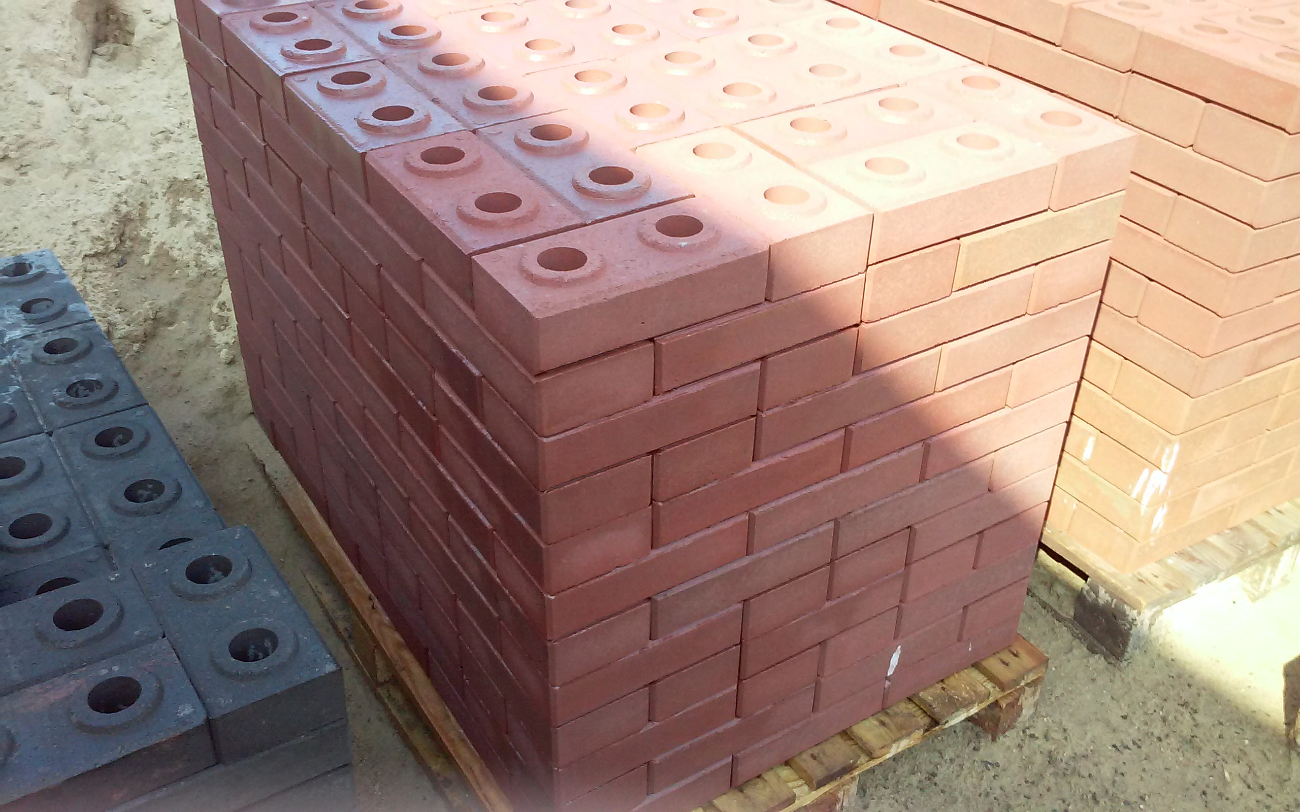

Product range

Before starting production, it is worth deciding on the type of product. Using special machines and dies, you can get the following types of Lego bricks:

- Standard. The most popular option, because most of the equipment on the market involves the manufacture of such products. Even in the absence of money to purchase other dies, the classic Lego brick should be on sale.

- Rail-like. This type of building material is in demand among professional builders. The main feature is the block stacking according to the rail principle. If there is a desire to enter a large market, the purchase of this matrix is mandatory. Its cost is within 25-50 thousand rubles.

- Simple. Lego bricks are produced by the piece. For aspiring entrepreneurs, this option is considered the most affordable.

- Original. The peculiarity of the matrix lies in the manufacture of individual sizes. These "templates" are purchased to fulfill specific orders.

- Combined. The main difference of the matrix is the possibility of simultaneous production of two or three blocks.

- Fitting. Lego bricks are combined not only from above and below, but also on the sides.

Lego brick making equipment - price

For the production of Lego bricks for commercial purposes or to meet the need for this type of building material, you will need to purchase the appropriate equipment. Production machines can be divided into two types: manual and electric. The former do not require additional costs from the owners, however, they differ in less productivity.

Machines, the productivity of which does not differ in high value (production of about 1 thousand pieces during a shift), can be purchased for 78-300 thousand rubles. If we talk about medium-power machines (about 2 thousand pieces during a working day), then they can be purchased for 350 thousand rubles. The equipment, which can be classified as a mini-factory or industrial-grade machine tools, is capable of producing about 750 bricks in one hour. The cost of such devices is more than 2 million rubles.

