Types

As mentioned above, according to its structure, the briquette in question is produced on the market:

corpulent;

Corpulent

hollow.

Hollow

In the first option, there are no voids. The briquette in question is not famous for its thermal features, but it is optimal for foundation work, as well as for the construction of load-bearing structures.

Foundation

The M 150 also stands out for its insignificant level of sound isolation. The hollow analogue, which has voids in its structure, is significantly lower in weight. It perfectly retains heat in the room, so it is used for the construction of load-bearing structures and partitions between rooms.

Interior partition

Thanks to its improved soundproofing properties, the briquette is ideal for the construction of partitions between rooms and apartments. If you have purchased the M 150 cladding type, it can be used for wall decoration.

A briquette of 150 marks is:

facing imported or domestic;

Facing

ordinary construction.

Private construction

To ensure optimal adhesion, the manufacturer provided this material with special edges that have a relief structure.

Relief structure

If ordinary briquettes are used for the construction of supporting structures, they are additionally processed - either they are covered with a layer of plaster, or a special paint coating is applied.

Therefore, such a briquette, according to its external characteristics, is as simple as possible, its front part is never processed. In addition, a briquette can be produced in a non-uniform shade and its distorted shape is allowed by GOST.

Facing

Facade cladding bricks with appropriate markings have found their widespread use in the construction of various objects. This became available due to the fact that different companies supply the market with a variety of shade variations, as well as briquettes of numerous textures.

Facade

The cladding analogue is used for real estate decoration - thanks to it, the object acquires ideal external characteristics. Facing bricks decorate the front side of the building, fences, openings on staircases, underground passages and even arches. Here is its size.

Private

Single corpulent building brick, marked m 150, the price of which depends on the density, can be sold from 10-20 rubles.

In addition to density indicators, the cost of a product is also influenced by its quality and the manufacturing company. Therefore, when purchasing the basis for the construction of objects, you should not look for cheap options.

In the future, this may lead to a series of unpleasant events, which will find their expression in the premature deformation of real estate. The material considered in the article is universal and can be used for all types of structures.

The surface of a solid briquette is often smooth, but embossed counterparts can also be found on the market. The latter are designed to improve the adhesion of the product to each other.

This characteristic is very important, especially if, in addition to its mass, an additional load will act on the building.

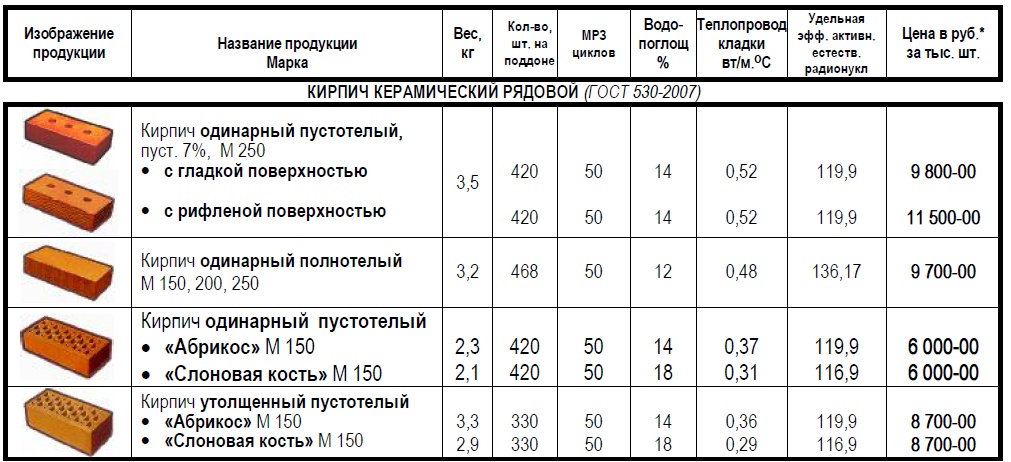

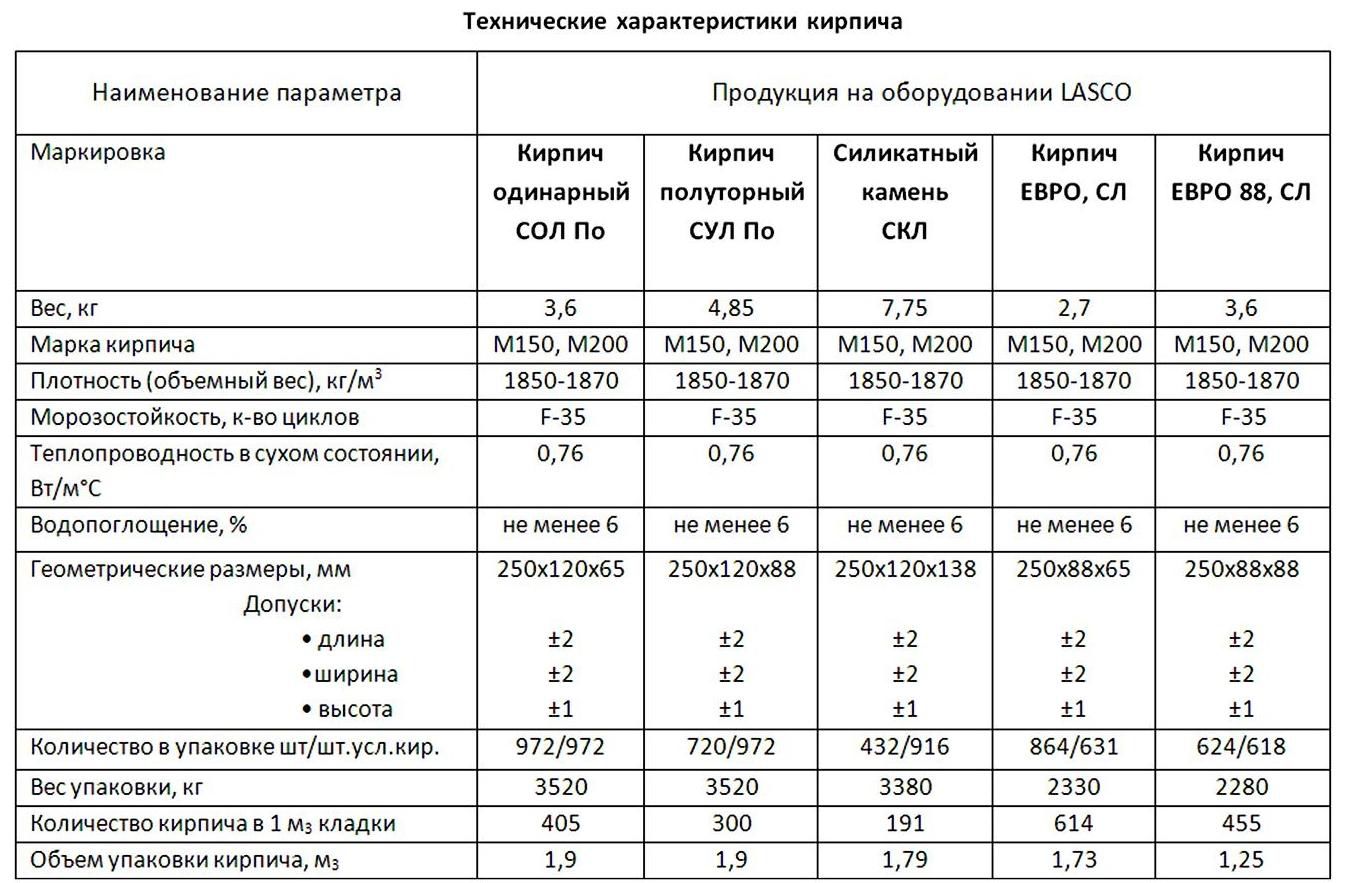

Characteristics of a briquette of 150 brands.

