Where is a brick of this brand used?

The higher the brand, the higher the price of the brick. Therefore, when building private houses and outbuildings, it makes no sense to spend money on expensive material, if the cheaper one will perfectly cope with the load imposed on it.

A house made of this material always looks solid.

It can also be used for the construction of internal non-bearing walls and partitions in multi-storey construction. But the scope is determined not only by the brand, but also by the type of brick.

Types of brick M100 by voidness

Artificial stone of any composition and any brand can be solid or hollow.

Products that have no pores and voids at all or their volume does not exceed 13% are called corpulent. This is an ordinary brick with a very wide range of applications. It is used for the construction of load-bearing walls, foundations and plinths, being the main material for such structures.

Note. The thermal insulation properties of solid bricks are lower than those of hollow bricks, therefore, walls made of it require additional insulation

In hollow or porous bricks, the volume of voids is more than 13%. The presence of air-filled voids increases the thermal insulation capacity of the material, therefore it is used mainly for the construction of external walls, as well as for their cladding. However, the same voids make the brick not sufficiently resistant to moisture: the water penetrating into them increases in volume during freezing and leads to its destruction. For this reason, it cannot be used for the construction of plinths and foundations, wells and damp walls.

Voids can be both through and non-through, and their shape is oval, square, round or slot-like.

Both solid and hollow M100 products are not very durable, therefore there is an instruction that does not recommend them for the construction of multi-storey buildings.

Unlike facing bricks, which have high-quality smooth edges, ordinary bricks have a rough surface, which provides good adhesion to mortar and plaster mixture used for exterior and interior decoration.

Some manufacturers go further and produce products with grooved edges.

Types of bricks M100 by composition

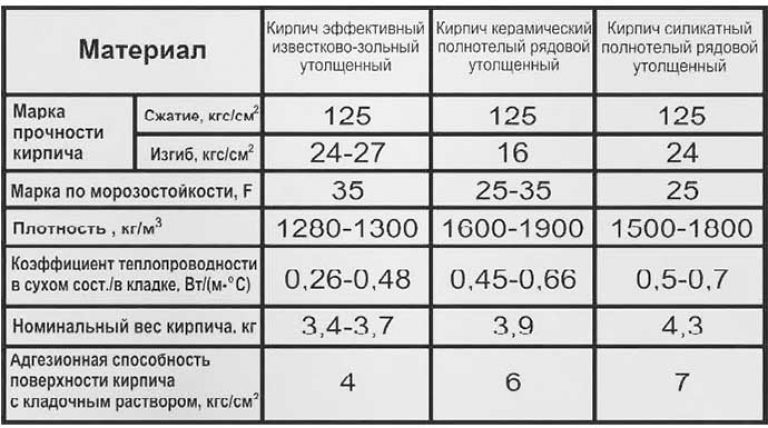

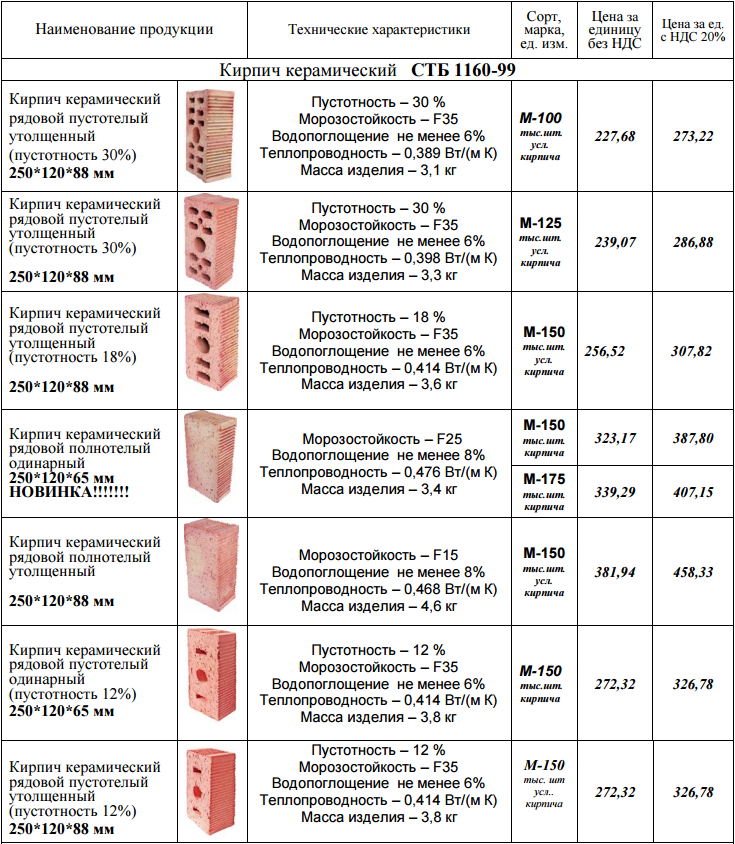

Both ceramic and silicate bricks can have the M100 brand.

Despite the external identity, these are materials that are completely different in technical parameters, each of which also has its own field of application.

- Ceramic stones of this brand are used very widely, restrictions are associated only with the presence of voids and those conditions that were described above. The technical characteristics of the ceramic brick M100 allow it to be used for the construction of structures operating at high temperatures or in direct contact with fire. For example, for household stoves and fireplaces.

- Silicate stones of a similar strength grade, regardless of the presence of voids, are not allowed for the construction of objects in contact with moisture or high temperatures. This is due to their low moisture and heat resistance. Of these, only walls and partitions are erected, which are distinguished by excellent sound-absorbing properties.

Single solid silicate brick of the M100 brand

Thus, when choosing a brick of the brand specified in the project, it is necessary to take into account the specific requirements for the object. This will allow the most rational use of finances and will be a guarantee of the quality of the finished structure.

