Where is it applied?

Continuing the story about pit sown sand, it is worth pointing out its excellent ecological properties. After all, the chemical-physical composition of the substance is normalized, and therefore no problems should arise during its operation. After correct standard processing, the proportion of impurities does not exceed 9% by weight. Often seeded dry construction sand is shipped in bags with a capacity of 25-50 kg. However, it is also practiced to ship in bulk in truck bodies or in the so-called big-bets (MCR) of 1000-1500 kg (of course, this is more suitable for large construction projects).

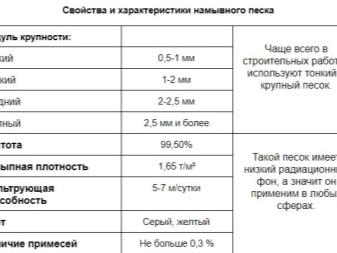

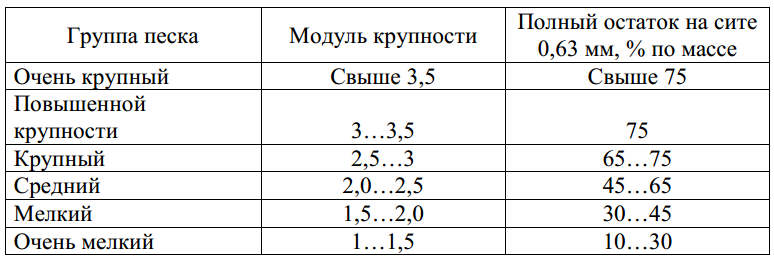

Well-processed sand is slightly more expensive than raw materials. However, it is used much more. In the overwhelming majority of cases, customers are interested in sandy raw materials with a fraction of 2-2.5 mm. Not only filtration capacity, but also wear resistance (even already as part of a frozen solution) depends on the purity of the product. The specific use of sand depends on its fraction in the first place.

Lots with the finest structure are in demand by factories supplying gypsum-based dry mixes. After all, the finer the grains of sand, the more "graceful" the texture of the finished mixture will be after laying. It's just that fine sand is needed to make bricks (it is used as an additive to clay). Also, this fraction is appreciated by manufacturers of plaster, building mixtures and mortars.

But do not assume that sand with coarse grains is of no interest to anyone. The situation is exactly the opposite! A coarse-grained quarry product is a part of extra strong concrete and various mortars for masonry. Their plasticity increases with the addition of such a component.

This material is also in demand:

- in the creation of reinforced concrete structures (including rings for wells);

- in the production of paving slabs and curbs;

- as a component of asphalt concrete;

- as a bedding under the roadway;

- as an important component of drainage systems;

- as an auxiliary raw material for various construction;

- in filters of water supply and sewerage systems;

- as a sprinkling of roads and sidewalks with the threat of ice;

- in the improvement of various sites (in landscape design, as they say);

- as a component for planting soil.

The cost of seeded sand is determined not only by its purity and grain size, but also by the location of the quarry. The farther it is from the consumer, the more expensive, naturally, the transportation costs. It is also worth considering the influence of the filling method. Even all other things being equal, it determines the difference in price from 5 to 30%. Moreover, the seasonal factor, the situation on the market, the scale of the order, the possibility of organizing self-pickup are also influenced.

Washed seeded sand is in any case superior to its river counterpart. The more treatments are carried out, the higher the characteristics of the product. Granules from 1.6 to 2.4 mm are perfect for forming aerated concrete. But this material is also useful for lightweight concrete.

For more on the features of sown sand, see the next video.

What sand to choose for making concrete

For the release of PB solution, river modifications of medium or large fractions are mainly used. You can add a little washed out gravel from the quarries to them.

The brand of building concrete carries especially important information for selection. In the case when it is less than M300, raw materials with inclusions less than 2.6 mm are recommended. A similar mixture is usually used for arranging the foundation directly for a car garage, low-rise buildings, and home structures.For a brand more than M350, used in the construction of high-rise buildings, floor slabs or reinforced belts, you need to use river raw with a grain composition of 3.6 mm or more.