dimensions: 25x12x6.5cm;

Single

- weight: from three kilograms;

- strength index: 150;

- resistance to subzero temperatures: from 50;

- moisture absorption: eight percent or more;

- shade: can be anything from ivory to red. Here is the size of a red solid brick;

- surface: it can be as smooth as possible, and with the presence of corrugations.

If you want to build a brick object, choose only high quality material and never give preference to cheapness.

Before you start laying, carry out something like an analysis: why are you building the building, what functions it will perform, what role is assigned to this or that element, whether the building will come into contact with aggressive environmental factors.

Other components of real estate can be created from cheaper grades of briquettes, thus you will reduce construction costs and the structure will not be overloaded.

For more information about an ordinary solid building brick, see the video:

Varieties

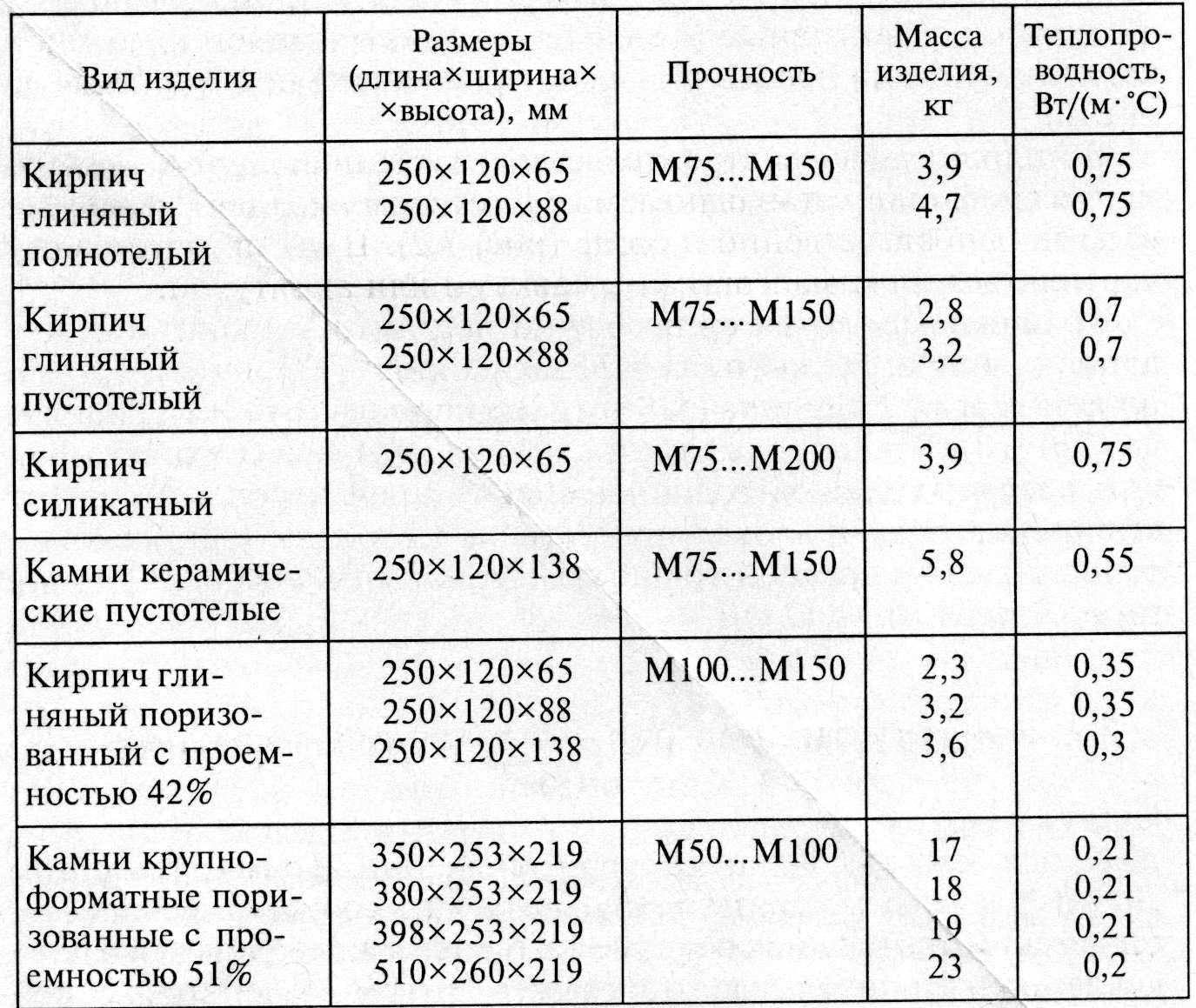

The classification of red solid bricks occurs according to a number of signs, the main of which is the purpose of the material. According to this criterion, ceramic models are divided into several types.

Ordinary brick

It is the most popular and demanded type and is used for the construction of foundations, load-bearing walls and interior partitions. The raw material for the brick is ordinary red clay, and it is made in two ways.

- The first is called the semi-dry pressing method and consists in the formation of workpieces from clay with low moisture content. The pressing takes place under very high pressure, so the fired raw material sets quickly enough, and a dense and hard material is obtained at the exit.

- The second method is called the method of plastic formation and consists in the design of the raw material by means of a belt press with further drying and firing of the blanks. It is in this way that most modifications of red brick are made.

Fireclay brick

It bears the name of refractory and is made of fireclay clay. Its share in the total mass of the product reaches 70%, which makes the material practically invulnerable to open fire and allows the masonry to withstand its impact for five hours. For comparison, it should be noted that reinforced concrete structures are able to withstand a flame for two hours, and metal structures - from 30 minutes to an hour.

Facing brick

It has a smooth or corrugated surface and is widely used for finishing facades of buildings and interiors.

Shaped or shaped bricks

It is produced in non-standard forms and is used in the construction and decoration of small architectural forms, including arches, columns and pillars.