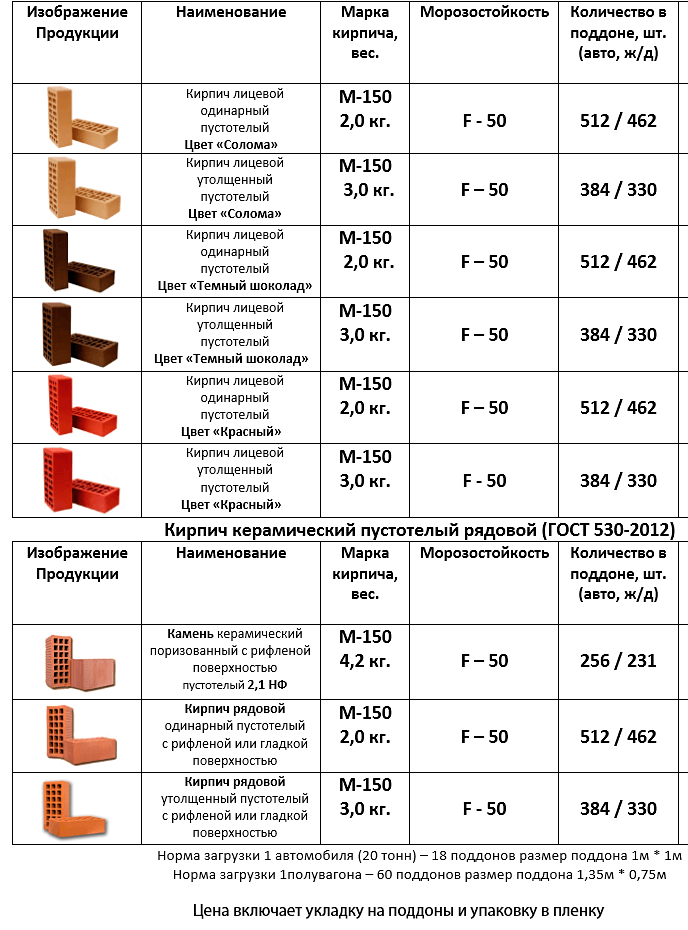

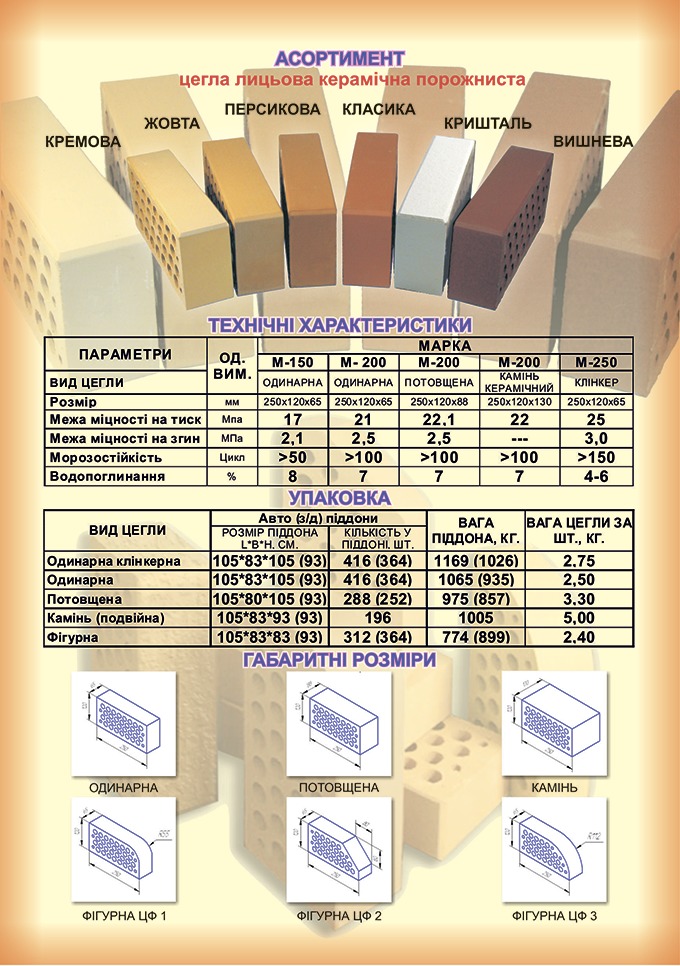

Varieties and application

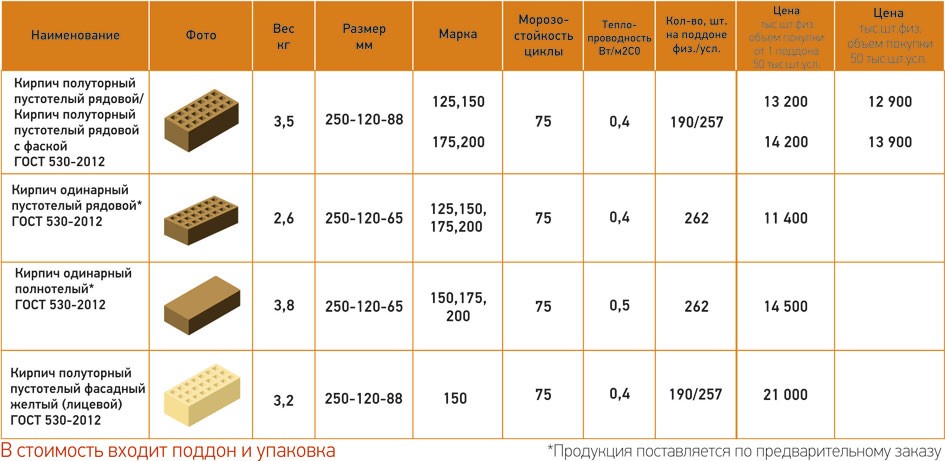

Depending on the purpose and characteristics, the following types are distinguished, which are presented here:

| Type of stone | Brick characteristics | Application |

| Corpulent | Small void volume, less than 13% | Foundation |

| Conducts heat well | Column erection | |

| Product weight 3.5 kg | Ground floor | |

| Hollow (poo) | Holds voids up to 50% of the volume | Strength buildings |

| Less durable than corpulent, but warmer and lighter | Wall masonry | |

| Has good sound insulation | Multi-storey buildings | |

| Facing | Has no bundles | For walls with ideal surfaces |

| Cracks excluded | Indoor finishing work | |

| Smooth shape | ||

| Glossy finish | Buildings of internal structures | |

| High price | ||

| Figured | Custom form | Round column construction |

| Various colors | Arches | |

| Interesting relief | Ornamental decorative elements | |

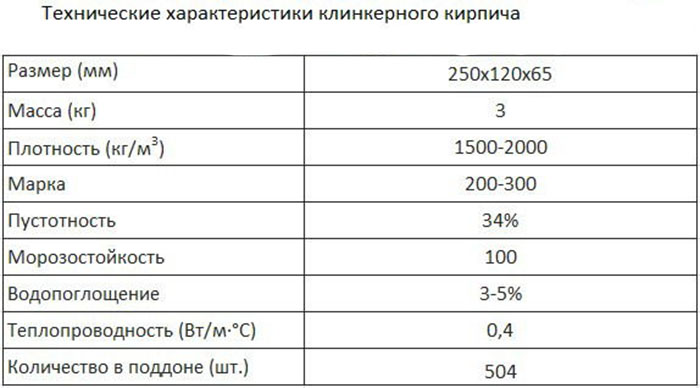

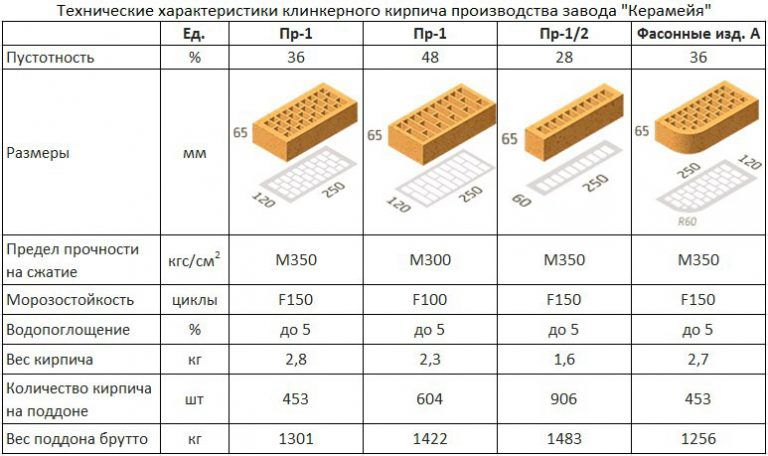

| Clinker | High frost resistance from F100 to F 300 | Pavement of roads |

| Large selection of colors | Construction of sidewalks | |

| Chamotny | Withstands temperatures up to 1800 degrees | For buildings that will interact with fire |

| Strength building |

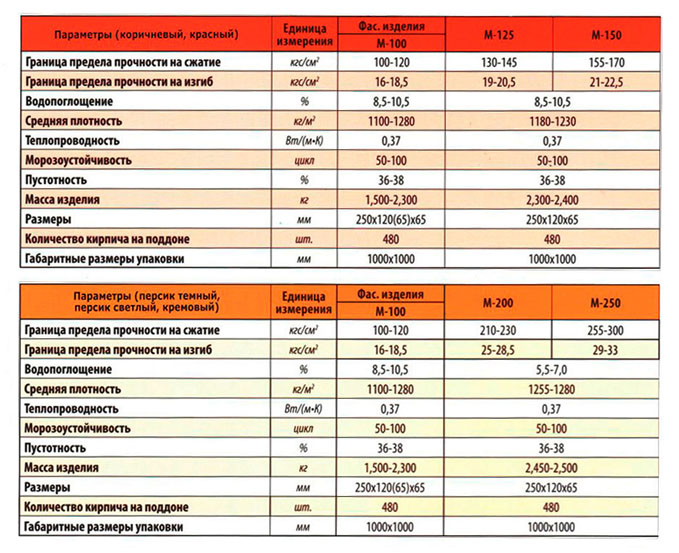

Application of brick M-200

Technical characteristics of brick M-200.

The characteristics of bricks marked M-200 allow them to be used in a wide variety of areas of construction.

Ceramic building material is used mainly for the construction of structures that are especially important in this complex. These include external walls, foundations, plinths. It would seem that there is usually no point in using red bricks of increased strength for cladding and decorative work, with the exception of some specific situations. However, in practice, it is often used precisely as a front when designing the appearance of a building. This eliminates the need for additional cladding in the form of plaster, paint, tiles or special facing bricks.

The characteristics of a solid building material with the M-200 marking allow it to be used in the construction of buildings located in places of high humidity. This option is also chosen for those buildings, the operation of which involves working with objects of high humidity. These include swimming pools, baths, laundries, industrial complexes that use technologies involving water.

In addition, for the construction of stoves and fireplaces, not just stove bricks are used, but also its full-bodied ceramic version. The advantage in this case is precisely the high thermal conductivity of this building material, since it is required from heating sources to transfer heat to the air of the dwelling as quickly as possible.

The furnace version of the M200 differs from the usual high strength material in that it can withstand temperatures up to 1000 ° C. For non-specialized material, this figure is 200 ° C less. This feature makes it possible to use thermally hardened material in the metallurgical, glass and porcelain industries.

It should also be noted that it is not customary to use the conventional furnace version of the M200 grade material in combustion chambers. The fact is that, despite the increased strength, it cannot stand prolonged contact with open fire and quickly collapses. There is a special fireclay option for fireboxes.

For white silicate solid brick of the M-200 brand there are also prohibitions and restrictions. It is never used for the construction of thermally stressed structures. It is not suitable for laying the foundation and forming basement rooms. There is only one reason - this material has a too high ability to absorb moisture. For this reason, the silicate version is used mainly for the construction of load-bearing walls and internal partitions.