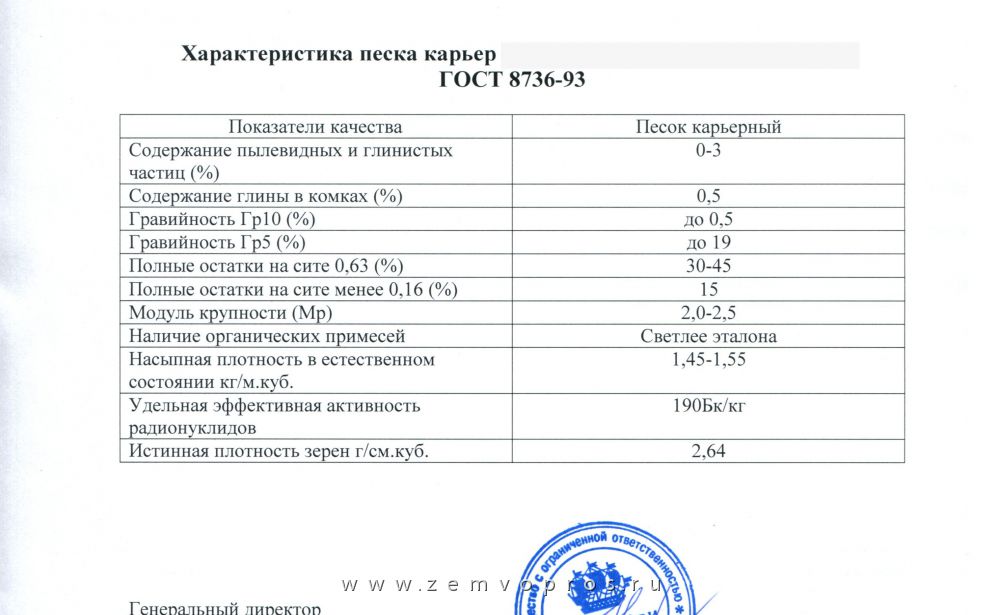

Density

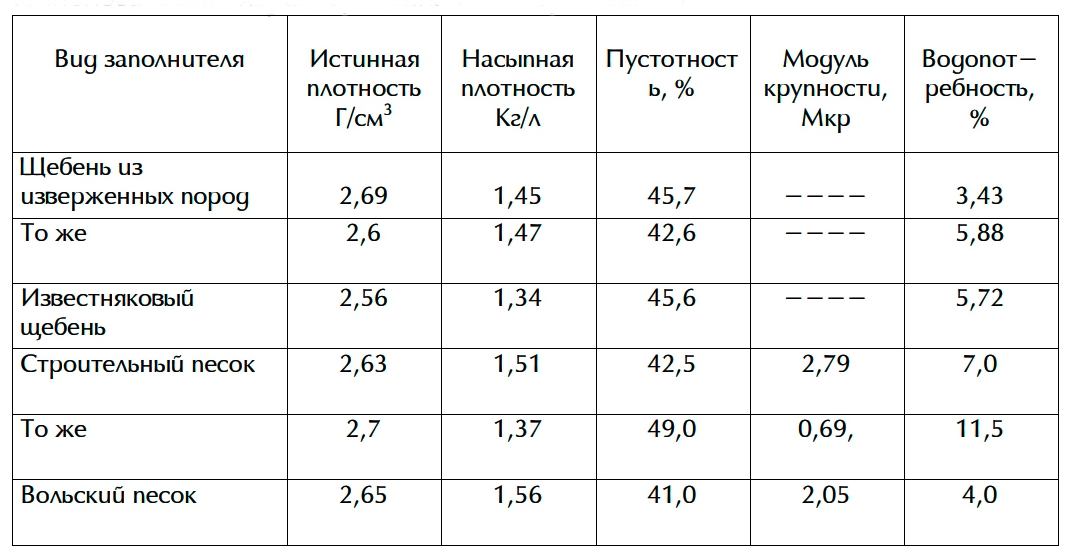

GOST 8736 sand is a material that is poured. The indicator under consideration is based on the dimensions of the air layers that are located between the main elements.

There are some types of body weight per unit of its volume:

- real;

- technical;

- bulk. It is determined by the ratio of the mass of the material used to the volume that it will take. Few take into account the void for the final indicator, as well as the porosity of the material itself;

- conditional or true indicators. This is the maximum limit of the density ratio that the material occupies, while the cavities N2 and O2 are not taken into account.

