Step-by-step guide to action

At the preparatory stage, the state of the foundation is studied: one of the requirements of the technology is to lay bricks exclusively on well-established structures that have gained strength, reliably protected from moisture. In particular, brick walls are erected on a tape or grillage completely covered with roll waterproofing. The diagonals and the level of the foundation are checked, the permissible difference is 20 mm, if it is exceeded, leveling work is carried out.

Before starting work, the components are prepared (sand is sieved in a sieve with cells of no more than 3 mm) and tools: a concrete mixer, containers for transporting mortar, a shovel, a trowel, a carpenter's corner, a building level, a cord and a marker for marking. To eliminate errors, a material placement plan is drawn up, taking into account the selected dressing scheme, and its required amount is calculated (with at least 10% stock).

When laying bricks with your own hands, it is recommended to adhere to the following step-by-step guide:

- Marking the lines of the walls, pulling the cord.

- The first row of bricks: without the use of mortar, bonded masonry from exclusively whole products.

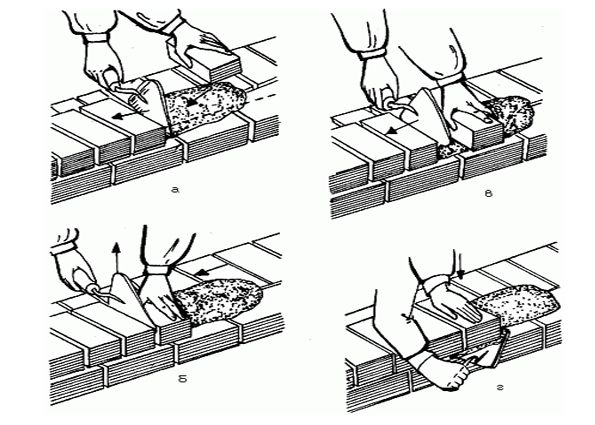

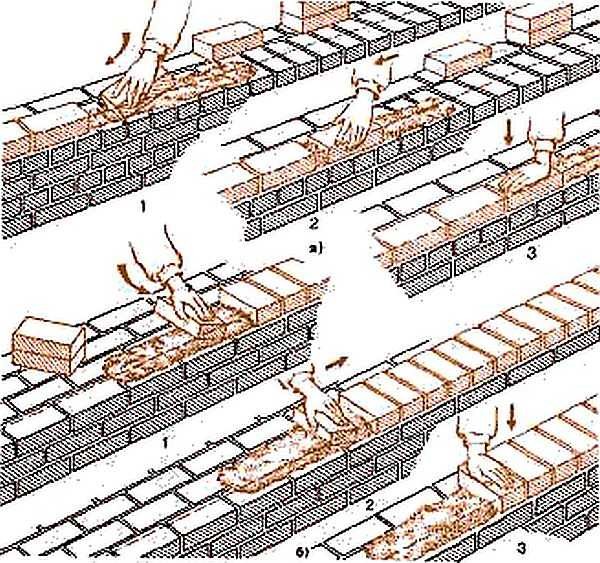

- Preparation of masonry mixture in volume, no more than 1-2 hours of work, its placement and leveling with a trowel.

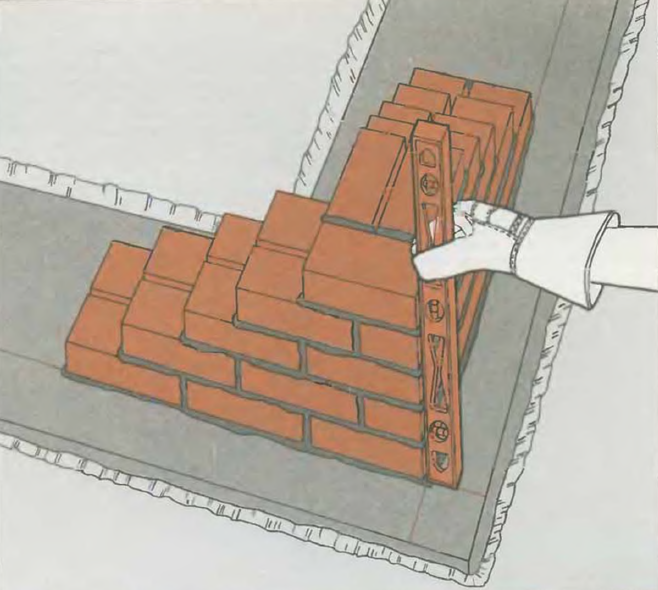

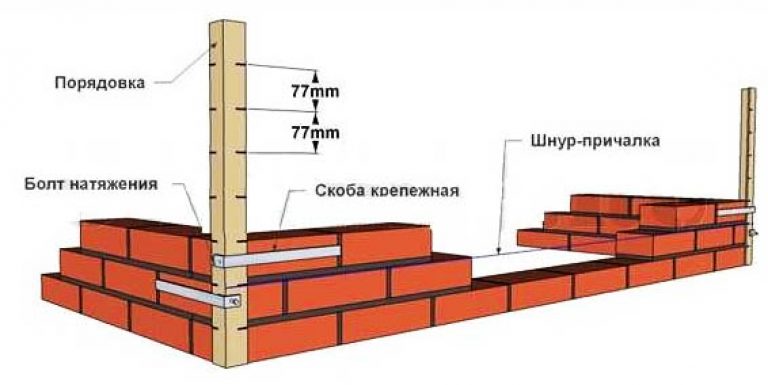

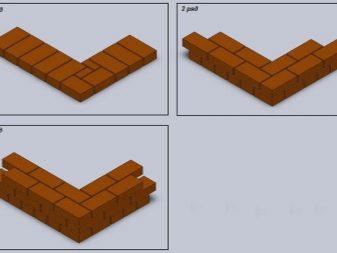

- Corner masonry, starting with two bricks set at a 90 ° angle and checked with a construction triangle. For clearly verified products, you need to lay out a few more pieces with control of the level of each. Thus, the wall rises at least 3 rows up, the process is repeated at all other corners. This rule - the corners above the walls by 2 bricks are relevant for all structures. For fixation, an aluminum order is used, secured with metal brackets.