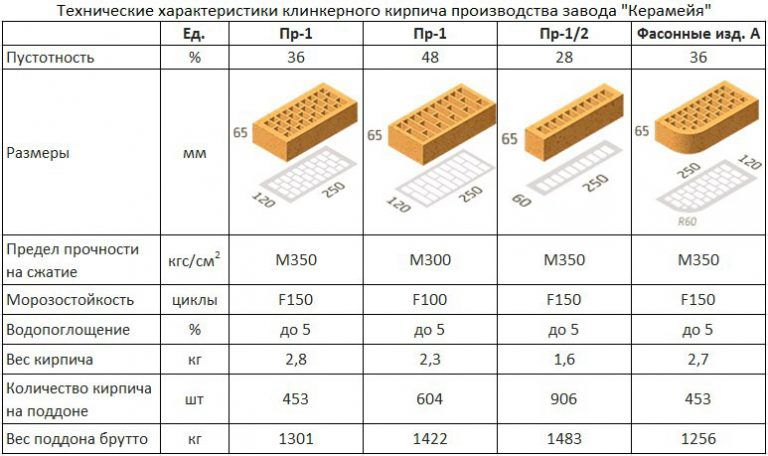

Clinker brick

It is the most durable type and is widely used for paving sidewalks and roadways. The clinker has a long service life, high strength reaching the M1000 index, and increased frost resistance, which allows the material to withstand up to 100 freezing cycles.

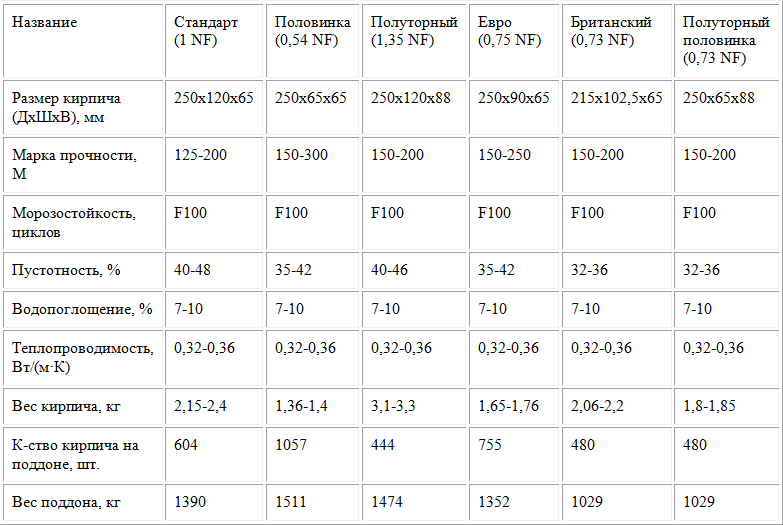

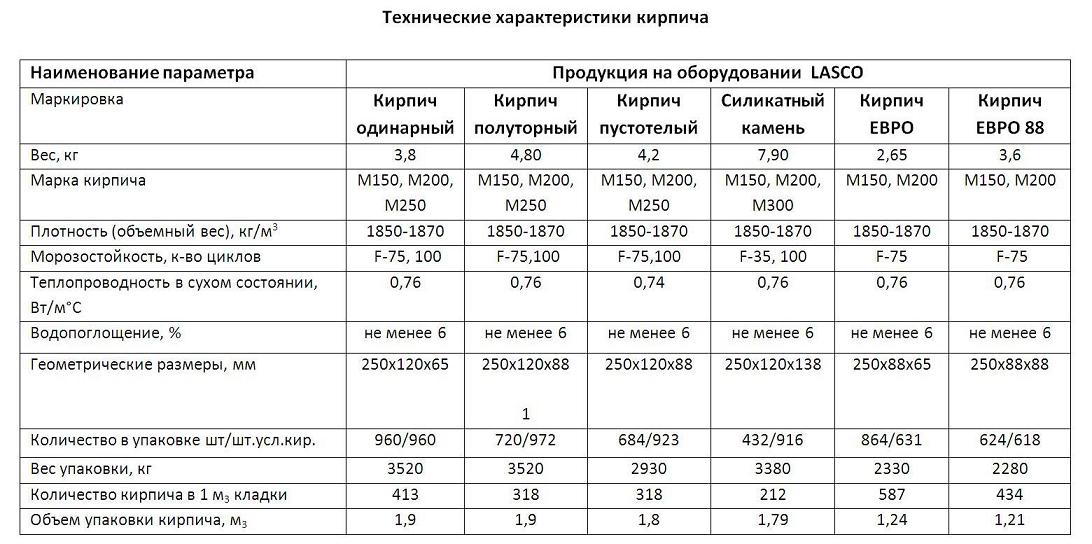

In addition to their functional purpose, ceramic full-bodied models differ in size. According to the accepted standards of GOSTs, bricks are produced in thickness in single, one-and-a-half and double versions. The most common sizes are single (250x120x65 mm) and one and a half (250x120x88 mm). Dimensions of double bricks reach 250x120x140 mm.

However, in addition to products with standard sizes, there are often options with unconventional dimensions. These include eurobricks with dimensions of 250x85x65 mm, modular specimens with dimensions of 288x138x65 mm, as well as non-dimensional models with lengths of 60, 120 and 180 mm and a height of up to 65 mm. Bricks of foreign manufacturers have slightly different dimensions, of which the most popular are 240x115x71 and 200x100x65 mm.

In the next video, you will find a film about the technological process of the production of clay bricks.

Decoding of marking

The strength and density of red and silicate bricks is determined in accordance with GOST. Quality control and determination of strength is carried out by a special method using the example of a selected 1 stone from a batch. It is designated as a brick marking. Red brick marks are written using an alphanumeric system:

| Designation | Peculiarities |

|---|---|

| M75 | Weak strength |

| Low price | |

| M 100 | Durability allows building up to 3 floors and uncomplicated construction |

| Low cost | |

| M125 | Ordinary clay brick |

| High strength of bricks, construction of buildings up to 3 floors is allowed | |

| Construction of partition columns |

The M150 marking is more durable and is represented by the following types of building stone:

- Private 1nf 150. It is used in the creation of foundations, plinths, walls for high-rise buildings.

- Double. It is used for masonry of load-bearing walls, as it is distinguished by its high strength.

M200 and M250 brands of ceramic bricks are similar in characteristics, the difference is small in the ability to withstand the load. The first makes 200 kg, and the second 250. And also have high water resistance. The following types are used in construction:

- Brick cr. It is used for load-bearing walls of multi-storey buildings, strength foundations.

- Facing. It is used for decorative paths.

M300 brick strength grade is considered the most expensive. Differs in durability and strength, it is also called non-destructive. Often used only in the form of solid bricks, less often hollow bricks. Sometimes builders use it instead of refractory for laying stoves, baths, fireplaces. Also suitable for exterior walls and basement construction.

Brick brands.

Factories make different types of bricks and label them according to their properties. In this article, we will look at the most popular brick brands such as M100, M125 and M150. And we will decipher what these mysterious numbers mean, and what are the differences between them.