To organize the production of small volumes, you will need a machine weighing 750 kg. Thus, when creating your own Lego brick production, it is worth choosing a suitable room. The dimensions of a low-performance machine are: width - 1 m, height - 2 m, and length - 1.5 m. To ensure the operation of one such machine, there will be a sufficiently small area. At the same time, when buying more productive equipment, you should initially worry about providing free space. The same applies to business. Over time, the premises will have to be expanded to accommodate new machines.

Advice

When buying a Lego brick making machine, pay attention to the number of working cycles that it can withstand without the need for repairs. Manual ones usually withstand about 500 thousand cycles, while electric ones are more durable in this respect - about 0.6-1 million cycles

An important parameter is the amount of time that needs to be spent on the production of one brick. On average, this will take 15-30 seconds.

In addition, it is important to estimate how many bricks can be produced in one cycle. The more the machine can produce at a time, the faster the cost of its acquisition will pay off.

The strength of the brick depends on the pressure applied during its creation. Some of the machines develop an indicator of 2 tons, which is completely insufficient for the construction of a number of buildings. To obtain a brick that can be used in the laying of load-bearing walls, you need to create a pressure of about 30 tons or more.

Today, Russian manufacturers have been able to take their place in the segment of the production of machines for Lego bricks, displacing almost all importers of similar equipment. This is a rather rare case, as it is often cheaper to order a supply of equipment for small businesses from China. Some large companies are used, as a rule, to create large batches within a short period of time. Swiss steel is usually used for production. All products of foreign suppliers can be evaluated remotely, since they often leave reviews, which highlight both positive and negative aspects. One thing is invariable - their cost is several times higher than domestically produced machines.

DIY brick Lego. Brief overview of equipment and manufacturing technology

Before thinking about the organization of production, you need to accurately weigh the pros and cons, including data on costs and costs in the analysis. The first and most important thing to understand is the scale and organization of the technological process. Brick making is not a garage size. This process is large-scale, requires large production areas and verified logistics for the supply of material and delivery of finished products. This is when it comes to business.

If you make a Lego brick for yourself, you need to calculate the profitability of this venture based on the volume of your construction site and the cost of production at the construction site.

According to the standard technology for making Lego bricks, the following composition and proportions of the mixture are recommended:

- Sand - 10%

- Crushed stone screening - 70%

- Cement M500 - 20%

Cost of materials :

- Sand - 520 rubles / ton

- Screening - 185 rubles / ton

- Cement - 175 rubles / bag

Consumption and estimated cost per 1 ton of mixture

- Sand - 52 rubles

- Elimination - 130 rubles

- Cement - 700 rubles

From 1 ton of the mixture, 285 pieces of bricks are obtained. The cost of purchasing materials - 882 rubles. The cost of one unit is 3 rubles 09 kopecks. The number of ready-made Lego bricks per shift is from 900 to 4000 pieces in 8 hours (depending on the power of the machine).

The cost does not include:

- Possibility of purchasing unpackaged cement, which is significantly cheaper

- The cost of the plasticizer, they are different in consumption and efficiency. This needs to be analyzed separately.

- The cost of transport services for the delivery of materials

- Workers' wages

- Equipment depreciation and maintenance

- The cost of electricity if the press is not manual

Equipment for the production of Lego bricks on the Russian market is presented in a wide range. The simplest and cheapest solution is a manual molding press and a small concrete mixer. The cost of this device will be in the region of 45-65 thousand rubles. Of course, it is not necessary to count on serious volumes of manual production, here we are talking about 500-800 pieces per shift with intensive work with a partner.

The obvious advantages of hand-held equipment are low cost, compactness, mobility and the possibility of associated use. For example, having a manual machine for the production of Lego bricks on the farm, you can provide yourself with briquettes for heating from wood sawdust.

The cost of equipment directly depends on the effort that the press produces and the amount of automation that speeds up the production process. Also, the higher this indicator, the better the quality of the manufactured products. The cost of such a configuration starts from 200 thousand rubles for the simplest hydraulic press with a capacity of 1,500 pieces per shift and reaches 7-8 million for complete lines with an output of up to 10,000 pieces per shift.

Semi-automatic machine

Semi-automatic machine

Serious manufacturers offer services for calculating and drawing up a business plan for such industries, develop formulations of mixtures based on local conditions, and provide technical support to the manufacturer at all stages of operation.

High performance automatic equipment

High performance automatic equipment

The point of this article is not limited to advertising individual manufacturers and does not provide a one-hundred-percent get-rich-quick solution. Here we tried to formulate an idea, a dream direction for a person with an active life position. Reviews on numerous forums are also not the ultimate truth, here you can easily get to advertising techniques that sometimes do not give real information.

The main thing is to show perseverance, common sense and dedication, and the rest will follow and will definitely work out.