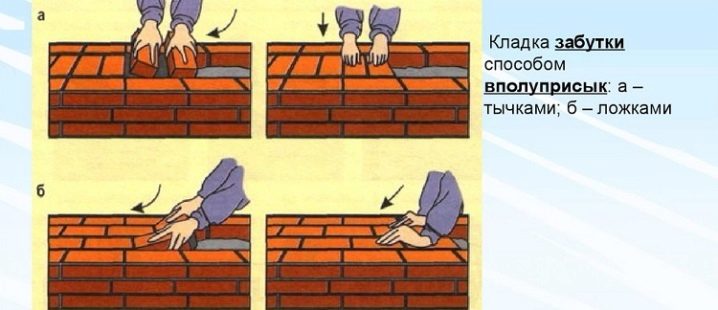

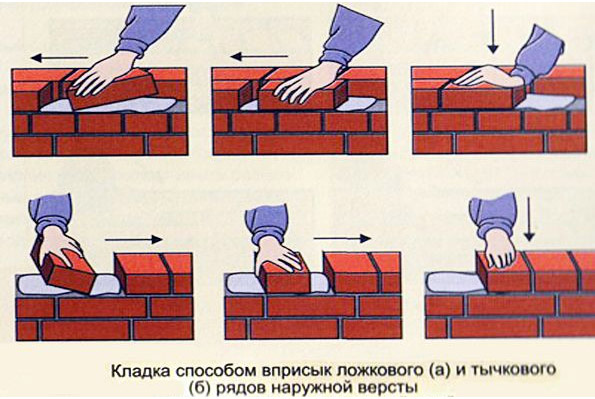

- After that, you can lay brick walls: each element is brought to the right place, the coincidence of the markings and the location of the ribs are checked, after installing the blocks, they are tapped with a hammer or trowel until they are in full contact with the cord. Excess mortar is removed (placed on top of a brick or in vertical joints), the level of the row is checked.

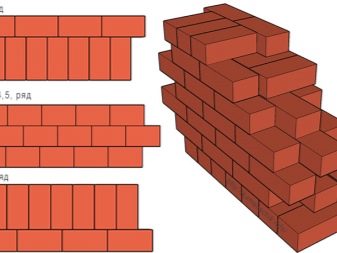

- The next rows are laid with a mandatory offset (it is advisable to note the number of completed rows in a prepared plan). Regardless of the chosen method of laying the seams (in a wasteland, undercut or decorative), their thickness is controlled (the recommended limit is 6-12 mm, for defective or uneven products - 10-15).

During the laying process, all the bricks are wetted; after a break in work, it is recommended to smear the lower rows with a damp brush. In especially loaded walls, reinforcement is placed: a metal rod of about 4 mm in longitudinal and transverse seams or a mesh every 4-5 rows of brickwork. The final stage is grouting and the formation of seams, when plastering it is lowered (it is enough to remove excess from the outside). If necessary, the frozen solution is carefully washed with water or special compounds.

At the slightest doubt, how to lay a brick, the work is entrusted to professionals. In the absence of experience, it is worth starting with simple enclosing or unloaded structures. The next stage of construction (installation of floors, finishing) is passed after 70% of strength gain (1-1.5 weeks in the warm season), the final hardening of brick walls takes 28 days.

How to lay a brick on a foundation

Working tools should be prepared in advance:

Working tools should be prepared in advance:

- trowel (or trowel) for spreading mortar, removing excess mortar, leveling;

- a bricklayer's hammer to split bricks into pieces of the desired size;

- a plumb line checks the verticality of the masonry;

- the cord helps to lay out rows in straight lines, observe one height indicator;

- the ordering marks the rows according to the thickness of the seam and brick;

- a rule of wood checks the quality of the outer surface;

- shovel;

- container for stirring the solution (or concrete mixer).

First, we lay roofing material to isolate the cleaned foundation from moisture. There are two ways to go.

The first way is to lay out the first row and then the corners. In this case, the angle should always be several bricks higher than the walls. We check the observance of the straightness of the corners, the verticality of the masonry with a level, a square, a plumb line.

The second method consists in the initial removal of all corners, after which the walls are laid. The corners are checked using the same tools. It is necessary to correct irregularities by tapping on incorrectly lying bricks with a hammer. The stage ends with tying a cord for a guide in the corners. Now you can start the main part of the work.

