General information about the strength of bricks

The strength of a brick is indicated by the letter "M" and a number indicating what kind of load per square meter. cm is able to withstand the product. The brick is marked in strict accordance with GOST. For this, several bricks are taken from each batch of finished products, which are subsequently tested for compression and bending. In the course of research, the grade of stone is established from M 75 to M 300. The established marking corresponds to all types of material, for example: solid face brick M 150, has the same strength as hollow brick. But each brand of product has a different purpose, due to the technical characteristics and properties.

Among all the variety of materials, the most common building brick of the M 125 brand, which, due to its reliability, strength, is used for the construction of the upper floors of multi-storey buildings, internal and load-bearing walls, pillars and columns, partitions and others. The price of brick M 125 is quite democratic and depends on the type of product. But in order to make the right choice, it is necessary to study the properties and characteristics of the product more carefully.

Weight of 1 m3 of brickwork

The quality factor of brickwork depends on the type of building material and the correctness of its laying.

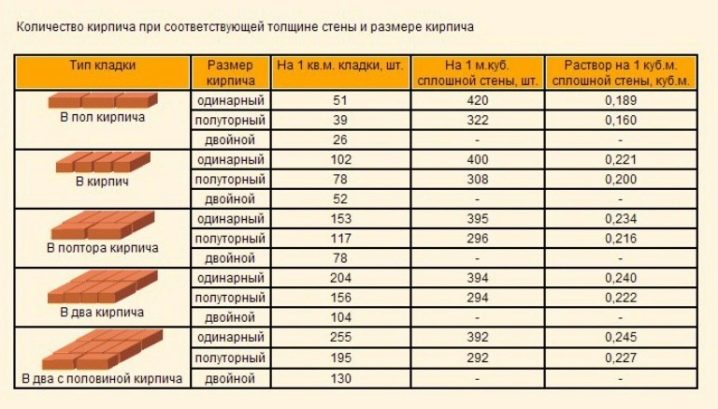

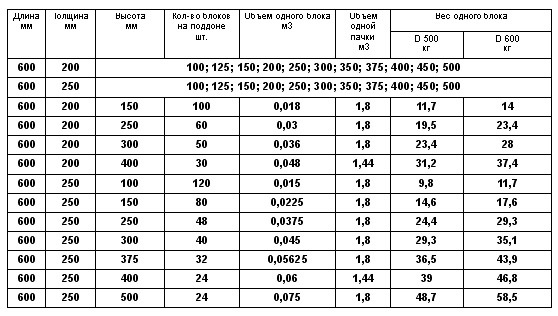

To decide on the number of bricks per cube of masonry, it is necessary to take into account the volume indicators of the entire structure. In addition, the consumption of material is determined by the typical characteristics of the brick and the thickness of the joints.

The raw materials used in the manufacture and the processing conditions determine the dimensions (see. Standard red brick size ) and the specific gravity of bricks (see Weight of silicate bricks). With regard to brickwork, this parameter also depends on the number of seams, the mass of the mortar used and the type of masonry. Thus, the specific weight of brickwork is in the range of 1400-1990 kg / m3. The next value required for calculation is the volumetric weight (unlike the previous one, the presence of voids and pores is taken into account).

The mass of the masonry wall must be calculated in order to determine the optimal and boundary loads on the base. This value predetermines not only the type of foundation to be built and its material, but also many other design and design parameters.

Today, brickwork remains the most common type of wall. It is characterized by stability and strength, along with this, it has a decent mass, which affects the foundation of the building.

The most demanded material in this case is red brick, the standard dimensions of which in millimeters are 250x120x65, weight - about 4 kilograms. A rough estimate takes place because each brick has structural voids, which are allowed by the standards, but their number is not constant. That is why it is more expedient for calculations to take the weight of 1 m3 of brickwork, and not one brick.

When designing any structure, many nuances must be taken into account. In order to fully compose a picture of the upcoming loads on the building, plan the base and correct the dimensions of the building, you need to familiarize yourself with the technical characteristics of the material - brick.

By means of these parameters, it is possible to give an objective assessment of the bearing capacity and strength of the future building, therefore, when designing, they must be taken into account.

Quite often, the decent weight of a brick wall prevents the use of this material. This is not possible if the ground is unstable, moist or mobile under the base of the building. In such cases, alternative materials are used that have an advantage over traditional red bricks in weight:

- expanded clay concrete blocks;

- foam concrete;

- gazosipikate;

- cinder blocks.

