Diy fireclay brick

It is interesting to know that you can make a refractory brick with your own hands if you have the necessary equipment. For this you need:

- Fire-clay... We need plastic and refractory.

- Chamotte... Crushed bricks from past firing can be used.

- Sawdust... It is best to take small sawdust from the furniture industry.

- Wallpaper glue... Increases the strength of bricks.

- Liquid soap... Used cheaply in large bottles, it prevents bacteria in the material.

How to make a molding solution:

- Dilute 5 kg of dry clay with water, add 1 kg of chamotte, 50 g of soap and 50 g of wallpaper glue.

- Pour 4 kg of sawdust into the mixture in small batches.

- Leave the solution to stand for 2 days.

How to mold fireclay bricks:

- Prepare molds of the required size, taking into account that the brick will decrease by 10-15% when it dries.

- Form the raw into molds.

- Dry the brick on a board or fiberboard for 2-3 days.

- Burn the material in a homemade oven, inside the chamber, which has spirals. The process lasts 7 hours, during which the temperature is gradually increased to 1200 ° C and another 3 hours at the same temperature.

- After firing, fireclay bricks are ready for use.

How to cut fireclay bricks?

It is important to know how to cut refractory bricks, because this material is very durable. Experienced builders advise using a grinder with a diamond disc for this, it can be used for a long time

It should be written on it that it is intended for bricks as well. It is better to soak the brick in water for 20 minutes before cutting. Then make markings on it and start sawing. To trim the material, you can take a grinder with an abrasive wheel.

Advantages and Disadvantages of Refractory Bricks

Like any other building material, fireclay bricks have specific advantages and disadvantages. The advantages include, first of all:

- high heat resistance... In addition, fireclay blocks withstand cyclic temperature loads well;

- low thermal conductivity. The use of heat-resistant blocks can significantly reduce the temperature outside the combustion chamber;

- slight volumetric and linear expansion. When heated, the dimensions and shape of the structure practically do not change;

- slow warm-up. Due to the low heating rate of the working surface of the brick, hot combustion products are promptly removed through the chimney;

- long period of operation;

- high mechanical strength.

Among the disadvantages, the most significant are:

- high price. High-quality fireclay bricks are 50-200% more expensive than conventional ceramic counterparts. In this regard, it is advisable to use heat-resistant brick exclusively for heat-resistant masonry;

- insufficient moisture resistance. When moisture enters the structure of the material, further heating leads to the formation of steam, which creates internal stresses in the blocks, which can lead to their premature destruction;

- the need to use special adhesive mixtures... For laying fire-resistant bricks, expensive fireclay compositions are used as a binding material;

- the material is difficult to machine.

Despite the disadvantages inherent in the material, fireclay refractory bricks are the best option for laying structures operating at high temperatures.

Advantages and disadvantages

Most customer reviews distinguish fireclay refractory bricks due to a good combination of price and quality. But to create optimal conditions for the operation of factory furnaces, carbonaceous and basic types remain predominant.They have a higher price, but they have an increased service life in difficult conditions.

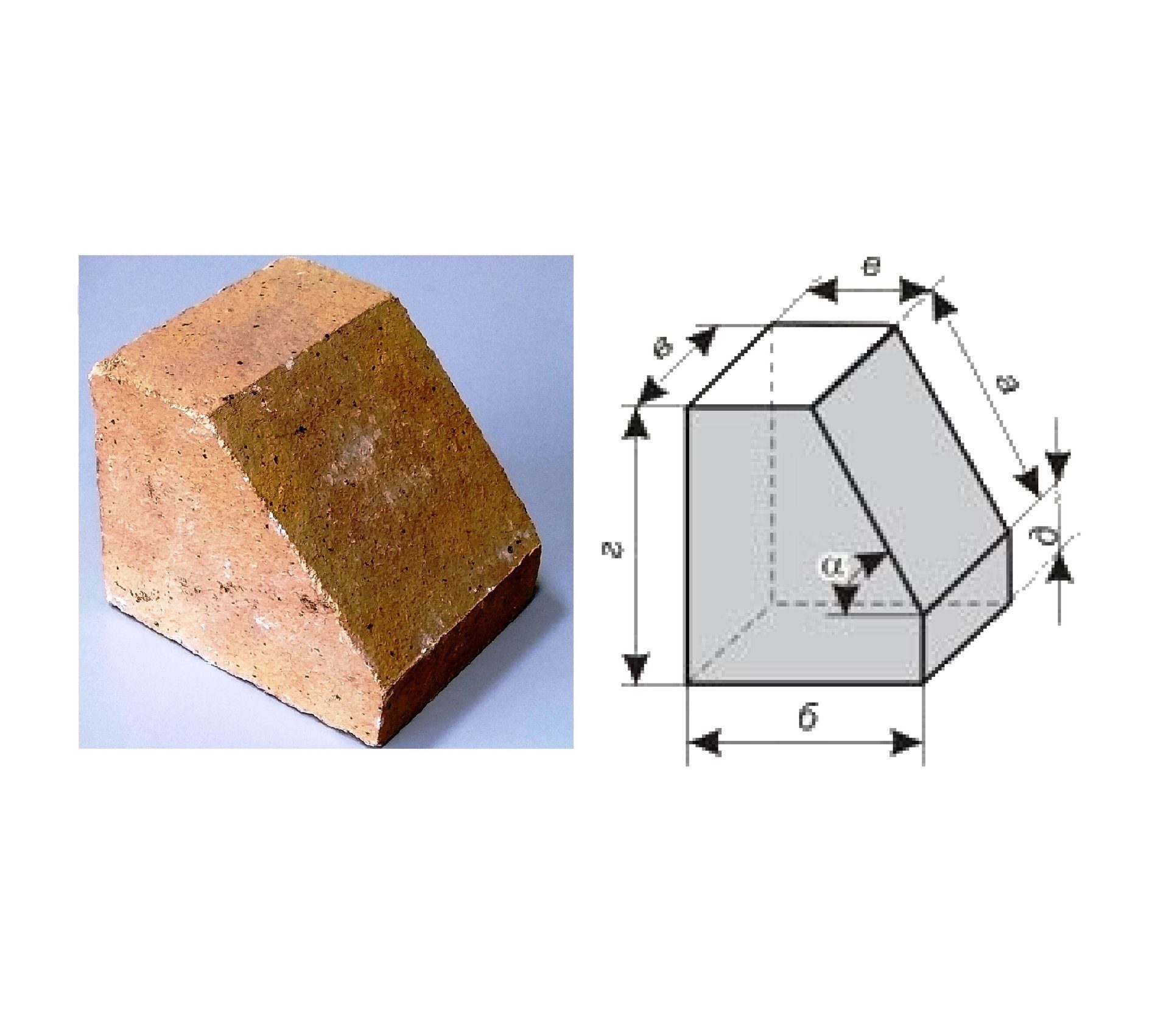

In the photo, according to the peculiarities of the laying of refractory bricks, one can assess the complexity of the work: the presence of the slightest irregularities is unacceptable. An uneven layer of mortar can lead to the destruction of the narrowed part of the joint under the influence of temperature. The mixture itself must comply with building codes. Correct placement of refractory bricks allows you to maintain the integrity of the industrial structure for many years

Carrying out the construction of a fireplace or a household stove is equally important. In this, users will be helped by professional video compilations with instructions for the storage and subsequent use of different types of refractory bricks.

