construction areas and facades of buildings and road works, scaffolding;

- for drainage of load-bearing walls, horizontal terraces, identification of underground utilities;

- for reinforcing concrete, brickwork, floors, facades, walls, arches;

- for mechanical protection of anti-corrosion plating of steel pipelines;

- for fastening brickwork;

- for reinforcing reinforced concrete structures with abnormal strength;

- for reinforcing road surfaces, etc.

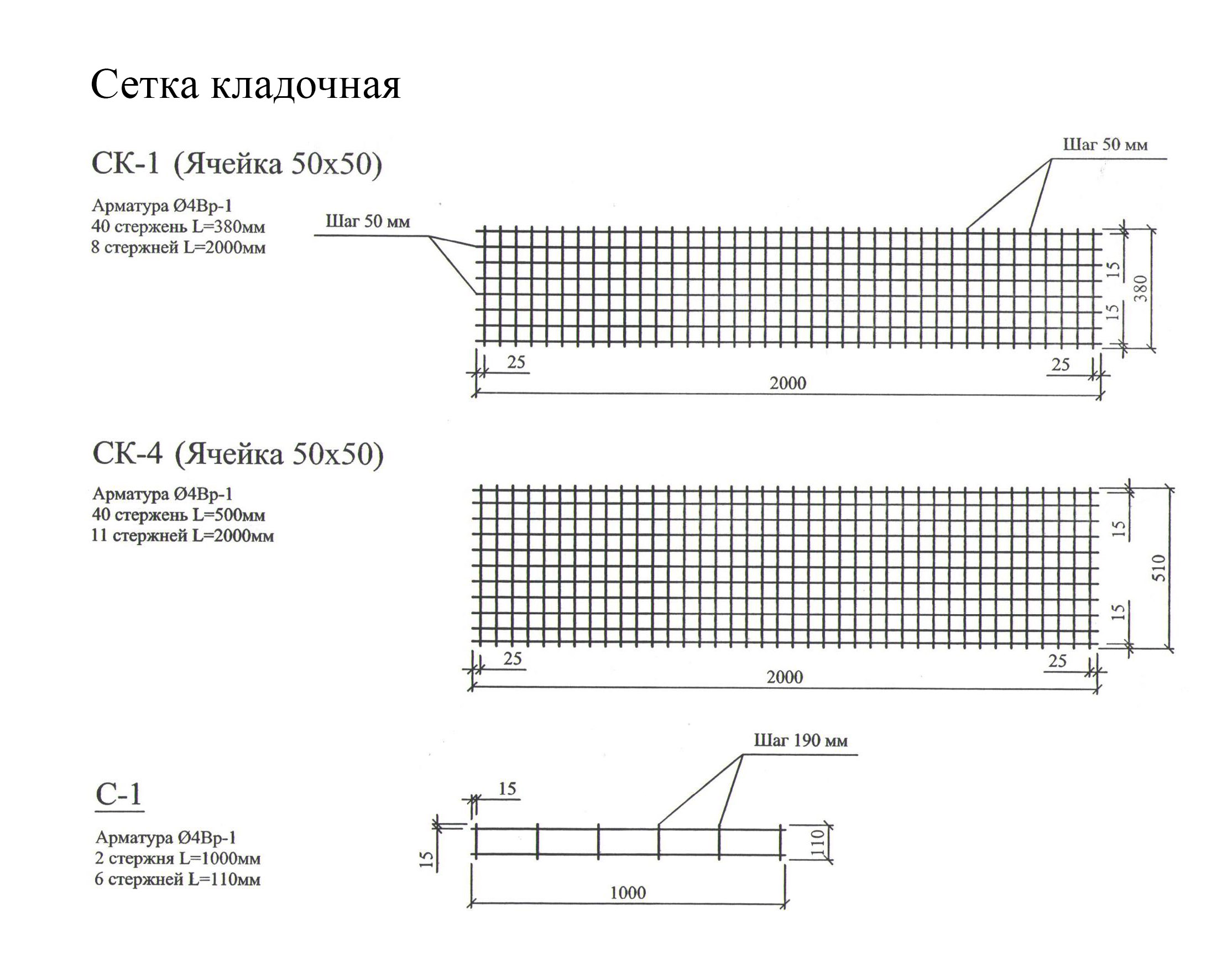

The dimensions of the outlets of the longitudinal and transverse rods should be taken equal to 25 mm.

