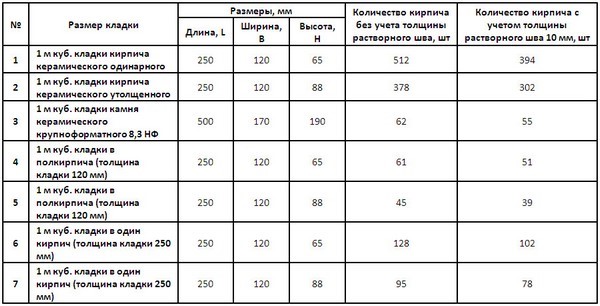

Standard type brick size - Table.

Brick is a stone of the correct form of artificial origin, which is very widely used in construction.

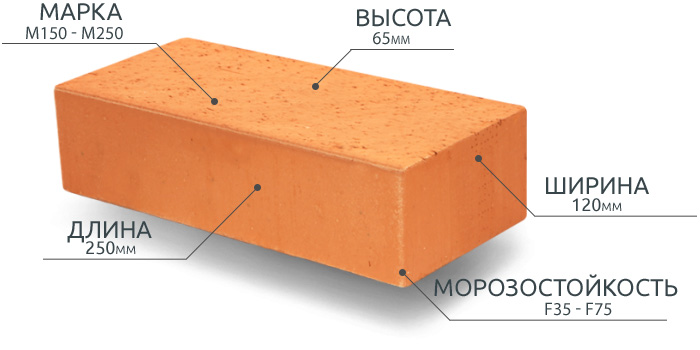

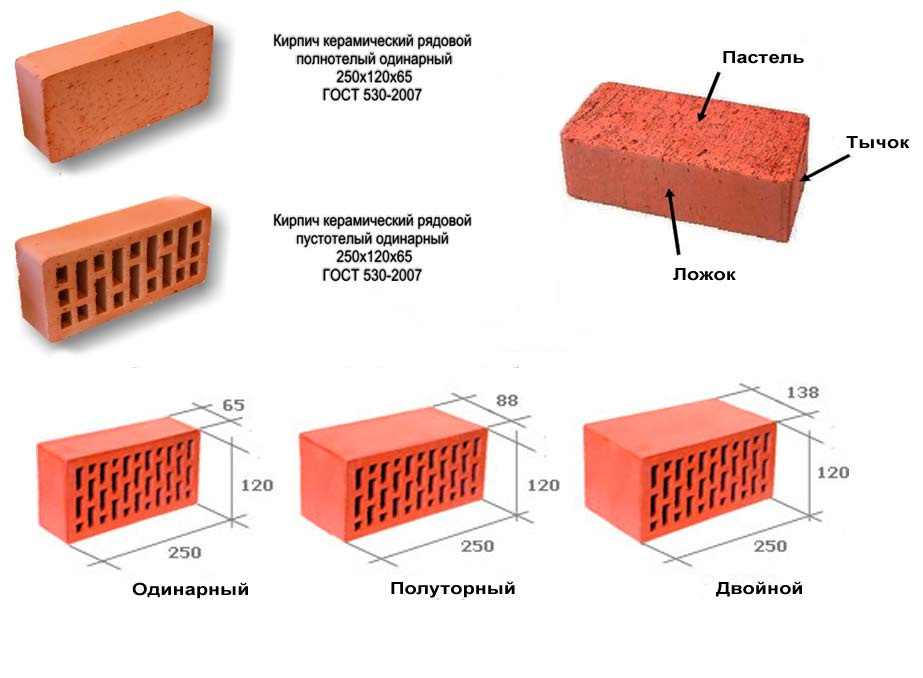

He has three surfaces:

- the bed is the largest;

- spoons - medium;

- butt is the smallest surface.

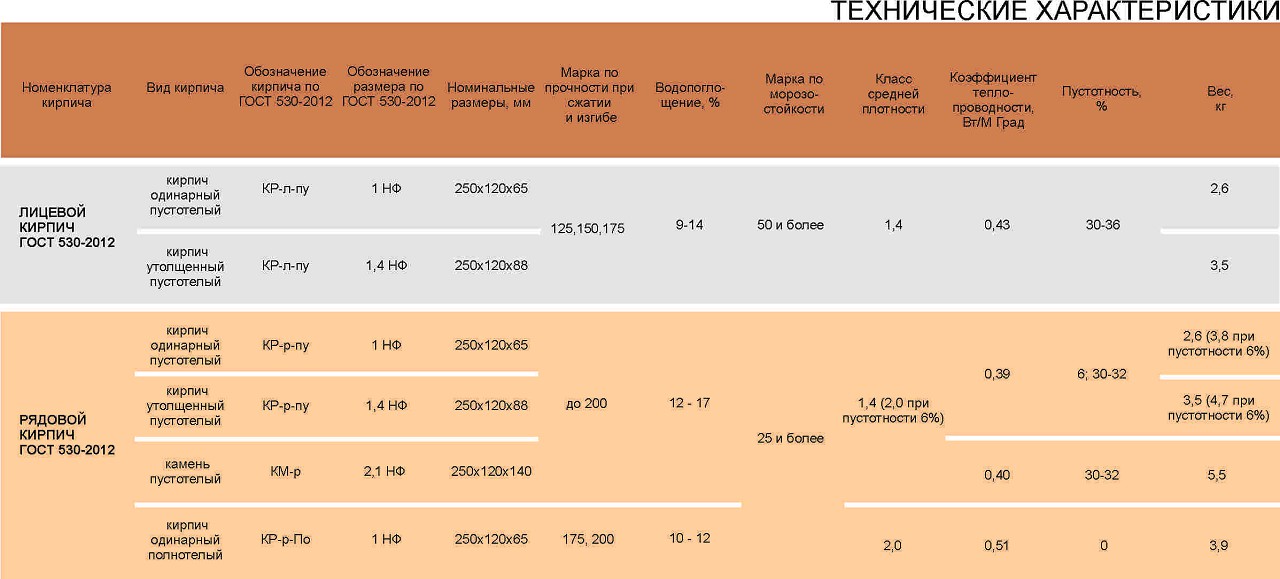

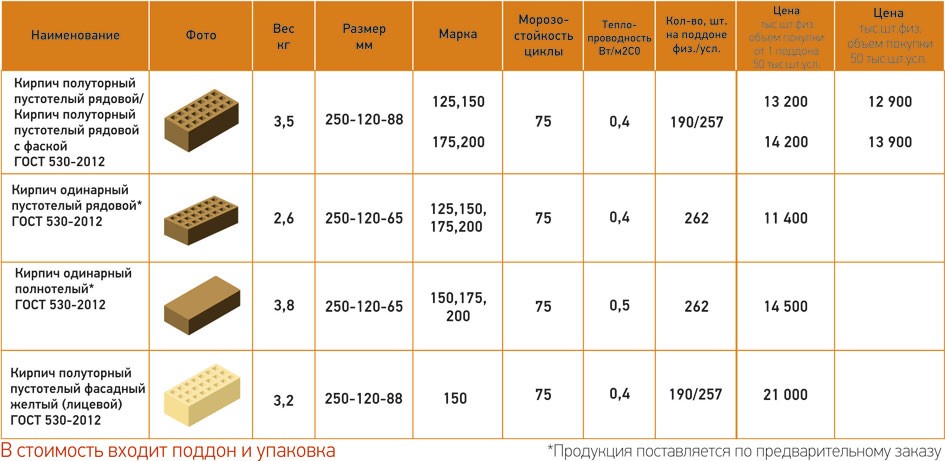

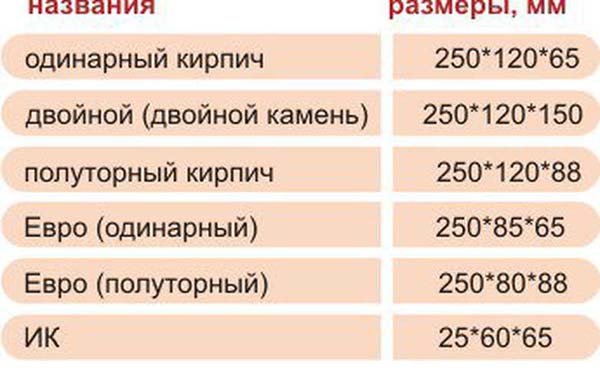

Dimensions and marking of bricks from domestic manufacturers.

