Manufacturing technology

Among all types of bricks, fireclay is the most durable and resistant to strong heat and temperature extremes. The material owes these qualities to its composition and specific manufacturing technology, which consists in firing a clay mixture with the addition of chamotte powder. As a result of exposure to high temperatures, the brick acquires a characteristic gray-brown or yellowish color, by which it is easy to distinguish it from other varieties.

The composition of fireclay bricks determines its performance characteristics. Depending on the proportions of clay and powder, several types of material are distinguished. A colossal role is played by the method of processing, or rather, the time of baking the bricks. So, if you overexpose it in the oven, then a strong glassy film forms on the surface, which will make the brick incredibly strong, but less refractory. If it is not fired for a long time, then such a material will absorb and retain moisture well, but it will completely lose its strength. Only if you adhere to the "golden mean", you can make a brick, ideal for laying stoves and fireplaces.

So that the products do not crack during the firing process, a certain amount of special refractory clay - chamotte - is added to them. Sometimes coke powder, graphite or coarse-grained quartz are placed instead. The result is different types of bricks with individual characteristics. Moreover, the result depends not only on the raw materials and the processing method, but also on the characteristics of the fuel for burning and the resulting ash.

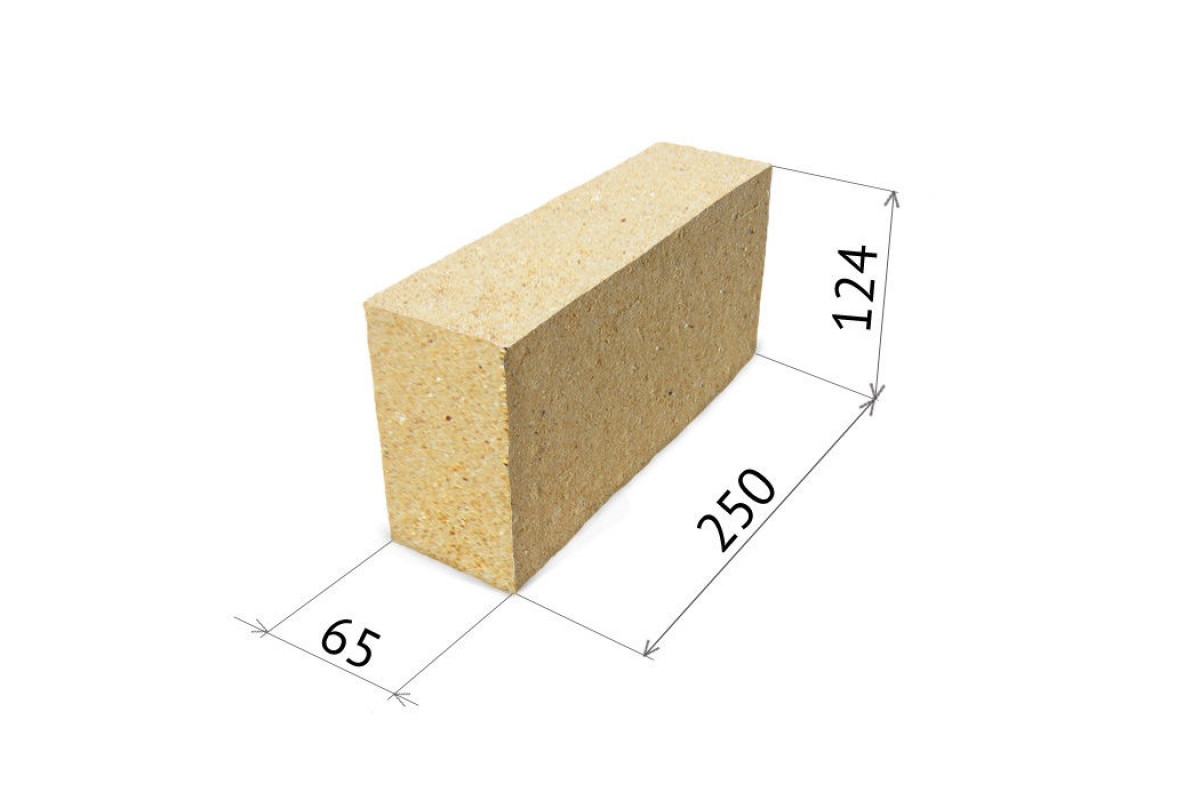

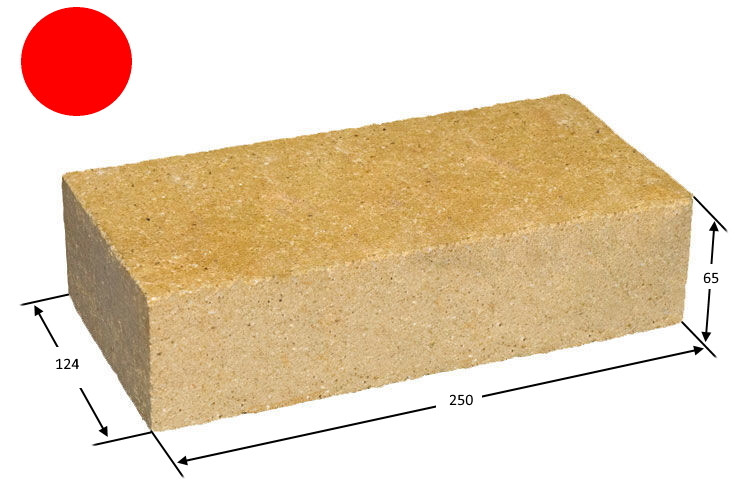

The production of fireclay bricks is carried out in accordance with GOST 390-69, and depending on what it will be used for, the production technology, weight and dimensions of the material differ. So, the mass of fireclay bricks can vary from 2.5 kg to 6 kg. Differences also lie in the density, porosity and composition of the bricks. There are uniform size standards that most manufacturers adhere to: 230x113x65 mm, 250x123x65 mm and 300x150x65. These are the most convenient dimensions for construction and transportation.