Varieties of bricks and their use

First you need to decide on the goals - what exactly do you need a brick for? For example, you need to build a house - in this case, it is better to use clay brick, also called ceramic. In general, this brick is notable for sufficient strength, has sufficient density, withstands frost well, and has a long service life.

For facing internal and external walls, ceilings, silicate bricks are produced, which are produced by mixing lime and ordinary sand. This type of brick has a smooth, dense surface. But its heat and moisture resistance is much lower than that of ceramic.

If a brick building is exposed to high temperatures, a special type of brick is needed, not only will it not melt and not change its shape, but also will not lose its properties when cooled. Due to these qualities, refractory bricks are used in the construction of hearths, fireplaces, stoves - that is, where fire insulation and the ability to accumulate and give off heat is needed.

Depending on the addition of quartz, coke or graphite powder to the composition, different types of refractory bricks are obtained, used for different purposes. The choice of a particular type of brick depends on the heating temperature and the chemical properties of the substance included in their composition, on the properties of fuel and ash.

The industry produces several types of refractory bricks: quartz, basic carbon and alumina.

Quartz brick, unsuitable for contact with alkali, lime, iron oxides. It is better to use it for the manufacture of vaults of stoves, fireplaces.

Basic and carbon bricks are used in metallurgy and special industries.

Fireclay or alumina bricks are formed when more refractory clay and special powder are added to the brick composition. This powder - chamotte - gave the name to this type of brick. If you overexpose such a brick, then its surface will look like glass. This will give it much greater strength, but it will be much worse to bond with the solution. Therefore, it is better not to use such a brick in the construction of stoves and fireplaces, but it is just suitable for laying the foundation.

Fireclay brick

Unlike quartz bricks, refractory fireclay bricks can withstand much higher temperatures and are not affected by alkaline materials and iron oxides. Such a brick conducts heat well, which contributes to the rapid warming up of the room. And the variety of shapes of such a brick is great. For example, wedge-shaped, which are used when laying vaults and arches. In view of all these properties, this building material is better than others for household use. In appearance, it differs from others in color - from light brown to sandy yellow, with an admixture of granular inclusions.