It is allowed to take the dimensions of the longitudinal rod outlets from 30 mm to 200 mm in multiples of 5, and the dimensions of the transverse rod outlets equal to 15 mm, 20 mm and 30 mm, as well as from 25 mm to 100 mm in multiples of 25 mm.

An example of a symbol:

Masonry mesh 50x50x4 in cards 2350 mm wide, with longitudinal and transverse rods made of wire of the VR-1 class, 4.0 mm in diameter, pitch of longitudinal and transverse rods 50 mm:

Masonry mesh 4Вр1 50/50 mm (mesh size) 2350 GOST 23279-75

Masonry mesh 100x100x4 in cards with a width of 2000 mm, with longitudinal and transverse rods made of wire of the VR-1 class, with a diameter of 4.0 mm, a pitch of longitudinal and transverse rods of 100 mm:

Masonry mesh 4Вр1 100/100 mm 2000 GOST 23279-75

How to buy a masonry mesh at low prices:

Terms of sale:

- Wholesale and retail of metal products;

- Cashless payments by transferring funds from a bank account;

- The possibility of deferred payments;

- Free consultations of our specialists;

- We provide packaging services for goods according to customer requirements;

- We are ready to manufacture products of any complexity to order according to the customer's drawings.

Delivery terms:

- Delivery of products is carried out from the warehouse from stock;

- If necessary, we can provide a response storage service;

- We are ready to provide a discount on delivery in accordance with the terms of partner programs of transport companies;

- Possibility of self-pickup of goods from warehouses.

Guarantees:

- All products are certified, released after technological control;

- Hardware, fasteners, ropes, mesh, wire, electrodes and other metal products comply with GOST and TU;

- The possibility of returning goods in accordance with the legislation of the Russian Federation;

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

1 Features and benefits of plastic nets

The key advantage of polymeric materials used to create plastic masonry nets, namely, non-corrosiveness, determines the wide demand for this material in construction.

Unlike metal used to create ordinary masonry nets, plastic is not exposed to the aggressive action of the solution in which it is placed, does not rust or deform, as a result of which, over time, the initial strength characteristics of the masonry do not decrease, and rust spots do not appear on the walls of the building. ...

An important advantage is its low weight, which makes the transportation and operation of plastic more convenient than using metal counterparts. For example, the weight of one running meter of a mesh with a mesh size of 20 × 20 millimeters is about 150 grams.

An important feature is the fact that, with a low weight, the fiberglass mesh made of high-quality polymeric materials has a strength that is not inferior to metal structures produced in accordance with the requirements of GOST 23279-85

Plastic mesh for masonry with mesh size 20 × 20 mm

As you know, plastic is a material with minimal thermal conductivity, as a result of which plastic masonry mesh does not increase the overall thermal conductivity of the walls of the house. This is a very significant factor to consider when building houses in cold climates.

And the last, which is, however, one of the most important advantages of such products, is their availability and adequate price. Plastic masonry nets are much cheaper than metal ones.

So, a roll of the most popular mesh for laying brick walls made of polypropylene with a mesh size of 5 × 5, 100 meters long and 40 cm high will cost you about six hundred rubles, while the cost of a metal analogue starts from 70 rubles per square meter.

As you can see, with virtually identical performance characteristics, the products have a radically different price. Based on this, we can conclude that the use of plastic masonry mesh is many times preferable to metal structures, especially for the implementation of budget house projects.

1.1 Types and differences of products

The classification of masonry nets is carried out according to the manufacturing technology. Depending on which, ordinary and biaxially oriented grids are distinguished. The last category is distinguished by greater mechanical strength, which is achieved due to the technology of reinforcing the connections of polymer threads with each other.

Biaxially oriented meshes are the best option for reinforcing aerated concrete and brick masonry, as well as for reinforcing concrete screeds.