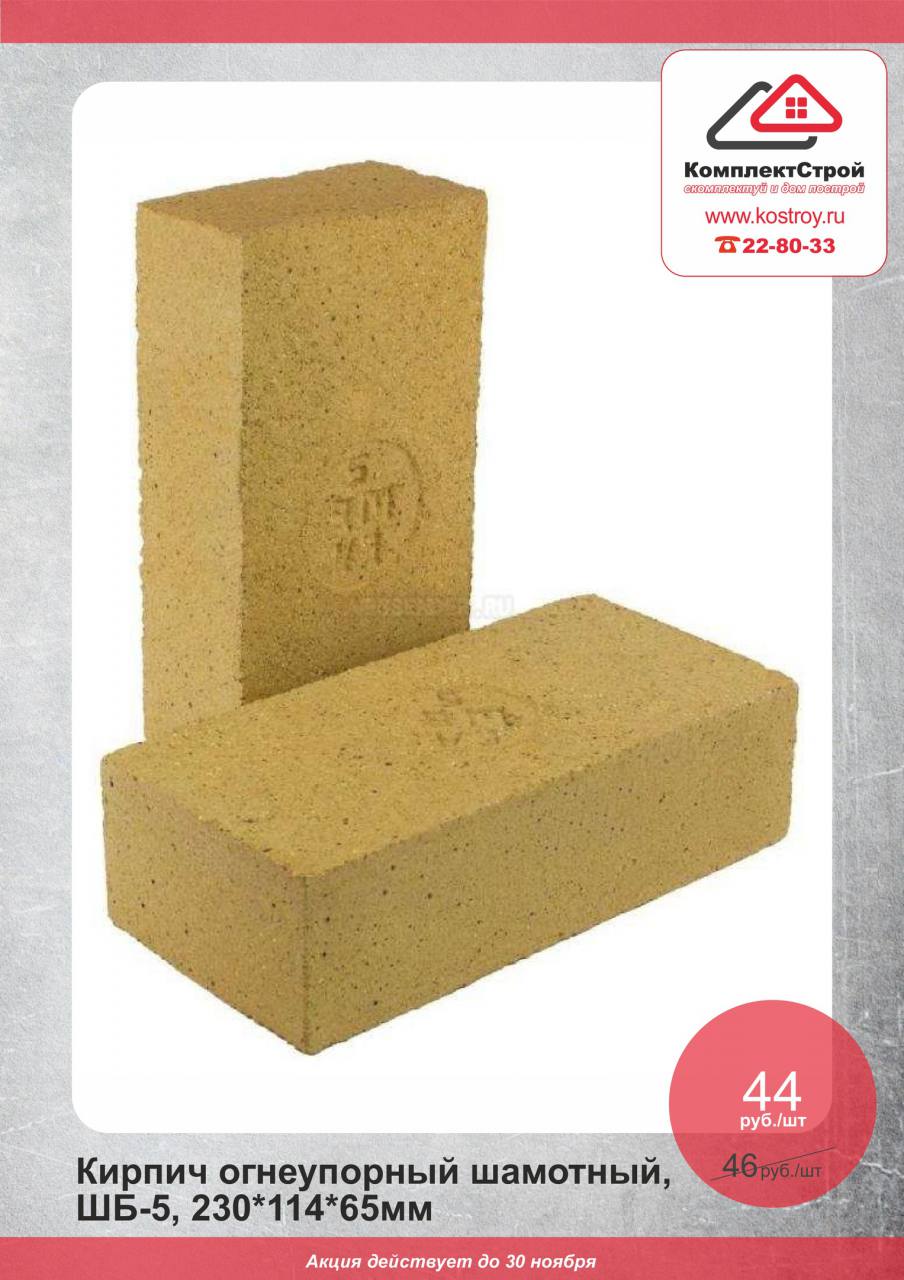

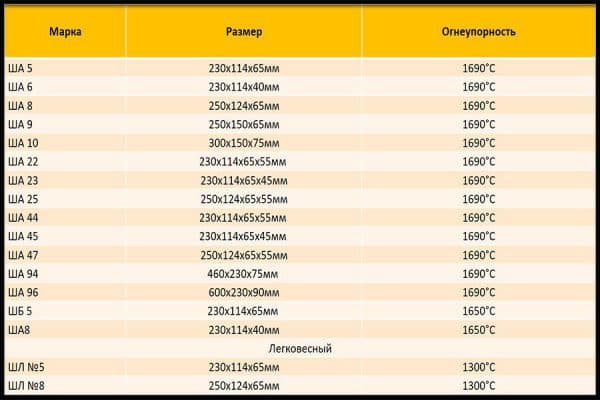

The most frequently used brands of fireclay bricks are: ШБ №5, ШБ №9, ШБ №22, ШБ №44, ШБ №47. The letters in front of the number can be different, for example, PB, SHB, SHUS, SHL and others, but for domestic use it is better to choose bricks marked "ШБ". The first letter indicates that the brick is chamotte, the second means to which class of refractoriness it belongs, and the number is the aspect ratio.

Lightweight brick

Lightweight fireclay brick has established itself as a good insulation. It contains peat, oily clay, sawdust and other organic components. During the firing process, they burn out, leaving behind pores of various sizes. This manufacturing technology makes it possible to obtain a very lightweight porous material with high energy-efficient characteristics.

Since lightweight bricks are made entirely from organic matter, they are environmentally friendly materials that cannot harm human health or the environment. At the same time, high refractoriness remains - the brick can withstand extremely high temperatures up to 1800 ° C.

Lightweight bricks can be rectangular or wedge-shaped in shape. In order for the material to fully retain all its operational properties, it must have the correct structure with smooth edges and perfectly right angles.

There are several types of lightweight bricks, depending on the scope of application:

- trapezoidal;

- shaped;

- straight;

- rib wedge;

- end wedge.

The marking of lightweight bricks is indicated by the letters SHL and SHTL (T is the presence of talc in the composition). It is usually used to create an insulating layer in the construction of electric furnaces, heaters, evaporators, steam pipelines, heat exchange boilers, etc. Such protection can significantly reduce heat loss by 20-70%, reduce the mass of thermal devices and their dimensions. If you buy fireclay bricks for building or lining a furnace, the heating and cooling time will be reduced by 5 times, and fuel costs will decrease by 10% in continuously operating furnaces and by as much as 45% in periodically operating ones.

Types, forms, brands and purpose

According to the method of forming brick blocks, types of fireclay stone are cast from slip, made by semi-dry or plastic method, fused, hot-pressed and thermoplastic-pressed. According to the geometric shape, such subgroups of fireclay oven bricks are distinguished:

- Straight - rectangular with smooth edges.

- Trapezoidal.

- Wedge-shaped brick, it is also arched or arched:

- wedge rib;

- wedge end.

- Shaped - has a wide selection of shapes, allows you to erect structures of complex design.

- Suspended - used for industrial furnaces.