Some recommendations for the accuracy of laying bricks on a foundation

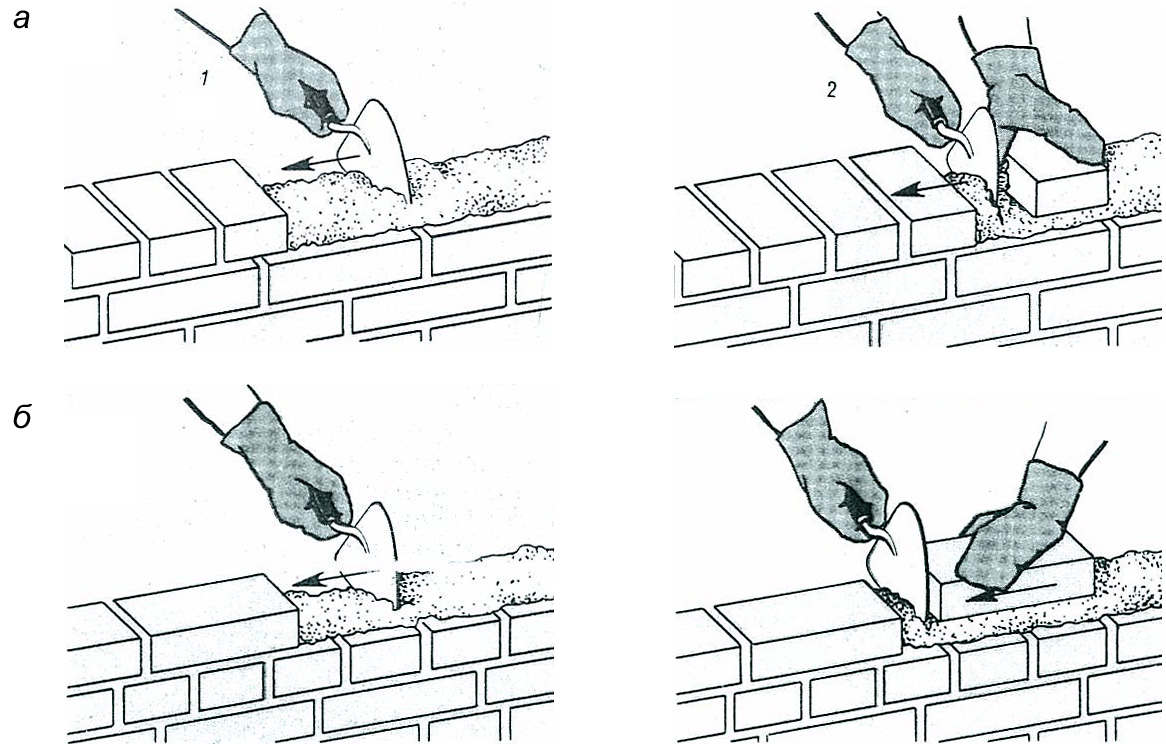

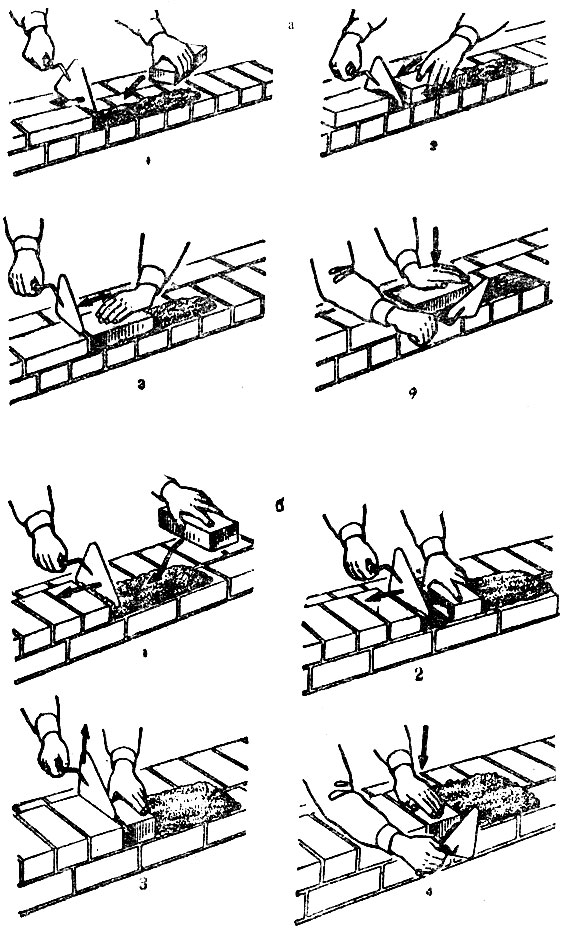

The masonry technology is simple:

- lay out and level with a trowel the width of the solution up to one and a half centimeters;

- lay a brick, slightly pressing it down to evenly distribute the binder mixture;

- gently tapping with a hammer, level the stone, observing the line indicated by the cord;

- collect the excess mortar with a trowel, fill the vertical joint between the two bricks.

Some experienced builders pre-apply a small amount of a binder mixture on the side face of the brick to bond with the adjacent one.

It is necessary to constantly remember to control the verticality, straightness of lines and the thickness of the seams.

How to make

How to make

calculation of a shallow strip foundation, you will learn from our next article.

And here is an article about the columnar grillage foundation.

How to prepare

Laying gypsum tiles is possible only after preparing the tools and carrying out preparatory work on the surface.

Often, to fully fill the site with tiles, you have to resort to pruning. A hacksaw for metal is used to cut the required plaster elements.

If communications are supposed to be carried out along the wall, then this is done before processing the plane and laying the tiles. The necessary holes are made with a drill, perforator, etc.

To increase the adhesion of materials, it is recommended to process their surfaces with sandpaper, which gives a certain roughness.

Materials and tools

It is worth preparing materials and tools in advance so as not to be distracted by searches during work. Materials:

- primer mixture, preferably deep penetration;

- gypsum tile itself;

- tile adhesive;

- joint grout;

- acrylic-based paint for the seam;

- varnish for finishing the finished surface.

Instruments:

- spatula with a notched base;

- level or laser;

- for marking: ruler, pencil;

- to form a seam: a plastic tube with a diameter of 10 mm (cut along);

- roller, brush for priming work;

- for applying varnish, a brush is used only from natural materials;

- painting the seam in a different color is done with an artistic brush 4 numbers;

- cut, the formation of tiles of the desired size is made with a hacksaw for metal.

Preparing the wall

The preparation of the walls is carried out in compliance with the rules, recommendations:

- Plane alignment. This is an important procedure, as the quality of the masonry depends on it. If there are defects, then they are eliminated with putty. Even small cracks must be repaired.

- Clearing the plane. The working surface is cleaned of dirt, dust deposits. If liquids were used, then the plane is completely dried.

- Priming the wall. This procedure will provide enhanced fixation when using the wet fixing method.

Basic principles of the process

Brickwork technology is the key points that are considered common for the construction of any object. The subtleties of the process may change when choosing a particular masonry method, but it is imperative to master the basic techniques.

First of all, it is important to decide on the type of foundation and the width of the masonry. The height is calculated according to a special table that contains information about the thickness of the brick, the corresponding thickness of the mortar and the number of blocks per 1 square meter

A foundation is a must for any heavy construction. For non-residential buildings on one floor, a columnar foundation is sufficient. It is better to install a reliable house on a strip or solid foundation. Brick is considered a heavy material and therefore requires a solid base. The higher the number of storeys in the house, the stronger the foundation should be.

The heat-insulating and sound-insulating qualities of the building, as well as its refractory properties, depend on the thickness of the masonry.