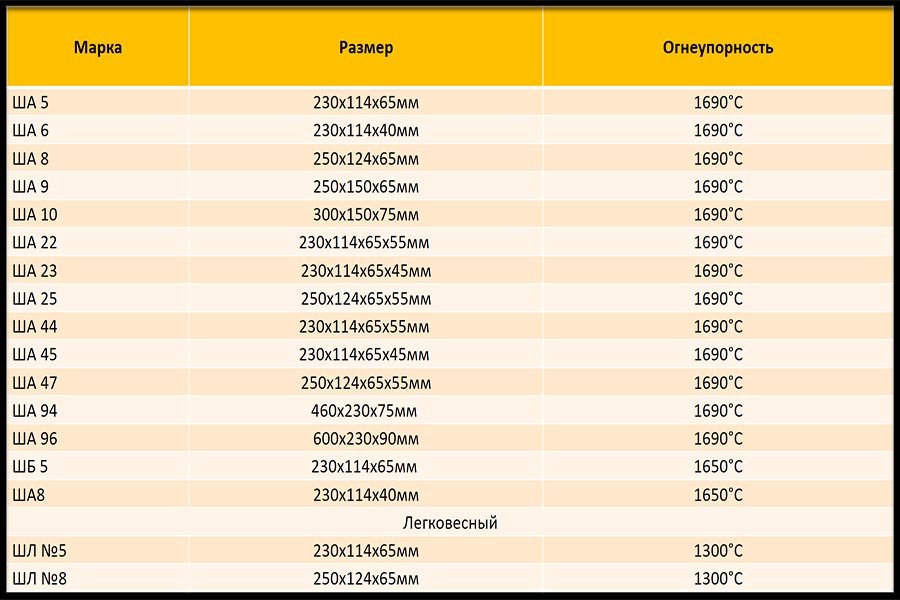

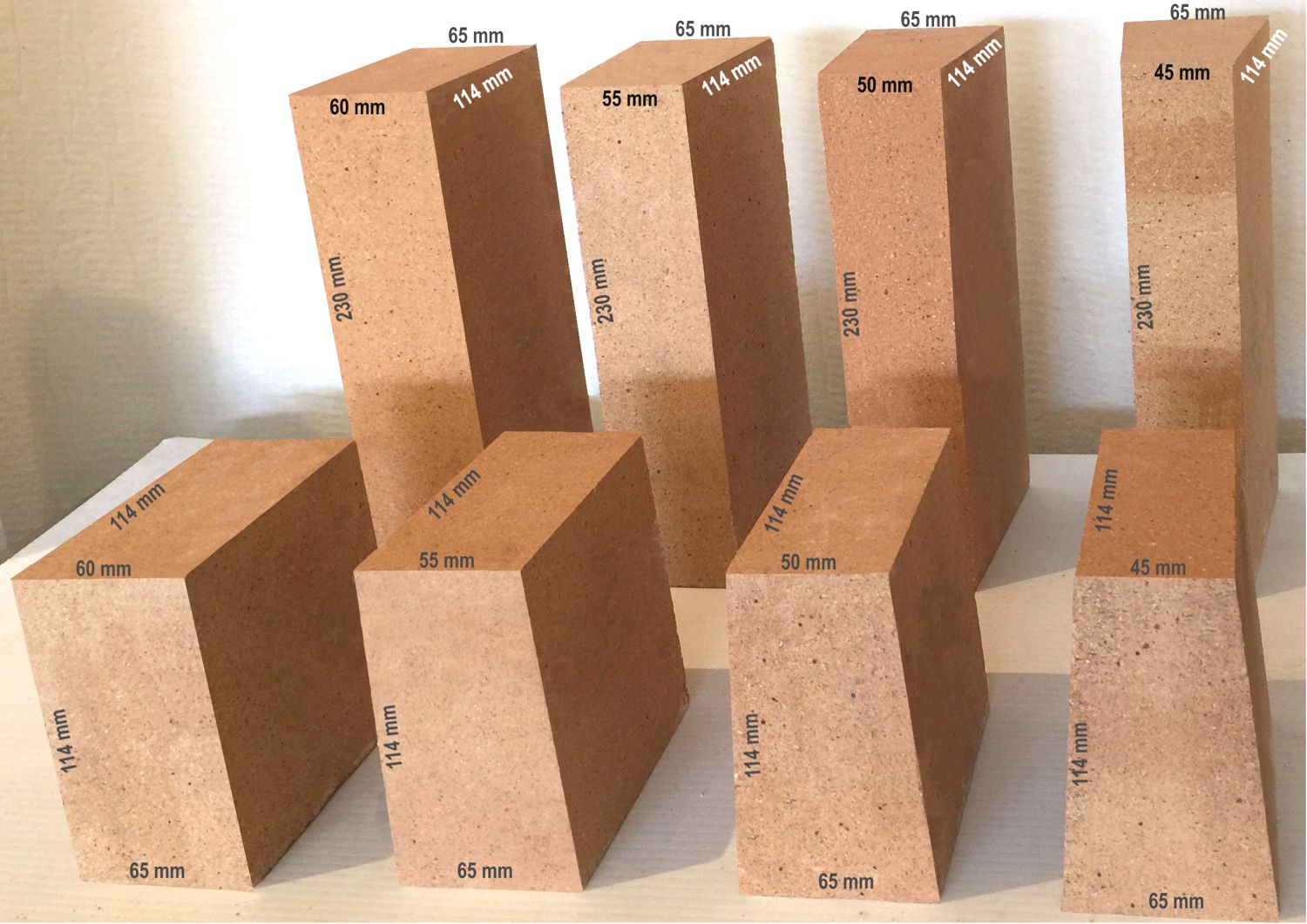

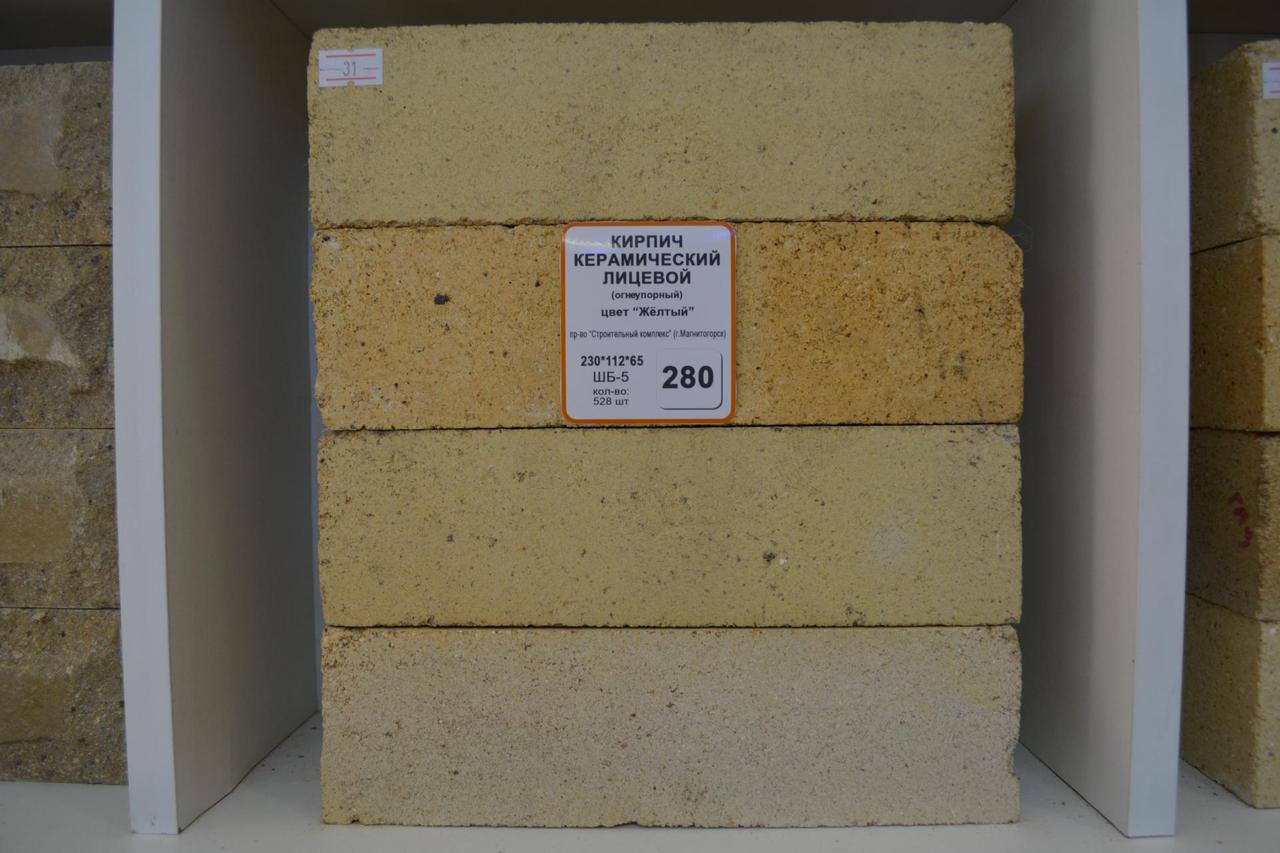

Depending on the composition and density, this building material has several markings. The most suitable for laying stoves and chimneys are bricks marked ША-5, ШБ-5, ША-8 and ШБ-8. This is due to the average density and weight.The chemical composition of refractory bricks is standardized by GOST 390-96, and the dimensions are determined by GOST 8691-73. When laying such a brick, it is necessary to carefully adjust them to each other so that the seams are as thin as possible. As a solution, a special mixture of refractory clay and crushed refractory bricks is used. One of these solutions is called fireclay mortar.

Important material indicators

Fireclay bricks of brands ША, ШБ and ШВ are made from 2 components: fire-resistant kaolin clay and fine fireclay powder extracted from minerals based on aluminum oxide. The components are mixed in certain proportions. Refractory products are made from the mixture by molding and heat treatment using specialized equipment. Making fireclay stone at home is unrealistic.