Features of lego brick masonry, or a fast-paced startup for novice builders

At the beginning of this article, it is no coincidence that we were ironic about botanical scientists. We in no way wanted to offend anyone, but the events of recent years, due to financial turmoil, are increasingly driving people out of their homes, forcing them to look for themselves in new, more profitable and demanded industries. One of these niches was and remains construction, in particular, the work of a bricklayer.

It is difficult to assume that waking up in the morning on a difficult Monday, a person decides to take a trowel in his hands and immediately begin to issue high-paying volumes. To become a skilled bricklayer, you need to drive out more than a dozen cubes under wise guidance, make and fix a bunch of "jambs", spend a lot of time and effort. Lego brick will help a beginner to save this resource and quickly move from the rank and file to the honorary officer corps.

The fact is that it is almost impossible to lay an interlocking brick unevenly. You just need to learn a small theoretical part, be careful and diligent. Everything else will happen almost without your participation.

Here is a short video that clearly explains the main aspects of laying Lego bricks.

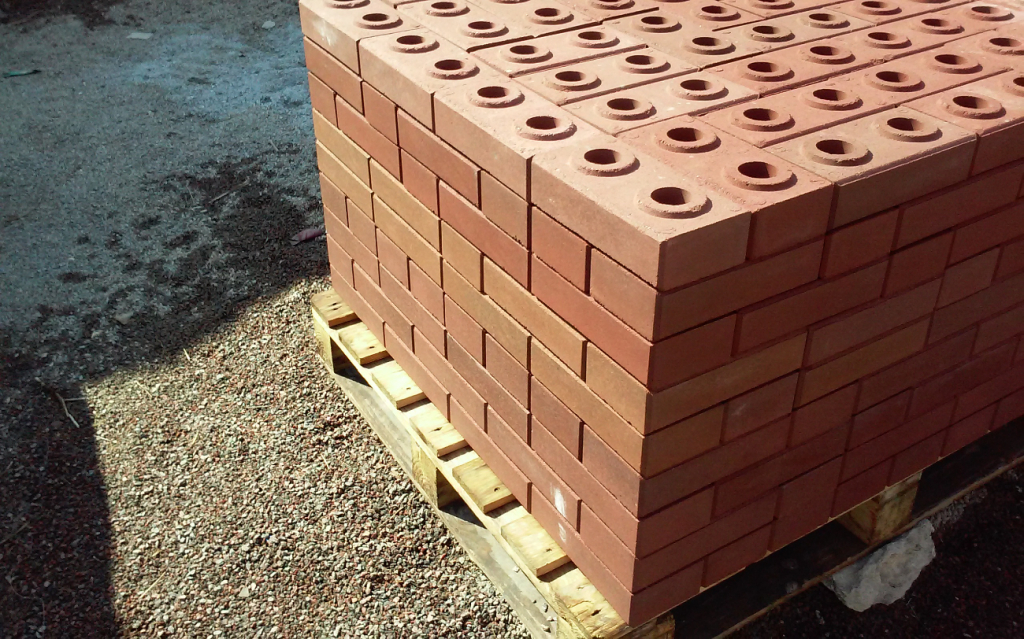

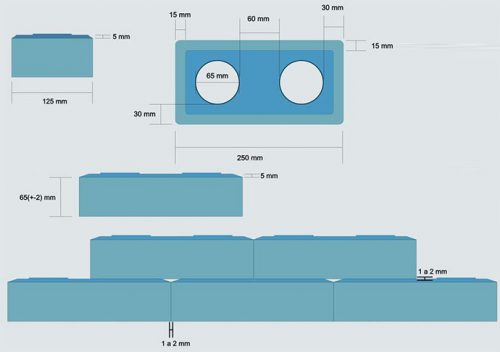

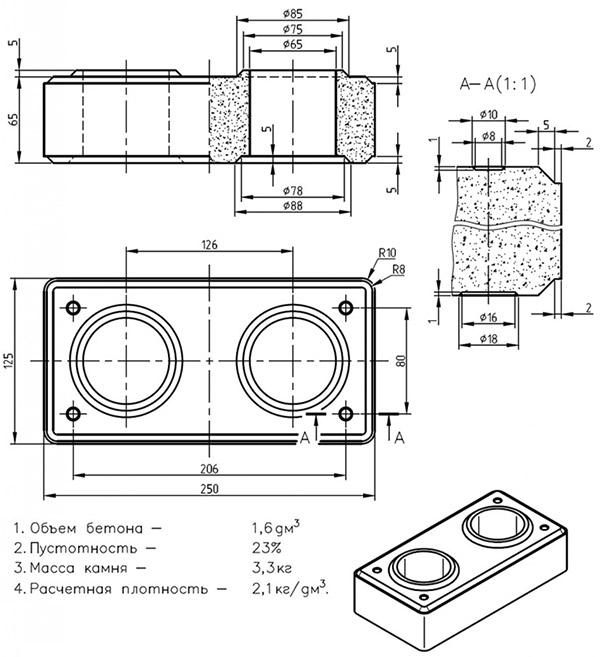

So what do we see? In a short period of time, the nimble Malaysian worker laid 154 bricks to cheerful music. With standard dimensions 250x125x65 of one piece, we have 0.3 cubic meters of masonry. The prices for masonry are different on the territory of our huge country, but for the base one you can take at a minimum, for example, 2000 rubles per 1 cubic meter. It turned out - about 600 rubles of earnings. Not bad?