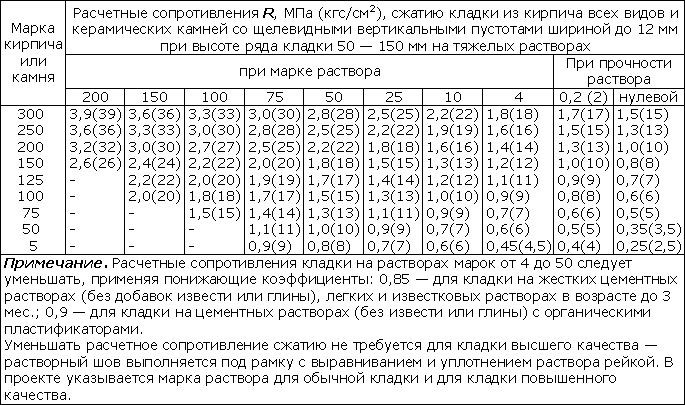

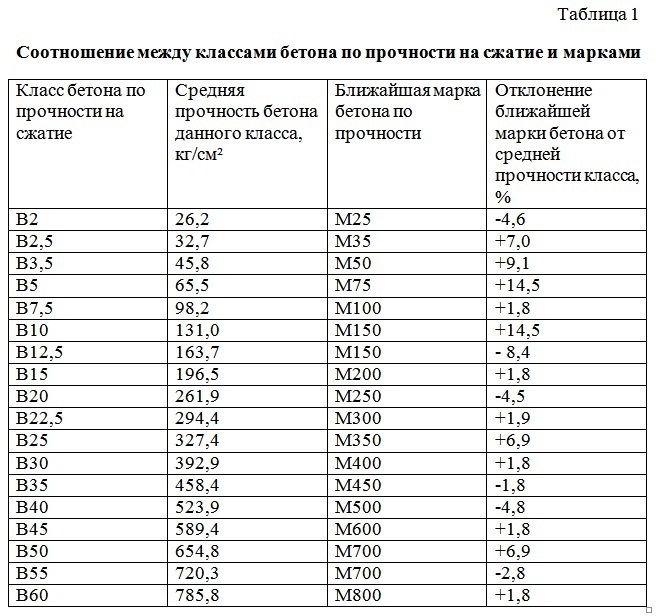

The number that is indicated after the letter M (brand) will indicate to you the ultimate strength of the brick. In the markets, you can find various types of bricks with brands ranging from 75 to 300. Of these, the most popular are M100, M125 and M150. The strength of the brick determines its place in the structure. The higher the indicator on the brick grade, the higher its strength. That is why bricks with the greatest strength are most often laid in the base of the building, and in the main walls. For the construction of private houses, M100 is considered ideal bricks. For high-rise buildings, it is better to use bricks of the M150 brand. The strength indicators are not affected by whether the brick is full-bodied or slotted.

If you have bricks of different brands for building a house, you can put the most durable M150 bricks in the base of the house, thus bringing the so-called "zero" along the foundation slabs. For the middle, bricks with a lower strength are suitable, grade M125, and on the top, use brick M100.