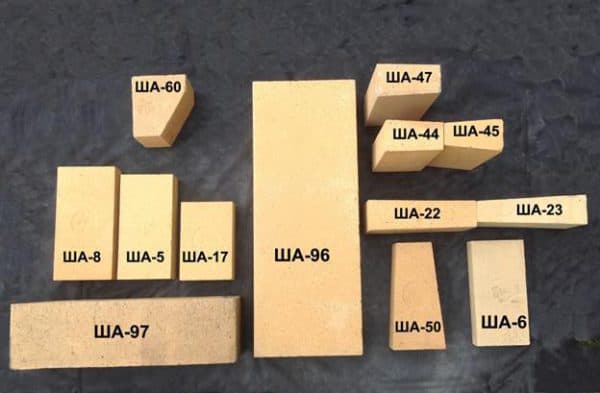

The kiln brick has a wide range of applications and, according to GOST, there is a marking on each block. The first capital letters are the designation of the material in the composition and the fire resistance class. After them there is a number that indicates the block size. For example, brick ША-5 contains 30% aluminum oxides, and the size is 230 × 114 × 65 mm. Brick ША-8 is the same in composition, the only difference is in size - 250 × 124 × 65 mm. After the designation of the dimensions, the abbreviation of the manufacturer is put.

Grades of bricks used in private construction

ША, ШБ - have a fire resistance of +1690 degrees Celsius and contain 30% aluminum oxide in the ША version, in ШБ - +1350 degrees and 28%, respectively, are quite dense. When laying the vaults of furnaces in boiler rooms, brick ШБ-8 (straight) is used for the inner lining of the furnace pipes. The SHA-10 brand has the same properties, but the size of the stone is much larger: 300 × 150 × 75, which facilitates construction on an industrial scale. Laying arches, tandoor and rounded structures will help wedge brick SHA-25 (end), SHA-44 and SHA-47 - ribbed. It has the same characteristics indicated in the marking, only it differs in size.

PB and PV - semi-acid fireclay brick (PB (PV) -5 marking) with a high content of silicon oxide and with a smaller amount of aluminum oxide, which means it is slightly less durable in compression and has a lower refractoriness. Withstands a maximum temperature of 1350 degrees, full-bodied, with less ideal geometry than the SHA brand. It may well replace the brand in the lining of pipes, the construction of fireplaces, barbecues, stoves. The price on the construction market for this refractory is cheaper than the SHA brick grade.

ШЛ - lightweight fireclay block with refractoriness from +1100 to + 1300 degrees. It also has a large number of shapes and sizes, a low coefficient of linear expansion. If on the marking (ШЛ-0) the numbers from 0 to 1 mean that the product is ultra-lightweight - weighing up to 1 kg. An index of 1.0 and higher indicates a lightweight stone - the weight range is 1.7-2.2 kg.

Industrial

ШВ and ШУС - fireclay material that can withstand a maximum of +1250 degrees. Used only in enterprises. The blocks are laying gas-fired shafts at heat stations, steam generators. They have a high price, but a small range. SHKU and SHK - fireclay ladle products and equipment for coke production. ШЦУ - end double-sided products, with refractoriness up to +1710 degrees. Purpose - laying of protective cladding in rotating heating facilities. Broadband - used for blast furnaces. Melting point +1750 degrees.

Properties and characteristics

The choice of brick for the construction of the planned hearth can be made after comparing the physical and technical characteristics of the stone with the regulatory requirements. Manufacturers always indicate the properties of the building material. The types have common characteristics that differ depending on the purpose of the stone, the ratio of raw materials, and the method of production.

Brand and size

When laying the stove, the standards allow the use of stone with strength M-150. The marking indicates that 1 cm² of the material is resistant to a mechanical load of 150 kg. For the construction of a large, dense kiln, a higher grade of brick is used. The standard size of 25X12X6.5 cm is often used for masonry, but other formats are allowed. Therefore, when choosing a ready-made project, it is recommended to clarify for what size of stone it was developed. The parameters are clearly regulated.

Frost resistance and hygroscopicity

The material is not frost-resistant.

The material is not frost-resistant.

Such properties are taken into account during the installation of parts of the structure, which are subsequently exposed to temperature changes. Heat-resistant stone is not characterized by high frost resistance. Hygroscopicity - the ability to absorb and retain moisture. Areas of the structure that can be exposed to moisture are built from materials with low hygroscopicity.

Strength and heat resistance

Refractory bricks are subjected to enormous thermal stress. The strength index should be high. The strength value is different for each grade. For furnaces, materials with a large temperature limit are used. The indicator reaches a value of 1700 ° C for materials that will be constantly exposed to fire.

Density and thermal conductivity

For a fireplace and stove, it is recommended to use a stone with a thermal conductivity index of at least 0.61 W / (m * ° C), which easily passes heat and heats the room. When finishing the chimney, the heat-resistant material retains heat, thereby preventing overheating of the adjacent wall or structure. In this case, low thermal conductivity is preferable. Low density materials have low strength.