The true indicator will always be higher than the real one. This value is inherently conditional or theoretical. From a practical point of view, it is, in terms of its density, similar to bulk.

Density

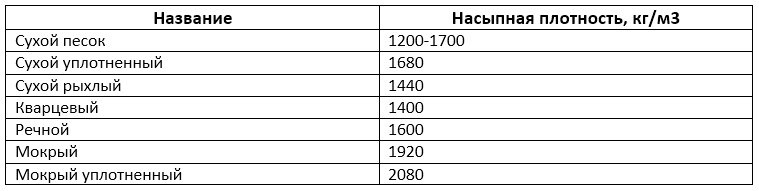

For sand with different characteristics, it is allowed to use the following bulk density (tons per m3):

- for dry extracted from the river - 1.4-1.65;

- for a wet river - 1.7-1.8;

- for a compacted river - 1.6;

- for fine-grained material extracted from quarries - 1.7-1.8;

- for a dry, based on a mineral, one of the crystalline varieties of silica — 1.5;

- for ground, made on the basis of a mineral, one of the crystalline varieties of silica — 1.4;

- for a compacted, based on a mineral, one of the crystalline varieties of silica-1.6-1.7;

- for material extracted by mining, grade 500-1000 - 0.05-1;

- for material made from blast-furnace, dump and granular solid residue after metal smelting from ore - 0.06-2.2;

- for molding material with normal moisture content in accordance with GOST standards - 1.7;

- for material with dust impurities - 1.6-1.7;

- for material that was mined high in the mountains - 1.5-1.6;

- for building material, normal moisture according to the standards of GOST - 1.5-1.7.

According to the degree of saturation of the sand with various valuable minerals, several types of placers are distinguished.

For more information on determining density, see the video:

Advantages and disadvantages

The advantages of river sand include:

- Wide range of applications.

- Ensuring the strength of the structure, which it is part of.

- Durability of the product if quality material is used.

- When the microclimate changes, it does not cause allergic reactions, which ensures its environmental friendliness.

- High level of noise absorption, which is a good indicator for the construction of concrete walls.

Sand is used not only for the concrete screed of a residential building or the manufacture of a columnar foundation for a fence, but also for such types of work:

- Building walls at home.

- Road bed laying.

- Creation of finishing materials for repairs (grouting solutions, dry mixes).

- In the production of paving slabs.

- During the installation of curbs.

- For making paints.

The main disadvantages of sand include its ability to quickly settle. This phenomenon is due to the fact that the sand particles have a rounded shape, therefore, when sliding against each other, they slide down. To avoid such settling, the solution must be constantly stirred.

Quantity calculation

In order for the grade of concrete to be high, it is necessary to comply with the requirements for the use of all its components. Often, a ratio of 1: 3: 5 is used, which means cement, sand and crushed stone, respectively. Little by little water is added in the amount of 50-70% of the total weight of the cement

But for the preparation of high-quality concrete for the construction of high-rise buildings or load-bearing floor slabs, it is extremely important to comply with accurate calculations.

To correctly calculate the proportions of all components, follow these recommendations:

- to prepare concrete grade 100, sand with grains of sand with a diameter of not more than 2.5 mm is used in a ratio of 1: 7: 4.6 (cement, crushed stone, sand, respectively);

- for brand 150 - proportions 1: 5.7: 3.5;

- for 200 - 1: 4.8: 2.8;

- for 300 - 1: 3.7: 1.9;

- for grades higher than 400 and 450, sand particles over 3.5 mm are used, the proportions will look like this 1: 2.7: 1.2 and 1: 2.5: 1.1.

Often, not enough attention is paid to the value of fine sand in concrete mortar. And in vain, since by choosing this element correctly, and calculating its weight in the solution, it is possible to reduce the price of concrete (by reducing the consumption of cement), to make its strength and brand higher.

To create a high-quality solution, it is optimal to use coarse river sand, but with a considerable number of small particles. It is also supposed to connect a washed open-pit type, using which, it is possible to significantly reduce the cost of concrete. But we must not forget that if you overdo it with savings, then the strength and stability of concrete products can significantly deviate from high performance.