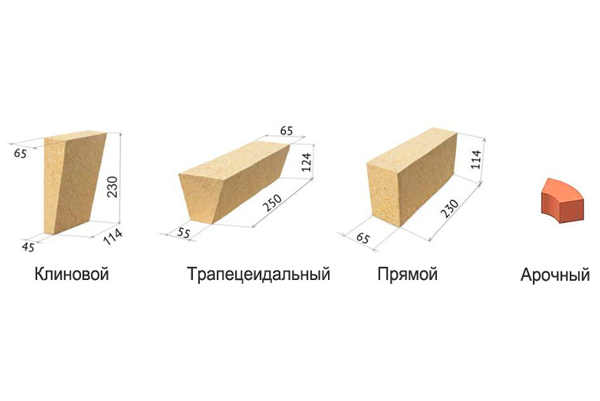

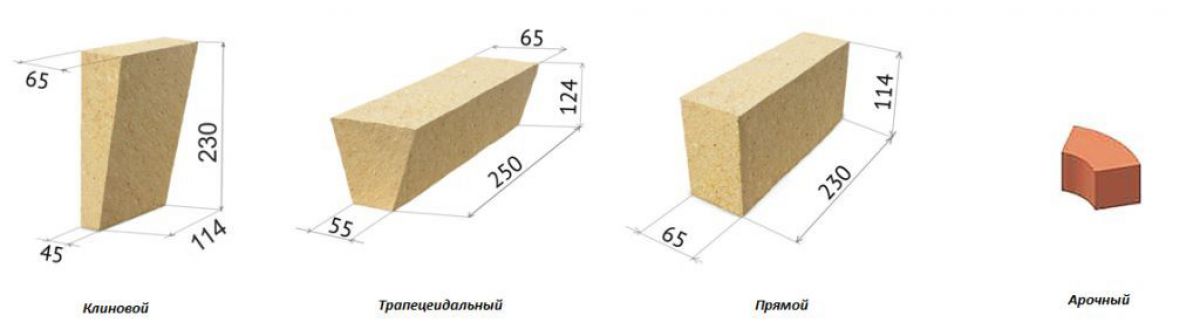

Unlike ceramic and silicate bricks, fireclay bricks are produced in a variety of forms:

- standard straight line;

- bream;

- hearth tile;

- wedge-shaped for laying semicircular vaults;

- trapezoidal;

- ribbed;

- heel;

- suspended.

Scheme of fireclay bricks production.

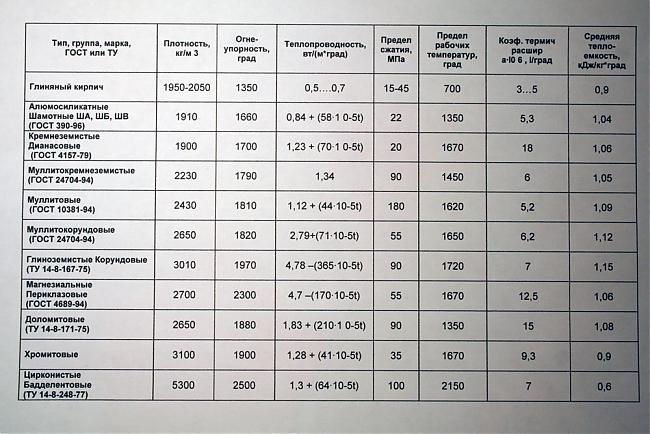

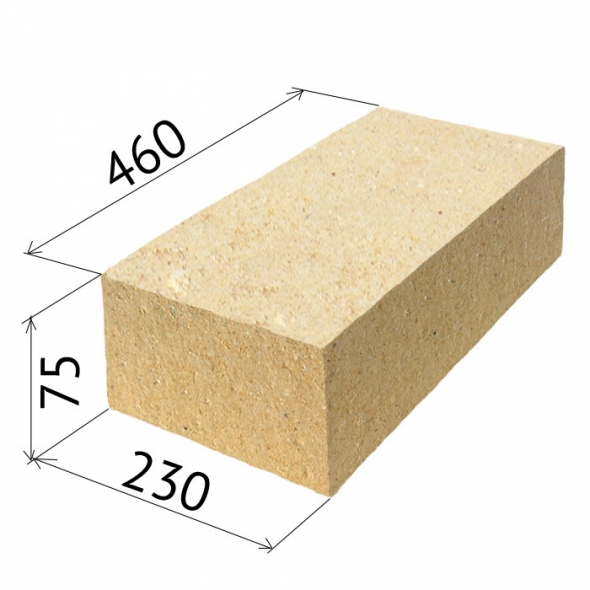

In private housing construction, direct fireclay bricks are most often used, the rest of the varieties are used in industrial production. The material plays the role of the inner casing of furnaces for various purposes, where the temperature reaches 1400 ° C and above. This is facilitated by the special technical characteristics of the material given in the description of GOST 390 of 1996, which it must comply with:

- The maximum allowable temperature (refractory index) for grade ША - 1690 ° С, ШБ - 1650 ° С, ШВ - 1630 ° С.

- Working temperature - 1400 ° С.

- The density of the refractory is from 1500 to 1700 kg / m3;