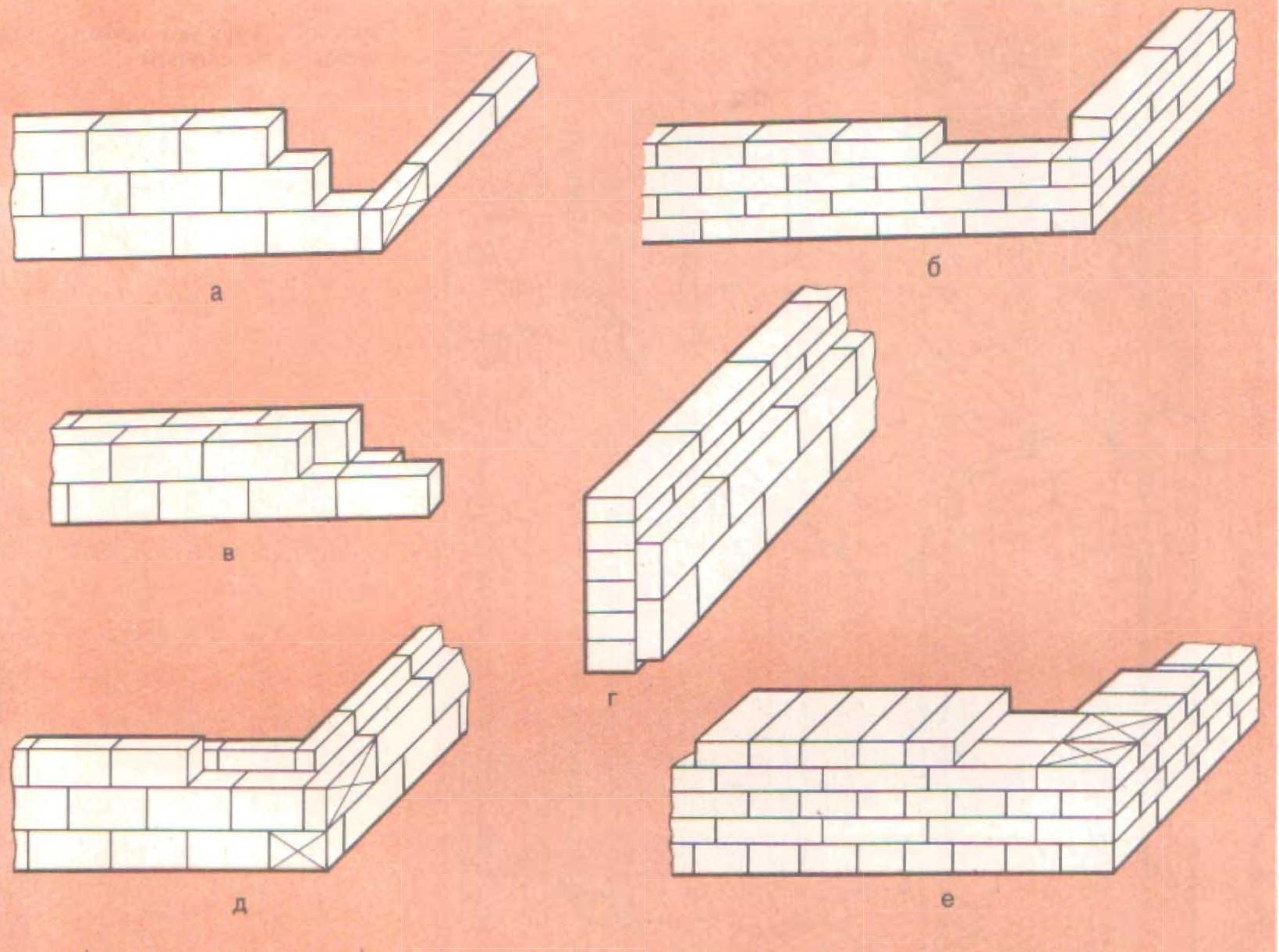

There are 5 types of masonry in thickness.

- In half a brick. The thickness is equal to the width of the bed - 12 cm. This option is suitable for non-residential one-story buildings.

- One brick. The wall thickness is equal to the length of the bed - 24–25 cm. Enough for a one-story house with thermal insulation.

- One and a half bricks. The thickness of the structure is formed by two rows of blocks. It is equal to 36–37 cm, respectively. Such masonry will be reliable for one-story and one-and-a-half-story buildings.

- Two bricks. This option consists of the length of two beds - 48-50 cm. You can safely build a two-story cottage on a solid foundation. The total weight and cost of such a building is quite high.

- Two and a half bricks. The thickness of the walls is 60–62 cm. It is rarely used for multi-storey residential structures. In addition to its heavy weight, such a building will require investment in a heating system.

Having determined the required width and type of building material, you can start building a foundation and laying bricks. In the process, you need to follow the rules.

- Use devices to control the horizontal and vertical lines so that the masonry turns out to be even. The most important step is to lay out the first row correctly.

- First, the corners are erected, then the middle part of the wall. The corners serve as guidelines to lay out even horizontal rows.

- The direction of the ordinal masonry is from left to right.

- The blocks are placed on the mortar in such a way that in the horizontal rows the upper brick rests on the two lower ones. The support area is not less than one quarter of each of the two lower blocks.

- The mortar is placed on horizontal and vertical joints. This protects the brickwork from cracking.

- An obligatory element of the masonry is the dressing. It guarantees strength and protection against delamination.

- For additional strengthening of the building, metal reinforcement is used.

- Waterproofing (roofing material or mortar) is required between the masonry and the foundation.

- If the wall is to be plastered, the joints do not need to be completely filled. This will help the plaster set better.

- Facing and working bricks are laid out according to the same rules.

Basic terms

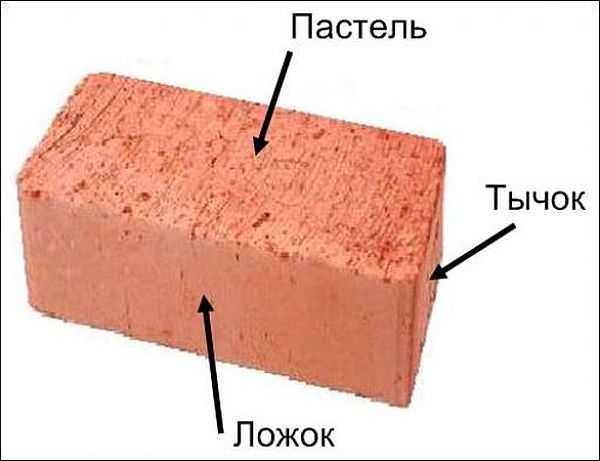

Let's start with general concepts. Everyone knows exactly what a brick looks like, that it is ceramic, and that there is silicate, too. But here's how the facets of this material are correctly called, not many in the course. And in the description of masonry technology, they are very common.

Brick face names: pastel, spoon, poke

The largest edge is called "pastel", the middle - side - "spoons", and the smallest - "poke".