In the table below, you can find out the size of the required brick block, as well as its marking, which is used in our market.

| Name | Dimension marking | Dimensions, mm. | Name marking |

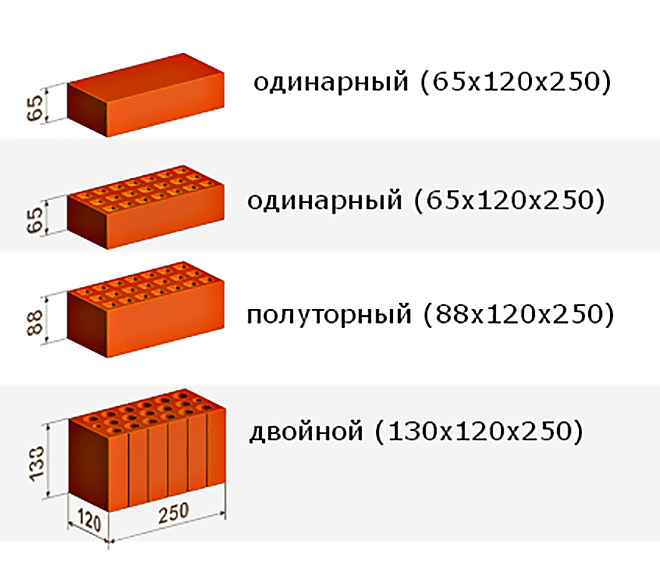

| Single | 1-NF | 250x120x65 | O |

| "Euro" | 0.7-NF | 250x85x65 | E |

| Modular single | 1,3-NF | 288x138x65 | M |

| One and a half | 1,4-NF | 250x120x88 | Have |

| Thickened brick with horizontal voids | 1,4-NF | 250x120x88 | UG |

| Double brick (stone) | 2,1-NF | 250x120x140 | TO |

| 3,7-NF | 288x288x88 | ||

| 2.9-NF | 288x138x140 | ||

| 1,8-NF | 288x138x88 | ||

| 4,5-NF | 250x250x140 | ||

| 3,2-NF | 250x180x140 | ||

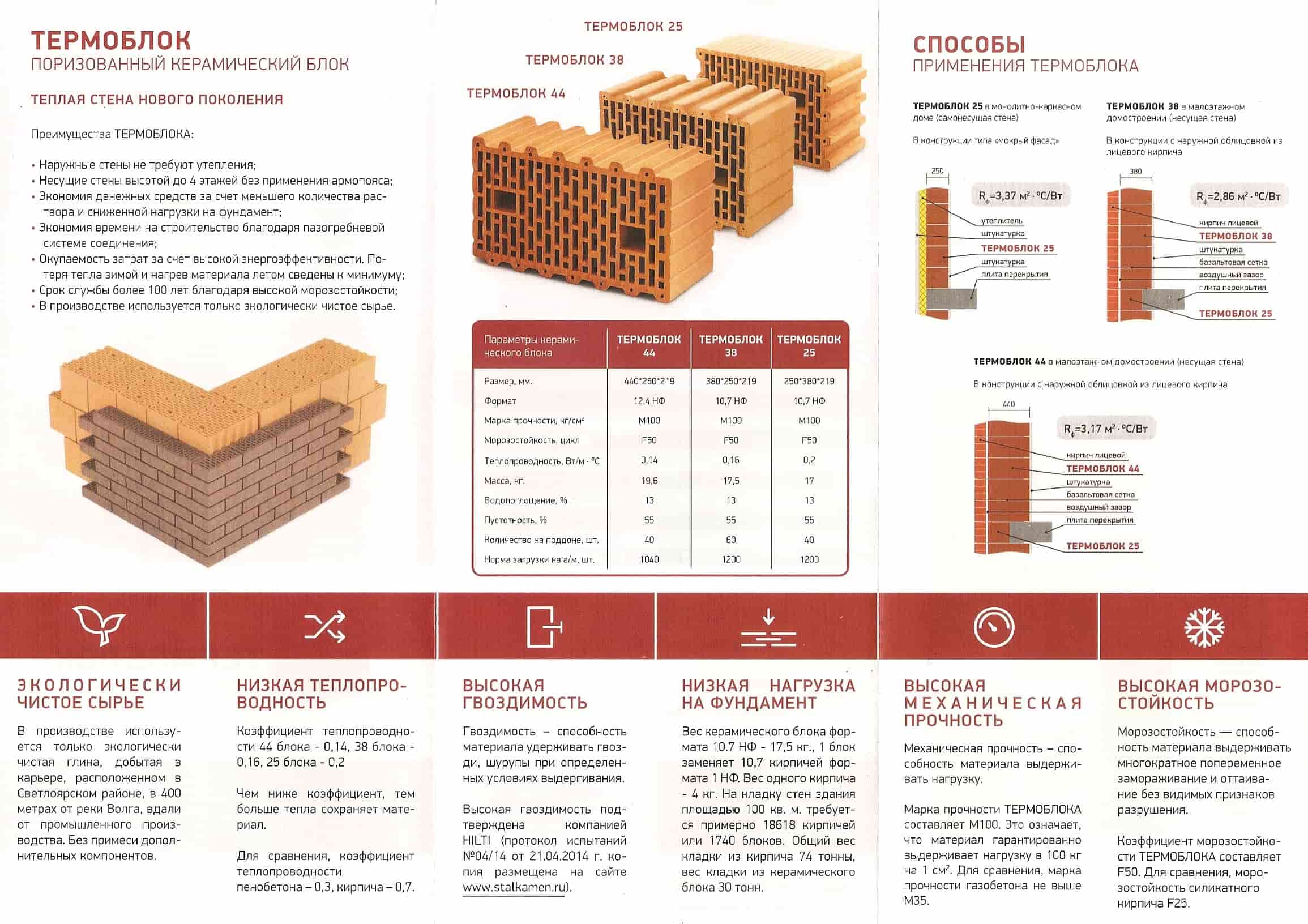

| Large-format stone (porous ceramic block) | 14,3-NF | 510x250x219 | QC |

| 11,2-NF | 398x250x219 | ||

| 10,7-NF | 380x250x219 | ||

| 9,3-NF | 380x255x188 | ||

| 6,8-NF | 380x250x140 | ||

| 4.9-NF | 380x180x140 | ||

| 6.0-NF | 250x250x188 | ||

| Stone with horizontal voids | 1,8-NF | 250x200x70 | KG |

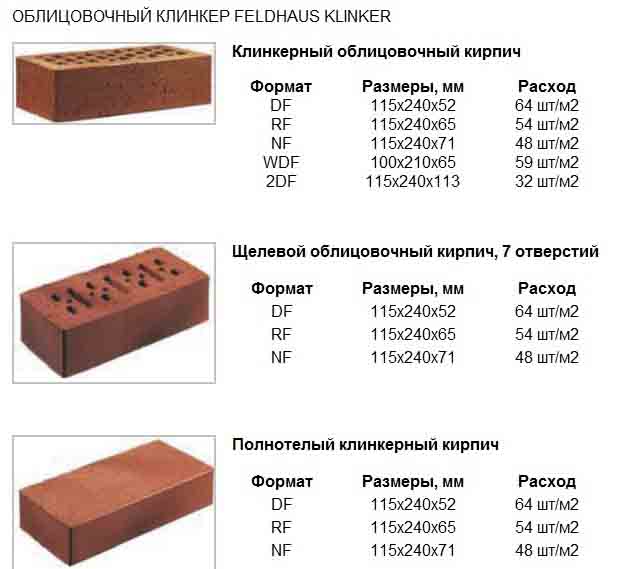

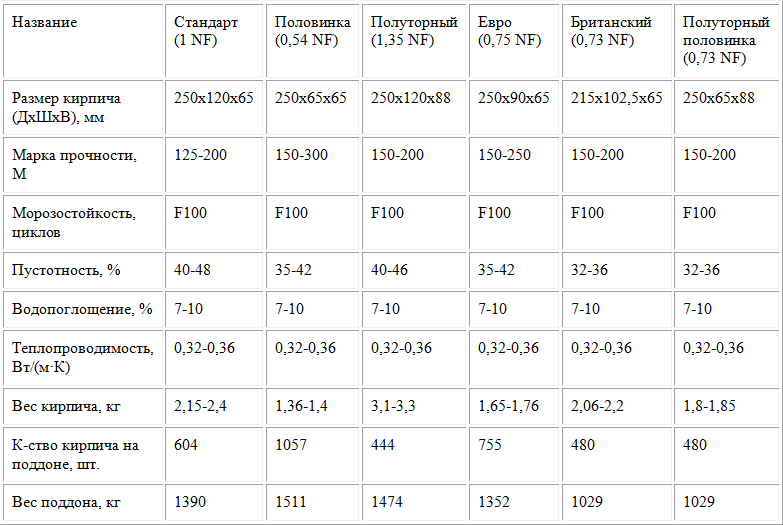

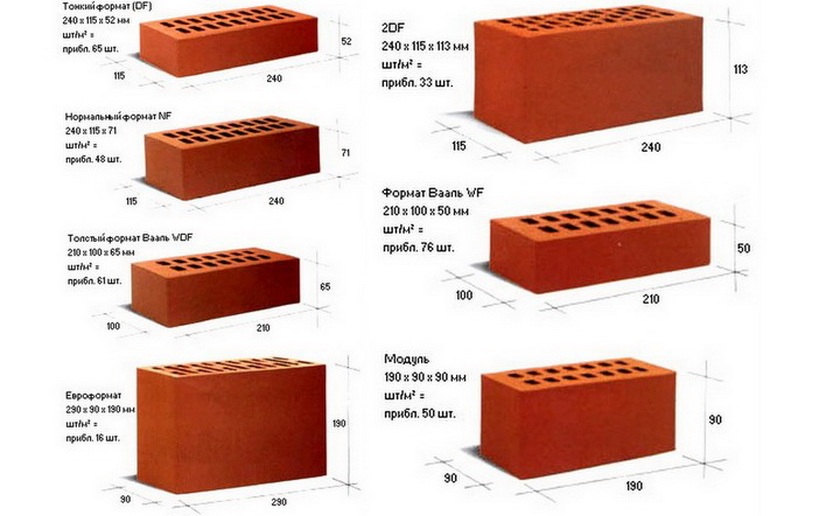

Size marking of European bricks.

Foreign manufacturers have completely different standards and sizes differ from domestic ones. Therefore, for complete convenience, the following table of brick sizes is presented:

| Marking | Dimensions, mm |

| DF | 240x115x52 |

| 2DF | 240x115x113 |