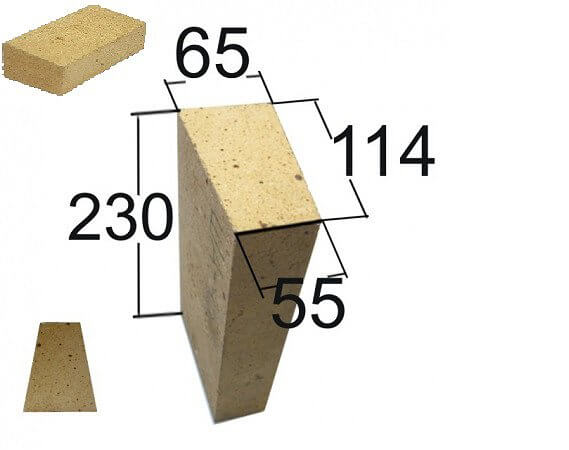

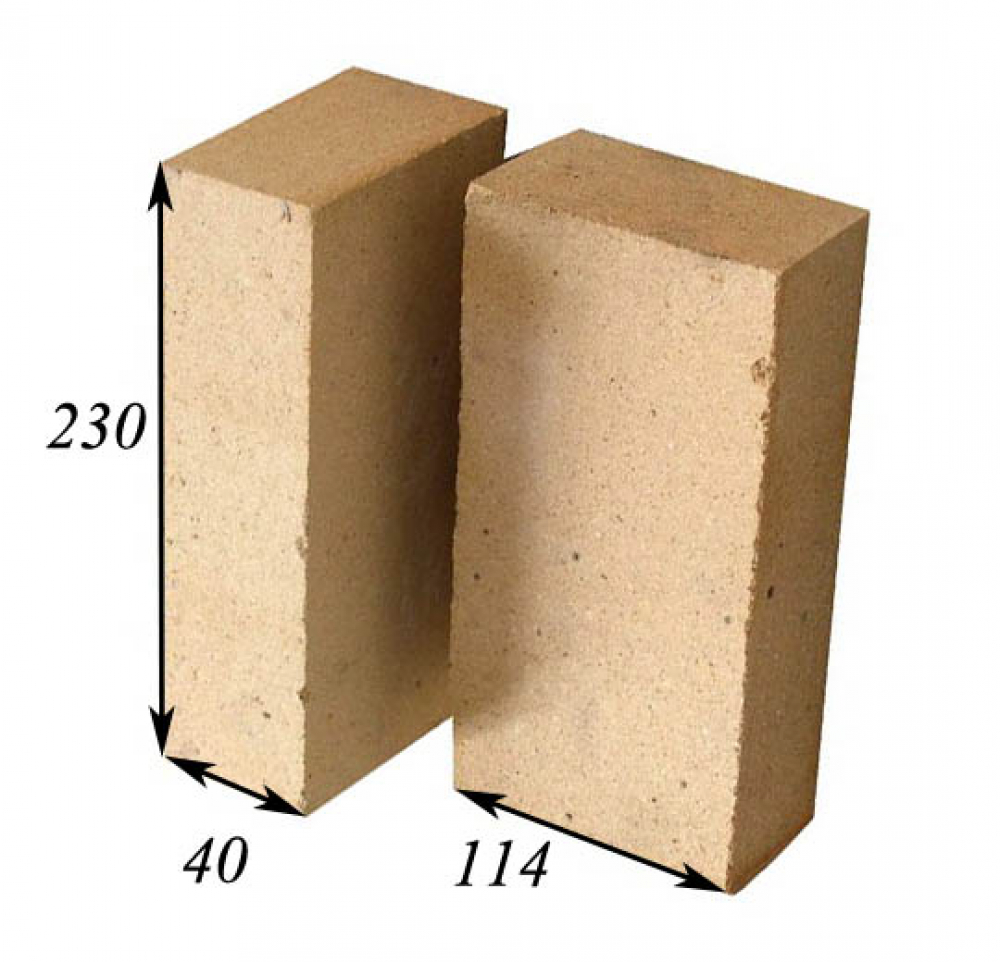

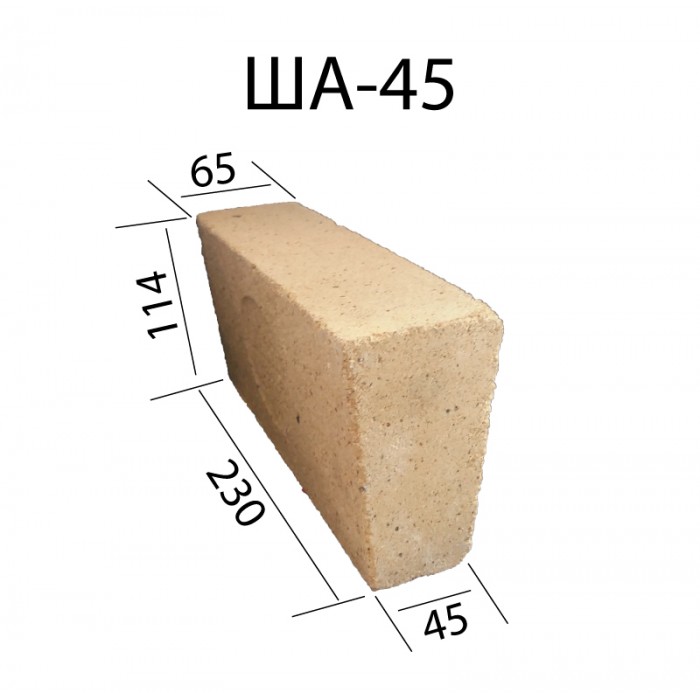

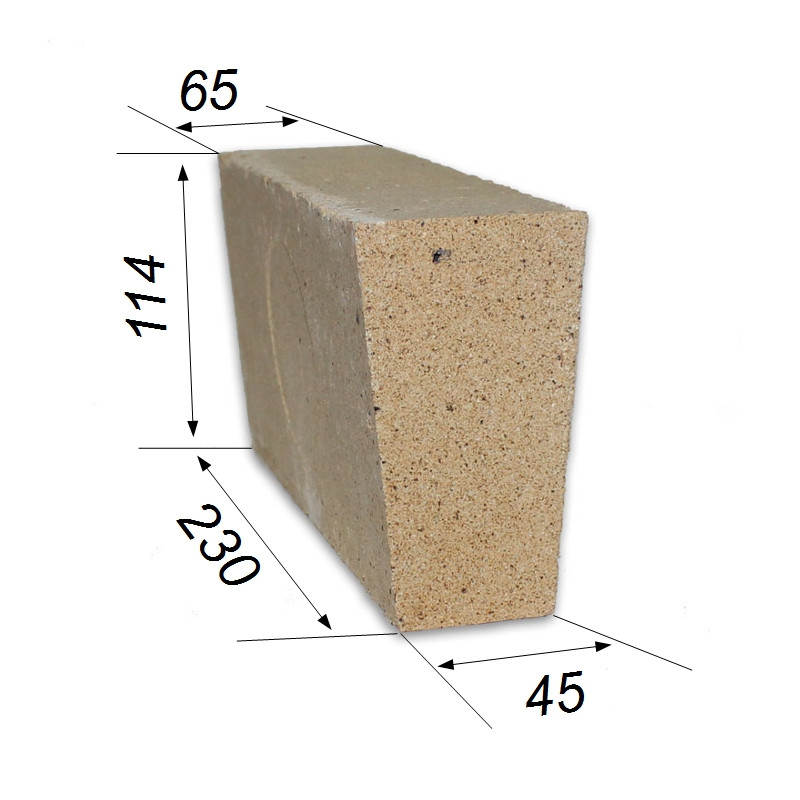

- A standard stone ШБ 5 has a weight of 3.6 kg, while its dimensions are 230x114x65 mm.

- The thermal conductivity coefficient is from 0.6 to 0.7 W / m ° C. For comparison: for silicate bricks it is 0.95 W / m ° C, for ceramic - 0.35 W / m ° C.

- The volume fraction of open pores for SB grades is no more than 24%. Hollow fireclay stones are not produced.

- The maximum compression that the piece can withstand without destruction is 20 N / mm2.