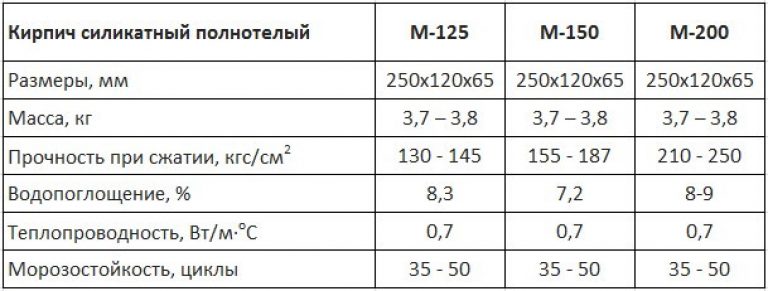

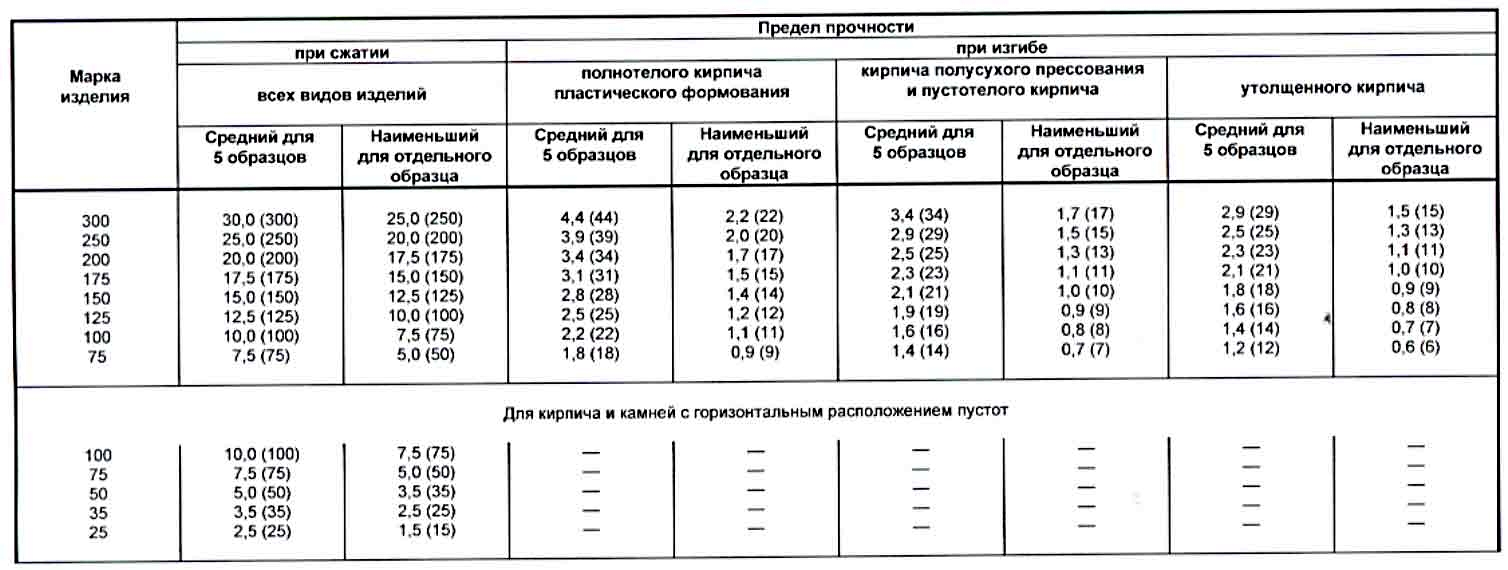

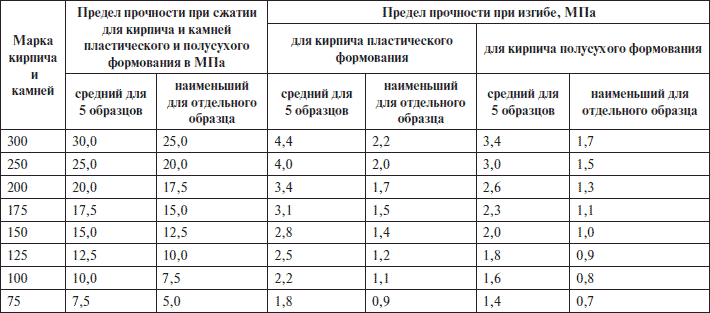

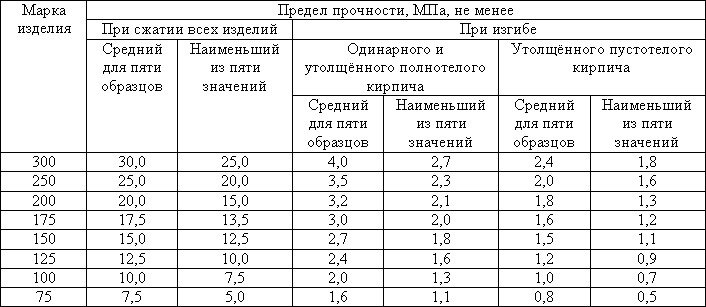

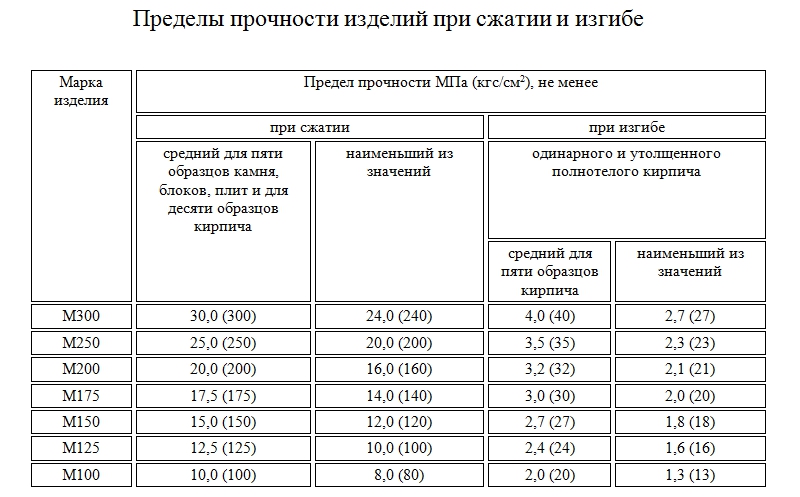

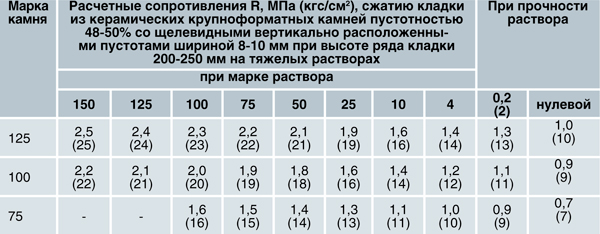

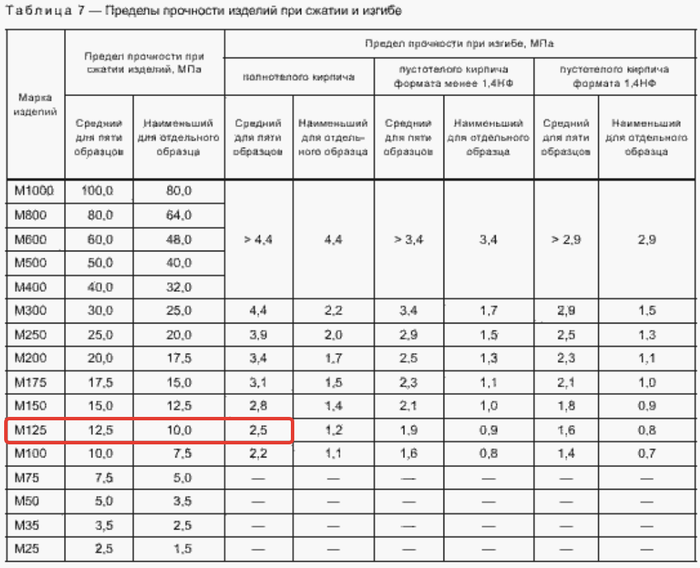

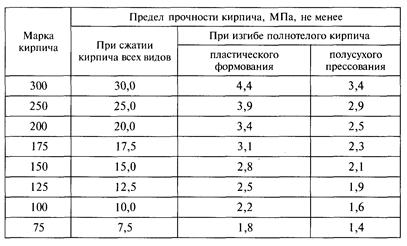

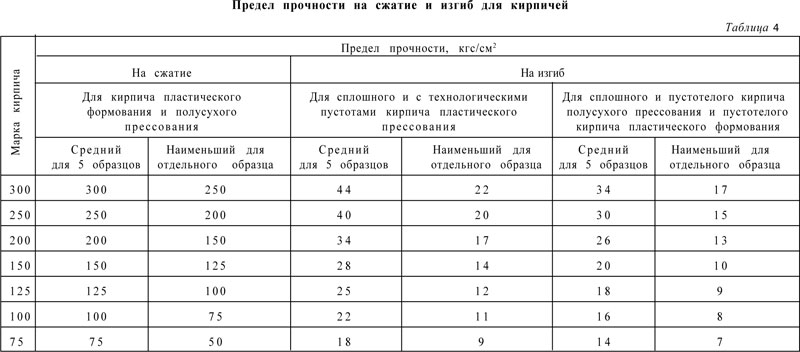

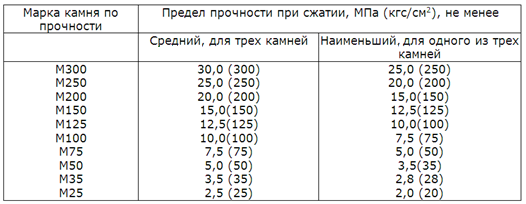

The brick grade is set according to the value of the compressive and bending strengths. Silicate brick is divided into grades 75, 100, 125, 150, 200, depending on the ultimate strength of the brick. Determine the brand of bricks in terms of compressive strength, usually it is 7.5 - 35 MPa.

Brick grade

Ultimate strength, MPa, not less

when compressed

bending

for all types of bricks and stones

for plastic molding solid bricks

for solid bricks of semi-dry formation and hollow bricks

average for five samples

smallest for a single sample

average for five samples

smallest for a single sample

average for five samples

smallest for a single sample

The brick grade (strength) is considered the main characteristic - this is a special property of a brick to resist internal stresses and deformations, while remaining intact. This indicator is indicated by the letter "M" and a number. The figure indicates the maximum load that a brick can withstand by 1 cm 2. For example, a brick grade 150 (M150) indicates that the brick is capable of withstanding a load of 150 kg / cm 2. The strength index can vary from 75 to 300. On sale you can often see the brand of brick M100, M125, M150 and M200.

Brand M 200

Hollow M 200 has a relatively low thermal conductivity, so its use is mainly limited to wall masonry.

Since solid bricks of grade 200 have good water-repellency, they are often used for laying foundations and plinths of buildings.In addition, the corpulent M 200 is used for the construction of stoves and fireplaces. In this case, the thermal conductivity index plays an important role, since it contributes to the rapid heating of the furnace body and good heat transfer inside the building. But I must say that in no case should they lay out the combustion chambers, since with constant contact with fire, it will become fragile and subsequently completely collapse.