| NF | 240x115x71 |

| RF | 240x115x61 |

| WDF | 210x100x65 |

| Wf | 210x100x50 |

Knowing the size is good, but you also need to know the species, and there are many of them.

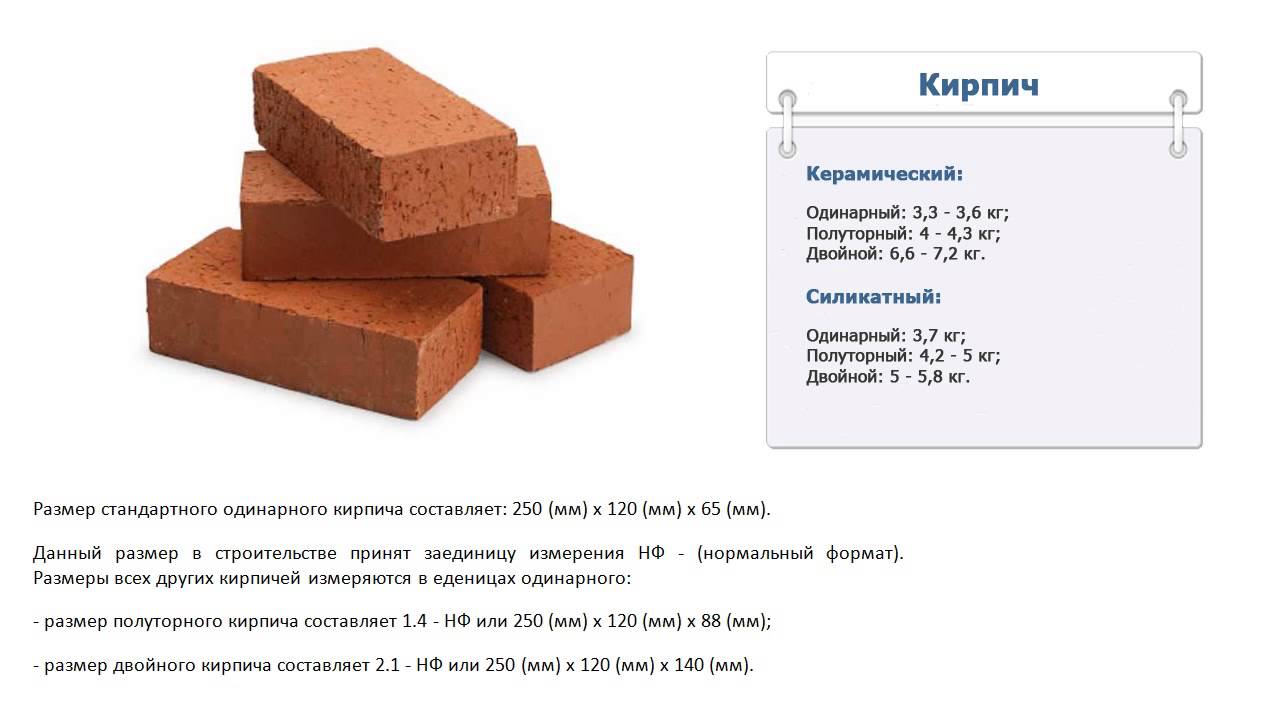

Red brick size.

The standard size of a red brick product was introduced at the beginning of the 19th century, and finally established itself relatively recently, in 1927, and is 250x120x65 mm.

Often such dimensions of single ceramic bricks are called normal or basic format. It is a product of this size that is considered the most convenient for the production of wall masonry work, more precisely, for alternating the arrangement of bricks when bandaging the masonry.

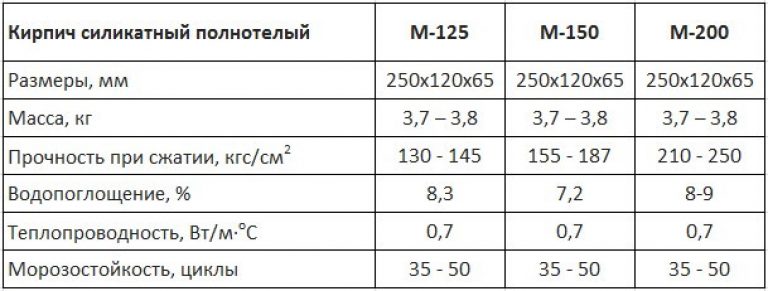

The size of the silicate brick.

SC is used in many cases when high strength is required from the building.

A brick is produced with the following dimensions:

- single - 250 mm long, 120 mm wide and 65 mm thick. The weight of the product depends on its type - hollow or corpulent;

- one and a half - or thickened, with the same length and width, the thickness of the product is 88 mm;

- double - or silicate stone, has a thickness of 138 mm.

There is a whole category of SC of non-standard size and shape rather far from a parallelepiped. These products are designed to form various architectural elements: arches, rounded corners, vaults, and so on. Their dimensions are regulated by TU and annexes to GOST.