Indeed, all of the above materials make it possible to build fairly practical and lightweight buildings in a shorter period of time and with some savings. Nevertheless, they are significantly inferior in strength to classic bricks, and some of them shrink during operation.

Do not forget that the weight of the masonry cube can be affected by the reinforcement of the walls or individual components of the supporting structures. Sometimes the mass of mortar and reinforcing mesh is not inferior to the weight of the entire wall (see.Cement consumption for brickwork)

It is customary to call a brick wall material, which is obtained as a result of firing various types of raw materials. For ceramics, these are separate types of clays, and for silicate products - sand, lime and water. Each of the considered types of wall products has its own characteristics, which means that their weight per unit volume (in our case, a cubic meter) will not be the same.

The mass of each individual brick will depend not only on the raw material composition, this indicator is also influenced by the production technology (firing temperature, the presence of voids, etc.). It should be noted that each wall material has its own tolerances for individual characteristics, including weight.

Hyper-pressed brick

This type of product is the leader in the finishing materials market. Its technology is very simple, and production is established everywhere, so the price and delivery costs are quite affordable.

Brick is made from semi-dry mixtures of cement, lime and crushed stone. Due to the high pressure, the components interpenetrate, which ensures the strength of the finished products (minimum M250). Frost resistance is set at least 150 cycles. The peculiarity of cladding made of hyper-pressed bricks is that over time it increases by 40 - 50%. The water absorption of masonry is no more than 5% - this is the best indicator among all types of finishing stones.

The range of colors of the products is wide, the coloring is persistent. Due to the relief of the molds, products with a different texture are obtained: smooth, chipped stone, semi-antique.

In terms of their properties, hyper-pressed products are close to natural stone, so they are quite massive. The weight of a single facing brick with standard dimensions is 4.2 kg, a half-block with dimensions 250 x 60 x 65 ("American standard") weighs half as much - 2 kg. Bricks "like a stone" are produced in a shortened version: 250 x 90 x 65, weight - 4 kg.

Ceramic cladding brick

The manufacturing technology of the products is rather complicated: they are made from red clay with additives, most often by plastic molding, followed by drying at 150 o and high-temperature firing at 800 o. The resulting products have strength M150 - M250, their frost resistance - 25 - 50 cycles. Moisture absorption of ceramics - 10%

Products are produced both in full-bodied and in hollow versions (air cells increase the thermal performance of the masonry). The surface is smooth, matte, with an imitation "like a stone". Various methods of painting are used: volumetric, superficial (engobing), glazing. In the latter case, the glaze is applied only to the front side.

Ceramic masonry products are strictly standardized. Facing bricks have the dimensions and weights indicated in table 2.

How much does a silicate brick weigh?

Silicate brick belongs to the category of artificial building materials for the construction of vertical enclosing structures. The characteristics are excellent, the scope of application is wide, but do not forget that the type of foundation or supporting elements depends on such a parameter as the mass of white brick. Therefore, even for the simplest calculations, you need to know the weight.

Types and characteristics

White brick is produced by a non-fired method from a mixture of lime binder, silica filler (quartz sand, fly ash, sludge, etc.) and a small amount of water to moisten the mixture. In production conditions, raw materials are pressed and autoclaved.Due to this, the finished block gains the required parameters:

1. The compressive strength is marked with the M75-M300 brand.

2. Thermal conductivity - up to 0.87 W / m * K.

3. Frost resistance: withstands from 15 to 50 complete freeze-thaw cycles when fully immersed in water.

4. Density: porous or lightweight up to 1500 kg / m³. Products with an index exceeding this indicator are called dense.

5. Water absorption - 6-16%.

Plants produce a silicate block of the following dimensions:

- Single: 250x120x65 mm.

- One and a half or thickened: 250x12x88.

- Double: 250x120x103.

- Embossed: 250x90x65.

By the field of application, a distinction is made between working or ordinary brick and facing. The latter is used for finishing facades, foundations, basements, fences.

The structure for all sizes is typical:

- full-bodied or monolithic product;

- hollow products, with a void content of up to 15% (3-void), 25% (11-void) and 31% (14-void).