In general, the products presented on the market from different manufacturers differ from each other mainly only in the size of the cells. The masonry mesh is characterized by cells ranging in size from 5 × 5 to 45 × 45 millimeters. It is realized, as a rule, in rolls from 40 centimeters to one meter wide.

Today, the market leaders are such domestic companies as "STREN" and "Protect", whose products meet all the requirements of GOST.

Using hollow brick masonry mesh

The choice of the required type of masonry mesh depends on the bricks used, wall thickness, and masonry technology. The most common in construction today is hollow brick, which has good strength, but is much cheaper than conventional brick, which reduces construction costs.

For hollow bricks, the best option is to use a masonry mesh with small cells of 10 × 10, or even 5 × 5 mm. Small cells will prevent the ingress of cement mortar into the brick, which will significantly reduce material consumption.

It also helps to improve the thermal insulation of the building, since a large ball of mortar affects the increase in the thermal conductivity of the walls. For laying solid bricks, depending on the thickness of the walls, material with cells from 10 × 10 to 40 × 40 mm can be used.

2 Parameters and characteristics

We have already partially touched on such a moment as the size of the masonry mesh for bricks or plaster, but this is a much broader topic. The specific mesh size influences its price, weight and consumption.

Mesh with cells 100 × 100 mm

The size is indicated by a record of the type 50 × 50x4, where the first two digits are indicators of the width and height of the cage, and the last is the diameter of the wire involved.

Therefore, a sample marked 50x50x3 will be 50x50 mm and 3 mm in diameter.

The model with dimensions 50x50x4 is the most popular and demanded on the market. It combines strength, moderate consumption, light weight and overall efficiency. An irreplaceable thing when it is necessary to strengthen the laying of bricks or blocks, as well as to fill in solid, crack-resistant floors.

There are also other sizes, for example, 25 × 25x3 mm or 40 × 40x3 mm. Composite materials are produced much finer. In them, the size of 10 × 10x2 mm is quite acceptable, which is partly due to the scope of application.

The weight of the mesh is the weight of the wire used in it. You do not need to read it yourself, all parameters are specified in advance. We only note that the weight of a 50 × 50 mm cell made of 3vr1 wire is 2.21 kg, and a similar sample, but made of 3vr1 wire, already weighs 3.61 kg.

Models with 100 × 100 mm cells weigh 0.99 and 2.02 kg, respectively.

The last frequently mentioned indicator is consumption. Consumption is calculated in m3. Determination of consumption per m3 is reasonable when calculating a masonry mesh from bricks or blocks.

This means m3 of brickwork. The standard consumption of mesh with cells of 50 × 50 mm per m3 of brickwork is 3 m2.

It is impossible to say the exact figure for many reasons. You need to first find out what reinforcement is needed for, what the size of the blocks is, what mortar is supposed to be used, what is the total weight of the building, etc.

2.1 Application

This material is used very simply. The technology is based on strengthening horizontal joints between blocks.

Using lightweight masonry mesh

The mesh is placed on a layer of glue or plaster mortar previously poured on the upper level of the masonry, it is heated, and another layer of glue is placed on top.

Further, the worker continues to mount the next level of brickwork, which obviously will not be difficult for him.

In a reinforced form, the probability of cracking of the seams of reinforced masonry, as well as cracking of the walls themselves, tends to zero. For which the masonry mesh is appreciated.

Reinforcement portal »Mesh» What should be a reliable masonry mesh?

Mesh dimensions for brick or block masonry

Variations in the size of masonry nets, depending on the conditions of use, have a wide range of values. The main size of such reinforcement is the diameter of the rods, varying from 2 to 4 millimeters (3-5 mm - for metal). Also, the size of the cell is important for use, it varies from 5 to 100 millimeters (30-150 mm - for metal). The cell shape can be square or rectangular.