Kinds of furnace material

Now on the market there is a huge selection of materials for building a furnace: ceramic, silicate, fireclay, hyper-pressed. In construction, they use simple building bricks, clinker, fire-resistant. And according to the internal structure, there are corpulent and hollow ones.

Before starting construction, you need to study all the advantages and disadvantages of the material, if any. What exactly are the criteria for choosing a brick?

There are three most common types:

- fireclay;

- periclase;

- quartz.

The popularity of fireclay bricks for the construction of furnaces.

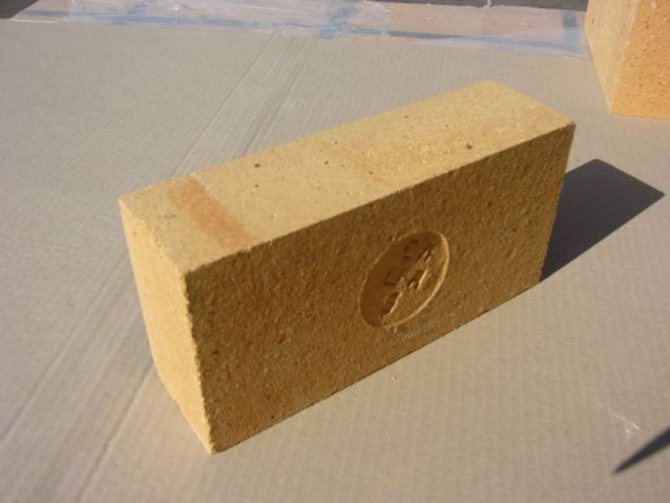

If it is made according to technology, it will perfectly keep heat and withstand temperature extremes without losing its main characteristics. Very often a fireclay brick oven is built. When you come to the market where they sell fireclay bricks, you should look first of all at the color. It should be straw yellow in color, then it is made according to the rules and will keep warm perfectly. If it has a white, light color, then it is not worth buying. It will not meet the declared characteristics, you need to choose another one.

Pereklazovy kiln solid brick withstands extremely high temperatures very well.

Quartz is made from sandstone, a small amount of clay is added to it.

Ceramic kiln bricks are made by mixing red and blue clay and then fired. Firewood burns at a temperature of 800-900 ° C, which it can withstand. However, only high-quality bricks are needed for construction, and many types of ceramic material now cannot withstand temperatures even at 800 ° C. Some sellers indicate a temperature regime of 700 ° C. It is better to choose a material that can withstand temperatures of 1000 ° C and above.With this material, you will always be confident in the quality of your oven.

Ceramic bricks are not suitable for laying stoves, as they do not have sufficient fire resistance.

Silicate brick for the kiln is made from refined sand and lime additives in a ratio of 90% and 10%. It is produced under high pressure, due to which it has a dense structure. It is warmer than ceramic, but cannot be used in construction for several reasons. Firstly, it does not fit well on clay, and secondly, it is very afraid of temperature changes, during which it begins to absorb moisture into itself, which leads to its destruction. The only place it can be used is for the chimney, which is right under the roof.

Hyper-pressed brown is made from limestone, marble, dolomite. Components are obtained from open pit mining. Manufacturers quite often attribute to it characteristics that it does not have, and recommend it for masonry and cladding of the stove. The material is suitable for cladding, but not for masonry. It's all about the limestone that is in the composition. Limestone does not cope well with high temperatures, which leads to its destruction.

Ordinary red brick is a standard building material. It is used for masonry walls and partitions. It may have flaws, chips, grooves - this is permissible. Such a red brick is not suitable for stoves, as it will not withstand high temperatures and will crumble.

Features of production and classification of fireclay bricks

The technology for the production of refractory bricks requires precision adherence. If it is kept in the oven for a little longer during the firing process, the surface of the products will acquire the appearance and properties of a glassy film, which is unacceptable for construction work.

Otherwise, when the firing time was insufficient, the resulting building material will lose its strength due to its ability to absorb and retain moisture. Therefore, unlike ordinary ceramic bricks, fireclay refractory products of even popular brands SHA-5, SHA-8 are produced in smaller volumes, their price is higher, but relatively few of them are required.

According to their composition, fire-resistant stone materials are divided into four groups. This is a basic brick, obtained from a lime-magnesian mixture. It is widely used in metallurgy, for example, for steel smelting. Carbon bricks, also used in blast furnaces in the steel industry, are coke or pressed graphite.