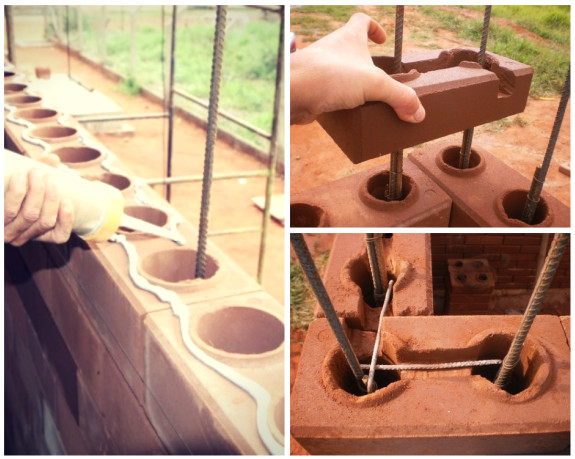

The most difficult and responsible thing is to lay the first row, here an exact level and correction of each brick is required. When erecting a building box, such a place will be the corners of the future building. If there is no experience, it is better to entrust this business to a professional. But then you just need to follow the installation scheme, do not forget about the reinforcement and embedded elements - things will go much more cheerful.

Of course, it is impossible to grasp on the fly all the details of the construction of walls, but if desired and due persistence, the learning process, and with it the paid or saved result, will come much faster.

Raw materials for lego bricks

In order to get a quality product, you need to buy raw materials for the production:

- A filler, its share is approximately 80 to 92% of the total mixture. In this capacity, crushed limestone screening is most often used.

- Components for knitting: cement or Portland cement, part of it - 8-10% of the total mass.

- Pigmenting ingredients are needed to color the bricks. It is usually yellow, black, red and brown.

- Various plasticizers, their use is optional, but the bricks made with its use have increased strength and density, their structure is more uniform, and the surface is characterized by increased smoothness.

When buying equipment for the production of Lego bricks, please note that in the instructions you can find several recommended recipes for this machine. There is no ideal recipe, as each region has its own characteristics of the starting material

If you calculate the cost of one Lego brick, you can find out that it is about 4-6 rubles. And on the market, manufacturers offer to buy the same, already for 11-12 rubles.With good performance and constant sales markets, it will take about one year for the payback of all equipment.

How to work with Lego bricks?

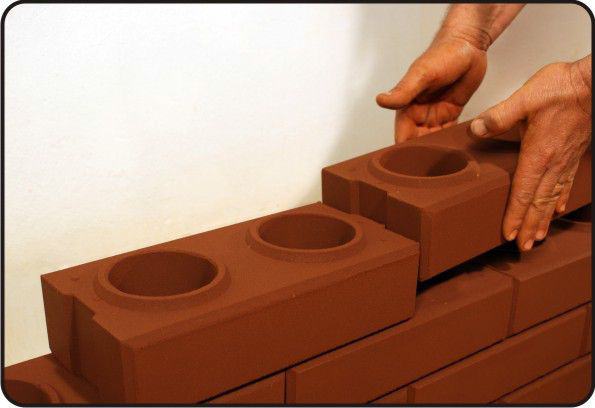

One of the main advantages of working with a product such as a Lego brick is its ease of installation. Compared to the "classic" analogue, installation will not cause any difficulties. Possessing a special shape and having two guide holes, the Lego brick is laid quite simply:

- It will be sufficient to carry out the installation of only the first row using a level and guides. There is no difficulty in this either. Further, the rest of all the rows themselves are aligned during the laying process, thanks to the corresponding guides.

- A minimum amount of glue is required for installation. Lego bricks fit perfectly together. As a result, no more than 25 kilograms of glue is used for 500 pieces.

- Even an inexperienced master will be able to carry out the perfect dressing of the seams, since the installation of Lego bricks along the guides completely eliminates the presence of traditional mistakes. At the same time, the laying speed is 2-3 times higher than that of a conventional analogue.

With low water absorption and high density, Lego bricks are not afraid of dirt. If excess glue leaves the seam, it can be easily removed after complete drying with a spatula.

Since the masonry, during the construction of which Lego bricks are used, has through holes along the entire height, it is very convenient to carry out reinforcement. If it is planned to erect low structures (for example, fence elements), then installation can be carried out without glue or mortar at all. Lego bricks are laid out “on dry”, and then reinforcement having a diameter of 10-20 mm is inserted into the holes of the masonry and filled with cement. As a result, the strength of the masonry increases, as well as the stability and reliability of the wall geometry. It must be borne in mind that the filling should be carried out in stages, that is, no more than 6 rows in 1 run.

It is convenient to use holes for laying utility lines. The presence of cavities in the walls is great for this. Then you can fill the holes with concrete.