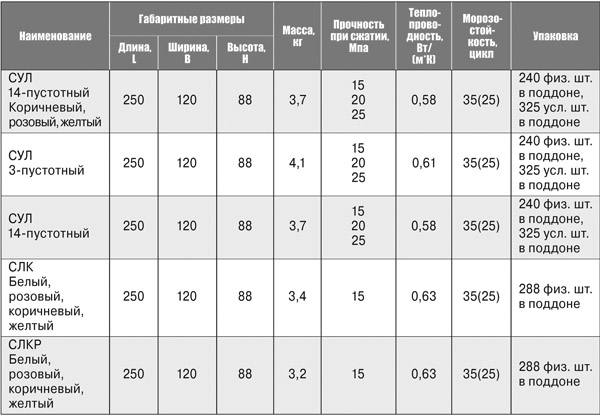

White brick produced in accordance with GOST 379-95 "Bricks and silicate stones" must have a standard weight according to the table below.

The data from the table are corrected for the weight of auxiliary materials. That is, for example, the weight of one one-and-a-half solid silicate brick made according to the basic recipe from lime and sand is 4.2 kg / pc. The total weight of the building material laid on the Euro pallet is 840 kg, but the pallet itself, protective film and fixing straps are added to this. Accordingly, the cargo prepared for transportation will weigh approximately 846 kg.

The weight of a hollow silicate block 250x120x88 is less than a solid analogue precisely due to the cracks, but during the construction process they will be filled with mortar, so the total mass of the masonry will increase significantly. This must also be taken into account when calculating the project plan.

Before buying, you need to carefully inspect the proposed product. The surface must be firm, even, free of chips, chamfered corners, cracks and cavities. If the product crumbles in the hand, slightly crumbles, it means that it was overdried or underdried, therefore it is not suitable for the construction of walls - it will quickly collapse.

White silicate bricks, along with red ceramic bricks, occupy a worthy place in the category of building materials for fencing.

Before starting any type of construction, you need to accurately calculate how much consumable material, including.

With the advent of new building materials, which significantly speed up and reduce the cost of construction of buildings, but do not have.

Types and characteristics of ceramic bricks

The variety of brick products allows them to be divided and classified.

Brick types

Artificially produced stone, with given shapes, sizes, mass and composition, can be divided into bricks:

In common parlance, it is often divided into red (ceramic) and white (silicate). The difference is mainly in the raw materials in their manufacture. For red it is clay, for white it is a silicate mixture (sand and lime).

Ceramic products, in turn, according to their purpose and application, are divided into the following type:

- Private. It is used in the masonry of load-bearing, enclosing walls and partitions.

- Facial. Used for cladding.

- Special. It is used in the laying of stoves, fireplaces, chimneys (stove, refractory fireclay bricks).

Sizes, their designations

According to the above regulatory construction documentation, all types of this building material in Russia are standardized in their standard sizes.

Size designation

Since 1927, brick products have been standardized. There is a normal format (NF), its geometric dimensions are 250x120x65 (mm).

The name of other standard sizes comes from the normal format:

- 250x120x65 - single (NF);

- 250x120x88 - one and a half (1.4 NF);

- 250x120x140 - double (2.1 NF).

In the current documents, they are divided, classified according to other sizes:

- 250x85x65 - "euro" (0.7 NF);

- 288x138x65 - modular single (1.3 NF).

By the absence or presence of voids in the body, they separate solid and hollow brick products. By voidness, the following varieties are distinguished:

The mass of the product, the weight of the masonry, the cost of its construction, and most importantly, the heat-shielding characteristics of the wall, depend on the number of voids (the percentage of voids from the total volume).

Layout: Two-layer wall (full-bodied front and hollow "warm ceramics")

Weight characteristics

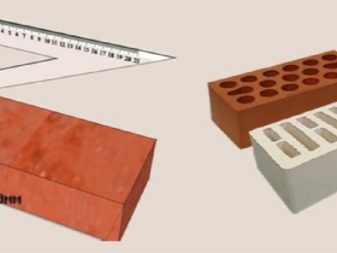

Photo: the weight of a single ceramic brick depends on the volume of voids in it

Designers should take into account the mass to calculate the load of the masonry on the foundation, to determine the carrying capacity of transport, warehouse equipment (loader, crane) during logistics operations with it.