Using different mesh sizes in construction

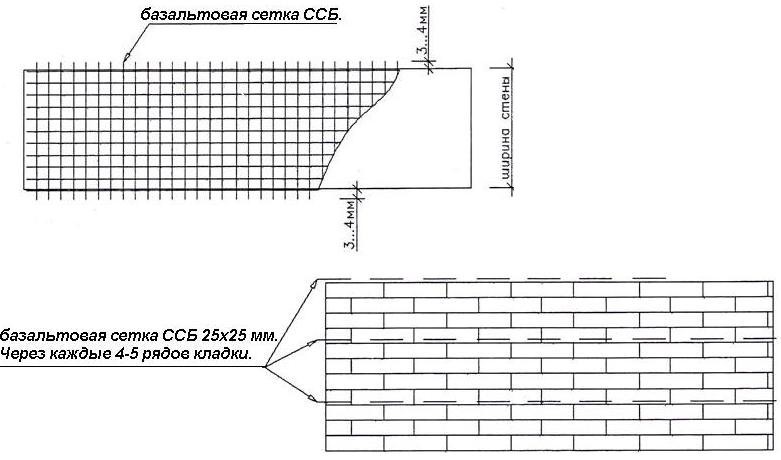

The most common cell size for masonry is 25 × 25 mm. Mesh composites are flexible and soft, therefore, they are mainly produced in rolls. The width of the rolls is a multiple of the dimensions of the main wall materials (bricks and foam blocks) - 37 mm, 50 mm, 100 mm. It should be noted that the basalt mesh is easily cut even with ordinary scissors, therefore, if necessary, you can cut strips of any required width.

According to GOST, basalt mesh can be made from rods 2 mm thick, which allows the use of such new construction technologies as laying wall material on glue. In this case, the thickness of the seam can be only 1 mm more than the thickness of the reinforced material, and the wall itself becomes more uniform and monolithic.

The possibility of making a small cell from composite materials, for example, 25 × 8 mm, which is unattainable for a metal welded mesh, allows you to achieve savings in mortar several times for masonry from hollow bricks (blocks).At the same time, the thermal insulation properties of the wall are significantly improved - the solution is held by the mesh and does not fall into the voids of the blocks of the previous row, that is, the air-void thermal insulation is preserved in the erected wall.

Out of competition, the composite mesh for plaster is 5 × 5 mm mesh, does not require a thick plaster layer, it is technologically easier to create a smooth plane.

Advantages of basalt mesh for brickwork reinforcement (GOST R 57265-2016)

Composite masonry mesh, especially basalt mesh, is superior to steel welded mesh in all respects:

no corrosion effect for basalt mesh;

increased tensile strength;

preservation of the original shape even if the integrity of the structure is violated;

very low thermal conductivity;

unchanged physical and chemical characteristics for a long time;

reliable adhesion to any materials;

ease of transportation, movement and use.

The use of a composite masonry mesh made in accordance with the requirements of GOST is justified from all points of view - economic, technological, quality. Considering the large negative pressure on the environment from industry, it is extremely important to improve the environmental friendliness of the complete "basalt" cycle - extraction of raw materials, production, application, operation.

Masonry mesh. How to choose?

Any structure made of brick, concrete or stone requires special reinforcement - reinforcement. For this process, a special masonry mesh is used, which is a construction of wire segments in the form of cells. The masonry mesh is different, it differs not only in the diameter of the cells and the thickness of the rods, but also in the type of material from which it is made.

Types of masonry nets, which one to choose?

There are four main types. The first type is necessary for aerated concrete, since aerated concrete blocks do not have sufficient strength, without reinforcement, the structure can quickly crack. The mesh for aerated concrete blocks has its own gradation, it can be:

- steel with a wire diameter of 3-4 mm and a mesh size of 50 * 50;

- composite and fiberglass mesh.

The polymer structure is made of basalt fiber, which is the most popular type for reinforcing the following structures:

- overlapping of multi-storey buildings;

- for road surfaces;

- for floor screed;

- before plastering the walls.

Basalt material is especially popular for aerated concrete block buildings. Polymer mesh can be called the most popular type, as it has a number of advantages, such as:

- the fiber is not subject to corrosion;

- masonry with polymer fiber reinforcement is much stronger;

- basalt construction is cheaper than metal;

- able to withstand heavy loads even when bending, rather plastic;

- suitable for masonry with different materials: brick, aerated concrete blocks, stone, etc.

Galvanized steel mesh protects the structure from corrosion.

- when pouring the foundation;

- for greater durability of the screed;

- for intermediate floors;

- before plastering, etc.