Density calculation in a state of natural moisture

The bulk density of building sand can be determined in various ways:

- using conditional conversion factors. The main disadvantage of this method is that it gives an error within 5 percent. It is not too big, which is why it is admitted;

- take measurements using a specific, clearly calibrated container. The disadvantage of this method for determining the bulk density is that it is sometimes very difficult to carry out. To do this, you should take a specially prepared bucket, the capacity of which is 10 liters at a height of 10 centimeters;

- after that, it must be filled with sand, pouring it in and without tamping it. When the amount of material in the container forms a hill, it must be cut off along the upper edge, being careful not to seal. It remains only to weigh the vessel together with the sand;

- in further calculations, you need to use a special formula.

In fact, it is quite easy to determine the bulk density. This is due to the fact that the formula for the calculation has been known to many since school years - it is studied in the physics course:

P = M / V, where M is the mass of sand in the container, and V is the volume that the material occupies.

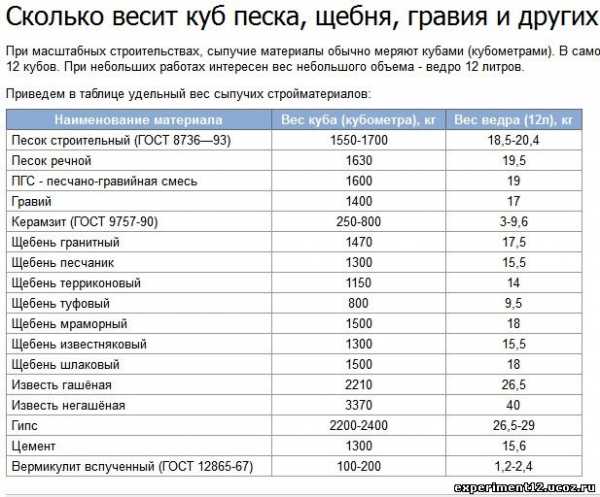

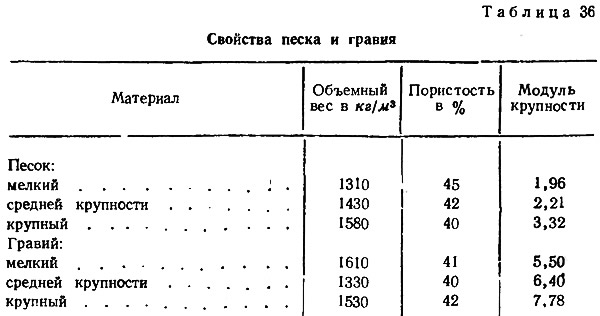

There are the following indicators of bulk density, expressed in the table:

| Type of material | Bulk density value | unit of measurement |

| River dry sand | 1400-1650 | kg / m3 |

| River wet sand | 1770-1860 | kg / m3 |

| Sea sand | 1500-1700 | kg / m3 |

| Quarry fine-grained sand | 1700-1800 | kg / m3 |

| Slag sand | 600-2000 | kg / m3 |

| Quartz dry sand | 1500 | kg / m3 |

| Quartz ground sand | 1450 | kg / m3 |

It should also be noted that the table indicates the bulk density of sand in a state with natural moisture and high

It is very important to pay attention to this when buying material.

For more information about the bulk density of sand, see the video:

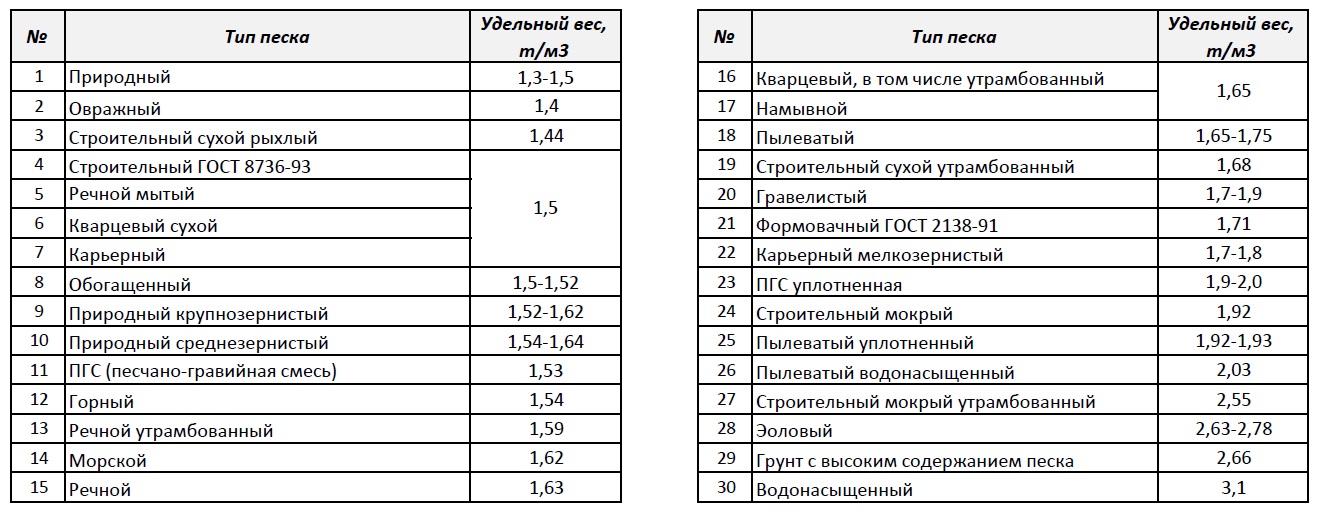

What affects the weight of sand in one cubic meter

The weight of sand in 1 m3 is expressed by such a physical quantity as the specific gravity of bulk material. It is measured in kilograms or tons per cubic meter. This value can fluctuate in relation to sand most often in the range from 1500 to 2800 kilograms per 1 m3.

Read about converting m3 to tons.

This is influenced by many different factors, among which builders and specialists distinguish the following:

- the degree of density of the material;

- chemical and mineralogical composition of sand;

- grain size module;

- a kind of sand mixture;

- sand moisture;

- the size of the fractions that make up the volume, etc.

The above factors and the coefficient of compaction and filtration directly affect how much a cube of sand weighs. This is due to the fact that this indicator for bulk materials may change periodically.

That is why you should always measure it exactly at the time of purchase or shortly before, since there is a possibility that after transportation or any additional intervention, the bulk weight of building sand will either be greater or less.

Varieties

Today, various types of sand, both artificial and natural, are used in construction. As for the second material, its classification takes place depending on where it was received. Thus, the following types of sand can be distinguished.

River mass

Such sand differs mainly in that it is quite clean and does not have various inclusions in the form of clay or crushed stone. Most often it has a yellow or slightly gray tint. The grain size of such material ranges from 0.3 to 0.5 millimeters.

River

That is why, in determining how much 1 cube of river sand weighs, builders are often faced with relatively large numbers.

Quarry building material

The density of this material is different from that of other types of sand. It can contain various inclusions in the form of earth, clay, stones, etc. The color of this sand is either yellow or brown. The sizes of the fractions are rather large and in some cases heterogeneous - from 0.6 to 3.2 millimeters.

Career

Because of this, when it is determined how much a cube of quarry sand weighs, you can get a very diverse data, depending on the place of extraction of the material.

Nautical

The quality of such sand is one of the best due to the fact that it is quite clean and its fractions are small. At the same time, the presence of some organic impurities is possible in it.

Nautical

Artificial material is also quite popular. This is due to the fact that there are no impurities in it, and its structure is mostly homogeneous. Moreover, the grains differ in that they have sharp corners. This happens because of how the production takes place.

Experts identify the following most common types of artificial sand:

Quartz

Quartz material. This mixture is produced by crushing and dispersing white quartz. Quartz sand has a rather large bulk density, since its particles are relatively small. Because of this, their density is quite large, and the number of air layers is minimal;

Quartz

Expanded clay material

Most often, the production of this sand is carried out by firing. The object of this process is the remains of clay rocks, which is why the material is called clay.

Expanded clay

How much does a slag cube weigh

The method of production of this sand is completely different - it is based on cooling the slag with water, which allows it to be crushed into small pieces. In this case, the size of the grains is very large - from 0.6 to 10 millimeters.

Slag

Thus, we can conclude that the weight of 1 cube of sand directly depends on what type of it and by what method it was produced.

What should be the sand for a sandbox

There are four main criteria for determining which sand is best for a sandbox.