It is useful for an estimator, foreman or bricklayer who works with him with his own hands to know that, for example, 1 m3 of single solid brick masonry (about 500 pieces) is approximately 1690 - 1847 (kg). A cube of one-and-a-half brick is about 380 pieces, and of a double brick - about 200 - 240 pieces.

Attention! When calculating, you can focus on the following numbers: about 7 rows of double, 10 rows of one and a half and 13 rows of single bricks fit in a 1 meter high masonry. Here are the main weights for standard sizes (in accordance with the current documents on building materials)

Here are the main weights for standard sizes (in accordance with the current documents on building materials).

Designation according to GOST

Hollow double silicate brick m 150, dimensions 250x120x138, weighs 5.4 - 5.8 (kg), and hollow double ceramic brick m 150, 250x120x140, weighs 4.3 - 5.0 (kg).

The mass of a full-bodied 250x120x65 is 3.3 - 3.6 (kg), and the same porous volume - 2.4 kg.

Thus, we see that a large volume (size) does not necessarily mean that its mass will be large. Its weight characteristics are more influenced by the structure.

When choosing the type of building material for walls, one must take into account their thermophysical characteristics, structure, weight and geometric parameters, what is the price of their acquisition, delivery and their further operation.

When laying a large array of walls, it is advisable to pay attention to one-and-a-half and double bricks, to large-format blocks of "warm ceramics". To simplify approximate calculations, you can focus on the average weight indicators.

Solid with less than 13% void - about 4 kg, hollow with more than 15% void - about 2.5 kg

To simplify approximate calculations, you can focus on average weights. Solid with a voidness of less than 13% - about 4 kg, hollow with a voidness of more than 15% - about 2.5 kg.

Basic elements and colors of the material

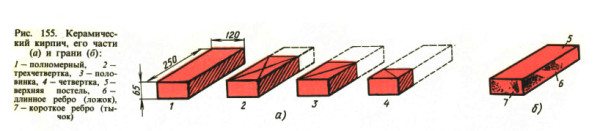

According to GOST, introduced in 2007, product planes are named:

The name of the sides of the brick.

- bed;

- spoons;

- jab.

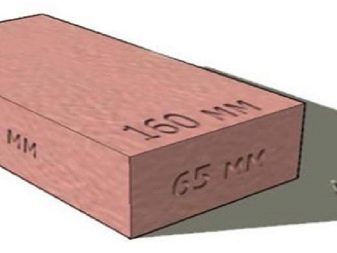

The bed is a plane with dimensions of 250x120 mm (image No. 1). The spoon has dimensions of 250x65 mm. The length of the butt is 120, its width is 65 mm. The material itself has been used since ancient times. Technology has improved over time. This led to the emergence of new varieties of material. But its dimensions remained unchanged. Knowing them, you can calculate the number of items in the masonry.

The requirements for the construction of buildings were constantly growing, which led to the creation of new materials. The size of an ordinary brick 250x120x65 mm today has a European marking - RF, although the eurobrick has slightly different dimensions - 250x85x65. The most popular bricks in Europe are marked with NF (normal). These are blocks of 240x115x71 mm. There is a material of 240x115x52 mm. It is marked DF (thin). Blocks of 200x100x50 mm are in less demand. On the modern market, you can buy blocks 50 cm long.

Image 1. The size of a single brick.

The density of the brick depends on whether it is solid or slotted (hollow). The weight of the finished product also depends on this indicator. A solid building block may have some defects:

- chips of a long rib (1 or 2 pieces) with a size not exceeding 1.5 cm;

- curvature of edges or edges up to 3 mm;

- spoons can have a crack along the block width up to 3 cm.

Hollow brick (image No. 2) may also have some tolerances:

- up to 2 bumps, the length of which can reach 1.5 cm if they do not reach the internal cavities;

- cracks in the bed, which can extend to voids;

- 1 crack on the spoon and on the poke.

According to the architectural concept, it is sometimes required to use standard sizes of bricks of different colors. The construction market offers to purchase materials of many shades and textures: this is artificially aged stone, texture options, variegated brick (image No. 3).

Image 2. Types of semi-wall bricks.

One-and-a-half and double-sized stones are usually produced in a hollow version. Internal cavities reduce the density of the brick. Its mass is significantly reduced. The weight of the entire structure is also reduced.

The type of material for manufacturing allows you to divide finished products into types:

- ceramic (red);

- silicate (white);

- clinker;

- fireclay;

- facing.