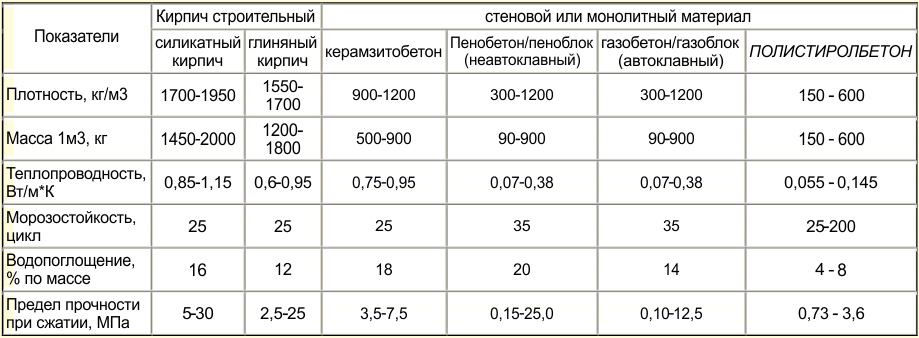

The evolution of building materials is increasingly acquiring a vector of development in the direction of diversity, cost reduction and convenience of the process of building buildings. This places high demands on both specialists and customers. It becomes more difficult for those who decide to build a house on their own. They have to navigate a lot of information.

However, the variety of materials is usually accompanied by a simplification of the technology for the construction of buildings. In addition, variety is always cost effective as it allows you to find more profitable options.

Concrete preparation B25

Composition

B25 concrete consists of the following components:

- Cement;

- Water;

- Crushed stone;

- Sand;

- All kinds of additives (anti-freeze or plasticizing).

In the photo - rubble

I must say that the components used to prepare the solution may differ in strength, particle size and some other parameters.

For example, placeholders can be:

- Coarse, medium and fine-grained sand.

- Crushed stone;

- Granite or limestone gravel.

Also, from the features of this solution, an increased cement content can be distinguished, due to which the material hardens relatively quickly.

Plasticizer

Technology

The composition of the proportion of concrete M350 per 1m3 is as follows:

- 400kg of cement M500;

- 752kg of sand (cleaned from impurities);

- Ton of crushed stone or other solid aggregate;

- 175 liters of water.

To obtain high-quality concrete, it is necessary not only to strictly observe the given composition of concrete M350 per 1m3, but also thoroughly mix all the components so that the mass is homogeneous. The fact is that a poorly mixed mass significantly reduces the strength of the material, which, of course, reduces the technical and operational characteristics of the structure.

Preparation of the solution

As mentioned above, various additives can be used to improve the properties of the material. For example, if the construction is carried out in the winter, then to prevent the solution from freezing, an anti-freeze additive is added to it. In addition, plasticizers can improve strength and water resistance.

The instructions for preparing the solution are as follows:

- First, dry components should be added to the concrete mixer, i.e. cement and sand. Mix the components thoroughly.

- Then water is added to the composition. At this stage, a plasticizer or other additive can also be added to the solution.

- After that, the required amount of gravel or crushed stone soaked in water is added to the concrete mixer. In this case, the solution is thoroughly mixed until a homogeneous mass is obtained.

I must say that when performing construction work, it is not necessary to prepare the solution with your own hands. There are companies that sell ready-mixed concrete.

Pouring mortar from a concrete mixer

Of course, in this case, the price of the solution will be higher, but for that you will get a well-mixed mass. In addition, you do not have to waste time making it. Often, such companies also provide special equipment that simplifies the pouring process, which is convenient when performing large-scale work.

The cost of concrete M350 per cubic meter consists of the cost of the components that are used in the composition, the costs associated with its preparation and delivery, as well as the manufacturer's margin. Therefore, each company has its own market value of the material. If additives are used in the composition, for example, for frost resistance, then, accordingly, the cost of the solution will be higher.

Packaged sand concrete

It should be noted that in hardware stores you can buy M350 sand concrete in bags. In this case, the developer, in order to obtain a sandy mortar, only needs to stir the dry mixture with water in the proportion indicated on the package. Of course, the cost of such a material is much lower than the finished solution.

These are, perhaps, all the main features of B25 concrete that you should know when choosing a material grade for concrete work.

Types

As mentioned above, according to its structure, the briquette in question is produced on the market:

corpulent;

Corpulent

hollow.

Hollow

In the first option, there are no voids. The briquette in question is not famous for its thermal features, but it is optimal for foundation work, as well as for the construction of load-bearing structures.

Foundation

The M 150 also stands out for its insignificant level of sound isolation. The hollow analogue, which has voids in its structure, is significantly lower in weight. It perfectly retains heat in the room, so it is used for the construction of load-bearing structures and partitions between rooms.

Interior partition

Thanks to its improved soundproofing properties, the briquette is ideal for the construction of partitions between rooms and apartments. If you have purchased the M 150 cladding type, it can be used for wall decoration.

A briquette of 150 brands is:

facing imported or domestic;

Facing

ordinary construction.

Private construction

To ensure optimal adhesion, the manufacturer provided this material with special edges that have a relief structure.

Relief structure

If ordinary briquettes are used for the construction of supporting structures, they are additionally processed - either they are covered with a layer of plaster, or a special paint coating is applied.

Therefore, such a briquette, according to its external characteristics, is as simple as possible, its front part is never processed. In addition, a briquette can be produced in a non-uniform shade and its distorted shape is allowed by GOST.

Facing

Facade cladding bricks with appropriate markings have found their widespread use for the construction of various objects. This became available due to the fact that different companies supply the market with a variety of shade variations, as well as briquettes of numerous textures.

Facade

The cladding analogue is used for real estate decoration - thanks to it, the object acquires ideal external characteristics. Facing bricks decorate the front side of the building, fences, openings on staircases, underground passages and even arches. Here is its size.

Private

Single corpulent building brick, marked m 150, the price of which depends on the density, can be sold from 10-20 rubles.

In addition to density indicators, the cost of a product is also influenced by its quality and the manufacturing company. Therefore, when purchasing the basis for the construction of objects, you should not look for cheap options.

In the future, this may lead to a series of unpleasant events, which will find their expression in the premature deformation of real estate. The material considered in the article is universal and can be used for all types of structures.

The surface of a solid briquette is often smooth, but embossed counterparts can also be found on the market. The latter are designed to improve the adhesion of the product to each other.

This characteristic is very important, especially if, in addition to its mass, an additional load will act on the building.

Characteristics of a briquette of 150 brands.