Some manufacturers produce fire-resistant building stones according to their own specifications, which do not coincide with the requirements of GOST. Such refractories have a different marking, for example, brick Ш 8 (the second letter is missing). The letter "W" means that the product has a proportion of chamotte powder of at least 30%, the figure indicates the dimensions, the values of which are prescribed in the standard. The second letter indicates the class according to GOST, for example, fireclay brick ШБ 2 with dimensions of 230x85x65 mm.

Manufacturing technology

High-quality fireclay bricks can be obtained only with strict adherence to the technology of its production. Otherwise, it loses some of its properties. A conforming product is defined by:

- by the correct geometric shape;

- thin edges;

- rough surface;

- distinct granular structure;

- characteristic sandy color;

- the metallic ringing it makes on impact.

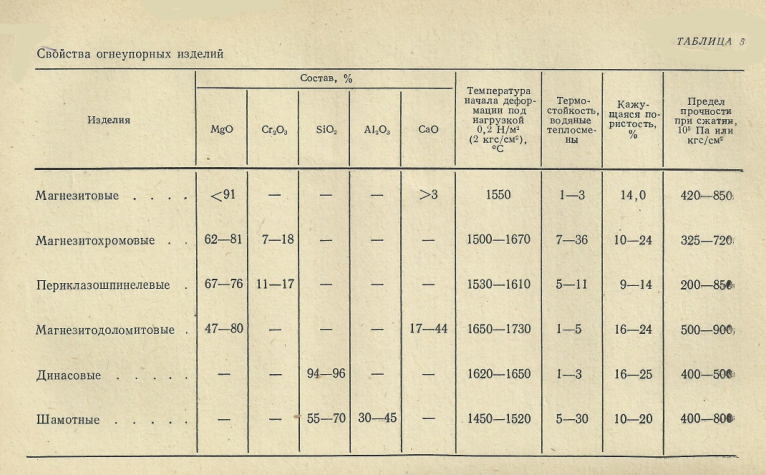

Refractory Comparison Chart

Getting fireclay

The peculiarities of making fireclay bricks consist in firing special refractory clay with fireclay powder at a high temperature. All raw materials used in the original raw material mixture are highly refractory.

Chamotte is a powder obtained by intensive firing of kaolin at 1300-1500 degrees. The hydrous aluminum silicates, of which it is composed, lose water molecules during firing and partially sinter. Clay loses its plasticity. Depending on the composition of the raw materials used, chamotte can be:

- high-alumina;

- corundum;

- zircon.

The degree of sintering determines the type of chamotte:

- highly burnt chamotte has a hygroscopicity of 2 to 10%;

- the hygroscopicity index of low-burnt bricks is 20-25%.

Preparation of the raw material for firing

Refractory clay, when entering production, consists of lumps of different sizes, which are crushed and ground. And then they are sorted by volume. After adding all the components, the raw mass is mixed until a homogeneous mass is obtained, at the same time liquid components are introduced into it.

At the initial stage, the blocks are dried. The finished mass is distributed over previously prepared forms. They are covered from the inside with a special compound that prevents overheating of the mass in any part. During drying in the chamotte mass, physicochemical processes take place associated with the destruction of bonds and the removal of water molecules. During the drying process, the moisture content of the products is reduced to 2-4%.

Firing bricks

The quality of the final stage of production depends on the conditions of its course. When firing raw bricks, the following processes take place:

- evaporation of residual moisture;

- decomposition of kaolinite, accompanied by slight shrinkage of products;

- decomposition of calcium and magnesium salts;

- sintering a homogeneous mass.

Brick firing scheme

Violation of at least one of the specified process parameters will lead to a decrease in the quality of the fireclay block. A glassy surface and a darker shade indicate that the firing time has been exceeded.

Overexposure in the kiln gives the bricks additional strength, but reduces its refractoriness, and a smooth film reduces the adhesion of the brick to the mortar. Brick underexposed in the oven has increased hygroscopicity and low resistance to deformation.

Specifications

During the operation of the furnace, fire and the products of its combustion directly affect the refractory brick. Moreover, its contact with acids, alkalis, and other aggressive media is practically zero.

Accordingly, the manufacturer and the buyer do not impose any special requirements for the durability of the material.

Due to its technical characteristics, fireclay bricks are not recommended to be purchased for the construction of structures that will be in direct contact with acids and other representatives of an aggressive environment.

Moisture accumulation

Fire-resistant material is produced on the basis of clay, which is fired, and as a result changes its structure (the brick becomes porous).

Kiln firing

The voids in the brick itself contribute to the insignificant accumulation of moisture that occurs during contact with water. Porous heat-resistant bricks can accumulate forty percent moisture. This feature of the fire-resistant material must be taken into account during warehousing and storage.

Frost resistance and fire resistance

Products where heat-resistant bricks are used, due to their design, are distinguished by high frost resistance and fire resistance. According to current regulations, these characteristics are assessed by the ability to withstand the specified freeze and thaw cycle.

Let's pay attention to the indicators SHAK, SHA, B and B. In this case, they cannot be more than 15 cycles

Refractory material should not be used in the construction of basement structures. Also, it is not suitable for outdoor cladding.

When a building is provided with stove heating, it is necessary to always maintain a positive temperature. Cooling down to extremely low temperatures on a regular basis will affect deformation and possible fracture.

Refractory materials of different types are presented on the market in 11 standard sizes, each of which stands out for its length, thickness and height.

| Number | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 6 a | 7 | 8 | 9 | 10 | |

| D | 23 | 23 | 23 | 23 | 23 | 23 | 23 | 25 | 25 | 30 | 34.5 |

| T | 6.5 | 6.5 | 11.4 | 11.4 | 11.4 | 11.4 | 15 | 12.4 | 12.4 | 15 | 15 |

| V | 6.5 | 6.5 | 10 | 7.5 | 6.5 | 4 | 6.5 | 7.5 | 6.5 | 6.5 | 7.5 |

Refractory bricks of different types can have maximum deviations:

- length. An error of no more than 0.5 cm is allowed;

- width. An error of no more than 0.3 cm is allowed;

- thickness. An error of no more than 0.1 cm is allowed.

Before entering the market, finished products must undergo control of manufacturing accuracy, as well as conformity of shapes.For this, special independent departments are being created at the enterprises. Products are checked selectively from each batch produced.

Strength indicators

Special fire resistant bricks will resist these factors. The strength of all future products is based on strict adherence to technological standards and recipes. The admissible maximum strength stands out for fireclay bricks. The indicator of the SHAK brand is equal to twenty-three N / mm 2.