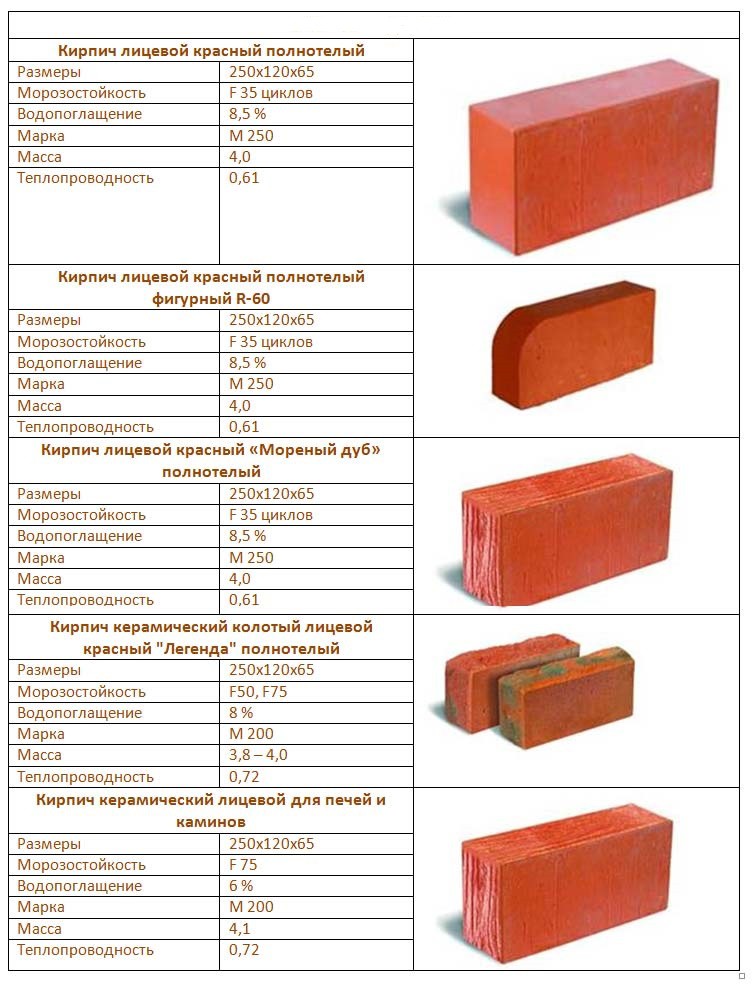

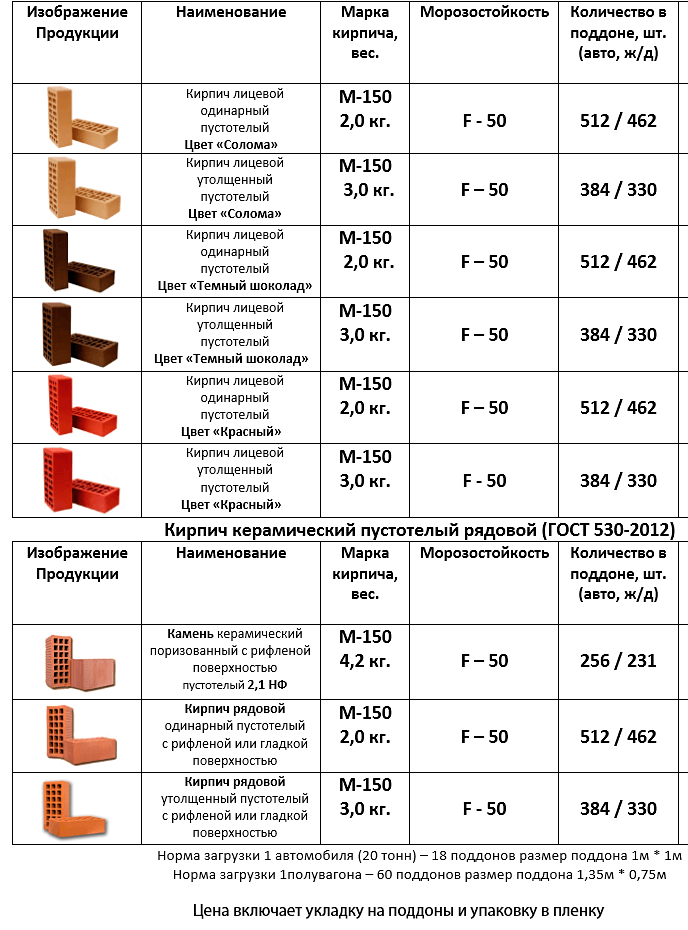

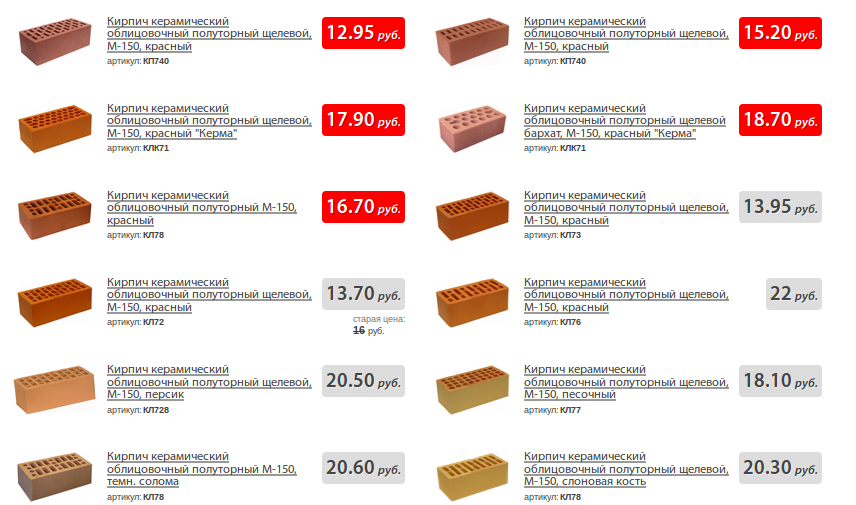

The size of the facing brick.

The usual size of decorative bricks can have the following parameters - 250x120x65 mm, 250x90x65 mm and 250x60x65 mm.

As you can see, the height can change, but the length and width of the brick remain unchanged. The only exceptions are the elongated elements, the parameters of which are 528x108x37 mm.