Quartz refractory bricks are based on a mixture of sandstone or quartz, into which clay is added for the purpose of bonding. Contact with alkalis is undesirable for this material, therefore its use is limited to the production of metal alloys and the laying of stove (fireplace) vaults.

It has no narrow specifics of operation, due to which it is in the greatest demand, alumina brick. Its temperature range is slightly lower (up to 1300 ° C) than that of other types of refractory materials, but it tolerates multiple temperature changes well and is suitable for most household furnaces. It is the most versatile and has the widest range of applications. Moreover, its manufacture is distinguished by a relatively simple production process.

In everyday life, most often for the construction of stoves and fireplaces, standard varieties of refractory bricks ШБ-5 and ШБ-8 of a straight form are used. The marking of these products includes the first letter of the word "fireclay" and the second, meaning the fire resistance class corresponding to the maximum possible temperature of use. The number of the brick mark indicates the ratio of the dimensions of its sides.

Features of the classification

Designation and marking of ШБ-5, ШБ-6, ШБ-8, ШБ-9; SHA-5, SHA-6, SHA-8, SHA-9

Dimensions, mm 230x114x65, 230x114x40, 250x124x65, 300x150x65; 230x114x65, 230x114x40, 250x124x65, 300x150x65

Shape: straight

All materials made from refractory clay are marked with letters and numbers. The first should be the letter "Ш" - shows that the brick was made from aluminosilicate clay. The second letter exists in two variations "A" / "B". The letters indicate that the product is used for all types of masonry.

Marking

The presence of only one of these letters informs the buyer that the manufacturer is guided exclusively by GOST standards. The designation “SHA” means that the product contains a huge percentage of aluminum oxide.

That is, approximately 30%, which increases the fire resistance up to + 1690C. “ШБ” aluminum oxide has approximately 28%, which makes it possible to carry up to + 1650С. If after the letter "Ш" there is a number, for example "Ш5", this means that the manufacturer did not use the Gost indicators, but applied its own manufacturing technology.

The product with the “5” mark corresponds to the dimensions of 230x114x65 mm. The last two indicators indicate the manufacturer.

The standard shows similar abbreviations for a refractory product:

- SHA, SHB - general purpose;

- SHKU - bucket;

- SHAV - cupola;

- Broadband access - domain;

- ШЦУ - double-sided for lining.

Heating devices are equipped using a general purpose product. Let's analyze the standard dimensions of refractory bricks in detail. The alumina type is considered to be more in demand, including refractory clay and fireclay product.

Accurate firing must be followed for this type. For furnaces, only products of the first type are used, which crack when heated. Refractory brick size “ШБ5” looks like a yellowish rectangle. Scales 230х114х65 mm.

Dimensions ШБ5

According to the standard, the material must meet similar characteristics:

- part of the binary compound of aluminum and oxygen - 28%;

- fire resistance - not less than 1,650oC;

- when softening, tºC is absent.

"ША8" product is used in industrial and private buildings. Possesses an increased index of aluminum oxide. Used for internal laying of chimneys.

Product rating:

- percentage of aluminum oxide - 30%;

- fire resistance - 1,690oC;

- softening tºC is not less than 1,300oC.

SHA-6 is used in the construction of heating units at t 1 690ºC. The main properties of the product do not differ from the “ША8” marking. The difference is solely in size. Product weight per piece - 3.4 kg. Scales - 230х114х40 mm. Cost from 30 rubles / piece.

Types of Sha

Refractory bricks "ША5" are 230х114х65 mm in size. The mass is the same as that of the "SHA8". The price of a refractory grade is 30 rubles / piece. Dimensions are the main criterion in the selection of refractory bricks.

Areas with a very thin ball of mixture should be avoided. The calculation of the costs of refractory bricks is carried out using the construction scheme.

Marking ША5, ША6, ША8, ШБ5, ШБ8.

Size, mm 230x114x652, 30x114x602, 50x124x652, 30x114x652, 50x124x652, 30x114x652, 50x124x65, 230x114x652, 30x114x65.

Refractoriness, C 1 690, 1 690, 1 690, 1 690, 1 690, 1 300, 1 300, 1 150, 1 465.

Marking

When choosing a material for masonry, one should understand how much red bricks are needed for a particular area and a number of key properties that are responsible for the quality of the product. Only by using a high quality product can a smooth and reliable stove be created.