Currently, Lego bricks are considered as a new generation material. They are still treated with interest and vigilance. But more and more often "Lego" (brick) reviews of builders are receiving a positive character due to the quality of the material and ease of installation, as well as favorable prices, practicality and impeccable appearance. And these are pretty weighty arguments.

10 mystical places in the world where it is forbidden to step on the foot of a person There are certain directions where access is restricted or simply prohibited for people. Be it a beautiful cave or a mysterious island inhabited by huge ones.

Fashion for Naked: the best images of the stars. We select a Naked cosmetic bag for your make-up It's nice when fashion pushes us not only to experiment, but also to accept ourselves and our beauty. Fashionable positive attitude to your own body.

Toxicosis: causes, consequences, treatment The assumption that nausea worries a woman only in the morning is incorrect. It can last all day, but is most pronounced in the morning. It comes from.

What does the shape of your nose say about your personality? Many experts believe that looking at the nose can tell a lot about a person's personality.

Therefore, when you first meet, pay attention to the nose of the unfamiliar

Our ancestors slept differently from us. What are we doing wrong? It's hard to believe, but scientists and many historians are inclined to believe that modern man sleeps quite differently from his ancient ancestors. Initially.

20 photos of cats taken at the right moment Cats are amazing creatures, and, perhaps, everyone knows about this. They are also incredibly photogenic and always know how to be at the right time in the rules.

How much can you earn

The most important question for an entrepreneur is how much money will the business bring? The production of building materials is a promising business. When using a cheap filler, the cost of the finished product will be about 4-5 rubles / piece.

If you sell goods only in bulk, then you can earn 10 rubles from a unit of production. The more products are sold, the more money the entrepreneur will receive. Having sold 10,000 pcs. Lego he will earn 100,000 rubles. If sales are at the level of 50,000 units, its proceeds will be 500,000 rubles.

When using waste (crumbs, dust, etc.), the cost of the finished product will decrease even more, and the profit will increase.

Business registration features

Before starting an enterprise, it must be registered with the tax authority.

The owner chooses the form of organization at will.

What documents are needed for registration

The type of organization (LLC or individual entrepreneur) will not affect the work of the enterprise. This will affect the number of documents required to register a company.

If you open an individual entrepreneur, the main package of documents will be:

- completed application - not only personal data (name, place of residence by registration, passport data) are entered into it, but also OKVED;

- copy of a civil passport (all pages);

- copy of TIN;

- copy of SNILS;

- confirmation of payment of the state fee.

Additional package of documents:

- notification of the transition to the simplified tax system - it is drawn up in 3 copies when choosing a simplified taxation system;

- power of attorney - useful if another person will register the individual entrepreneur;

- parental consent - only minor citizens need.

When registering an LLC, add to this list:

- articles of association;

- decision to establish LLC;

- minutes of the meeting of founders.

Which OKVED to indicate

In the registration documents, the entrepreneur indicates OKVED (classification of the type of activity). Their number is not limited, you just need to highlight the main activity code.

Lego building materials are produced from several types of materials. Therefore, OKVEDs may differ (23.20, 23.20.1, 23.61). If you sell finished products through specialized stores, add clause 47.52.72 to the registration documents.

Which taxation system to choose

The choice of taxation system will directly affect the profit of the firm. When opening a small workshop or garage production, it is worth stopping at a simplified system (USN).

What kind of "simplification" to prefer, you decide by calculating the business plan, just as we did in our example.

Advantages and disadvantages

In addition to ease of use, Lego-type products have a number of positive properties:

- low material cost;

- the possibility of placing a system of communication wires inside the masonry without the use of gating;