Such material is often used for masonry of household and technological structures at industrial facilities. It is also often purchased for arranging fireplaces and stoves. When a buyer chooses a certain brand of brick, it is strength that plays a decisive role here.

Indicators of exposure to temperatures

When firing, chimney ducts and pipes cannot do without high-temperature combustion products. Therefore, the materials used that are purchased for the construction of the structures described above must be characterized by increased temperature standards.

The requirements that the materials of other components of the stove or fireplace must meet are not so stringent. So, a brick for a chimney can withstand up to six hundred degrees Celsius.

Brands and sizes

According to GOST 8691-73, the following brands of furnace blocks are distinguished:

- ША is an ordinary refractory brick that can withstand a heating temperature of +1730 ° С. Its apparent density is 2-2.1 t / m 3. despite the rather high content of aluminum oxide.

- ШБ - the same chamotte, but for general purposes, which operates at +1670 ° С. It weighs a little less than ША (1.9-2.0 t / m 3), and is popular among private builders.

- PB and PV - semi-acid fireclay brick, which contains a large amount of silicon oxide (SiO2 ). It has a voidness of about 30% and a density of 0.9 t / m 3, which allows it to heat up more slowly and cool down just as long. These brands are used in the construction of barbecues, tandoors, barbecues and chimneys - they can be purchased at a very affordable price.

- SHL is a heat-resistant material with low weight already discussed by us above.

There are other types of refractories, but they are more in demand in the metallurgical and chemical industries. Regardless of the brand, the dimensions of fireclay bricks established by GOST must be maintained. You can determine the standard parameters for a specific single product by the index that comes immediately after the letter designation.

Truly working legal way to save money. Everyone needs to know this!

Brick can be made from fireclay clay by different methods: casting from slip or melt, semi-dry molding, hot or thermoplastic pressing. And this is not a complete list of existing technologies, since today many factories are seriously engaged in the development of new methods for the production of refractories with different characteristics.

Particular attention is paid to methods that make the brick also resistant to ultra-low temperatures.

For consumers, the most useful classification is where the refractory material is divided into types in shape and size:

- Straight and wedge-shaped (the latter can be bought for laying out arched openings and vaults).

- Shaped - found application in finishing works.

- Suspended - also go to the inner vaults, but already in powerful industrial furnaces.

Chamotte is also used to make pipes, heat-resistant casings, laboratory crucibles and other products.

Purpose and application

The refractoriness of chamotte clay has determined the main scope of use of products made from it. This is the construction of various furnaces or lining of furnaces and chimneys. After all, the combustion of fuel in their chambers and the removal of incandescent gases increases the temperature of the metal elements to such a high level that at the contact, ordinary brick melts and loses its plasticity, crumbling into crumbs when it cools.

The unsurpassed temperature resistance of chamotte allows the use of refractory bricks not only for the construction and lining of sauna stoves or home fireplaces. It is in great demand in hot industries: metallurgy, thermal power plants, chemical industry and glass-blowing industry.

Specifications

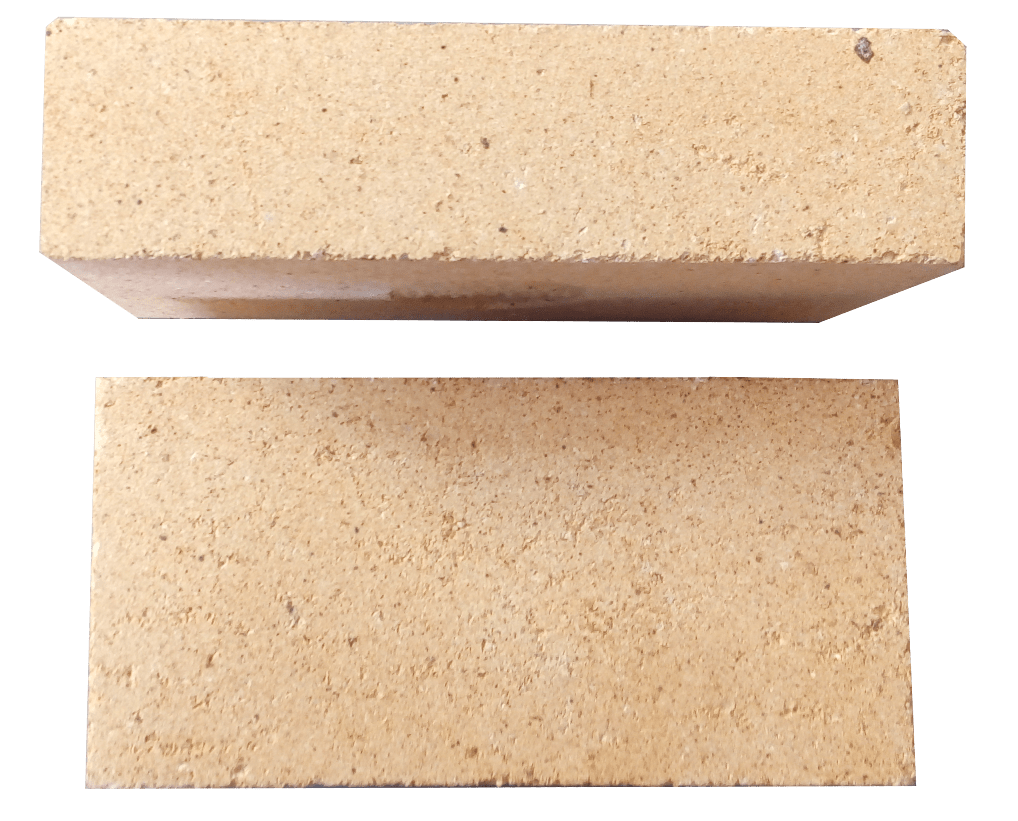

Fireclay building material made according to the existing technology has a number of operational features:

- the color of the product should be light yellow, rather straw with an admixture of brown blotches;

- the structure of the brick is only granular;

- when hitting a brick, a ringing like metal is heard;

- the material is characterized by an increased degree of strength, therefore, with a slight damage, the structure of the chamotte remains unchanged.

The advantages include the following parameters.

Strict geometry of parts is extremely important when using materials with a wedge-shaped bevel.

Heat resistance. The internal structure of the brick is not affected in any way by prolonged exposure to elevated temperatures, such a material can withstand heating up to 1500 degrees or more

It should be noted that, in principle, heating of more than 1000 degrees from all types of bricks can only withstand fireclay.

Low thermal conductivity. This characteristic, as well as the low density of certain types of material, make such a brick the best option for installing chimneys and various pipes.

Fortress. Fireclay materials have the ability to withstand even fairly strong mechanical stress.