Note! How the smaller the cell size, the larger mesh strength. Also, the strength depends on the weight of the structure, the larger it is, the more the mesh is able to withstand the load.

Polymer-coated fiberglass mesh is used to reinforce walls, but without much stress. Such material is not suitable for a foundation or load-bearing walls, it is worth giving preference to a metal structure, it is more durable and capable of withstanding heavy loads.

Plastic mesh is the most economical option; it is made of propylene. Also, this type is the easiest to install, has a long service life due to its resistance to an alkaline environment.

To achieve the most even overlap, the installation of the mesh should take place using a special technology.The mesh is laid along the guides made of a metal profile, while it should not lie on the waterproofing itself, in order to prevent this, you can use special plastic supports. The future fate of the structure and its durability will depend on the quality of the reinforcing mesh and the professionalism of its installation on a straight line.

Buy masonry mesh

Regarding the price - galvanized mesh is the most expensive, plastic mesh is the cheapest. Also, the price will depend on the size of the cells and the diameter of the rods.

You will find masonry nets at a budget price and with a quality guarantee on our website. We have excellent service, 100% quality guarantee and reasonable prices.

Here you will find:

- metal nets: chain-link, CPVS, welded, twisted, woven;

- polypropylene nets: painting, geogrid, plastic, facade;

- fences and barriers;

- rolled metal and other metal products.

Our store provides a mesh delivery service in Moscow and the Moscow region. We will deliver your order at exactly the agreed time to the right address. Shopping with us is:

- budgetary;

- qualitatively;

- quickly.

Grid Info - trust professionals!

.

Getting ready for work

If the mesh will be made directly at the construction site, then the following materials and tools will be needed:

- reinforcing bars, suitable in diameter;

- wire for tying rods;

- special hook for tying reinforcement.

Knitting the lattice is not particularly difficult. The length of the rods is marked, and the length of the transverse reinforcement is made slightly larger than the thickness of the masonry. The rods are cut and tied into a mesh with the same links, this is done with a knitting wire and a crochet hook.

Cross strengthening of walls

The transverse reinforcement of a brick with a mesh occurs by superimposing it on a brick layer. In addition to the mesh, you can also use reinforcing rods. In one structure, it is permissible to use only uniform reinforcing elements, the use of both mesh and rods is simultaneously unjustified. In this way, an increase in compressive and flexural strength is achieved. Most often, this type is used for inclined planes (for example, arched masonry).

Having laid out the first row of bricks on the foundation strip, it is laid on top of the finished fittings

Having laid out the first row of bricks on the foundation strip, it is laid on top of the finished fittings

The transverse view of hardening is performed during the laying of walls, partitions, columns. Reinforcement is placed on the brick row and a layer of mortar for laying bricks is applied on top, the thickness of which should be at least one and a half centimeters.

Features of lateral reinforcement

A transverse view of brickwork reinforcement involves the use of mesh or rods. Meshes are more in demand. They are made with different link shapes:

- rectangular;

- square;

- zigzag.

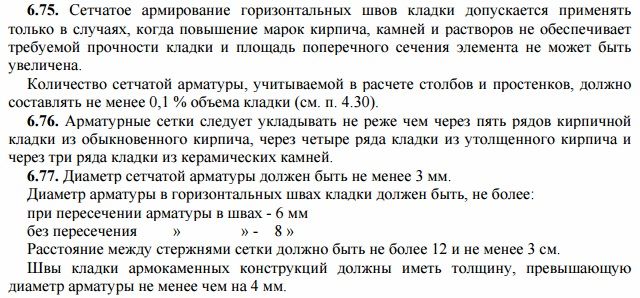

Mesh reinforcement with rectangular and square links is made from steel rods with a cross section not exceeding 5 mm. The links have sides from 3 to 10 cm. The mesh reinforced in this way is placed on every fifth row. If a thicker brick is taken, then reinforcement is performed more often - after 4 rows. It should not be forgotten that the ends of the reinforcement should protrude outward from the inner side of the wall. This arrangement helps to keep track of the number of rows and not miss the next layer. At the end of construction, the protruding ends are cut off and plastered.