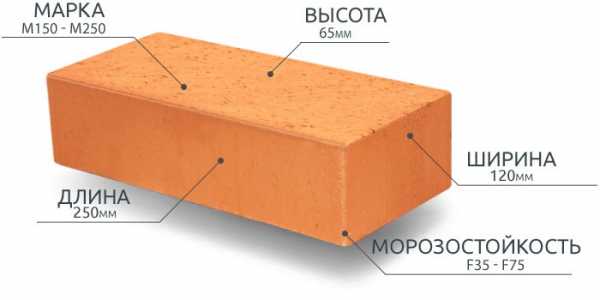

dimensions: 25x12x6.5cm;

Single

- weight: from three kilograms;

- strength index: 150;

- resistance to subzero temperatures: from 50;

- moisture absorption: eight percent or more;

- shade: can be anything from ivory to red. Here is the size of a red solid brick;

- surface: it can be as smooth as possible, and with the presence of corrugations.

If you want to build a brick object, choose only high quality material and never give preference to cheapness.

Before you start laying, carry out something like an analysis: why are you building the building, what functions it will perform, what role is assigned to this or that element, whether the building will come into contact with aggressive environmental factors.

Other components of real estate can be created from cheaper grades of briquettes, thus you will reduce construction costs and the structure will not be overloaded.

For more information about an ordinary solid building brick, see the video:

Brick M 100

Ceramic brick grade 100, or the so-called one and a half, is used for the construction of external and load-bearing walls. It belongs to the budgetary and most popular types of red brick.It is not used for cladding, since the construction market is saturated with other materials that are more suitable for this purpose.

M 100 is practically not affected by unfavorable weather and other environmental conditions. It is very durable and does not deteriorate during operation, and also has excellent resistance to various kinds of internal deformations.

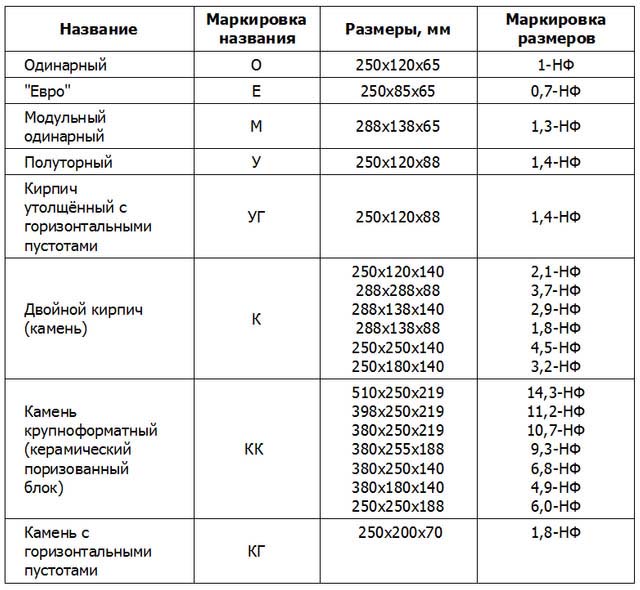

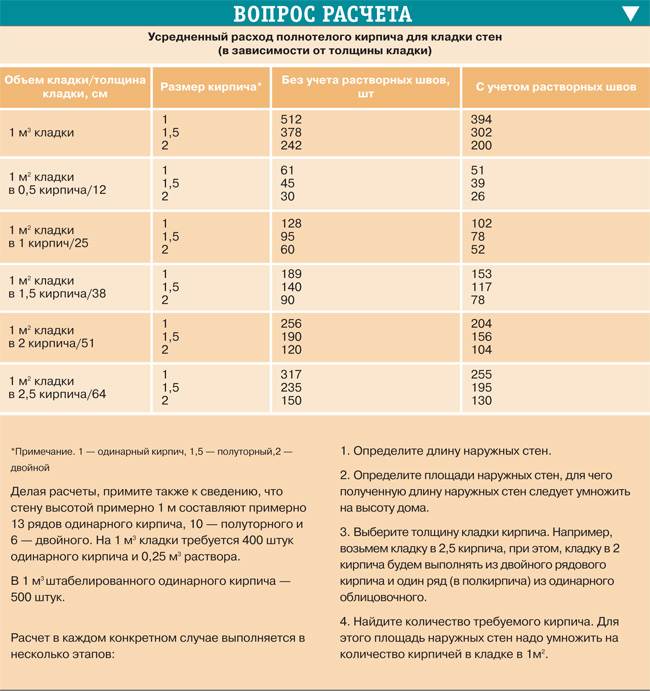

It is worth noting that the size determined by GOST for a single ordinary brick M 100 is 250 x 120 x 65. This standard allows you to lay out walls of various thicknesses - from 65 mm and more.

Due to the fact that the length of the brick is equal to two widths and four heights, its parameters are considered universal. Builders lay it out in rows, while combining them with spoon or poke methods.

Specifications

Red solid brick is a type of ceramic brick and has high performance properties. The material is used in the construction of objects, the walls of which will be subjected to regular or periodic weight, shock and mechanical loads. Solid products are often used to erect columns, arched structures, and pillars. The ability of the material to withstand heavy loads is due to the high strength of the clay composition from which it is made.

Each of the types of solid bricks is assigned a certain strength index, which greatly facilitates the selection of the required material. The index consists of two characters, the first of which is denoted by the letter M, and the second has a numerical expression and shows the degree of strength of the material.

The strength of a material is greatly influenced by its density, which indicates how much mass of a substance is contained in one cubic meter. Density is inversely proportional to porosity and is considered the main characteristic of a material's thermal conductivity. The average density of solid red brick is 1600-1900 kg / m3, while its porosity varies in values of 6-8%.

Porosity is also an important performance indicator and affects thermal conductivity and frost resistance. It is measured as a percentage and characterizes the level of filling of the brick body with pores. The number of pores depends entirely on the purpose of the material and the technology of its manufacture. So, to increase porosity, straw, peat or crushed sawdust are added to clay, in a word, all those materials that, when burned in a furnace, leave small cavities filled with air in their place.