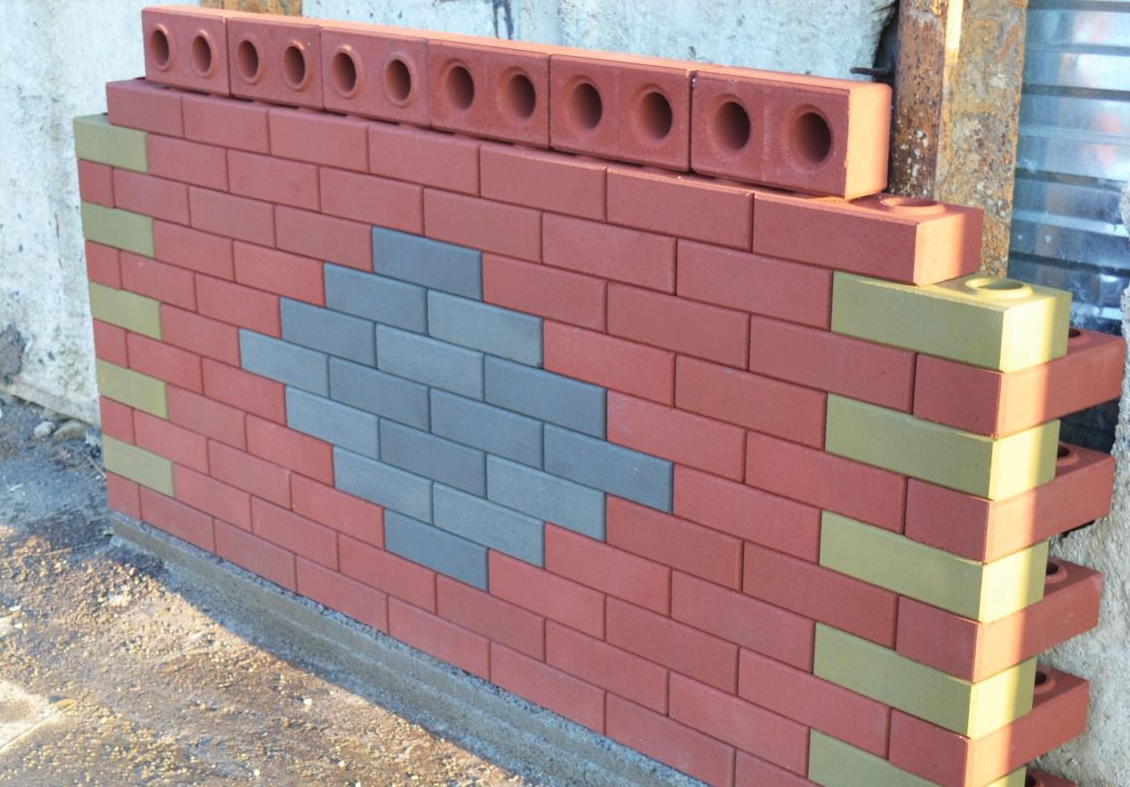

- due to the inclusion of dyes in the composition of Lego bricks, it is possible to obtain a wide variety of colors of the material;

- a house made of Lego bricks does not have to be finished - a smooth front surface and the absence of the need to perform jointing implies getting perfectly flat facades;

- the weight of the product is noticeably lower than the standard material, and therefore, when erecting low-rise buildings and structures, simpler and cheaper types of foundation can be used;

- due to its external data, this material is excellent for finishing already built buildings, for erecting decorative brick elements, fences and laying out the framing of fireplaces and stoves.

The negative aspects include the relative novelty of this material in the domestic market and the lack of statistical data on the actual durability and operation of the product under load.

In addition, there are currently no trademarks on the building materials market that could confirm the high quality of such products and craftsmen have to build objects based on the assurances of the owners of small factories.

Application area

According to the technical characteristics provided by manufacturers, this material can be used for the construction of load-bearing walls, single fences and used as a finishing material for wall cladding.

Due to the increased strength of the masonry, exceeding the usual brickwork in this characteristic, buildings and structures made of the material in question cope perfectly with the seismic load.

Specifications

The technical indicators of Lego products are comparable to those of ordinary hollow bricks, therefore, when considering the issue of the durability of the product, the durability of red bricks, which ranges from 30 to 50 years, can be taken into account. Specifications:

Specifications:

- Frost resistance: from 200 cycles.

- Moisture resistance: the material absorbs no more than 6% moisture, which makes it possible to erect objects from it in areas with high air humidity.

- Density: 1550 kg / m3.

- Thermal conductivity: 0.45 W / (m * K).

- Strength: M100 – M200 (the material is intended for the construction of multi-storey buildings and structures).

- Weight: 3 kg.

- Lego brick sizes: 250 * 125 * 65 or 300 * 150 * 100.