To obtain a zigzag reinforcing mesh for brickwork, steel wire is taken. It is bent in a zigzag with a distance of 5-10 cm between each knee. The diameter of the reinforcement for this type of mesh is from 5 to 8 mm. In the masonry, it is placed in every second layer. This changes the location in subsequent layers - directly perpendicular to the previous layer.

A problem area can also be areas of abutment of parts of the house of different heights.

A problem area can also be areas of abutment of parts of the house of different heights.

Instead of zigzag ones, an all-metal reinforcing mesh is sometimes used, exhaust or with notches.

Rod reinforcement of the transverse view

Straight reinforcement is used to reinforce brickwork in the case of an even arrangement of rows. The rods are placed in width at equal intervals from one another, from 30 to 120 mm. The rods are inserted into the inter-brick seam across, the depth is up to 2 cm, the procedure is repeated after 2-3 rows. The cross-section of the reinforcement is from 3 to 8 mm, the size depends on the width of the seam.

To give the structure even greater durability, bar reinforcement with a cross-sectional shape other than round is used. Steel strips are also used. The parameters of the reinforcing elements are determined based on the characteristics of the brickwork.

Longitudinal reinforcement technology

Taking into account the location of the reinforcing parts, the longitudinal reinforcement is subdivided into:

- internally;

- external.

Sometimes the enclosing structures of buildings are laid out without bandaging the seams.

Sometimes the enclosing structures of buildings are laid out without bandaging the seams.

The most common element in the longitudinal arrangement of the reinforcement is the rods. If their placement is external, then the gap between each rod is 15 times the size of its diameter, and if it is internal, it does not exceed 25 times its size.

With horizontal reinforcement, the goals of longitudinal reinforcement are pursued. This gives a bunch of vertically arranged reinforcing rods. The horizontal view allows the use of steel reinforcement, strips, corners, wire. The parameters correspond to the parameters of the vertical reinforcement.

It is possible to protect the reinforcing parts of the longitudinal technological process from aggressive environmental influences by covering them with concrete - for external placement, the thickness of the mixture is from 100 mm to 120 mm, at high humidity - up to 300 mm.

Brick masonry mesh: features of work

Basalt grating for facing bricks is laid in three ways:

-perpendicular;

-parallel;

-longitudinal.

Usually, a reinforcing mesh for brickwork is installed in a transverse way. Although this method somewhat increases the time required to complete the reinforcement work and the financial costs of construction, it is fully justified. After reinforcement, such a wall becomes 50% stronger in terms of supporting functions.

The size of the cells and the thickness of the mesh depends on the size of the planned load on the wall.

Depending on the planned loads, it is important to choose the appropriate type of product, and then the following manipulations should be performed:

1. The mesh must be planted with an adhesive solution on the formed row of bricks.

2. The material is covered with a layer of masonry mortar so that the grating is completely underneath.

3.Bricks are being laid, while it is necessary to constantly monitor the immersion of the mesh in the mortar according to the level.

Helpful advice! For each type of bricks there is a special technology for laying basalt mesh for reinforcement. For example, for sand-lime bricks, you need to lay a grid in every fifth row, for a double one - in every fourth, and for ceramic - in every third row.

Longitudinal reinforcement of masonry: a - external arrangement of rods, b - internal arrangement of rods

Construction basalt masonry mesh 50x50x4: price per 1 m2

Basalt masonry mesh is a versatile modern material that is confidently replacing the classic reinforcing mesh from the market. This product is capable of withstanding significant loads, and its weight is much less than the mass of a metal grill of the same size. In addition, basalt material is versatile, which means that it is suitable for reinforcing walls built of any material.

It is profitable to buy a basalt mesh, since the material is not only reliable, but also cheaper than a metal mesh by more than 30%. The cost of the masonry mesh is formed depending on the thickness of the rods and the parameters of the cell. Also, the price depends on the manufacturer. It is cheaper to buy a basalt masonry mesh, the cost of which varies from 70 to 150 rubles / sq. m. The price of basalt masonry 25x25 starts at 90 rubles / sq.m, but usually stores sell this material immediately in rolls of 0.37 / 0.63 / 1/2 / 4x50 m. Many sellers practice price reductions for wholesale buyers.