As for the thermal conductivity, its values for full-bodied models are quite high. This imposes certain restrictions on the construction of residential buildings from solid material and requires additional measures to be taken to insulate the facades. So, the thermal conductivity index of solid products is only 0.7, which is explained by the low porosity of the material and the absence of an air gap inside the brick.

Solid ceramics are widely used in the arrangement of structures, which are subject to increased fire safety requirements. This is due to the high fire resistance of the material and the ability of some of its modifications to withstand temperatures up to 1600 degrees. In this case, we are talking about fireclay models, for the manufacture of which a special refractory clay is used with a higher firing temperature during production.

An equally important indicator is the frost resistance of the material, which is also indicated in the marking and denoted by the symbol F (n), where n is the number of freeze-thaw cycles that the product can withstand. Solid brick has an F75 index, which allows it to last up to 75 years, while maintaining its basic performance characteristics and not undergoing deformation. Due to its long service life, the material is often used for the construction of fences, open gazebos and outdoor stairs.

Water absorption also has a large effect on the performance of a material and refers to its ability to absorb and retain moisture. The hygroscopicity of a brick is determined empirically in the process of selective test tests, in which a dry brick is first weighed and then placed in water for 38 hours. Then the product is taken out of the container and weighed again.

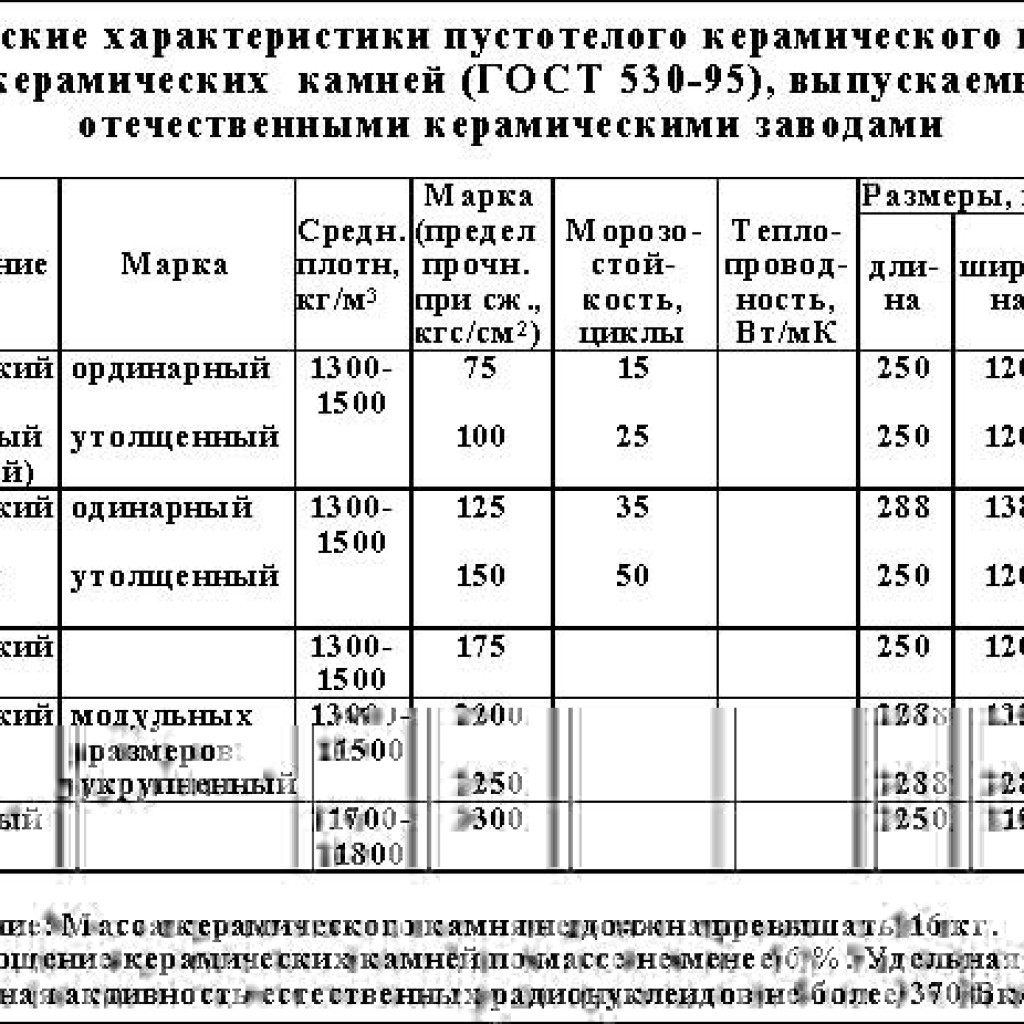

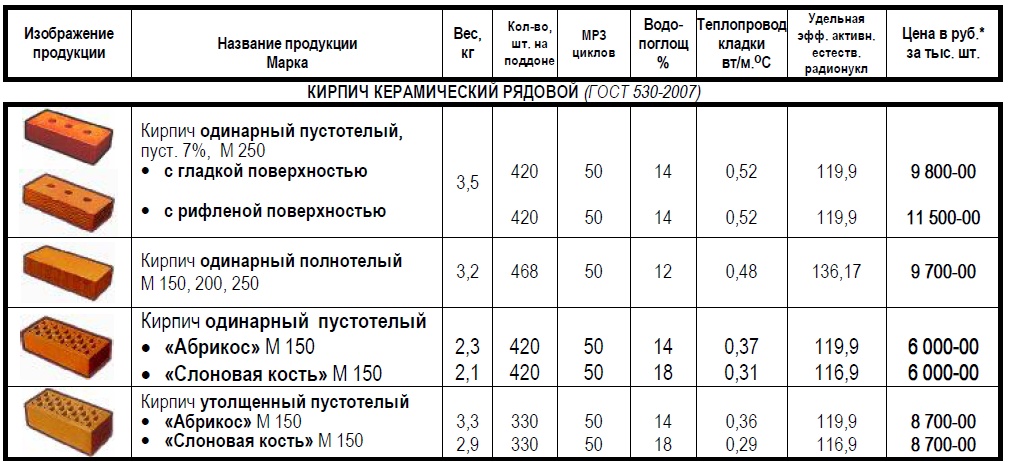

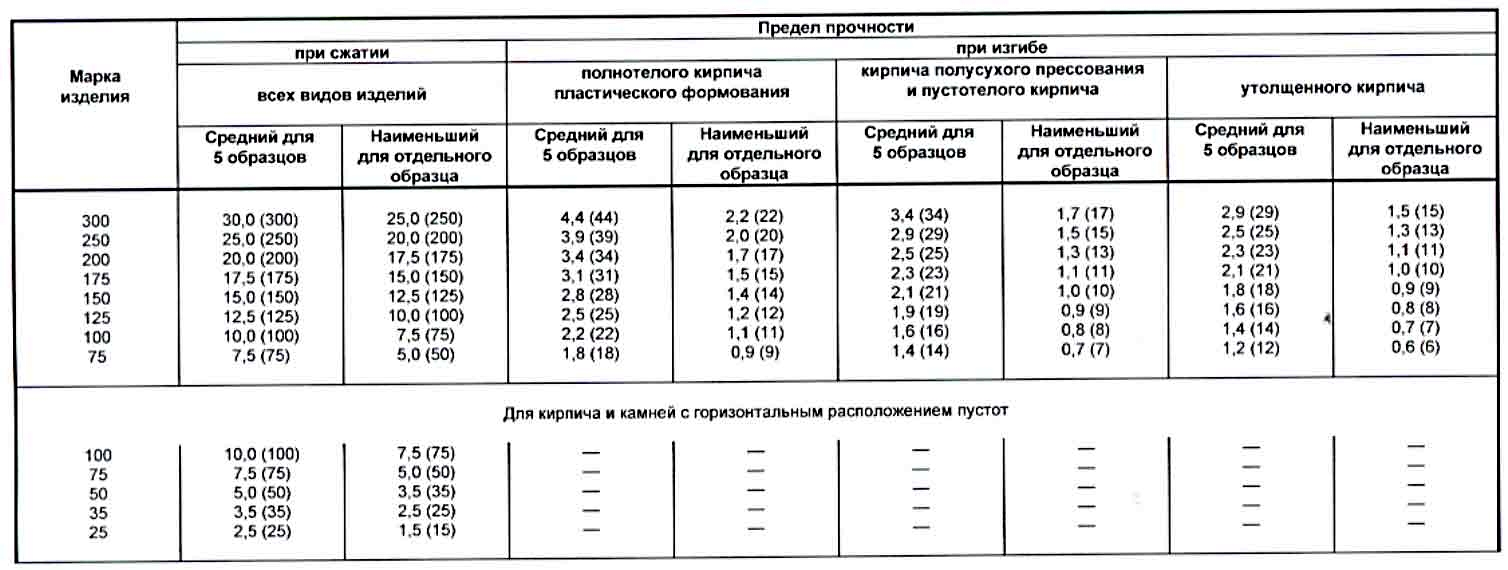

Specifications

The standard defines strength grades, frost resistance and density class. Strength grades represent the load that a material can bear. It is easy to decipher this value. The number that follows the letter "M" is the number of kilograms per square centimeter that the material can withstand without destruction. Example: M150 means that ceramic bricks of this batch will withstand a load of 150 kg / cm².