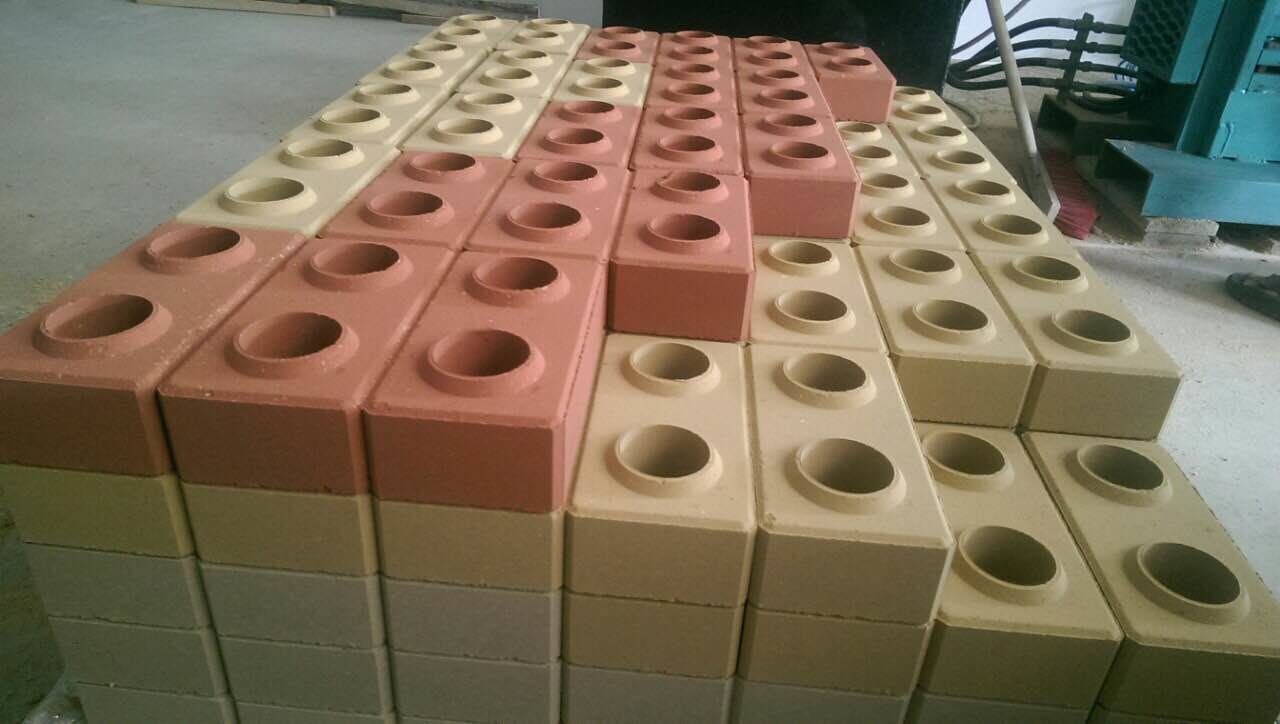

- Colors: in the preparation of raw materials for the production of Lego bricks, dyes are used, as a result, products of various colors are obtained, from light beige and red, to gray and dark blue.

If we compare an ordinary hollow brick and a Lego product, it will be found that their strength and frost resistance are identical, the density of a standard brick is slightly higher, and water absorption is almost three times greater, while Lego is 30% lighter.

The disadvantages include the poor thermal conductivity of Lego products, compared to ordinary bricks, but this issue is solved by using insulation in the backing.

To form a mixture for the production of bricks, the following components are used:

- limestone screening;

- cement mortar as a binder;

- water;

- dyes.

The instructions attached to the equipment will help to correctly calculate the proportions of each ingredient. The production process consists of forming bricks by high pressure pressing. The strength of the product depends on the pressure level and the size of the fractions of the bulk material.

Lego brick making is a business idea that won't burn out

The economic situation in the country has led to a change in the assortment of consumption. The population now buys cheap analogs instead of well-known brand models. Building materials are no exception. Expensive ceramic bricks are losing ground, yielding to affordable competitors.

The Lego brick construction market is especially active. A couple of years ago, no one knew about this modification, but its popularity is rapidly gaining momentum. And this is a good opportunity to open your own profitable business.

Entrepreneurs are looking for just such niches: with high demand and quick payback.

The idea of launching the production of such a building material is also good because the demand for:

- finished products, which means that the business will be profitable;

- equipment of production lines - if you are carried away by the idea of producing something else, you will return your investment by selling the purchased equipment;

- operating business - by launching your mini-factory, you not only get a profit from the sale of goods, operating production itself is capital with a high level of demand.

Brick production technology "Lego"

The manufacturing process of this product includes several stages. Namely, carrying out:

- preparatory work;

- molding;

- pressing bricks;

- storage of finished products with appropriate exposure for a certain time.

Next, we will consider each stage in more detail. Preparatory work includes the delivery of the required raw materials, the implementation of its sorting and preparation of the required mixture for molding. To increase productivity, it is recommended to use additional equipment that will allow you to bring the components to the required fraction (if necessary) by sieving and mix the raw material additives. In the presence of large volumes, the finished mixture is fed to the equipment receiving hopper using a conveyor.Then the dispensing device sends the required volume of the substance into the matrix for formation. This is done automatically with the help of an operator. After that, the batcher returns to the sub-hopper space. Then, the valve is opened, which supplies oil to the press. After that, the mixture is compressed for a certain time. Then, with the help of a pusher, the finished brick is moved out and transferred to a temporary warehouse site, where the resulting products must be kept for three days. After that, the products can be shipped to the consumer. The period of time before the start of application of the product must be at least 21 days.

What is the relevance of the brick making business

During the economic downturn, brick sales decline due to the lack of money from the population to improve their living conditions. Nikolay, the owner of a small brick factory, will help us understand the intricacies of the building materials market today.

Our expert believes that brick production during a crisis is a profitable business because:

- Instead of buying expensive apartments, private traders began to improve their summer cottages: they attach verandas, improve household blocks, build baths.

- Consumers began to save on materials and services of builders. Primitive structures (fence, toilet) are erected by themselves.

- With modern equipment, it is not difficult to organize production in a garage or on a personal plot. This reduces production costs.

There are cheap building materials on the market that are not inferior in characteristics to classical ones. So, aerated concrete confidently entered the niche of silicate bricks, and ceramic (classic "red" bar) ousted its hollow counterparts (Lego).