The dimensions of the brick, in principle, are standardized (250 * 125 * 66 mm - single and 250 * 125 * 88 mm - one and a half), but the technology of its production is such that they can differ significantly from different manufacturers: by 2-3 mm in each faces, and this is a rather significant difference when you take into account the number of pieces in one row. Therefore, before ordering a batch, it is advisable to measure samples from several firing in order to determine how accurately the technology is maintained.

It is also important to pay attention to the geometry: the faces must be located strictly at 90 °. Otherwise, bursting loads will occur, and the wall may crumble.

Practical advice

If you still doubt whether it is possible to glue tiles on a brick wall without plaster, or do not know how to do such work correctly, listen to the recommendations of experienced specialists.

First, you need to choose the right glue that is suitable for laying tiles on brick stone. To this end, carefully study the accompanying instructions posted by the manufacturers on the packaging material.

Prepare the adhesive following the same information. The recommended number of servings is 0.7 - 1.0 per square meter.

For the convenience of working with an unplastered surface, some craftsmen use sheets of drywall, fixed on profile strips. In order to increase stability and form a monolithic structure, the joints created by sheet material are sealed with putty. After that, the surface is primed twice, and you can start laying the tile material.

On the plasterboard surface, the tile is laid out in the same way as on any other that has been pre-prepared in the form of applying a plaster layer:

- glue is applied to the surface, distributed over an area equivalent to one square of area;

- each tile is pressed against the wall with effort, while it is allowed to tap on its surface with a rubber hammer;

- so that the rows are displayed evenly, use special plastic crosses;

- the time required for the final drying of the glue is maintained;

- seam areas are rubbed and covered with a special moisture-repellent varnish.

When performing such work, one should not rush so as not to worsen the final result. Having laid the tiles in four to five rows, it is necessary to take an hour break so that the glue has time to set, and the tension that has arisen in the base is relieved.

If you are not sure if you can handle such a job, entrust it to an experienced technician.

The procedure for self-execution of brickwork

It is important to adhere to 3 basic principles:

- observance of the correctness of the linear position of the elements;

- the same height for each row;

- the same thickness of seams, vertical should be parallel to each other.

A person who has no experience often has questions about how to do the work correctly and compliance with which is especially important, we will try to highlight these points

- How to properly lay a brick on a foundation. The surface of the foundation slab must be carefully leveled and free of dirt. Horizontal control is performed using a laser level. To exclude the ingress of moisture into the wall from the foundation structure, it is imperative to perform high-quality horizontal waterproofing. For this, two layers of waterproofing are glued along the entire perimeter using bituminous mastics.

- Marking the position of window and door openings, places of interfacing with internal load-bearing walls and partitions.

- Preparation of the solution. The solution is prepared in a small trough or on a base with arranged sides. First, cement ≥ M400 is thoroughly mixed with quarry sand, cleared of debris and stones by sieving. For one part of the cement, 4 parts of sand are taken. Then mixing with clean water is carried out until a thick consistency is obtained. Mixing is carried out with a shovel, trowel or a drill with a petal attachment.

- Laying out the corners.

Correct execution is the key to the success of all further work. Several rows are laid out in height with horizontal and vertical level control. The corners should be permanently laid out 2 rows above the main wall.It is easy to create evenness and rectangularity of corners using ordering - a metal corner fixed in the corner with special brackets or clamps.

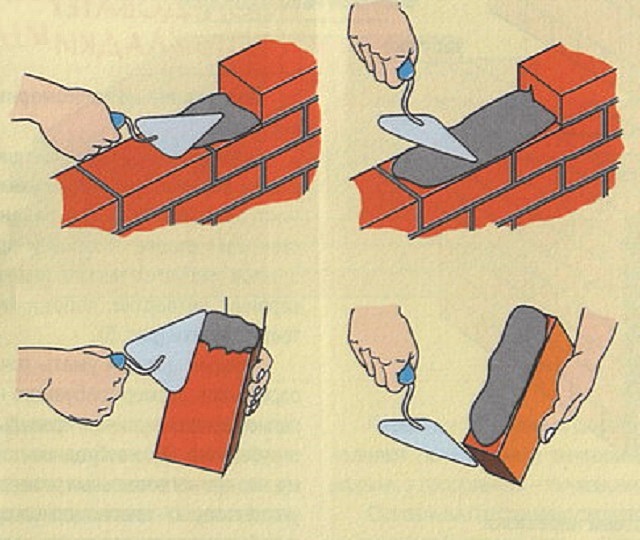

- How to lay the first row of bricks? The first one is necessarily performed with a poke one. If you put it crookedly or with a slope, then all the following will be exactly the same. Therefore, special control is required. It is recommended to lay it dry to determine the location of the brick products. The horizontalness is checked by the building level, it is good to use an aluminum rule equipped with a bubble level. First, the corners are laid out to a height of several rows. A strong cord is fixed in the corners, along which the bricks are laid. The edge of the products should not touch the cord, the recommended gap is 2 mm. In order for the bricks not to draw moisture from the solution, they must be dipped in a container of water before laying. On the base, about one meter long, a mortar is thrown with a shovel and leveled to a thickness of about 1 cm with a trowel. The brick is laid on the mortar with light settling (tapping with a hammer or trowel handle) and leveling along a string, control of the horizontal position with a building level.

- The following rows are laid, depending on the selected type of masonry and the thickness of the wall: in brick, one and a half or two with the obligatory dressing of the seams according to the chosen method. The thickness of the seam of the brickwork is regulated: horizontal 12 mm (permissible deviation -2 or +3 mm), vertical - 10 mm (tolerance -2 ... + 5 mm). A vertical joint is created by applying a layer of mortar to the adjacent brick edges. Further, the excess mortar is removed with a trowel and, after its slight setting, the joints are sewn with a special device (if further plastering of the wall is planned, then the jointing is not performed).

- To increase the masonry strength, reinforcement is performed through each calculated number of rows (can be done through 3 or 4).

- Reinforced concrete or metal lintels are laid over window and door openings.

- Can bricks be laid on tile adhesive? It is possible, but impractical. Firstly, the glue can "float" at a thickness of 1 cm. Secondly, there is a high probability of the formation of air bubbles. Thirdly, it quickly freezes. It should be noted that the price of glue is much higher than that of cement mortar. If, nevertheless, such a decision is made, then the glue must be frost-resistant and combined with cement in a 1 to 1 ratio.