64-90 rubles / sq. m. - the approximate price of a masonry mesh is 50x50x3, the weight of 1 m2 does not exceed 300 grams, the strength of the model is 50 kN / m. The size of such a product is 4x50 m. The price per m2 of 50x50x4 masonry mesh with a strength of 100 kN / m is in the range from 120 to 160 rubles. per sq. m. Basalt material for reinforcement with a thickness of 5 mm will cost 190 rubles. per sq. m.

Basalt mesh with cells of 50x50x4 mm is the most common material for reinforcing masonry from various materials

-The cost of a mesh with a cell of 100x100, having a rod thickness of 3 mm and a strength of 50 kN / m, averages 70-90 rubles. per sq. m.

The price of a 100x100x4 masonry mesh with a strength of 100 kN / m starts from 125-140 rubles / sq. m. For comparison, a metal masonry mesh 100x100x4 has a price several times higher - about 200 rubles. per sq. m. Material for sale in rolls 1/2 / 4x50 m.

What materials is it made of

Outwardly, the material resembles the well-known mesh netting, which can often be found in the adjoining areas in the form of fences and barriers. In each case, so that the concrete solution does not slide off the masonry, a mesh with certain parameters is selected. The composition of the concrete and the brand of brick are taken into account. The main difference between different masonry nets is the material from which they are made. According to this criterion, grids are distinguished:

Steel mesh

It is based on cold-rolled low-alloy carbon steel of St3Kp grades. The material has a fairly high cost, but it has high strength and reliability. To protect against corrosion, the mesh is galvanized or coated with a polymer composition.

Please note: a protective zinc layer is applied to the surface by electroplating. The rolls are placed in a special drum, where electrolysis takes place, and the rods are covered with a zinc layer of 8-9 microns

Dimensions of steel masonry mesh

Other material features:

- Manufactured according to a long-established technology, which reduces the risk of marriage to zero.

- Depending on the thickness, they can provide the masonry with different strength and bearing capacity.

- They have increased strength, resistance to aggressive environments and temperature changes.

- Suitable even for capital construction, and not only for private ones.

For the best adhesion of the rods to the concrete solution during the production process, special notches are applied along their entire length. The main technical requirements for steel mesh, as it relates to welded products, are given in GOST 23279-85. According to this document, wire of classes Bp-I and B-I (classes according to GOST 6727) should be used for the production of steel mesh.

Please note: the difference in weight of the masonry mesh with the reference value should not exceed 5%. Otherwise, this will mean that a wire of a smaller diameter was used in the production or that the dimensions of the cells were not kept.

All-metal expanded metal mesh (CPVS)

It is made from cold-rolled sheet and is produced in coils, which, according to the manufacturers, are even stronger than regular steel mesh. The difference between CPVS is diamond-shaped cells. In the production of masonry mesh in rolls, sheets of different thicknesses are used, which are fed in different ways. This allows you to achieve a certain level of rigidity and other necessary properties.

Advantages of CPVS in comparison with other mesh options:

- Easier to cut and cut.

- It is cheaper than its analogue made of reinforcing steel.

- Lightweight for easy handling.

- Wide range of applications, including for thin masonry and with the use of adhesives.

Basalt mesh

Basalt masonry mesh has become the most popular in the construction industry. It is especially often used in the creation of brickwork.This is due to the advantages and properties of the basalt mesh:

- Provides a flexible connection between wall and cladding.

- In the process of cutting, it does not injure the hands of the master, but it is cut very easily using ordinary metal scissors.

- It is resistant to aggressive media, including alkaline ones, which are formed in concrete solution.

- Shows dielectric properties, excluding the effect of electric current on the object.

- It goes well not only with bricks, but with gas and foam silicate blocks, aerated concrete and stone.

- Has a thermal conductivity that is hundreds of times lower than that of metal.

What does basalt mesh look like?

Another advantage of basalt mesh is its low cost - it is about 3 times lower than that of steel mesh with the same parameters. The raw material for the manufacture of such a mesh is continuous basalt fiber, which allows reliable communication between the rows of blocks.