The size. The optimum diameter of grains of sand is 1-3 mm. The larger ones will be inconvenient for playing, the smaller ones will easily rise into the air, creating excess dust. The latter are dangerous to the health of the child, since they can settle in the lungs and lead to various diseases. The absence of dust particles is the main difference between children's sand and construction sand. We recommend staying on a homogeneous material - it molds better.

It is especially important to make sure that there is no garbage when buying material of river origin. It may contain sharp-edged seashells, needle stones, sulfur

The material must go through at least two stages of processing - washing and calcining. Certification. Most of the properties can be checked by examining the material certificate. If the seller does not have such documentation, it is better to refuse the purchase. The certificates must state that the sand is intended for children's play. This means that the products have passed all the necessary studies, are not radioactive, do not contain toxic substances. Color. In nature, the sand is light brown, it can be yellow or reddish. Other differences in color indicate unwanted impurities and may be harmful to the child. If you ask the question of which sand is best for a sandbox, for children, the answer will definitely be colored. Materials with safe dyes will help to diversify the game.All colors of the rainbow are offered by manufacturers!

When buying, you need to check the material for moisture content. In no case should you settle for wet or damp sand. After drying, it may not meet the declared properties.

Better to buy sand in bags. You need to make sure that the packaging is intact. This will be an additional guarantee that the sand is not old and that all the rules for its storage and transportation are followed.

River and sea sand

River composite initially has no clay in its structure. It probably contains the smallest amount of fine-grained stones. This type is very effectively used in repair and construction processes and allows you to prepare the highest quality mixture. It stands out for the possibility of natural precipitation, in this regard, during the preparation of the solution, it must be continuously stirred.

Before choosing the preparation of concrete for a river or a quarry composition, one must take into account that, in turn, the price of river sand is much higher than that of a quarry one. When making a choice, it is necessary to subject to analysis, which in turn is preferable - a decrease in the production cost of the PB of a building structure or a guarantee of the required strength characteristics.

Marine raw materials by their own indicators are close to lakes. Additionally, it is characterized by the purity and uniformity of the granulometric structure. Due to the likely presence of shells, additional cleaning may be required.

Marine raw materials by their own indicators are close to lakes. Additionally, it is characterized by the purity and uniformity of the granulometric structure. Due to the likely presence of shells, additional cleaning may be required.

Quartz composite is obtained as a result of mechanical crushing of natural raw materials, preserving similar inclusions. It is homogeneous, pure and chemically passive, and is manufactured in an artificial way.

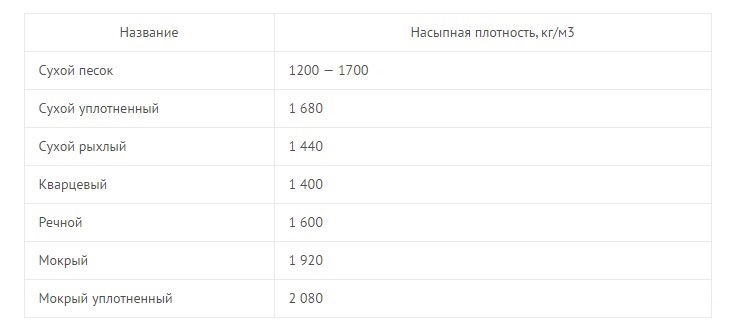

Density Determination Factors

The bulk density of sand depends on several factors:

- The fraction and shape of the grains of sand determines the density of the bulk material to a greater extent. The larger the fragments, the greater the distance between them and vice versa. Round and square grains of sand take up more space than flat grains.

- Breed of origin. The denser the mineral from which the sand was formed, the greater the mass.

- Residues of soil and organic impurities also affect the bulk of the sand. The technology for the preparation of mortars involves the use of a purified fine filler, therefore, this parameter can be adjusted by washing or sieving the embankment.

- Moisture after washing or sand extraction. Water penetrates the pores of the grains of sand and increases their weight. The bulk density of dry sand is up to 30% less than that of wet sand. As it dries, the mass decreases and the volume increases.

- Sand compacted during installation has a much higher density per unit volume than normally filled sand.