- Can you lay bricks in the rain? It is impossible in any case, this will lead to leaching of the solution from the seams, and when using ceramic products, efflorescence will inevitably appear. If urgent work is needed on the front of the work, a protective canopy made of plastic wrap fixed to the frame is arranged.

To study the numerous existing nuances, it is recommended to familiarize yourself in detail with the technical literature on the construction of brickwork before performing the work.

How to build a brick wall in the interior of a private house

So, we figured out the general questions, let's move on to practice. And building a beautiful brick wall is on the agenda. There are two fundamentally different ways of solving the problem.

The first, the most logical and correct one, is to think over all the interior nuances at the stage of drawing up the project documentation and already in the process of masonry and finishing work leave the section of the wall you need without plaster in clean brick.

As a result, you will not need to engage in any dismantling work, spend money on various plastic panels or gypsum, and, in general, you risk saving great money on finishing, because the planes outlined for the natural texture will not need to be subjected to additional processing.

It is much worse if your house is purchased and the previous owner was neither a dream nor a ghost about your "brick" plans. In this case, inhale a lot of dust. We guarantee this to you.

To begin with, you will have to arm yourself with a hammer, chisel and perforator and carefully, so as not to ditch the masonry, to clean it of putty and plaster. When you remove the bulk of the debris, proceed to a more delicate cleaning, for it you will need a metal brush, an unnecessary chisel and a rough brush. As a result of the work, the wall should be cleaned to the artistic state you need.

At the next stage, water procedures. It's good if you don't have a fifth floor, but your own dacha, which is not afraid of a flood. In this case, arm yourself with a "Karcher" and take a good walk through the masonry with some water, otherwise you will have to wash the bricks for a long time and tediously with a brush in soapy water.

Well, then a rather long drying process. Before you open a brick with a primer or varnish, you need to make sure that it is completely dry.

In more detail about how to put an old brick wall in order, we wrote here.

The wall thus "made", however, is not the greatest grief on the way to the desired beauty. More often it happens that the primary masonry will not suit you in quality, or it may be absent altogether.

Well, the truth is, brick is less and less used to create walls, giving way to more perfect, but less beautiful materials. In this case, for interior decoration you will need an imitation brick. Fortunately, there is plenty of such on the market.

The cheapest (within reason) would be to take gypsum tiles under the brick. It can be glued both from top to bottom and from bottom to top, using ordinary liquid nails as glue.

The main thing is to sometimes glance at the level and observe some accuracy. It is very easy to stain the imitation, but it is problematic to wash it off. And therefore, do not forget to open the wall made of such an artificial "stone" with varnish, otherwise it will not serve you for a long time.

Flexible decor made of polymers will cost much more. Lightweight, durable, wear-resistant material is perfect for creating a brick wall, but it will cost you 800-1200 rubles per square meter, and this is without taking into account the mounting glue and grout. How exactly to work with such material can be seen in the following video:

Let's just say that even though the brick is flexible, you should not refuse to buy corner elements, especially if you are doing the cladding for yourself.

Well, the last option is either for the very poor or for the very hardworking. It is not necessary to buy a gypsum imitation, you can draw it on the wall yourself with a spatula and plaster. On the Internet, it is really possible to find dozens of techniques and video examples on how exactly such a decor is made. We will focus only on the simplest version.

For its implementation, it is enough just to tighten the wall along the lighthouses with gypsum plaster for machine application. And while the latter is not too “frozen”, mark the plane vertically every 75 mm, and then, as a rule, clear the masonry joints in the wet plaster.

This must be done quite quickly, since it will be necessary to have time to draw vertical ones behind the horizontal seams. They are made in increments of 25 centimeters, that is, along the length of an ordinary brick. After priming and painting, you will get quite a brick texture. She will, of course, be far from the real one, but do not go broke.

Vasily Molka

Secrets of brickwork

Every 5-6 rows, you need to lay a reinforcing mesh, and remember about tying bricks (in adjacent rows, the seams should not coincide).

After going through the training period, constructing simple structures such as posts, retaining walls, steps, anyone in the future can lay it out with your own hands, for example, a brick barbecue or even a summer kitchen at a summer cottage.

In this case, it is best to use a facing brick with a smooth side or a special chocolate brick, which is smaller in size from the usual one and is very decorative. Or vice versa, rough brick, similar to natural stone.

Before making any building, you need to make an ordinal plan, that is, draw all the layers of brick on paper in order to avoid unnecessary costs, since brick is not really a cheap material. The size of the brick is 250x120x65 mm. When making a calculation, you need to throw 10% over the required amount, in case of a battle.

Having made all the calculations and having bought the right amount of material, you need to make a dry masonry of the structure, without mortar, in order to identify all possible flaws. If everything is in order, and there are no errors in the project, you can proceed to the direct laying of the brick on the mortar.

Before laying the brick, it is imperative to wet it by dipping it into a bucket of water so that the solution adheres well to it.

The most important thing is not to rush. Immediately lay the brick without mortar, see how it lays down, if everything is in order, apply the mortar and lay it by tapping on the top of the brick with a trowel handle or a mallet until the brick takes the desired position in the masonry. Remove excess mortar with a trowel back into the bucket. You don't have to rush with the cement mortar, this is not the "Moment" glue that dries up in one second, here you have a lot of time to play around with the installation, turn the brick in the right direction, remove and reapply the mortar until it turns out as it should be perfectly. When you have the skill, and you learn how to draw the required amount of mortar onto the trowel the first time, and immediately install the brick in the right place, only then the work will go much faster.

I would like to hope that thanks to this article you will learn how to lay bricks on your own, and at your summer cottage you will be able to please your family and friends, as well as friends, with the work of your own labor in the form of a stove or even a summer kitchen, or a garage.