Ceramic building material is obtained after firing pressed clay briquettes. Such material is used in the construction of walls and foundations, partitions and fences, when laying household stoves. Block grades can be from 75 to 300. These numbers indicate the pressure that 1 cm² of material can withstand in kilograms. Density of 1 m³ (480 pieces) - 1700 kg.

Image 3. Variety of bricks.

The base of the white block is silicates. They are softer and lighter than ceramics. But the strength of such a product is lower than the red analogue. The block consists of sand, which occupies 90% of the total mass and lime (10%). By adding a small amount of coloring pigments, a colored material is made. It is used for the construction of partitions and entire walls, when facing buildings. Its use is not recommended for laying foundations and plinths. White is not good brick and oven masonry and fireplaces.

Clinker bricks are distinguished by their high strength and low water absorption. It is an excellent decorative material that is not afraid of temperature extremes and precipitation.

Fireclay brick belongs to refractory grades. In everyday life, the material of the Sh brand is used. These are:

- Ш-5 with dimensions 230х114х65;

- Sh-6 - 230x115x40;

- Ш-8 - 250х124х65.

The facing block is smooth, chopped and imitating a wild stone. Its dimensions in millimeters:

- 290x140x85;

- 250x120x88;

- 250x80x65;

- 250x60x65;

- 250x120x65.

Products for facing works can also be wedge-shaped. They are used for laying vaults and arches. Their curvature is different. Ш-22 - wedge block with dimensions 230х114х65 / 55 mm. The front wedge of the Sh-45 brand has dimensions of 230x114x65 / 45 mm.

Application in construction

The first finds of houses using baked clay bricks date back to ancient times, already at that time ceramic products were used both in everyday life and in construction. People have long noticed that burnt clay is an excellent building material. Therefore, despite the constant appearance of new materials used for construction, ceramics continues to be at the top of the price and efficiency charts. This is largely due to a fairly convenient construction process. Due to its shape, the brick is easy to fit and the masonry process is not complicated by anything.

The device of the "sandwich" of the wall

Construction of this material does not require additional lifting devices, it effectively resists the effects of natural factors and has good durability. Nevertheless, bricks show excellent results in combination with modern building materials such as mineral insulation, they can reduce the amount of building material consumed, and at the same time improve the heat-shielding properties of the house. We should not forget about the raw materials for the production of products, clay is ubiquitous, its reserves are practically inexhaustible. In addition, the extraction of clay on an industrial scale is not very difficult and does not require expensive equipment.

If you have experience of using red brick in construction or questions about its use, then share your experience, leave and join the discussion.

Weight and other characteristics of red solid brick 250x120x65

Brick is a building material, without which no construction is possible today. Thanks to such a wide assortment, now each consumer can independently choose the suitable option for themselves. Sometimes people cannot understand what is the difference between a solid and a hollow product. Hollow brick is characterized by the presence of pores, due to which its weight is much less.

The name "corpulent" means that it will have a minimum amount of voids. As a result, it will have a lot of weight, but high strength indicators. Such material is actively used in the construction of foundations, walls, columns and other structures where a large additional load is required.

In the field of construction, the presented brick has shown itself on the positive side in the construction of cottages or private houses. The reason for this demand is associated with high performance, long service life and economy in terms of use.

Which brick for a bath is best used can be found in this article.

It does not lend itself to the influence of the environment, it can resist internal deformations and does not collapse during operation. As a rule, this building material is used in the construction of internal and external structures of houses, in the construction of external and load-bearing walls, as well as in the installation of pillars.

What is the weight of refractory bricks can be found in this article.

It can take on lighter and more saturated shades. It all depends on what kind of clay was used during the production of the product. But at the same time it is necessary to understand that a darker shade is inherent in burnt brick, and it is not recommended to use it in the field of construction. As a rule, such material is referred to as marriage. The reason is that it will have low strength indicators, will not be able to withstand frost, as a result of which various kinds of deformations will occur on its surface.

You can learn about the size of the shamatite brick from this article.

The video shows the weight of a red solid brick 250x120x65:

The type of red solid brick is presented in the form of a rectangular parallelepiped with walls that are at right angles. The nose today, most manufacturers introduce new technologies during the manufacture of this product, therefore the appearance of the final product may also differ.