The value of mass per cubic meter can be visually tracked in the table of the bulk density of natural sand:

| Sand condition | Density value, kg / m3 |

|---|---|

| Dry in normal condition | 1200 ... 1700 (depends on the type of rock and fraction) |

| Quartz | 1400 |

| Dry loose | 1440 |

| River | 1600 |

| Dry compacted | 1680 |

| Wet | 1920 |

| Wet compacted | 2080 |

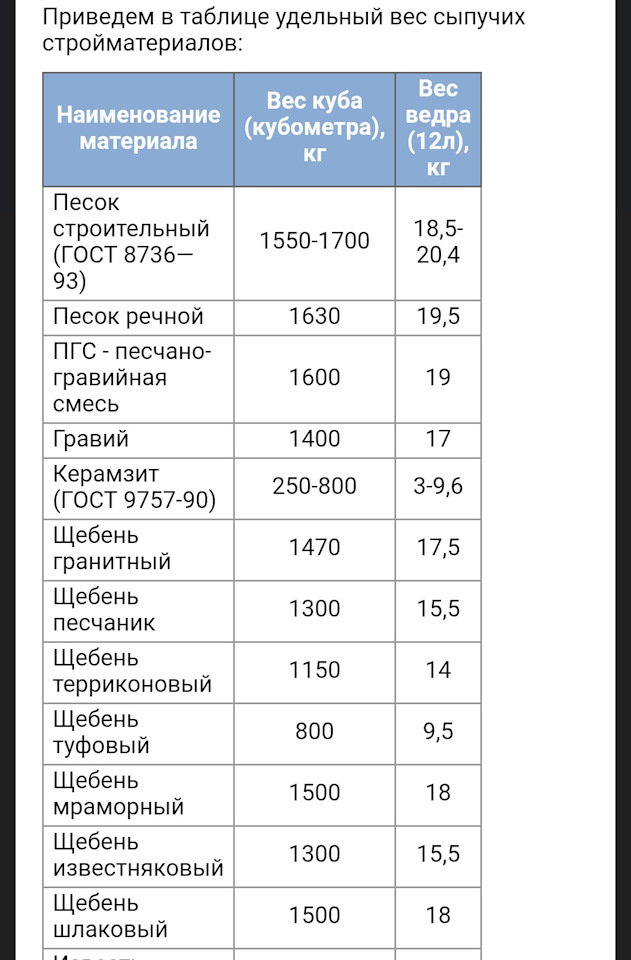

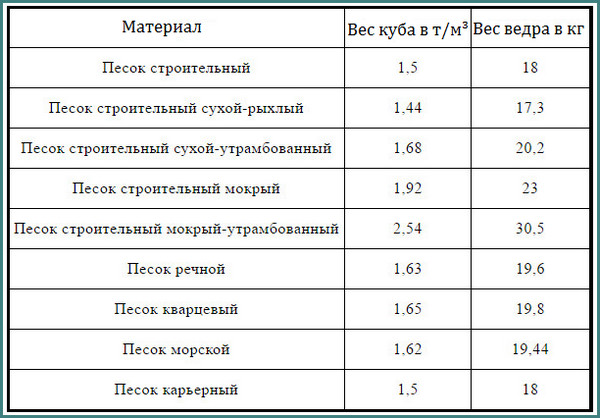

Varieties of construction sand: how much does 1 cubic meter of each weigh

How much 1 cube of sand weighs is influenced by its type, storage method and moisture level. According to GOST, the weight of standard building sand is 1550-1700 kg / m? (18.5-20.4 kg / bucket). The weight of dry loose sand is 1440 kg / m2, and the weight of compacted sand is 1680 kg / m2. Standard wet sand has a weight of 1920 kg / m2.

There are several types of sand. The classification is based on how and where the material was obtained. The sand used in construction is:

riverine - the production zone is located at the bottom of the rivers. The material is inherent in purity, the shade is gray or yellow. The size of the fractions varies in the range of 0.3-0.5 mm. It is used for the preparation of mixtures, solutions, the organization of the drainage system;

The most popular types of sand in construction are river and quarry sand

- open pit mining - mining is carried out using an open method. The size of the fractions varies within a wide range - 0.6-3.2 mm. The scope of application extends to foundation work, arrangement of sidewalks. In addition, sifted and washed quarry sand is used in finishing and plastering works, as well as in the recipe for the preparation of a cement screed;

- offshore - the mining area is the seabed. The scope of application is extensive, but the material is not in high demand, since its cost is high.