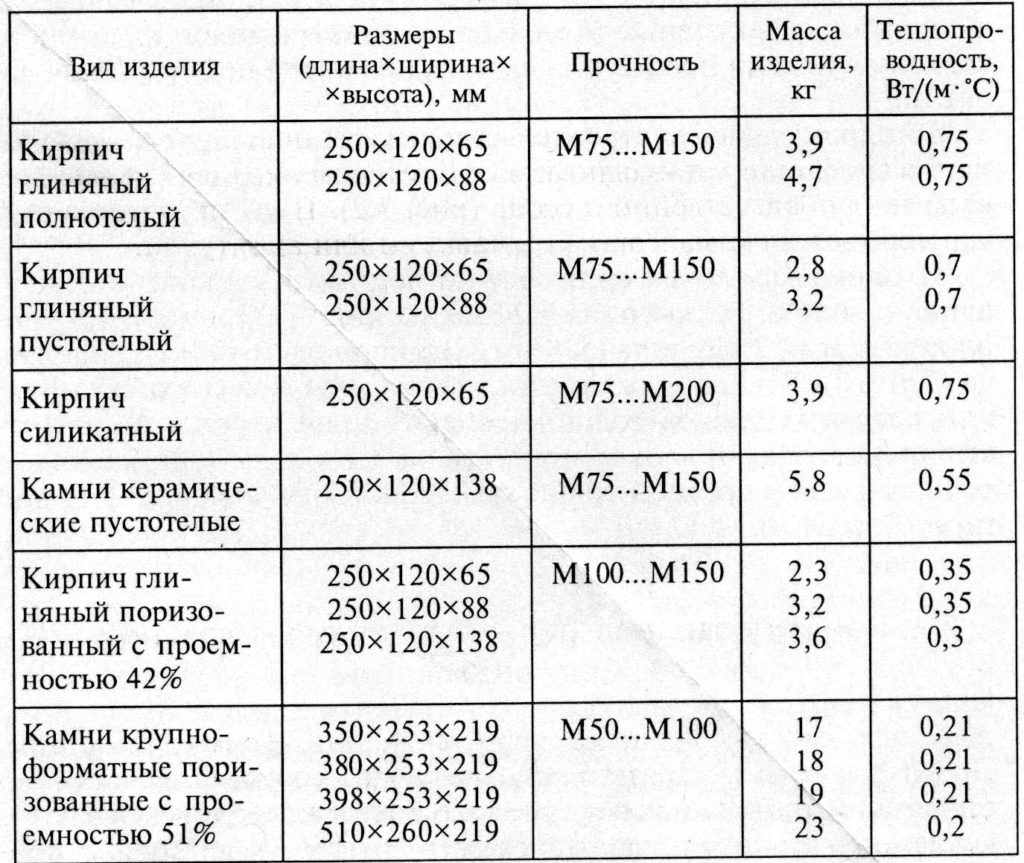

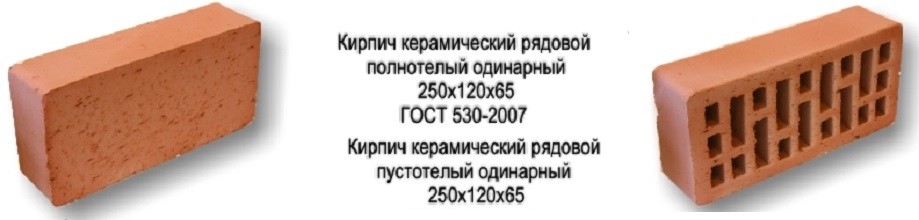

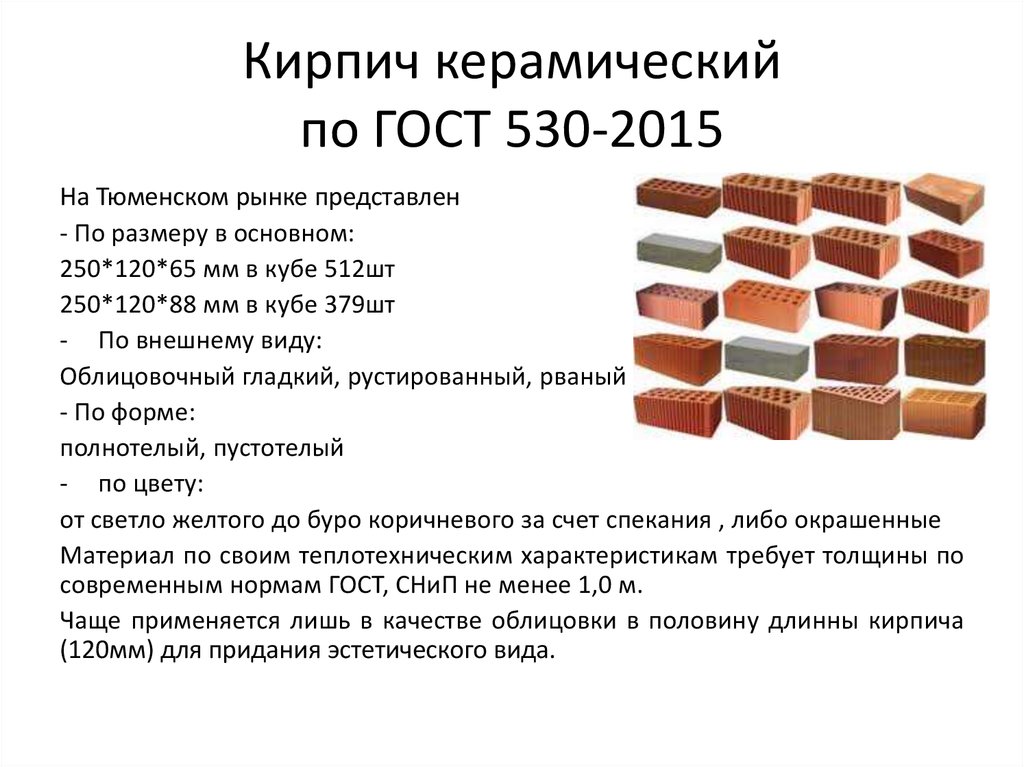

Dimensions of ceramic bricks.

KK is full-bodied, hollow, porous. The first modifications are made using a similar technology in various forms, into which the clay is filled. A unique technology is used in the production of porous ceramics.

The dimensions of the KK are as follows:

- single, perhaps the most common type. The standard dimensions of a single ceramic brick are 250 × 120 × 65, as you know, the dimensions of building materials are indicated in millimeters;

- the size of a one-and-a-half ceramic brick differs from a single one only in height, it is 88 millimeters, and the length and width remain unchanged.

- double, also higher than the standard, single, its height is 138 millimeters with the same length and width.

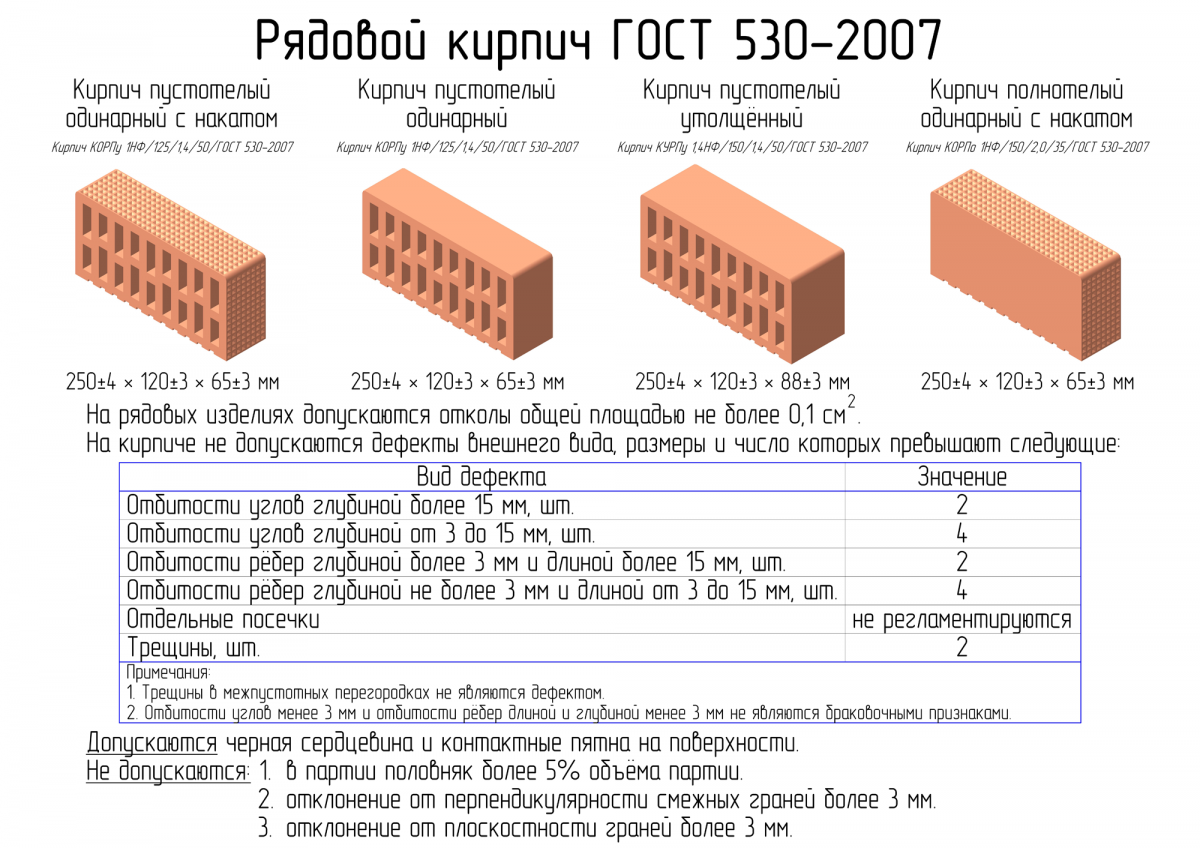

What are the markings of bricks.

Each batch of bricks is marked by the manufacturer, all information about the product is indicated on the marking in an alphanumeric code. It is not difficult to decipher the marking, it consists of: marking the name of the product, letters P - for privates, L - for obverse; size designations and designations: Po - for corpulent, Pu - for hollow; grades for strength and frost resistance; medium density class and designation of GOST.

For example: Brick KORPu 1NF / 100 / 1.4 / 50 / GOST 530-2007.

Marking of ordinary ceramic bricks, hollow, thickened, size 1.4NF, strength grade M150, average density class 1.4, frost resistance grade F50.

Or: Single silicate brick, ordinary grade for strength 150, grade for frost resistance F15 will be marked: Brick COP-150/15, GOST 379-95.