When selecting products, special attention should be paid to the following properties:

- homogeneity and uniformity of the plane must be almost perfect. You do not need to purchase a brick, in the plane of which you can identify the remnants of inclusions, stones, inclusions, as well as cracks;

- the material must have a uniform, identical tone;

- the correct formation of the stone testifies to the quality. It is necessary that all the edges are the same in length, without flaws. The presence of protrusions will cause damage during installation;

- a different mass of bricks with the same dimensions indicates density. The larger the mass, the denser the product, and also the longer it accumulates heat.To build the base of the building, you should know the information about the weight of the brick.

Types and marking

Modern manufacturing plants offer a large number of various types of fireclay bricks, which differ in weight and shape, production technology and degree of porosity.

Trapezoidal and wedge-shaped, capable of satisfying any requirements for structural elements, have become widespread.

Depending on the degree of porosity, fireclay bricks can vary from very dense (less than 3% porosity) to ultra-lightweight (porosity - 85% or more).

The main characteristics are very easy to determine by the marking of refractory bricks, which must be applied to each block. The following brands are currently produced:

- ШВ, ШУС.

The thermal conductivity of fireclay bricks of these varieties allows them to be used in industry - for lining the walls of gas ducts of steam generators and convection shafts.

Dimensions and refractoriness of different grades of fireclay bricks.

- SHA, SHB, SHAK.

The most versatile and therefore popular refractory blocks, used mostly by private owners. They are used especially often when laying fireplaces and stoves. Can be used at temperatures up to 1690 degrees. In addition, they are highly durable.

- ShK.

Used in the construction of coke production units.

- SHL.

A lightweight type of material used for lining furnaces with a relatively low heating temperature - no more than 1300 degrees. The low weight of refractory blocks is achieved by increasing the porosity index.

- PV.

Used in the construction of chimneys. They can also be used for laying internal fireplace walls.

- PB.

Most often they are used in structures for domestic purposes, an example of such a structure can be a barbecue oven.

It is the marking when purchasing the material that must be studied in the first place, which will allow any builder to choose exactly the type of fireclay brick that is most suitable for the design features. And after studying the information provided, anyone can be sure that fireclay bricks do not pose any danger to humans, and even more so mythical harm.

How is fireclay brick made?

This question is also asked quite often, so in the article we considered it necessary to give a detailed answer to it. In the Russian Empire, refractory bricks began to be used as early as the 17th – 18th centuries. The beginning of its use was due to the development of technologies and the need to obtain a heat-resistant material that could be used in industry.

Externally, fire-resistant bricks of the Enlightenment did not differ from those that were used everywhere, but, unlike them, they could without damage to yourself withstand temperatures of 1200 ° C and above.

We found such a solution experimentally, but since those distant times, nothing has fundamentally changed in the production technology of this building material. It's just that it contained clay that went through the firing procedure. She was the basis of the composition. Its content in the product could be 70% or even more.

Related article: The volume of mortgage lending for home purchases is growing

Graphite was most often used as a binder (it could be replaced with coke powder). But the general standard was adopted only in the XX century, or rather, in 1927. A German-made brick, with dimensions of 250 × 120 × 65, was used as a sample.

Chamotte, a material used in the production of refractory bricks, is formed as a result of firing clay at high temperatures - 1300-1500 ° C. This procedure, as a rule, takes place in shaft or rotary production furnaces. In a word, the task of firing is getting rid of the plasticity of the material and giving it subsequent refractoriness.

Chamotte can be roughly divided into two types - "highly annealed" and "low-burned".Their differences lie in the fact that the first type has a degree of water absorption - up to 10%, and the second - up to 25%.

Products from fireclay are used for interior facing of fireplaces, chimneys, stoves. Also, the material has become quite widespread in architecture and even sculpture (second half of the 20th century).

It is quite easy to recognize a fireclay product by its appearance. It has a sandy yellow color and a slightly grainy texture. Such material can be used not only from the point of view of functionalism, but also aesthetics. Let's just say that in appearance, brickwork made of refractory elements looks quite presentable. These bricks not only fulfill their direct function - the accumulation, preservation and release of heat without damage to themselves and deformation, but also give the fireplace an attractive authentic look. In general, to put it simply, it is not only functional, but also quite beautiful. Let's just say that the masonry will fit perfectly into the design of a cozy interior.

What properties should a refractory brick have? First of all, it is resistance to high temperatures, which is quite logical. Without damage to itself, the material must be able to withstand a lot of heat and cool. It must also have a low heat conduction capacity in order to retain heat inside the stove and / or fireplace. In addition, the material must have a large thermal inertia so that it can slowly release heat to the environment, as well as a large heat capacity, in order to be able to accumulate a large amount of heat.