| Strength grades | Ceramic bricks | M100, M125, M150, M175, M200, M250, M300 |

| Ceramic stone | M300, M400, M500, M600, M800, M1000 | |

| Clinker bricks | M25, M35, M50, M75, M100, M125, M150, M175, M200, M250, M300; | |

| Brick and stone with horizontal voids | M25, M35, M50, M75, M100 | |

| Frost resistance | F25, F35, F50, F75, F100, F200, F300. |

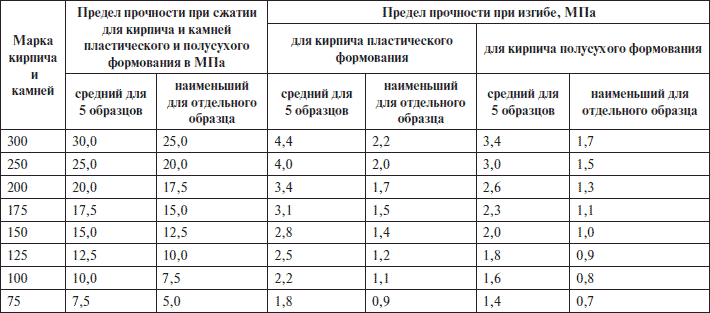

Strength and frost resistance grades for ceramic stone and bricks are indicated.

Frost resistance is indicated by the letter F and a number. The figure shows the number of freeze / thaw cycles that do not change characteristics and appearance. For example F50 - 50 frost and defrost cycles. For internal partitions in heated buildings, frost resistance can be taken low - a positive temperature will still be maintained.

Thermal conductivity and coefficient of thermal resistance

The density class corresponds to the average density of the material, but the energy efficiency of the material also depends on the density. The lower the density, the better the thermal insulation properties. But it will not be possible to significantly reduce the density for external walls. They must carry a certain level of stress. Therefore, in recent years, a brick house has been made with insulation.

The ratio of the average density of the product and the density class

How to work with the last two tables? The density class is indicated in the marking. By this characteristic, you can find out the mass of a ceramic brick cube. It is listed in the first table. The second table helps to compare the density of the material and the coefficient of thermal conductivity of masonry from it. For example, the density class of ceramic bricks is specified as 1.0. This means that the cube should weigh 810-1000 kg, and the masonry on a minimum layer of glue after drying will have a thermal conductivity coefficient of 0.20-0.24 W / (m * ° C).

Groups of ceramic bricks and blocks according to the thermal characteristics of masonry (with a minimum amount of mortar)

It is worth saying that according to modern standards, none of the types of bricks gives the necessary thermal resistance. Unless the thickness of the wall will be more than a meter.