What are the advantages of Lego technology:

- Light weight. Saving raw materials and fuels and lubricants leads to a decrease in the cost, and hence the selling price.

- Pressing technology. It is not necessary to install additional kilns for firing.

- Convenience of masonry. Assembling a wall is as easy as playing with a construction set. Everyone can lay out a simple structure from it without the help of a bricklayer.

- The bricks are held together with glue rather than cement mortar, which is cheaper.

- The masonry is perfectly flat, does not need additional plastering.

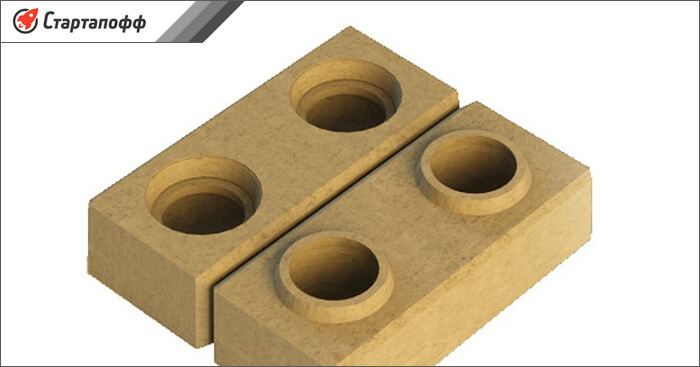

Two Lego fragments are tightly connected to each other, thanks to the docking elements

Two Lego fragments are tightly connected to each other, thanks to the docking elements

What is good about such a brick

Buying a new apartment is becoming an unattainable luxury for many. The small funds that can be postponed are spent by private traders on the improvement of the existing dacha or backyard economy. Gazebos, fences, baths and outdoor barbecue ovens are being erected.

All this requires an inexpensive, strong and aesthetic building material, and Lego is perfect for these purposes. It has good strength, climatic resistance and flawless appearance.

The low cost of the product consists of several components:

- Low cost of equipment. The technology does not require the installation of kilns, autoclaves, etc.

- The lightness of the final product. This modification of the hollow brick weighs less than the classic models, so its transportation is less expensive.

- Low raw material price. Construction material is produced from sand, dolomite, mining waste and recycled materials.

- Minimum advertising costs. Customers recommend these building materials to neighbors and friends. After 1-1.5 years of selling Lego, word of mouth is driving more buyers than ads in the local newspaper.

The main characteristics of Lego:

- durable - cuts under high pressure;

- smooth - a flat surface easily competes with facing modifications;

- easy to use - a person will lay out the masonry even without building experience, the elements are joined end-to-end, forming a flat wall;

- lightweight, which significantly reduces labor costs during production, reduces the consumption of fuels and lubricants.

In short, such a good building material, and even cheap, has every chance to continue to break sales records.

Production technology allows you to produce products of any color

Manufacturing features

Equipment for the production of Lego bricks is a manual or electric multifunctional machine that is not demanding in terms of space and placement conditions. Blanks are formed in special dies, at the initial stage the most simple and common ones are enough. The process takes place according to the scheme: loading of raw materials → grinding and mixing → forming bricks in matrices → steaming. On average, on electrical equipment, it takes no more than 12 seconds to make 1 piece, and another 3 seconds to remove it from the machine.

The quality depends on several factors: the composition of the mixture, the size of the fractions of the components and the value of the processed pressure

It is noted that for the release of Lego bricks with sufficient strength, a pressure of at least 150 kg / cm2 must be provided (you should pay attention to this before buying equipment). It is believed that the material is immediately suitable for work, but experienced builders advise to wait at least 3 weeks before using

The composition of the mixture for production

For the manufacture, they use crushed and sieved fractions of volcanic and limestone rocks, sand and clay with cement as a binder. The smaller their size, the more reliable the Lego brick is. In production, three types of compositions are used:

- From cement up to 10% and clay up to 90%, the amount of added water does not exceed 3%.

- The same, but with the addition of sand (up to 50-60%). To obtain a high-quality building material, such a mixture is subjected to a particularly high pressure treatment.

- Based on melusa (limestone cuts, up to 80%), high-quality Portland cement (up to 15%) and water.

The last type of mixture for making bricks is considered the highest quality and suitable for use in the Russian climate. To improve the moisture-repellent properties, plasticizers are introduced, their proportion insignificantly affects the proportions of the added binder. To make the product attractive, additional coloring ingredients are used: phthalocyanine paints or iron oxides.

Lego-style brick is appreciated for the ability to build walls without the usual masonry cement-containing mixtures. The rows are laid using special glue (the approximate consumption per 1 cube is 25 kg), the shape of the products allows you to create even and smooth structures without protruding mortar and ugly seams. But according to the builders' reviews, this approach is not enough, they recommend reinforcing the masonry with iron reinforcement and filling the central holes with concrete. The greater the thickness of the guides, the better; rods with a diameter of at least 12 mm are used on load-bearing walls.

Truly working legal way to save money. Everyone needs to know this!