Price

For the construction of fireplaces, barbecues, stoves, refractory bricks are used. The price of the material depends on the brand, size, design features and manufacturer. To compare prices for October 2015 in Ukraine and Russia, 4 types of popular fireclay bricks were selected. When ordering a pallet, there are 350-360 bricks. The cost is indicated for 1 piece.

- A rectangular product SHA-5 in Russia is estimated at 39.9 rubles.

- Similar to the previous refractory, ShA-8, which is slightly larger, costs 47.9 rubles.

- SHA-22 (end wedge): price in Russia - 49 rubles.

- SHA-45 (end wedge): the cost of the product in Russia is 41.2 rubles.

Fireclay brick brands

Each refractory chamotte block is sure to be marked by which you can find out the main technical characteristics and parameters of the material. Today fireclay bricks are produced in different brands. Let's designate them:

- SHA, SHB and SHAK. These all-purpose brick blocks are the most popular among private builders. Fireplaces and stoves are laid out on their basis. Bricks of these brands can easily withstand temperatures up to 1690 ˚C and are famous for their durability. In this case, you can see the ideal price / quality ratio.

- SHUS and SHV. The heat capacity of fireclay bricks of these grades is at a fairly high level, and therefore they are used in the industrial sphere - for lining the walls of convection shafts and steam generator gas ducts.

- PB. These products are more often used for domestic purposes, for example, for laying barbecue ovens.

- PV. Bricks of this brand can be used in the construction of chimneys and internal walls of fireplaces.

- ShK. Products are taken for the manufacture of units for the production of coke.

- SHL. This is a lightweight fireclay brick, which is actively used today for lining various types of furnaces with a heating temperature of no more than 1300 ° C. Due to its low coefficient of expansion, this material can also be used for cladding hearths. ShL brick is produced in more than 50 standard sizes. The most popular among builders subspecies of lightweight blocks: ШЛ-0,4; SHL-0.9; SHL-1; SHL-1.3. The products owe their low weight to their high porosity values.

- ShTSU. These are double-sided end brick blocks that are used for laying rotary kiln structures.

Each brand has its own dimensions of fireclay bricks, weight and specific technical characteristics.And every brand, moreover, is represented by a whole range of product varieties. As an example, let's take the brands ША and ШБ. Brick ША 8 contains in its composition more aluminum oxide, which somewhat increases the indicator of its fire resistance in comparison with the same size block of grade ШБ 8. Naturally, these differences also affect the final cost of the material.

It turns out that labeling is the first thing you need to pay attention to when buying material. How to read the markings on the product? Suppose that the block reads: "SHA-5 SL:"

Such a mark means that we have a fireclay aluminosilicate block in front of us. The letter "A" informs that the brick is made according to GOST and belongs to class A fire resistance. The number "5" indicates the geometric parameters of the products, according to the standardized table (in our case, it is 230 * 140 * 65 mm). And the last combination of letters indicates the manufacturer.

Which refractory brick is suitable for the oven?

Heat-resistant brick for the oven must be selected based on the power and size of the unit. For a home or sauna heater, it is better to use fireclay blocks marked ШБ for the interior decoration of the combustion chamber and the cooking cavity; blocks with the index "PB" are suitable for the chimney.

You can cover the outer layer, depending on the general color scheme of your room, with oven bricks marked M-150.

Construction of a firebox with fireclay bricks

Every detail can be made from the best material. For the manufacture of an external wall that will be plastered or a foundation, refractory bricks with geometric deviations can be used. Such a low-grade brick costs much less, but will require more attention during installation.

For a sauna heater, you will need to buy a non-chamotte and non-quartz material - this is work for ceramic waterproof block brands. For this, clinker tiles are best suited - but such material is expensive.

Important! When choosing a material for construction, one should not pursue its cheapness. Be sure to check all documentation and quality of materials.

Properties and characteristics of fireclay bricks

The maximum density of chamotte leads to high thermal conductivity. The blocks absorb heat and immediately release it into the environment. This is the result of the absence of air in the material. The pores are his receptacles. There are no pores, no gas filling of the bricks.

The absence of pores also makes it difficult for the blocks to adhere. The mortar for fireclay bricks must penetrate into its top layer. But as? We have to take adhesive mixtures with high adhesion, fluid, capable of penetrating into the smallest pores and cracks.

Losing the property of retaining heat, chamotte acquires hardness and strength. At the same time, the resistance of the blocks to chemicals and moisture is increasing. The minimum moisture absorption of fireclay bricks is 6%.