Masonry made of ceramic bricks of one and a half or two bricks does not meet modern requirements for thermal conductivity of external walls

In this case, a hollow brick or a building ceramic block wins, since they have the best thermal conductivity characteristics. The wall will be a couple of tens of centimeters already - not 147 cm, for example, but only 105. So, in any case, it is worth considering additional insulation of the outer walls.

Ceramic brick weight

The weight of ceramic bricks depends on the density and the presence / number of voids. The exact figure is recognized in the accompanying documents, and then, the spread within one batch is up to 10%.

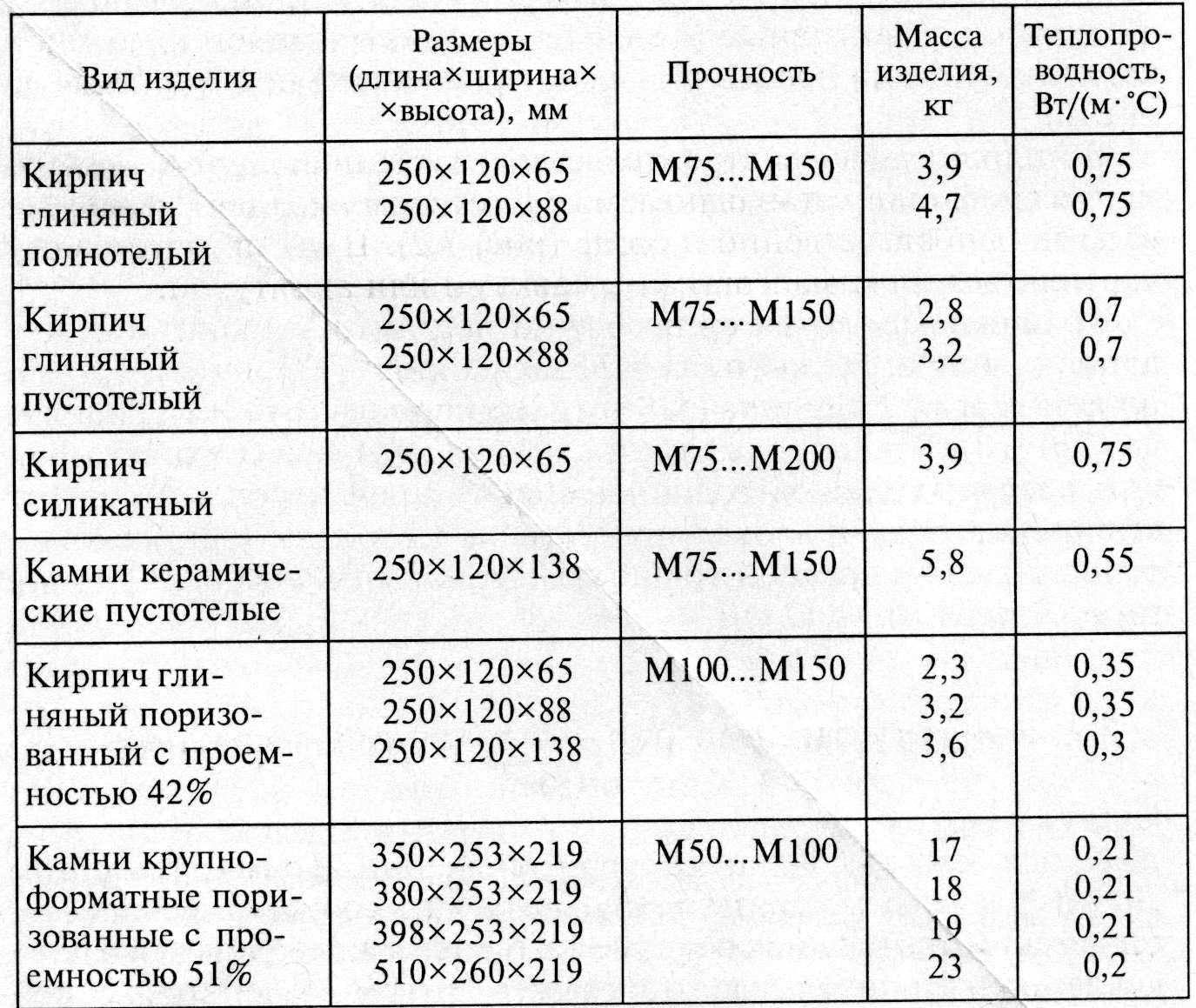

The characteristics indicate the weight of different types of bricks: masonry, finishing, with and without voids

Using the old terminology, the approximate weight of ceramic bricks will be as follows:

- Single (type 1 NF, size 250 * 120 * 65 mm):

- corpulent (private, masonry, construction) 3.3-3.6 kg / piece;

- worker (private, masonry) hollow - 2.3-2.5 kg / piece;

- facing (front, finishing) hollow - 1.32-1.6 kg / pc.

- One and a half has a mass (type 1.4 NF, dimensions 250 * 120 * 88 mm):

- full-bodied private - 4.0-4.3 kg / piece;

- hollow private - 3.0-3.3 kg / piece;

- facial hollow - 2.7-3.2 kg / pc.

- Double weighs (1.8 NF 288 * 138 * 88 mm.):

- ordinary corpulent - 6.6-7.2 kg / piece;

- ordinary hollow - 4.6-5.0 kg / pc.

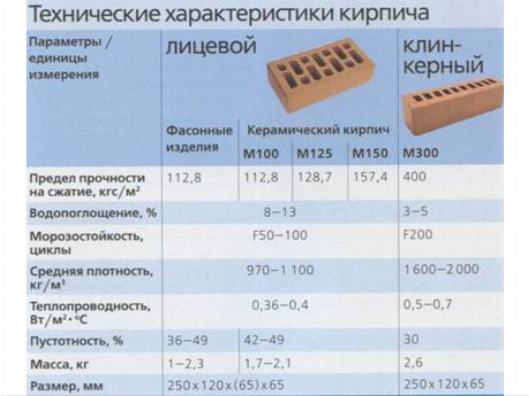

Comparison of the characteristics of ceramic bricks - hollow, different density, solid

We will give an approximate weight, since the density and number of voids for each plant can differ significantly. The number of voids is not regulated, so the finishing materials can be lightweight.