Table 2. Sea, river and quarry sand: how much does 1 cubic meter and 1 bucket weigh:

| Sand type | Specific gravity m? (kg) | Specific gravity of the bucket (kg) |

| River | 1630 | 19,5 |

| Career | 1500 | 18,3 |

| Nautical | 1620 | ? 19,4 |

The price of river sand with delivery per cubic meter is considered the most affordable of all, if the purchase of material of natural origin is required. However, there are other types of sand - obtained by artificial means.

Artificial types of sand:

- slag;

- quartz;

- expanded clay.

There are artificial types of sand with expanded clay, slag and quartz impurities.

Construction sand: how many cubes per ton

Specific gravity of sand per 1 cu. m of volume is calculated using the formula:

m = V * p, where

m is the mass of the material;

V is the volume;

p is the density level.

Using this formula, you can find out from the table how many cubes of sand are in a ton, and what is its specific gravity within the generally accepted unit of volume. For 1 cubic meter m, the weight of the material is equal to its density, and the bulk density can usually be obtained from suppliers involved in the sale and delivery.

To calculate the weight of sand, you need to know its volume and density.

Filling capacity of ZIL and KAMAZ dump trucks: how many cubes of sand are in the back

Despite the large tonnage of KAMAZ, all buyers still want to know how many cubic meters of sand in the back of a car, since it is this measure of weight that is the generally accepted value used in all calculations.

KAMAZ usually has 12 cubic meters of sand. How much ZIL holds in its body is also a useful value, since many suppliers carry out the delivery of building materials in smaller sizes. In this case, the capacity is 3 m?. MAZ is used to deliver 6 m ?.

The body of KAMAZ can hold up to 18.5 tons of sand

It is very important to find out in advance, when ordering sand, how much a cube of bulk material you need costs, and how much kg it contains. The average price of river sand is 8000 rubles / m

cubic meters, quarry - 500 rubles / m. cub. How much sand with delivery costs depends on the supplier, the amount of sand and the distance. Average prices for a service within one city and region are 2000-3000 rubles

The average price of river sand is 8000 rubles / m. cubic meters, quarry - 500 rubles / m. cub. How much sand with delivery costs depends on the supplier, the amount of sand and the distance. Average prices for a service within one city and region are 2000-3000 rubles.

Factors affecting density

It is far from always necessary to focus on a certain indicator of the bulk density of sand, since it can change over time depending on several fairly important factors.

These include materials scientists and builders:

the degree of compaction. There are small gaps of air between any particles of sand. The more pressure on the material, the less these layers. Accordingly, this also affects the density level. This is due to the fact that the mass of sand consists precisely of grains of sand, and not of air;

the bulk density of average sand according to its compaction is most often in values from 1400 to 1700 kilograms per cubic meter;

method of extraction and origin of the material. Most often, the sand that is washed out of the water has a higher bulk density than that which is quarried;

separately, we can also say about an artificially created type of material, which, due to the fact that the process of its manufacture occurs by means of mechanisms, also has higher quality characteristics;

emptiness. The more different gaps between sand particles, the lower its bulk density will be. In most cases, after transporting the material, the number of voids decreases, since the sand is compacted a little;

size of fractions. The bulk density of medium-sized sand is most often higher than that of a material with large particles, and lower than a material consisting of small grains of sand;

This is due to the fact that the smaller the fractions, the more tightly they adhere to each other, which accordingly affects the decrease in the volume of air layers. In general, the average density of sand is about 1450-1550 kilograms per cubic meter;

it is quite simple to determine the size of grain fractions - for this you should use several sieves with holes of different diameters;

mineral composition of the material. Quite often, many do not pay attention to this factor, although in fact sand can be based on completely different substances. These include quartz, mica, feldspar, etc .;

all these components, although in a crushed form, are very similar, but differ slightly from each other, including in weight. The material itself can be monomineral and polymineral.

In the second case, it is most often based on two different components;

humidity

This factor can change the bulk density of the material by about 20 percent, so it is very important to pay attention to it when buying sand. The higher the humidity, the higher the level of a given physical quantity.

All of the above factors related to sand, one way or another, to varying degrees, affect its bulk density.

Therefore, you need to pay attention to them. Due to the fact that some of them can change all the time, the compaction indicators should be checked immediately before handling the material.