It should be noted that the brands of bricks produced in different regions will slightly differ from each other in their characteristics. This is due to the fact that different factories have different equipment, and they use raw materials, that is, clay, which differs in its composition. But one way or another, the requirement for raw materials will be the same - this is its homogeneity.

Now you know what brands of bricks are.

Fashion for Naked: the best images of the stars. We select a Naked cosmetic bag for your make-up It's nice when fashion pushes us not only to experiment, but also to accept ourselves and our beauty. Fashionable positive attitude to your own body.

Toxicosis: causes, consequences, treatment The assumption that nausea worries a woman only in the morning is incorrect. It can last all day, but is most pronounced in the morning. It comes from.

10 adorable star children who look completely different today Time flies, and one day little celebrities become adults who are no longer recognizable. Pretty boys and girls turn into s.

Never do this in church! If you are unsure of whether or not you are doing the right thing in the church, you are probably not doing the right thing. Here is a list of the awful ones.

7 parts of the body that should not be touched by hands Think of your body as a temple: you can use it, but there are some sacred places that should not be touched with your hands. Research showing.

9 celebrity women who fell in love with women It is not unusual to show interest in someone other than the opposite sex. You are unlikely to be able to surprise or shock someone if you admit it.

Characteristics of frost resistance

This characteristic shows how many times the moistened material is able to withstand freezing and defrosting (the temperature during freezing should be minus 18 degrees Celsius with an error of up to 2 degrees). This indicator is in the designation of the brand after the letter "F". There are the following main brands for this parameter: F100, F75, F50, F 35, F30, F25, F15.

At the same time, it is worth knowing that brick tests are carried out in extreme laboratory conditions. So, let's say, Brand F50 can actually withstand not fifty freeze-thaw cycles, but much more. Moreover, winter and winter are different, some are very warm.

According to DSTU B V.2.7-61-97, the brick used for cladding must have a grade that is not lower than F25

Therefore, you should especially pay attention to the fact that for facing bricks, unlike ordinary ones, the F15 brand does not exist

This video will tell you about how the red brick is tested for strength:

vote

Article Rating

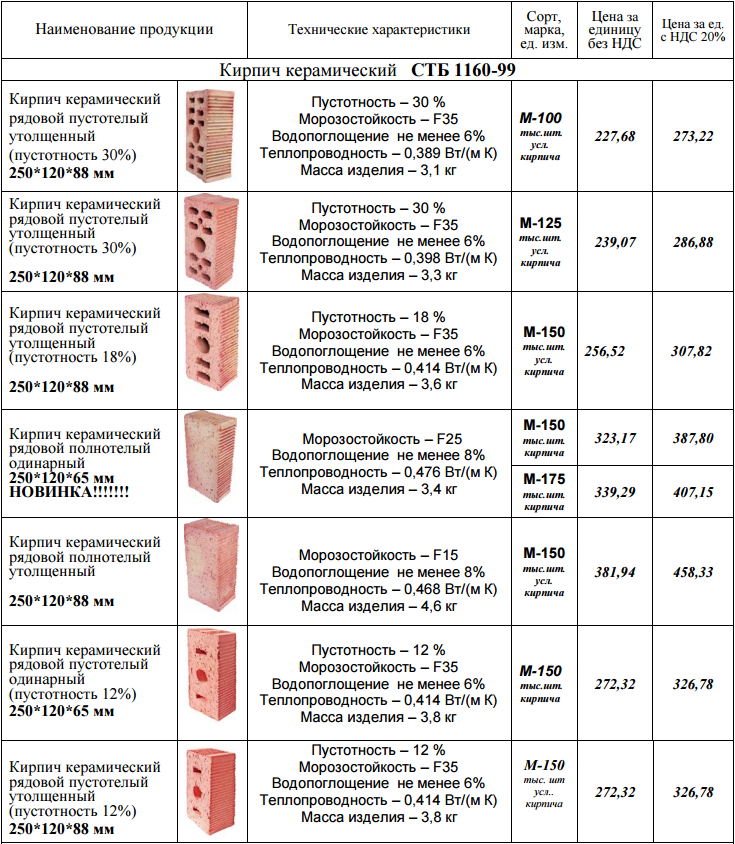

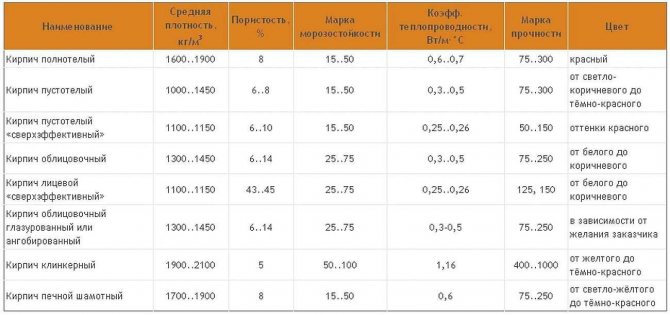

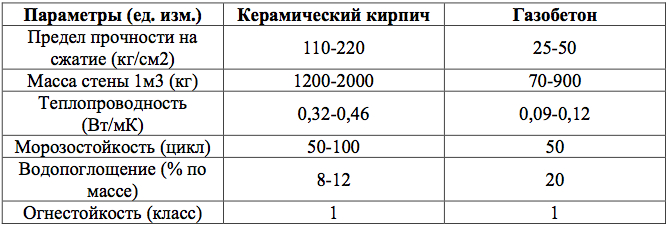

Ceramic brick grades in terms of density and strength

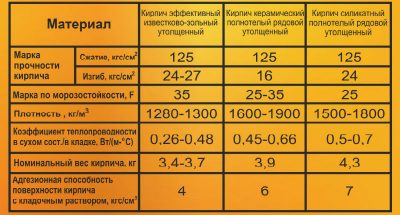

Density is a parameter that determines the weight of a material of a certain volume. For facing products, it reaches values from 1.3 to 1.45 tons per cubic centimeter. At the same time, the porosity indicator can reach up to 14 percent (minimum - 6 percent). As for the strength, it shows what kind of load (in kilograms) one square centimeter of the brick surface can take on.

Strength is indicated by marks, where after the letter "M" is this indicator. There are seven brands of ceramic facing bricks: from M75 to M300. But for cladding, as a rule, too high grades are not required - after all, the material does not experience such loads as, say, an ordinary brick when laying a foundation. Or load-bearing walls.Therefore, facing products of the M300 brand are not produced at all.

Ceramic bricks used for cladding work, for the most part, have voids inside. So you can solve two problems at once: to make its laying simpler and more convenient, and also to improve the heat saving of the walls lined with this material. But the hollowness does not affect the tensile strength. We decided not to present the strength grades of ceramic bricks in the form of a table, limiting ourselves to a brief description of the advantages of each of them.

This video will tell you more about the types and brands of red brick:

Products of this type are the least durable, but they are the cheapest. This allows you to significantly reduce the cost of construction work.

Basically, ceramic brick of grade 75 is of an ordinary type. It is used for the construction of walls of low-rise buildings, as well as various buildings.