How to make the right choice

Before starting construction, the consumer cannot help asking himself the question: which brick M 200 to buy, how to choose the material that is optimal for your needs, calculate its amount, and not be mistaken in density? Making a choice, you should inquire about the characteristics of the material you like. The same brands of bricks, but made at different factories, differ in their technical properties. The end result depends on the equipment used, the composition of the raw materials used and other factors. In order not to be mistaken with the quantity, you need to find out the dimensions of the M 200 brick. Depending on whether you buy a one-and-a-half brick (thickened), double or single, its dimensions differ significantly. So if double brick corresponds to the size 250x130x120 mm, then single is usually produced with dimensions 250x120x65mm.

Pros and cons of ceramic bricks

The advantages of ceramics include naturalness, harmlessness. If we compare ceramics and silicate, then clay products win a little in terms of thermal conductivity. If you look at the indicators, then the difference is very small. But a ceramic house is much warmer than a silicate one. The point is in the higher heat capacity. Clay can store more heat and is therefore warmer at home.

Ceramics are inferior to silicate in sound insulation properties, as well as in geometry and stability of characteristics. This is its main disadvantage. Moreover, at a high price, often efflorescence, with which it is very, very difficult to fight. Another drawback is that even the front surface is rarely even.

Ceramic brick is a traditional material for building houses, which is more than one hundred years old.

All these shortcomings are understandable. Ceramic bricks are obtained by firing pre-shaped parallelepipeds from clay mortar. Clay is a natural material that has various properties. The different properties of different types of clay are the main reason that the size of ceramic bricks does not differ in stability. Moreover, a significant spread can be within the same batch. And from party to party, in general, there may be significant differences. The different characteristics of the feedstock also cause a wide variation in the characteristics of the finished product. Such as strength and density.

Service life - reality is not happy

In many respects, ceramics should be better than the same silicate, but the reality turns out to be different. Recently, too often there is a red ceramic brick crumbling, dilapidated after several years of operation under normal conditions. The reasons are the complexity of the technology. For a good result, careful processing and preparation of the clay is required in order to exclude lime inclusions, which are the reasons for "shooting". And this is additional time in an already not short production cycle. And extra energy. And expensive equipment, which is not bought by everyone.

Not the best picture

The second point: holding the temperature regime of firing. Burnt ceramic bricks behave normally in masonry. It only looks worse, as it is darker than the "norm". It's not so scary.But the unburned one collapses, crumbles. And this is why he is dangerous. Ceramics are fired in the furnace for a long time, and so it takes a little to reduce the time in order to increase productivity. Hence the underburning. Or fuel economy, which is far from cheap. So compliance with the technology for the production of ceramic bricks is a high price for products. And expensive bricks are bought very reluctantly. So the collapsed red brick most likely had a low price. And everyone knows that cheap is very rare. Nevertheless, the budget for a construction site is usually not a rubber one and you have to save money.

In terms of thermal conductivity and some other parameters, ceramic bricks should be better

No matter how complex the production technology is, European supplies have a geometry close to ideal, and the dimensions are standard, and the quality is stable. Their price is far from budget, but quality problems are rare. So if the funds allow, they try to buy imported bricks. Domestic clay, even expensive, still cannot boast of stability of quality. That is why, although ceramics should be better in many respects, more and more often the choice is made in favor of silicate. Because for quite reasonable money you can buy good quality building material. He is chosen even though he is much colder. All the same, in order to achieve the required level of energy efficiency, it is necessary to insulate the ceramics too.

What will the brand tell you about?

Many buildings made of red brick came to us from the past, which have survived practically unchanged. They are a vivid testimony to the strength and reliability of this building stone. What do these criteria depend on? Naturally, not only on the size and method of its manufacture.

It is based on the main parameter of this building product - its strength. It is from the ability to withstand pressure that the brick is divided into grades - 75, 100, 120, 150, 200, 250, 300. The higher it is, the stronger the stone.

M200

So, the designation M-150 says that this building stone can withstand a pile of 150 kg per 1 sq. see With this indicator, the structure will be distinguished by reliability and durability.

These are the main, internal walls, foundations, basements of floors, elements of structures that are in direct contact with the ground.

Usually these are the first floors of buildings, as well as multi-storey and high-rise buildings. But this brand is in great demand not only because of its strength. Such an artificial building stone is also distinguished by its excellent appearance. Having the dimensions of a solid brick, M 150 does not require any finishing.

M-150

Therefore, it is often used for building façade structures. And this stone is especially appreciated by developers for its ability to resist aggressive environmental influences, in particular temperature fluctuations, for its resistance to regular flooding, etc.

Single full-bodied ordinary brick M-150, the size of which is standard - 25x12x6.5 cm, in addition to strength, has significant indicators and thermal conductivity.

If you decide to build a house and are thinking about what material to use for its construction, pay attention to the option of using a brick of grade 150. This option, although not very cheap, is quite reliable.

And you can reduce costs by using less-cost brands of this stone in not quite critical building elements. This will even facilitate the construction as a whole.

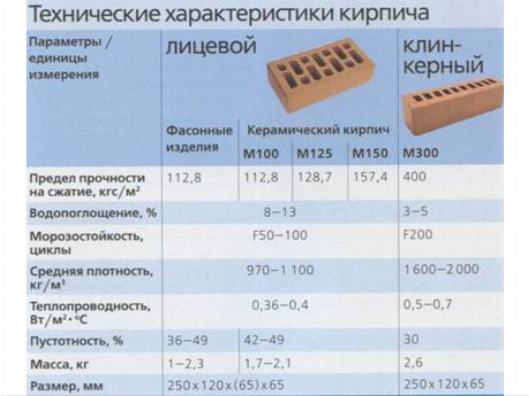

Specifications

The standard defines strength grades, frost resistance and density class. Strength grades represent the load that a material can bear. It is easy to decipher this value. The number that follows the letter "M" is the number of kilograms per square centimeterwhich the material can withstand without destruction. Example: M150 means that ceramic bricks of this batch will withstand a load of 150 kg / cm².

| Strength grades | Ceramic bricks | M100, M125, M150, M175, M200, M250, M300 |

| Ceramic stone | M300, M400, M500, M600, M800, M1000 | |

| Clinker bricks | M25, M35, M50, M75, M100, M125, M150, M175, M200, M250, M300; | |

| Brick and stone with horizontal voids | M25, M35, M50, M75, M100 | |

| Frost resistance | F25, F35, F50, F75, F100, F200, F300. |

Strength and frost resistance grades for ceramic stone and bricks are indicated

Frost resistance is indicated by the letter F and a number. The figure shows the number of freeze / thaw cycles that do not change characteristics and appearance. For example F50 - 50 frost and defrost cycles. For internal partitions in heated buildings, frost resistance can be taken low - a positive temperature will still be maintained.

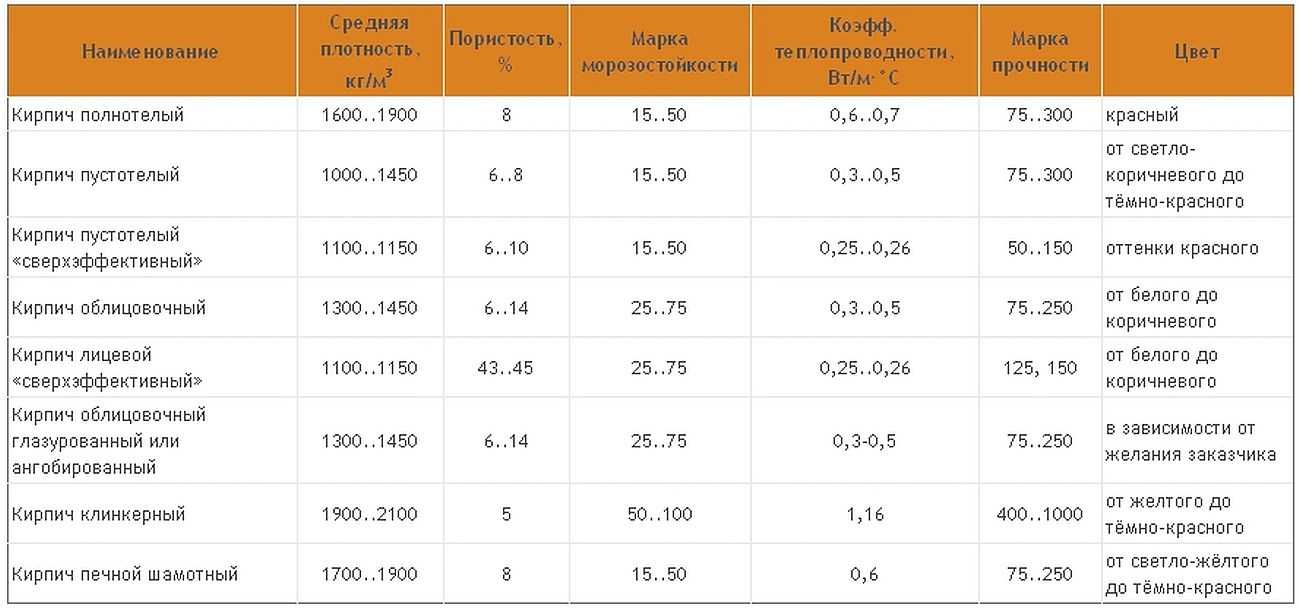

Thermal conductivity and coefficient of thermal resistance

The density class corresponds to the average density of the material, but the energy efficiency of the material also depends on the density. The lower the density, the better the thermal insulation properties. But it will not be possible to significantly reduce the density for external walls. They must carry a certain level of stress. Therefore, in recent years, a brick house has been made with insulation.