Calculation of the total mass of building material

In order for the constructed building to reliably serve for a long time, the quality of brickwork plays a huge role in its construction. Therefore, in order for the material to withstand the optimal and ultimate load, it is necessary to correctly calculate the mass of the material per 1 m3 of masonry. For this, the wizards use a simple formula: specific gravity of red solid brick multiply by its amount in the stack. At the same time, we must not forget about the mass of the cement mortar, and also take into account the number of rows, seams and the thickness of the walls.

The resulting value is approximate, since it may have minor deviations. In order to avoid mistakes during construction, it is necessary, when creating a project, to determine in advance the brand of brick, the method of masonry and correctly calculate the weight and width of the walls.

1 pallet

Before you purchase a building material, you also need to know its consumption. The bricks are transported in special pallets, where the blocks are placed at an angle of 45, in the form of a "herringbone". One such pallet usually holds from 300 to 500 pieces of fragments. The total weight of the material can be easily calculated by yourself if you know the number of blocks in the pallet and the weight of one unit. Usually, wooden pallets weighing up to 40 kg are used for transportation, their carrying capacity can be 900 kg.

To simplify the calculations, the buyer and seller must also take into account the fact that a single red solid brick weighs up to 3.6 kg, one and a half 4.3 kg, and a double one up to 7.2 kg. Based on this, it turns out that on average from 200 to 380 bricks are placed on one wooden substrate. After performing simple calculations, the approximate mass of material on a pallet is determined, it will be from 660 to 1200 kg. If you add the tare weight, you will end up with the desired value.

Cube m

For the construction of buildings, you should also have information on how many cubic meters of material will be required for brickwork, how much it will weigh. Up to 513 blocks can be placed in 1 m3 of a single solid red brick, so the mass ranges from 1693 to 1847 kg. For one and a half bricks, this indicator will change, since in 1 m3 its quantity can reach 379 pieces, therefore, the weight will be from 1515 to 1630 kg. As for double blocks, in one cubic meter there are about 242 units and a mass from 1597 to 1742 kg.

What buyers and builders need to consider

According to the requirements of GOST 530-2007, single ceramic bricks are produced only with a size of 250x120x65 mm. A similar material is used if you need to lay out load-bearing walls and a number of other structures. Its severity differs depending on whether hollow or full-weight facing blocks will be laid. A red facing brick that has no voids will weigh 3.6 or 3.7 kg. And in the presence of internal grooves, the mass of 1 block will be at least 2.1 and maximum 2.7 kg.

When using a one-and-a-half facing brick that complies with the standard, the weight is 1 pc. taken equal to 2.7-3.2 kg. Both types of decorative blocks - single and one and a half - can be used to decorate arches and facades. Full weight products can contain a maximum of 13% voids. But in the standards for material including voids, it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightening of the brick 250x120x65 mm allows to increase the thermal protection of the structure.

Additional Information

All of the above applies to ceramic facing bricks... But it also has a silicate variety. This material is stronger than an ordinary product, it is created by combining quartz sand with lime. The ratio between the two main components is selected by technologists. However, when ordering sand-lime bricks 250x120x65 mm, as well as when buying its traditional counterpart, you must carefully calculate the mass of the blocks.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined:

-

product size;

-

the presence of cavities;

-

additives used in the preparation of the silicate block;

-

geometry of the finished product.

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg. The so-called one-and-a-half corpulent (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that silicate brick is heavier than similar in size ceramic block. This difference must be taken into account in projects, to strengthen the foundation of buildings under construction.

Hollow sand-lime brick size 250x120x65 mm has a mass 3.2 kg. This makes it possible to significantly simplify both construction (repair) work and the transportation of ordered blocks. It will be possible to use vehicles of lower carrying capacity. In addition, there is no need to reinforce the walls. And therefore, the foundation of the building being built will be easier to make.

The situation is slightly different with hollow products. Such a single sand-lime brick weighs 3.2 kg. Standard packaging includes 380 pieces. The total weight of the pack (excluding the substrate) will be 1110 kg. Weight 1 cub. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now you can consider one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is still the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg.And 1 m3 of silicate one-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also chipped silicate 250x120x65 with a weight of 2.5 kg. In a regular container, 280 copies are placed. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, all calculations must be carried out very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you can skip calculating its volume in cubic meters. You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m there are:

-

13 rows single;

-

10 bands of one and a half;

-

7 strips of double bricks.