Stronger than M75, suitable for walls (load-bearing and external). The versatility of this material allows it to be used for many low-rise buildings (not exceeding three floors).

The facing brick of this brand is suitable both for covering the external facades of buildings with different numbers of floors, and for the manufacture of decorative buildings, fences. Buildings up to three floors, columns, pillars, partitions are built from ordinary bricks.

For cladding, as a rule, a hollow version is used with the following characteristics:

- The weight of one piece is from 2.2 to 2.5 kilograms.

- Strength (in compression and bending) - from 1.4 to 1.6 MPA.

- Absorption of liquid (water) - no more than 8 percent.

- The thermal conductivity coefficient is from 0.2 to 0.26 watts per meter per degree Celsius.

Solid brick of this brand has the same safety margin, but a high thermal conductivity coefficient (0.513 watts per meter per degree Celsius) and a more solid weight (up to 3.5 kilograms). Thickened ceramic bricks, grade 125, have a reasonable price.

One of the most popular brands (M150) is ceramic solid brick of the M150 gost mark.

- In the ordinary version, it is suitable for the construction of the basement part of buildings, as well as foundations, walls of houses (including multi-storey ones).

- For masonry walls, both load-bearing and external, double bricks of this brand are often used.

- The facing brick is suitable for cladding buildings, as well as the construction of various buildings (gazebos, fences, benches at the summer cottage).

M200 and M250

High quality and reliable products. They are able to withstand heavy loads and have excellent water resistance.

- Ordinary bricks of these brands can be used for the construction of the foundations of houses and for the construction of multi-storey buildings.

- The facing option is suitable not only for performing all of the above works, but also for laying out strong and beautiful paths (for example, on the site near the cottage).

For example, to lay the foundation of a house with many floors. Or basement structures, the walls of which need to be additionally strengthened. In the fireproof version, the brick of this brand is good for laying fireplaces and stoves.

Application of different brands

The field of application of cement depends on its brand and characteristics that determine its properties. The main types include:

- M300 is the cheapest brand used in one-story, private construction.

- М400 - applicable for the manufacture of reinforced concrete structures, preparation of standard concrete, plaster mortars, brickwork, concreting of ground and underground structures.

- M500 is used in bridge supports in water or on land, since it provides increased strength, it is used in the construction of communications and structures, and in repair work.

- М600 is intended for the production of high-quality prefabricated structures with high requirements for strength and frost resistance.

- M700 is used for concrete with strength class from B35, used in structures with high mechanical stress.

Various brands of Portland cement can change their properties due to additives that increase the setting rate, frost resistance, pouring at high humidity.

The use of cements depends on its type, composition and properties:

- Portland cement - concrete monoliths, reinforced concrete structures.

- Slag Portland cement - monoliths, including underground, underwater.

- Pozzolanic compositions - prefabricated structures, underwater and underground monoliths.

- Alumina - used for repairs, damage repair due to high setting speed. With an increase in the concentration of alumina, the heat-resistant properties of the materials obtained increase.

- Gypsum-alumina - used for waterproof concrete, expanding and non-shrinking materials.

- Colored and white materials - used for interior and exterior finishing works.

The correct selection of the brand of cement will allow you to obtain a building material with the given characteristics. The combination of the components of the mixture, in accordance with which the product is made, will make it possible to produce concrete of the required strength class, speed of hardening. Additional parameters provide the properties of the composition for its use in special conditions - high and low temperatures, high humidity, vibration, and other negative influences. The labeling and other properties of the binder are reflected in its packaging.

Ceramic brick M-150 and its application

Such material can withstand a load of up to one hundred and fifty kilograms and is suitable for any construction option: for the construction of office premises and buildings. Brick ceramic corpulent ordinary single m 150 is widely used in housing and for utility rooms.

- This material is available in two versions: solid and hollow. They have a fairly high strength, retain heat well, and also have high frost resistance.

- Single solid ceramic brick m 150 is perfectly used for the construction of foundations and plinths of any type. This is a fairly durable material that will withstand floor slabs;

- The corpulent version is also successfully suitable for the construction of fireplaces. it is also often used to install different types of ovens. An excellent solution for the material for the manufacture of a barbecue. in short, suitable for anything where solid fuels are not used. In these cases, it is worth using refractory bricks.

- Ceramic brick m150 is hollow, perfect for installing partitions indoors and for cladding a building. Voids make it not so strong and it may not withstand floor slabs.

- Due to its positive properties, such a material is able to withstand strong pressure. Such a brick is produced with a standard single size, as well as with a double and one and a half. This allows you to significantly save time on construction.

- Brick is subdivided into special, facing and construction, therefore it is used not only for the construction of buildings, but also for facing facades.

- Brick m150, the price is slightly higher than brick M75. But you get a stronger material and it has a wider scope of application.

- Clack of this material may well be carried out independently, this will significantly reduce construction costs.

- The weight of a brick m150 is standard there is nothing new here.

- It is not difficult to buy brick m150, it can be done at any point in the retail trade in building materials or at a manufacturing plant.

When building a solid brick structure, which assumes that it will last up to a hundred years, it is best to purchase a solid ceramic brick. This building material is perfectly suited for the construction of lower floors and foundations that use significant loads on themselves.

It is not enough to take brick in terms of parameters, you still need to take high-quality material. After all, you can simply be deceived

In the video you can see what is worth paying attention to

Delivery and storage of material

Varieties

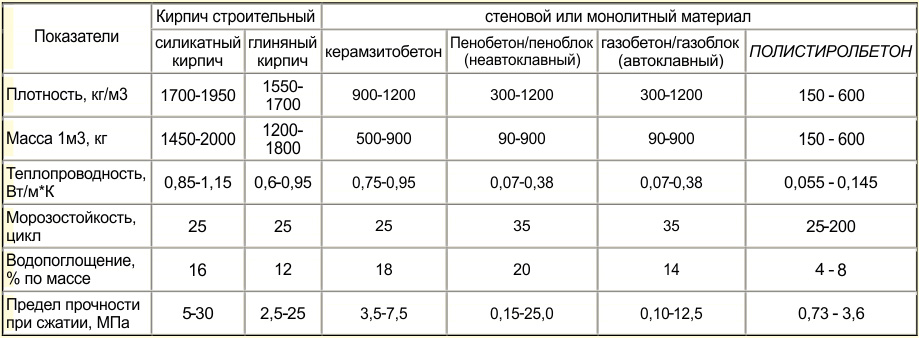

The material used in the production of bricks affects its density. Types of bricks (grade M100): single and one-and-a-half, solid and hollow, ceramic, silicate and hyper-pressed. The composition of ceramic and silicate bricks is fundamentally different. The first includes clay (sometimes several different clays). The mixture is shaped and dried, then fired at a high temperature. Such a brick is not afraid of moisture.

Sand lime bricks are made from sand and lime. This allows it to have better heat and sound insulation properties than ceramic. Silicate brick can be recognized by its white color. It does not like moisture, so it cannot be used in ovens and foundations. The characteristics of an ordinary brick are more important than appearance. Plaster or tile glue perfectly fits on a rough surface.