The ratio of the average density of the product and the density class

How to work with the last two tables? The density class is indicated in the marking. By this characteristic, you can find out the mass of a ceramic brick cube. It is listed in the first table. The second table helps to compare the density of the material and the coefficient of thermal conductivity of masonry from it. For example, the density class of ceramic bricks is specified as 1.0. This means that the cube should weigh 810-1000 kg, and the masonry on a minimum layer of glue after drying will have a thermal conductivity coefficient of 0.20-0.24 W / (m * ° C).

Groups of ceramic bricks and blocks according to the thermal characteristics of masonry (with a minimum amount of mortar)

It is worth saying that according to modern standards, none of the types of bricks gives the necessary thermal resistance. Unless the thickness of the wall will be more than a meter.

Masonry made of ceramic bricks of one and a half or two bricks does not meet modern requirements for thermal conductivity of external walls

In this case, a hollow brick or a building ceramic block wins, since they have the best thermal conductivity characteristics. The wall will be a couple of tens of centimeters already - not 147 cm, for example, but only 105. So, in any case, it is worth considering additional insulation of the outer walls.

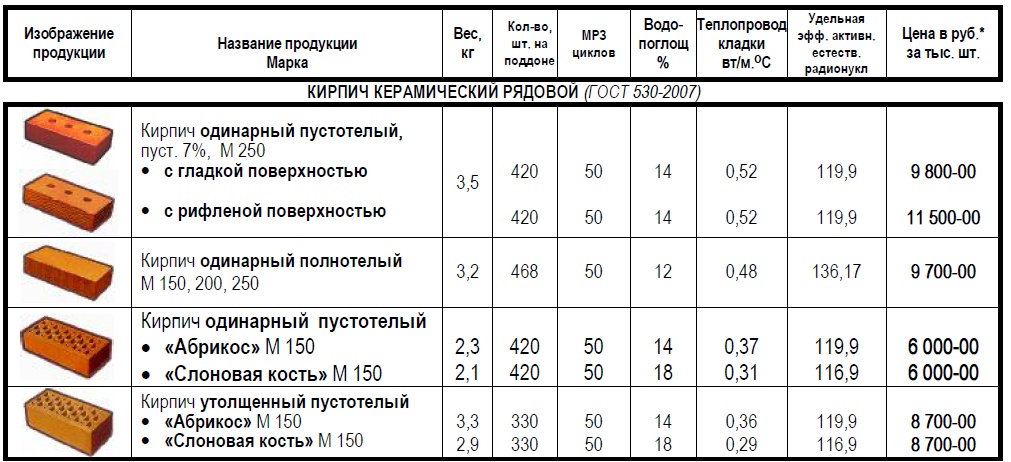

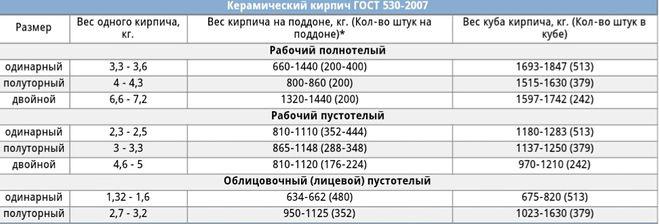

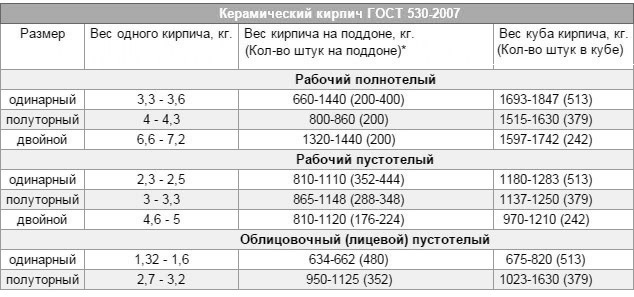

Ceramic brick weight

The weight of ceramic bricks depends on the density and the presence / number of voids. The exact figure is recognized in the accompanying documents, and then, the spread within one batch is up to 10%.

The characteristics indicate the weight of different types of bricks: masonry, finishing, with and without voids

Using the old terminology, the approximate weight of ceramic bricks will be as follows:

- Single (type 1 NF, size 250 * 120 * 65 mm):

- corpulent (private, masonry, construction) 3.3-3.6 kg / piece;

- worker (private, masonry) hollow - 2.3-2.5 kg / piece;

- facing (front, finishing) hollow - 1.32-1.6 kg / pc.

- One and a half has a mass (type 1.4 NF, dimensions 250 * 120 * 88 mm):

- full-bodied private - 4.0-4.3 kg / piece;

- hollow private - 3.0-3.3 kg / piece;

- facial hollow - 2.7-3.2 kg / pc.

- Double weighs (1.8 NF 288 * 138 * 88 mm.):

- ordinary corpulent - 6.6-7.2 kg / piece;

- ordinary hollow - 4.6-5.0 kg / pc.

Comparison of the characteristics of ceramic bricks - hollow, different density, solid

We will give an approximate weight, since the density and number of voids for each plant can differ significantly. The number of voids is not regulated, so the finishing materials can be lightweight.

Specifications

Solid bricks, with

indicators of strength M 100, M150 are quite in demand, thanks to the technical

characteristics and low cost.

In addition to strength, brick

products have the following characteristics:

- Moisture absorption;

- Frost resistance;

- Thermal conductivity;

- Refractoriness;

- Density;

- The size;

- The weight;

- Price.

And depending on the composition of raw materials and production technology,

these parameters can be very different from each other. That is, various types

bricks, with a strength grade M 150, are radically different in other

indicators.

Therefore, when purchasing a brick, you should clearly understand that

exactly what you need. For example, sand-lime brick cannot be used where there is too much

damp or hot. Since it absorbs moisture like a sponge, and it helps

accelerated destruction of the material from the inside.

And from high temperatures, silicate brick quickly deteriorates. But refractory fireclay bricks are not afraid of fire, but they also do not like moisture.

Single solid ceramic brick M 150

Ceramic brick of the M 150 brand is more resistant to moisture, therefore, it has a higher frost resistance index. These products can tolerate up to 100 freeze and thaw cycles without damage.

Ceramic bricks, in comparison with other types, are relatively cheap. At the same time, it surpasses analogues in many characteristics.

Clay bricks have low moisture absorption, high density. They are durable, strong. It is a non-combustible material that can withstand elevated temperatures.

Therefore, the range of applications for these products is quite extensive.

Application of ceramic brick M 150

Ceramic solid products of the one hundred and fiftieth grade of strength are used:

- When building one or two storey buildings;

- Fences;

- Chimneys;

- Fireplaces;

- Stoves (except for the firebox);

- Foundations;

- Plinths;

- Overlaps and so on.

How to choose a ceramic brick M 150

When buying a brick, in addition to the declared characteristics, pay attention to the size, shape, density

It is important that all products are of the correct geometric shape.

In order to avoid strong distortions during laying. Naturally, small discrepancies of 1 - 2 mm are allowed, but no more.

And the next thing to pay attention to is the presence of cracks on the surface. Sometimes manufacturers can violate production technology

At the same time, the products lose their properties and with the declared strength M 150, the brick can crumble from any weak impact, like glass.