Chemical resistance. Products made of chamotte perfectly tolerate the effects of various acid-base solutions and resist many other chemical reagents.

However, nothing ideal has yet been invented, and fireclay bricks are no exception. There are also negative aspects associated with its use.

- If the firing technology is followed incorrectly, then the dimensions of the products and their level of quality change significantly.

- Fireclay materials are not at all low cost, so they cannot be considered affordable for most of our compatriots.

- Not all solutions are suitable for masonry. Usually a special compound called "mortar" is used, and it must be applied very carefully, so that the layer is very thin.

- The increased strength significantly limits the ability to cut the material. It can only be cut with a special diamond blade for stone.

Standard sizes

Depending on the type of additive, firing method and purpose with refractory properties, products are divided into 4 classes:

- quartz (from sandstone or quartz);

- fireclay or alumina (clay products with the addition of fireclay);

- basic (differs in lime-magnesian composition);

- carbonaceous (from pressed graphite or coke).

The last two types are used in industrial enterprises. They can withstand significant temperatures. For home stoves, baths and saunas, a fireclay sample is usually taken. Quartz bricks withstand temperatures well, but break down under the influence of acids and other chemical factors.

The video tells about the dimensions of refractory bricks:

In construction, the following forms of refractory material are used:

- straight;

- corner;

- wedge-shaped.

A good brick for a stove can be used without fear for the quality of work.

Each type has its own markings and standard sizes. It is impossible to combine all types and brands of refractory bricks in one universal size. Initially, they had no standard at all. Their size was indicated in vershoks (inches). The standard appeared only in the 19th century. Until that time, each workshop produced bricks of its own size.

The first standard appeared on the territory of Russia in 1927. German brick was taken as a sample. Its dimensions: 250x120x65 mm are considered standard today. They were included in the GOST.It is generally accepted to consider this standard size as a normal format. It is marked with the letters "NF" (normal format).

The properties of ceramic bricks and its other features can be read in the article.

a sample of a normal format is easy to use: it is convenient for the master to hold it in his hand. All other sizes are derived from the normal format. Accordingly, the marking is as follows:

- 1 NF - 250x120x65 mm (single);

- 1.4 NF - 250x120x88 mm (one and a half);

- 2.1 NF) - 250x120x140 mm (double).

Fireclay brick size and other characteristics can be found in the article.

In GOST, there are other less common product sizes. This is the so-called euro brick - 0.7 NF (250x85x65 mm) and a single modular 1.3 NF - (288x138x65 mm).

The video shows the size of the furnace refractory bricks:

According to GOST 530-2012, all faces have a name:

Brick-like wall panels look very good for both exterior and exterior decoration.

The correct size makes the job easier. Standardization is used in the development of drawings and layouts. The documentation usually indicates a fixed size of the products.

Advantages and disadvantages

The main differences from red brick are the positive qualities of the material.

In addition to strength, high fire resistance and heat capacity, plasticity plays an important role and provides a wide range of shapes. Fireclay products look harmonious in combination with metal, wood and other natural materials

Long service life and appearance that does not require further finishing are also advantages. Chamotte is resistant to temperature extremes and negative environmental influences.

There are also disadvantages - the hygroscopicity of the material. Also, refractory bricks are more expensive than red ones. Due to its high density, the material is difficult to cut. To facilitate the work, use a grinder with a diamond disc. A special solution is required for styling. There is also a ready-made dry mixture - "fireclay mortar". You can make a solution yourself, no preparation is needed for this. It will be enough to grind the chamotte breakage, sift and add refractory clay in a 2: 1 ratio.

Fireclay materials are considered safe, because the main component - clay, which is an environmentally friendly substance, is not considered harmful to health. And even when heated, the brick block does not emit any hazardous substances into the atmosphere. therefore, rumors about the harmfulness of the blocks have no basis. Potential harm will be caused by material extracted for the production of bricks in contaminated or contaminated areas.

Types and marking of fireclay refractory bricks

Fire resistant blocks can be classified according to several criteria:

By molding method

The design of the molds and the features of the technological process provide for the following types of molding:

- casting from slips or melts;

- semi-dry forming;

- melting;

- hot pressing;

- thermoplastic pressing.

By block configuration

For the laying of various structures, the industry produces the following types of fireclay bricks:

- wedge-shaped;

- trapezoidal;

- rectangular (straight);

- arched profile.

By chemical composition

Depending on the additives used that affect the thermal stability and mechanical properties, and the characteristics of the production technology, the following modifications of fireclay refractory blocks are distinguished:

- basic. In the manufacture of such bricks, fire-resistant chamotte clay is used, the mass fraction of which in the working mixture is 70%. Coke or graphite powder can be used as a filler. The material is used for facing furnaces designed for melting Bessemer steel;

- carbonaceous. This modification is characterized by a high percentage of carbon. The main purpose of carbon refractory blocks is blast furnace lining;

- quartz. Due to the use of silicon oxide, the heat resistance of bricks is significantly increased, however, contact with an alkaline medium leads to intensive destruction of the material;

- alumina. Aluminum oxide is used as a special additive. Alumina fireclay brick can work for a long time at temperatures from 1100 to 1300C and is not susceptible to frequent temperature changes. This type of heat-resistant blocks is widely used when laying household stoves, fireplaces and chimneys.

The marking of fireclay bricks includes letters and numbers that reflect the chemical and physical characteristics and overall dimensions of the material. Below are the markings for the most common modifications.

SHA, SHB, SHAK. The materials have high strength and heat resistance (1600 - 1700C), which allows them to be used in all areas of industrial and civil construction. They contain aluminum silicate, which ensures a long service life and resistance to mechanical damage. Another advantage is the optimal price / quality ratio.

ШВ, ШУС. Brick is widely used in industry. High heat capacity indices allow the use of ШВ and ШУС blocks for the construction of gas channels of steam generators; from such blocks, enclosing structures are erected to protect convection shafts.

ShK. This variety is used for the construction of industrial facilities that produce coke.

SHL. SL brick is characterized by high porosity and low specific gravity. The maximum allowable temperature maintained by the blocks is 1300C. The main area of application is furnace lining.

ShTSU. Double-sided end brick. Most often, rotating elements of the furnaces are laid out from the ShTSU blocks.

PB. This modification is characterized by a high clay content, which significantly reduces the heat resistance of the blocks, but the price of the products is quite affordable for a wide range of consumers.

PV. The products are used for the interior masonry of stoves and fireplaces. PV blocks provide a long period of operation of the masonry and are capable of operating at temperatures up to 1300C. The scope of the material is limited by its high cost.