Technological process

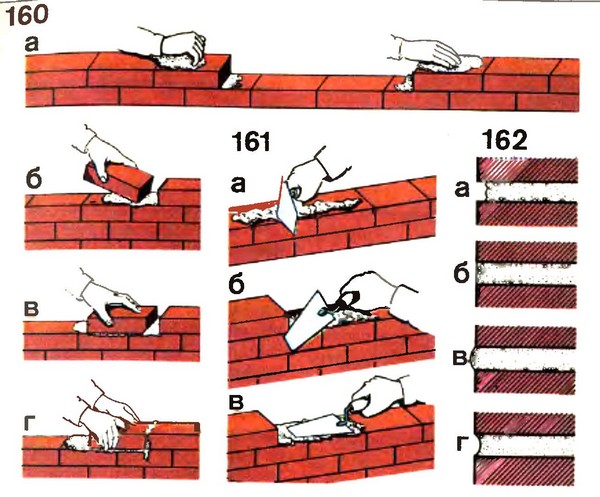

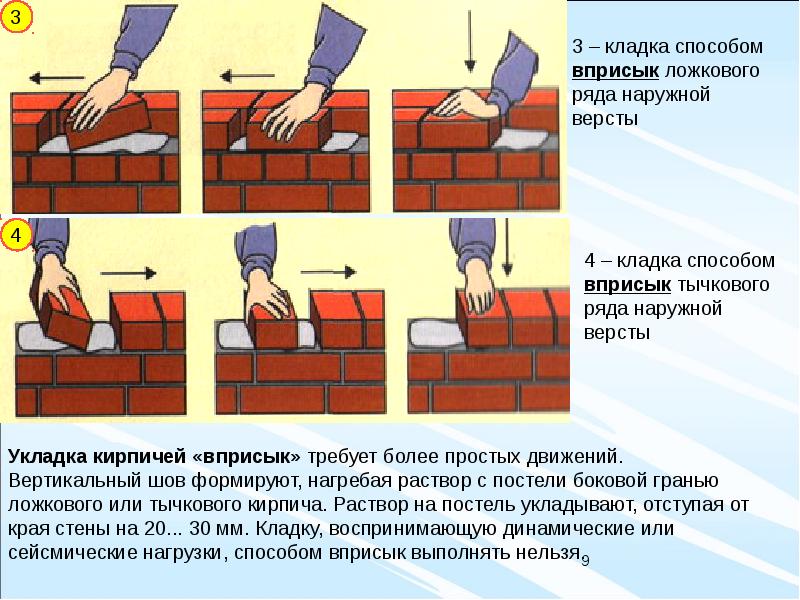

How to make brickwork for joining? When is it allowed to start such work?

If you decide to use the technology of laying facing bricks with the simultaneous design of the seam areas for joining, then the excess mortar mixture is removed with a trowel so that a common level with the plane of the wall is ensured.

As soon as the mortar mass begins to set, it is given the required shape using a joining template. The mortar between the brick rows is pressed inward by about three millimeters, compacting the mass well. This improves the quality of not only the masonry, but the entire wall as a whole.

With regard to the time when it is best to start such a procedure, the following points are observed, which are the most significant:

- monitor the consistency of the solution and the degree of its plasticity;

- control natural factors - the temperature regime of the air and the percentage of humidity in it;

- high-speed mode of work of the master performing the laying of brick stone.

Masonry with simultaneous joining

A similar procedure is started by preparing several rows of masonry, the solution in which begins to gradually harden.

It is necessary to act in a certain sequence:

- the brick stone is laid on a sufficient thickness of the mortar layer, slightly pressed. The mixture outside the joint is removed flush with the brick surface;

- the mortar that has seized, but did not have time to harden, is smoothed with a jointing or a piece of a simple hose, compacting and pressing the mass into the seam;

- if the joining will be performed a little later, then it is recommended to leave a little free space in the joints so that there is room for the jointing mortar.

Joining after masonry

Making bricks for joining is possible on long-built walls. To do this, you will have to remove a certain amount of old masonry mortar. The formed cracks are moistened, a new solution is laid in them, which is embroidered in a known manner.

It is recommended not to prepare the mixture yourself, but to purchase ready-made formulations in a dry form, which remains to be diluted with water. Such materials, after completing the jointing procedure, perfectly retain their shape.