When two bricks hit each other, there should be a ringing sound. It is desirable that the color of the products is uniform, without stains, indicating that the batch is burnt or not baked.

Choosing an ordinary ceramic brick, you can ignore the aesthetics, beauty, smoothness of the surface. Since it will be either plastered or covered with finishing material.

When choosing facing ceramic bricks, in addition to technical indicators, you should pay attention to the appearance. Since this brick is not covered by anything - it will serve as the face of your object

High-quality facing bricks will naturally cost more. However, this is where saving is irrelevant. After all, in essence, you are investing in the durability and beauty of your building.

Types of bricks:

- Flexible brick clinker, types, applications and reviews

- Waterproofing agent for bricks. Understanding, choosing, applying

- Hyper-pressed bricks, production equipment

- Dutch brick, types, manufacturing methods

- Decorative brick

Silicate and ceramic bricks

Silicate brick M 200

Silicate brick M 200 is a white building material, which includes quartz sand, lime and water. This raw material is treated with high-temperature steam under pressure until the material is solid.

Ceramic brick M 200 is made of clay with the addition of various kinds of impurities and its subsequent firing in autoclaves at 1000-degree temperature. It differs from silicate brick in its characteristic reddish color.Although its final shade depends on the minerals that are included in the clay, the elements added to it and the firing temperature.

In ordinary building (ordinary) brick, they usually do not pay much attention to the final color, since this material does not serve for interior masonry. Also, the surface of an ordinary brick can and should be rough and have slight fractures along its borders. This ensures better absorption of the mortar and therefore the strength of the supporting structure. But the existing cracks on the surface should not reduce the strength of the material and allow it to be broken manually. If a brick falls apart in his hands, this indicates his marriage.

Facing brick M 200, on the other hand, serves to give a decent look to the house, therefore special requirements are imposed on its surface. It should be not only strong, smooth, but also a certain color, which is achieved with the help of various additives to the clay. The cost of such a building material is always higher than that of an ordinary one.

Both silicate and ceramic bricks can boast of high strength and frost resistance, good sound insulation, and reliability. But silicate brick is characterized by high water permeability, therefore, when building foundations and plinths, it is preferable to use a ceramic material. At the same time, it is better and much more convenient to use silicate material for the construction of walls of load-bearing purposes and partitions. In addition, the price of silicate brick M 200 is usually lower than that of ceramic.

Types of ceramic bricks M-150

Ceramic brick M 150

All products of this brand are available in two types:

- working (corpulent or ordinary) brick;

- facing (hollow) brick;

This separation is caused by the structure of the building bricks. Full-bodied products do not contain voids inside themselves and have a rough appearance. Its main purpose is the erection of plinths, foundation structures, load-bearing walls and other structures that require subsequent finishing. It is used to lay out ventilation and smoke ducts.

The building brick of the M 150 brand owes its popularity to significant advantages, which favorably distinguish it in the line of other building materials. So, the weight of the brick M 150, depending on the modification, ranges from 2.2 to 3.5 kg. Such a small mass implies convenience for transportation across floors during construction work.

Of the main qualities of solid bricks, one can single out excellent strength and a high rate of thermal conductivity, which allows you to keep heat in the premises in winter, and in summer to provide the house with coolness. M-150 products also have high sound insulation, therefore, its use is advisable in cases where it is necessary to minimize the noise level from the outside.

Working single solid brick M 150 is also used for the construction of load-bearing walls of houses and other structures. Its difference from the hollow analogue is that it has voids in its structure, which significantly reduce the weight of ceramic blocks. Hollow ceramics are also highly frost-resistant due to the presence of empty spaces filled with air, which is a poor conductor of heat. The price of solid brick M 150 varies from 8 to 15 rubles. per piece, depending on the modification and manufacturer.

Modern production technologies make it possible to produce facing bricks M 150 with a beautiful and impeccable appearance. Such characteristics determine its use in facing the facades of buildings, columns, decorative fences.

Whatever brand or modification the building stone is, clay is the raw material for its production. The quality and composition of raw materials depends on the region of its production, but in any case, these raw materials should be homogeneous in structure and with the lowest limestone content.During firing, an excess amount of limestone contributes to shooting and spalling from the surface of the finished stone.

Ceramic solid brick M 150 can be produced in two ways:

- plastic molding;

- dry and semi-dry pressing.

The first manufacturing method is by far the most popular and cost effective. The peculiarity of the production is the use of clay, which contains up to 30% sand, which prevents excessive shrinkage of the finished products. The prepared mass of clay is moistened with steam and intensively mixed into a homogeneous mass with a complete absence of lumps.

At the next stage, a raw bar is formed with a volume that exceeds the finished product by 10-15%. After drying, during which the humidity decreases, the products are fired in an oven at temperatures up to 1000 ºС. Ordinary hollow brick M 150, made in this way, has high strength, water resistance and fully complies with GOST.

In the second method, although the finished product has less frost resistance, it has a more regular and clear shape. At the same time, the raw materials are selected with certain moisture indicators (from 7 to 12%). During the production process, the clay is ground to a powder. The finished powder is subjected to dry or semi-dry pressing, after which the raw stone is fired in an oven.

The manufactured products must have a quality certificate and comply with the approved certificates.

Modern production workshops allow the production of working bricks and facing bricks M 150 of various configurations and sizes:

- single;

- one and a half;

- double.

The variety of color shades allows the use of building stone in the widest spectrum of construction. The most common colors are red, brown, light yellow, straw, as well as more refined ones - ivory, frost, terracotta.

The dimensions of the M 150 brick supplied to the market may vary depending on the modification. The most popular today is a single brick 250 * 120 * 65 mm, used for the construction of capital walls of buildings and foundations.

What is it?

Brick grade M100 is a building masonry material that is often used. The digital designation means the load that it can withstand - up to 100 kg per 1 cm of the upper part of the brick. The technical characteristics of this masonry material allow it to be used to build a residential building no higher than 5 floors. Ceramic solid brick of grade 100 is resistant to atmospheric conditions and has a high degree of sound insulation. This building material does not have a specially treated front surface, but this does not prevent it from being used for interior decoration of housing.

Specifications

Ordinary ceramic brick M 100 has good parameters, due to which it has become the most popular among other masonry materials. The table describes the indicators that an ordinary brick block of this brand has:

| Options | Indicators |

| Type of raw materials used | Ceramics |

| Strength | 100 kg / cm2 |

| Frost resistant | More than 50 cycles |

| Moisture absorption | 8% |

| Color | Red |

| Upper layer | Smooth or embossed |

| Quantity on one pallet | 240 pieces |

Varieties

Depending on what components are used, what are the dimensions of the brick, it is divided into several types. Considering the materials used for the manufacture of the masonry product, there are the following types:

- Ceramic. You can distinguish this type of building material by its components. It consists of clay, one ordinary brick contains several varieties of the main component at once. The resulting raw material is given a brick shape and set to dry. Then they are fired at a temperature of 900 degrees. The difference between ceramic masonry material is moisture resistance.

- Silicate. The main component is sand, which is combined with lime.The thin product stands out for its high sound and heat insulation. The silicate material is white painted. It is not used for building a fireplace, stove or laying a foundation, since it has a low degree of moisture resistance.

- Hyper-pressed. The difference of this type from silicate or ceramic is the almost complete content of limestone. The composition includes no more than 8% cement. It is used for facing or finishing. It is produced in several colors:

- Ivory;

- Red;

- terracotta;

- straw;

- Brown.

The classification distinguishes several types of ceramic bricks M 100:

- Hollow. It has through holes, which make up 13% or more of the entire area of the masonry material. The thermal conductivity of such a product is higher than that of other types. The disadvantages include a low degree of moisture resistance.

- Corpulent. The holes cover no more than 13% of the M100 surface. If these indicators are not met, the product does not comply with GOST.

Brick parameters M100

Clay, silicate and other types of M100 masonry material are usually divided by size. The running dimensions and weight of bricks are presented in the table:

| View | Length and width, mm | Thickness, mm | Weight, kg |

| Single | 250 to 120 | 65 | 2—2,3 |

| Thickened | 88 | 3—3,2 | |

| Double | 138 | 4,8—5 |