Please note: for foam blocks, it is better to give preference to basalt mesh, since the glue can quickly destroy the galvanized coating, which will cause the metal to corrode

Basalt mesh application

Fiberglass mesh

In the production of fiberglass mesh, polyester epoxy materials, in particular, fiberglass, are used. Compared to metal, it has several advantages:

- The mass is 8-9 times less, which allows to reduce the load on the structures.

- Lower cost (in comparison with welded counterparts).

- Good compatibility with masonry mortar and aerated concrete.

- The strength is about 2 times higher.

- Lower thermal conductivity.

- Absolute resistance to corrosion, which provides the material with a longer service life.

Fiberglass masonry mesh

Reinforcement methods

In the technology of construction of load-bearing walls and internal partitions, reinforcement is laid in various planes in order to strengthen the critical places of masonry of walls, columns, window and door openings, arched ceilings.

Horizontal and vertical wall reinforcement is applied depending on the nature of the acting loads. In a rather fragile hardened mass of cement mortar, strong elements are laid along the entire length of the masonry. They evenly distribute local loads over the entire structure, preventing cracks from occurring in places of tension.

Taking into account the possible directions of action of critical forces, the reinforcement of brick walls is carried out in 2 planes:

- transverse (deep into the seam);

- longitudinal (along the surface or inside the masonry).

Additionally, the longitudinal reinforcement is divided according to the method of orientation of the element relative to the surface of the walls into vertical and horizontal arrangement.

In certain areas of the masonry, it is important to perform the correct reinforcement to maintain the integrity of the structure. Which method to choose in a particular case and how to place the reinforcing belts in the walls, through how many rows to lay them, depends on the consideration in the project not only of static weight loads, but also of wind, snow, and seismic components

Which method to choose in a particular case and how to place the reinforcing belts in the walls, through how many rows to lay them, depends on the consideration in the project not only of static weight loads, but also of wind, snow, and seismic components.

Compliance with the rules for the construction of walls and partitions refers to the creation of conditions for the safe operation of buildings and structures, ensuring the service life of individual housing construction not lower than that calculated in the project.

It is possible to increase the bearing capacity of a solid wall or a thinner partition if the brickwork is reinforced in the horizontal plane with a metal mesh or tied with wire. This method is also used to ensure the connection of the facing masonry with the backing wall.

Building codes formulate the requirements for reinforcing brickwork with a grid of horizontal joints as follows:

Basalt reinforcing mesh allows you to reduce the amount of mortar due to the thickness of the seam. In addition, it does not require additional anti-corrosion coating and careful protection from the environment.

Basalt reinforcing mesh allows you to reduce the amount of mortar due to the thickness of the seam. In addition, it does not require additional anti-corrosion coating and careful protection from the environment.

Easily cut to size with regular scissors. When choosing such a material, it should be borne in mind that the ratio of the strength characteristics of steel and composite is 4: 1, therefore, for the same loads, a metal wire needs a smaller section than a basalt one.

The following options are manufactured industrially from a steel bar according to standard cutting formats:

Best-in-class for individual construction (where large bar diameters are not required for increased strength) is the brickwork mesh. It is produced in rolls, manually cut to the desired size, has an anti-corrosion coating, and reduces the thickness of the seam compared to wire.

Mode of application

In most cases, the reinforcing grid is not installed in all rows of the wall plane. Most often it is placed on the basement level, as well as in the rows that are closer to the top. When constructing buildings on one floor, a lattice with a cell is used for masonry, which has a size of 25 to 30 mm. The reinforcement thickness is within 4 mm. The product is laid in a row even before the solution is applied. This is done so that it is possible to properly align the product and make bends in places of poor contact. This is done so that after applying the solution, the canvas does not rise from it, but is fixed inside the seam. If you are inattentive to this moment, then the seam will not be strong enough.

The width of the material is selected in such a way that, after trimming, the transverse elements have a length of no more than 7 mm. When trimming, it must be borne in mind that the width of the reinforcing element should be one centimeter less than the width of the wall. This is necessary so that the grill does not protrude from the seam on the sides. In the case of a metal structure, this will prevent contact with deposits, and therefore corrosion. A video about laying such a mesh is below.