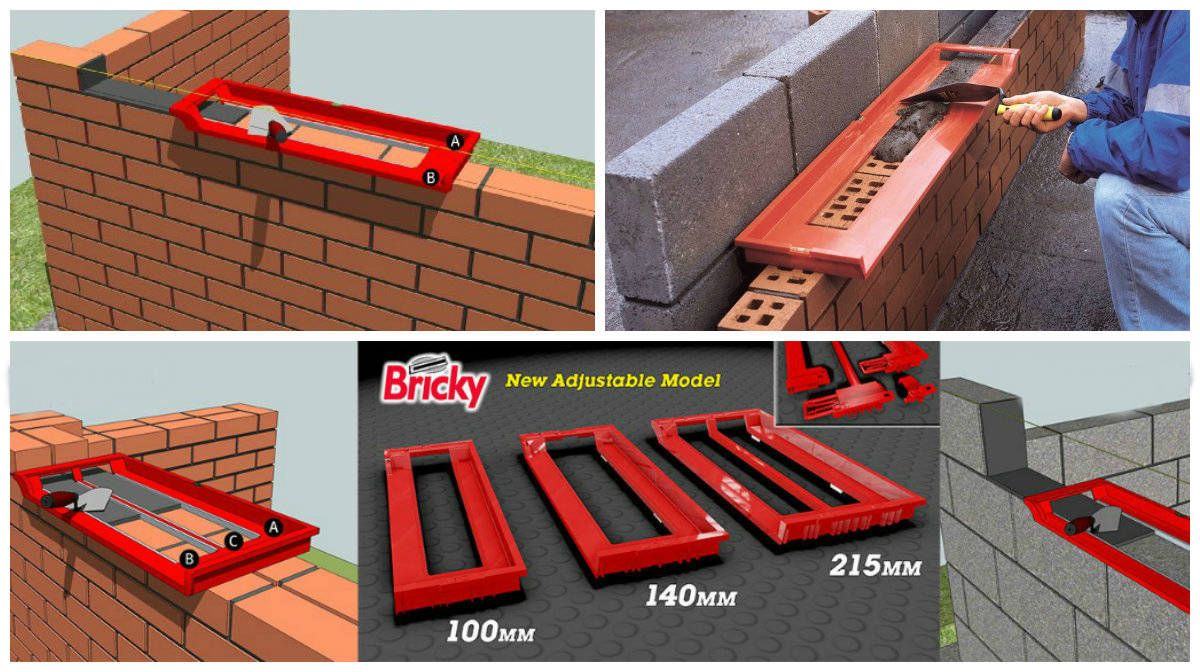

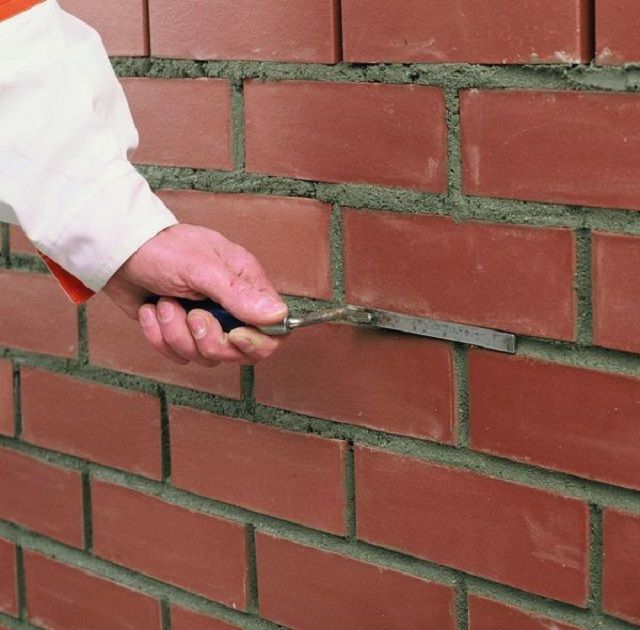

Masonry using a rod

This technique is based on the use of a round or rectangular steel rod, which is laid along the entire length of the bottom row on both sides. Then it remains only to fill the free space between the metal elements with a mortar mixture, lay out the brick stone in a row, adjusting it in place with a wooden mallet.

Carrying out such work implies a large supply of metal rods of the same section, since the laid steel elements should be removed after a certain number of brick rows have been removed from above. The rods are carefully pulled out, after which they are immediately washed with water from traces of the mortar mixture.

The advantage of this method of joining is that after removing the rod, an attractive and even joint remains, uniformly filled with sand-cement mortar. It does not have to be additionally modified, even cleaning with a metal bristle brush is not required

True, the performer of the work will need special attention on the layout of the first row - it should turn out to be ideal, displayed strictly in a line. The check is carried out at the building level

By expanding seams with a metal rod, you get the following benefits:

- masonry seams are perfectly flat;

- if all work is done carefully, then the front surface of the brickwork retains its cleanliness. This is especially true for expensive facing stone, the surface of which is difficult to clean from dried mortar particles;

- the need for the formation of seam areas is completely eliminated - all the work is performed by a metal rod.

By the way, many people prefer to use round steel elements, because square shapes do not always make it possible to maintain the general level for brick stone and mortar. This type of joint requires additional filling with jointing compound.

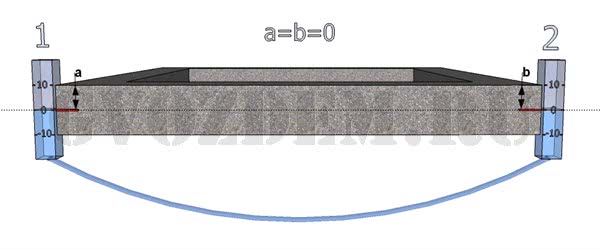

We check the horizontality of the foundation with a hydraulic level

First, you need to determine how flat we got the horizontal surface of the foundation relative to the ground level? For this purpose, we will use the water level and check the corners first, and then the entire perimeter along the foundation. (when filling the hydro level with water, make sure that there are no bubbles in the tube, otherwise the measurements may not be accurate).

In the picture, we see that both corners are at the same level. As the masters say, "is at zero." But this method of measurement cannot be applied if our foundation has discrepancies relative to the level. So let's move on to a more practical way.

Let us lower the 1st flask of the hydrolevel relative to the foundation so that the “0” mark is 5 cm below the upper surface of the foundation (provided that the maximum difference in the foundation at our maximum point is slightly less than 5 cm). Opposite the "0" mark on the flask, we put a mark on the foundation. We will not touch this flask now. To begin with, let's check all the outer corners of the foundation, in our case there are 4. To do this, we will transfer the 2nd flask to all 3 corners, and put a mark on the foundation opposite the mark "0", which is on the 2nd flask. Then we repeat the steps with the 2nd flask, transferring it to other measured points on the foundation.

When we have placed all the marks, we begin to measure the distances between the mark on the foundation and the upper edge of the foundation. In the figure, we measured the distance on two segments: a and b. Suppose the distance is a = 5cm and b = 5cm (a = b). Consequently, the foundation at these points is brought to "0".

The second option is a = 5cm, b = 3cm. Therefore, there is a difference of 2 cm relative to zero.Such a foundation must be leveled, while we take the highest point on the foundation as zero. There are several ways to align:

- leveling screed on a cement-sand mortar using formwork,

- brickwork, changing the thickness of the horizontal joint.

If the difference is large, then it is better to level it with a solution, if it is small, then it is possible with the help of masonry. Just remember that the permissible thickness of the horizontal seam according to SNiP should be 12mm with a tolerance of + 3, -2mm (according to SNiP 3.03.01-87). When reinforcing, the maximum joint thickness should not exceed 16mm. And also for reference: the permissible permissible deviation from the horizontal by 10 m of masonry is up to 15 mm, which is then eliminated by the next row.

Gypsum tiles for interior decoration under a brick: advantages and disadvantages

Gypsum is a lightweight material that, if necessary, takes the required shape, structure, relief. The use of this material in the decoration of the interior space of a room is a simple, materially feasible and physically feasible task.

Advantages of plaster stone finishing inside the building:

- A wide range of products that differ in texture, price, size and appearance.

- Relatively low pricing policy.

- Natural formulations.

- The ability to customize the finished tiles to the surface features.

- Simple design, wall mounting.

- Light weight of the finished product, which allows it to be used on any surfaces without the risk of wall deformation.

Among the disadvantages are such features as moisture absorption, lack of resistance to mechanical damage and crumbling. However, such disadvantages are insignificant, and during operation the material will not require labor-intensive maintenance. If necessary, you can replace damaged broken tiles with new ones without damaging the integrity of the wall.