The basis of hyper-pressed bricks is limestone. Cement and coloring pigments account for only 10%. It is used most often for decoration and cladding. This use brings to the fore the visual characteristics: color, size and surface smoothness. There are five main colors of facing bricks: red, brown, terracotta, thatch and ivory.

Only ceramic bricks are hollow and solid. In full-bodied, their number should be less than the specified value, and the surface can be flat or corrugated. The advantages of a hollow core are lower thermal conductivity and weight. However, it has poorer moisture resistance. The shape and size of voids are not regulated by GOST.

Types, properties and application

By designation, brick is divided into construction, special and facing. Construction is used for masonry walls, facing - for the design of facades and interiors, and a special one is used for foundations, road surfaces, masonry of stoves and fireplaces.

A narrower specialization is due to the different structure of products.

Solid brick

It is a solid bar with random voids less than 13%.

Bricks are full-bodied:

Silicate, ceramic - used for the construction of self-supporting walls, partitions, columns, pillars, and so on. Solid brick structures are reliable, frost-resistant, capable of carrying additional loads. Partitions provide good sound insulation with a small thickness, retain a large amount of heat.

In addition, the material is quite decorative and popular with many modern designers. But the high coefficient of thermal conductivity and water absorption forces to construct external walls of great thickness or to make them three-layer, combining with insulating materials and other types of bricks.

Fireclay - is made from special refractory crushed clay and fireclay powder by firing with an increased temperature regime. It is used for laying out fireplaces, stoves and other structures where fire resistance is required. The specificity of the application has determined a wide variety of product shapes:

- wedge-shaped and straight;

- large, medium and small sizes;

- shaped with profiles of varying complexity;

- special, laboratory and industrial crucibles, tubes and other equipment.

Clinker - made from refractory clays with various additives. Fired at very high temperatures until completely baked. Various components and variability of the firing mode give the bricks increased strength, water resistance and a wide palette of shades from greenish, when fired with peat, to burgundy with charcoal tan. It used to be widely used for paving sidewalks, now it is used in masonry and cladding of foundations. The thermal conductivity of ceramic bricks is quite high.

Hollow brick

The material allows 45% of voids from the total volume, and also differs in shape, structure and location of voids in the bar. The thermal conductivity of a hollow brick directly depends on the amount of air in its body - the more air, the better the thermal insulation.

A brick with voids is a block with two or three large through holes, which serve rather to facilitate and reduce the cost, rather than improve thermal insulation. It is used on a par with a full-bodied analogue, with the exception of foundations and other structures that require increased strength.

Slotted brick - the entire body of the block is pierced with holes of various shapes and sizes.

They are:

- rectangular;

- triangular;

- diamond-shaped;

- through and closed on one side;

- vertical and horizontal.

Quite good strength and low thermal conductivity determine its demand for the construction of external walls of residential buildings.

Porous bricks - available in several sizes. In addition to a large number of holes, it has a porous material structure, which is formed when special small fractions added to clay are burned out. Possesses the best set of qualities for the construction of external walls. Strength, low thermal conductivity and large dimensions reduce the construction time by several times, while observing the latest SNiP requirements. Warm ceramics are characterized by the lowest thermal conductivity, but due to their fragility, they have limited application so far.

Facing brick is also hollow, successfully combining artistic and insulation properties.

Table of indicators of thermal conductivity of building materials

| Material name | Thermal conductivity coefficient, W / (m * K) |

| Ceramic block | 0,17- 0,21 |

| Porous brick | 0,22 |

| Ceramic slotted brick | 0,34–0,43 |

| Slotted silicate brick | 0,4 |

| Ceramic brick with voids | 0,57 |

| Ceramic solid brick | 0,5-0,8 |

| Silicate brick with voids | 0,66 |

| Solid silicate brick | 0,7–0,8 |

| Clinker brick | 0,8–0,9 |

Almost always, in the construction of a house, several types of bricks with corresponding characteristics are used for different structural elements.

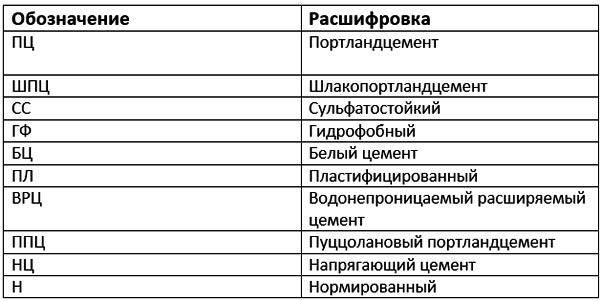

Classification of cement

Cements are classified according to several of the following factors:

- Depending on the type of the main mineral:

- Roman cement, characterized by the predominance of belite, is not produced in modern conditions;

- Portland cement, which is most widespread in the construction industry, is characterized by the predominance of alite;

- aluminous, in which the aluminate phase predominates;

- magnesian - based on magnesite, mixing is performed by salts dissolved in water;

- acid-resistant, consisting of sodium hydrosilicate, sodium silicofluoride and dry quartz sands, a mixture of water with liquid glass is used for mixing.

- biocements, unlike conventional cements, are manufactured using biotechnology.

- Depending on the additives contained, a distinction is made between:

- standard Portland cements (designation in the decoding of cement - PC);

- sulfate-resistant Portland cements, used in an aggressive environment (CC);

- white cements, in the production of decorative finishing works, various coloring pigments (BC) are added to them;

- Portland slag cements containing up to 20% of blast furnace slag powder, which significantly reduces their cost (SHPC);

- hydro-resistant, fast-hardening binders, gaining strength in air and in water after 15 minutes (VRTs);

- plasticized cements containing antifreeze additives that increase the frost resistance of working mixtures, which allows them to be laid at low temperatures (PL).

- According to the speed of hardening, cements are divided into the following 5 groups:

- CEM I - Portland cement without additives and with a content of mineral impurities ≤ 5%. The most durable, strong and fast-hardening, already on the 2nd day the strength of concrete reaches 50%;

- CEM II - impurities in percentages from 6 to 35, with an increase in the amount of additives, the strength gain slows down.By the type of additives, it is divided into 2 subspecies, in the designation it is deciphered as follows: pozzolan (P) and slag granules (W);

- CEM III - Portland slag cements, containing 35 ... 60% of granulated blast furnace slags, are characterized by a normal hardening rate;

- CEM IV - pozzolanic with a normal solidification rate, the composition contains from 21 to 35 percent of silica and ash. The designations are deciphered in the marking: P - pozzolans, MK - microsilica, Z - fly ash;

- CEM V - composite binding powders with normal hardening rates, consisting of from 11 to 30% fly ash and the same amount of blast furnace slag granules. Used for the preparation of lightweight concrete.

The normal speed of hardening is considered to be a time interval of 28 days after placing in the case, during which the working mixture gains its design strength.

The safety class of cement is 3, that is, it is classified as a moderately hazardous substance. The material in the air in the form of dust is capable of causing various allergic diseases in industrial conditions.