This ratio is equally true for both silicate and ceramic varieties of the material. If you have to clad a large wall, it is more correct to choose a one-and-a-half or even double brick. It is recommended to start your selection with hollow blocks because they are lighter and more versatile. But if there is already a solid, solid foundation, you can immediately order full-weight facing products. In any case, the final decision is made only by the customers of the construction or repair.

See below for details.

Number of bricks on a pallet

A correct calculation should take into account that the price is usually indicated per package. The number on different pallets (wooden boards for loading, transportation and storage) may differ. The standard size has 2 meanings:

- Small. Overall dimensions - 0.52 × 1.03 m, carrying capacity - 750 kg.

- Big. Area - 0.77 × 1.03 m, can withstand weight up to 900 kg.

If the seller does not provide information on how many bricks are in the pallet 250x120x65, then they use this method:

- the area of the pallet must be divided by the size of the larger face of 1 block (the number of pieces in the lower row);

- multiply the result by the number of rows on the pallet.

According to the established standards for carrying capacity on 1 pallet - 0.77 × 1.03 m.

The maximum weight can be:

- 420 pcs of single size 250 × 120 × 65;

- 360 facing (250 × 90 × 65);

- 390 one and a half (height 88);

- 200 double (250 × 120 × 138).

Fireclay straight bricks have dimensions of 230 × 124 (114) × 65 mm and can fit 297 (385) pieces on a pallet.

The weight of the pallet is important when ordering vehicles for transporting a large number of packages, calculating the number of flights and the cost of delivery to the construction site. A single sand-lime brick has a weight of 3.7 kg, one and a half - 5 (hollow 4 kg), double - 5.2. Ceramic products 250 × 120 × 65 mm weigh: hollow - 2.6, corpulent - 3.6, shortened - 2.1 kg. A full Euro pallet with 275 pcs of a single block (3.7 kg) has a net weight of 1017, and a gross weight of 1032 kg. Hollow has less weight, so it can fit on pallets more than the same size corpulent.

Masonry volumes

For 1 m3 of masonry, 500 pieces of full-bodied single products are needed. Their weight will be approximately 3.38-3.694 tons. A single hollow worker weighs 2.3-2.5 kg and a volume of 1 m3 will require 2.36-2.566 tons. A conventional facing block and its decorative counterpart have a weight of 1320-1600 g, for a volume of 1 m3, 1.35-1.64 tons are needed.

With a standard joint thickness of 10 mm, it is necessary to calculate how many bricks are contained in a square meter, taking into account its thickness. For a size 250 × 120 × 65, this figure is (with / without seams):

- Half brick - 51/61 pcs.

- 1 brick - 102/128.

- 1,5 – 153/189.

- 2 – 204/256.

- 2.5 - 255/317 pcs.

Quotes

Large construction firms, manufacturing plants can indicate the price not in pieces, but per pallet, or set a minimum batch for sale. In trading houses, retail products are offered by the piece. The upper plank is held by clinker, combining the characteristics of high strength, fire resistance and decorative appeal for the design of facades and interiors.

| Size 250 × 120 × 65, mm | Minimum order rub / pc | Price, rubles |

| facial corpulent red М300-М500, VKZ | 1 | 61 |

| Ceramic Lode Brunis corpulent | 10000/1000 | 83 |

| corpulent Voskresensky KZ M-150 | 2680/200 | 13 |

| ceramic Lode Dzintra corpulent | 10000/1000 | 125 |

| private corpulent M-150, VKZ | 1 | 11 |

| clinker Lode Janka full-bodied smooth | 1 | 125 |

| ceramic corpulent Lode Brunis smooth | 1 | 89 |

| front hollow red M-150, Vorotynsk | 1 | 13 |

| construction silicate solid single M150, | 1 | 17 |

| ceramic Lode Herkules hollow | 10000/1000 | 57 |

| fireclay refractory straight line ШБ-8, 250х124х65 | 1 | 50 |

The cost of the purchase can vary significantly depending on the remoteness of the region in relation to the manufacturer of the product, the weight and volume of the cargo. It is necessary to agree on all essential terms of delivery with the carrier.

The wholesale discount for a large batch reaches 15% and depends on the selling company. The cost of the material includes the purchase of the pallet itself. The average price is about 200 rubles per 1 piece. Systematic purchases of bricks can include the exchange of empty pallets for full ones.