Advantages and disadvantages

Insulation from "TechnoNIKOL" is a very popular product, as it is easy to use and has unique technical characteristics:

- provides a high level of heat and sound insulation;

- has a low thermal conductivity, which helps to retain heat in the room in winter and prevents it from overheating in summer;

- does not impede the passage of air, the "breathing" structure will provide an optimal indoor climate;

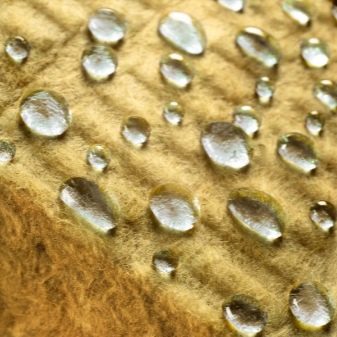

- has hydrophobic properties, protects walls from moisture and the appearance of mold and mildew;

- resistant to deformation (stone wool has a specific feature: return to its original shape after short-term compression);

- does not shrink;

- very durable;

- chemically neutral, does not interact with other substances;

- provides a high level of fire safety, since the melting point of basalt fibers is more than 1000 ° C;

- tolerates not only high, but also very low temperatures;

- has a light weight, lends itself to cutting with an ordinary knife, so installation can be done with your own hands;

- it is not subject to rotting and decay, rodents and other pests will not start in it;

- has a long service life - the manufacturer guarantees 50 years of service;

- reduces consumption and costs of electricity and heat for heating in the cold season;

- has a very reasonable price.

The material is available in hard, soft, medium hardness, differing in thread thickness and density. Rigid types can be used for structures where the insulation will be exposed to heavy loads.

Modern technologies make it possible to manufacture a product without using phenol.

Therefore, the material is suitable for indoor applications.

In order for the insulation to be reliable and to serve for a long time, it is necessary to remember and observe some nuances:

- select the type of insulation with suitable characteristics for the upcoming work (for example, hard insulation is not suitable for light structures);

- follow the installation rules;

- work must be carried out in a respirator, since when cutting the cotton wool crumbles and dust forms;

- the plates must be stitched, but if there are many seams, this will worsen the thermal insulation qualities of the coating;

- the plates cannot be bent, otherwise they will break;

- when heated above 600 ° C, the material can emit into the environment substances harmful to the human body (although in reality you are unlikely to encounter such temperatures when we talk about the use of insulation for residential or domestic buildings).

What it is?

Rocklight mineral wool from the TechnoNICOL company consists of synthetic fibers and thin crumbs of stone and clay. Due to its light weight, excellent evaporation and low hygroscopicity, this material cannot be overstated. On sale you can find it in the form of rolls and plates of different sizes and thicknesses - from 50 to 100 mm.

Heat is retained thanks to the multilayer structure, with interlayers. Unlike polystyrene, small rodents do not nest in rock wool. It can be noted that cotton wool quickly collects dust and does not withstand moisture, so water removal must be thought out more carefully.

The insulation has excellent thermal insulation. The material is made from natural compositions - fiberglass and quartz sand. It does not pose a danger to people and the environment, retains heat, absorbs noise and does not accumulate insects and rodents due to its inorganic origin. Mineral wool has a lifespan of about 50 years with no signs of decay, blooming or decay.

The safest and most famous type is basalt - it is a natural material, a stone that is turned into fine fibers at a factory. This insulation doesn't actually burn up to 1000 ° C.

Among the famous brands of basalt wool is Rocklight, which guarantees:

- excellent heat and sound insulation;

- lack of combustion;

- ease of installation.

In addition, the price is pleasantly surprising, as is the high quality. Fire safety at a height. "Rocklight" is durable, vapor-permeable properties remain throughout the entire service life

There is never fungus in mineral wool, the walls "breathe", which is important for insulating the attic

Mineral wool is made in the form of slabs or rolls. The material is quite soft, so it is not placed under the roof or filled from the inside. This material is made in various forms:

- rugs;

- lightweight, soft, semi-strong and durable plates;

- cylinders;

- in the form of loose wool.

According to GOST, mineral wool can be:

- glass;

- basalt;

- slag.

The composition may include binder resins. Also mentioned is an insulating material based on other minerals (not only basalt), which can include a variety of fibers and quartz shavings. The temperature limits for such heaters are 400-700 C.

Glass wool can be harmful in contact with skin and eyes, therefore it is necessary to work in special protective clothing, which is thrown away after use. When closed, the material is not hazardous.

There is also slag wool, but now it is almost never used. This material is cheap, but with low thermal insulation properties compared to others, it is not chemically neutral, so the presence of water can lead to corrosion of steel structures.

The general advantages of mineral insulation are that they are cheaper than most polymers, have good thermal insulation properties, and no water absorption.

Detailed description

Before buying, it will be useful to know its technical characteristics.

Thermal conductivity index

This factor depends on the type of material. On average, it varies within 0.034-0.047 W / m * C. According to this, it can be argued that wool 10 centimeters thick will retain the same heat as 38 centimeters of timber or 140 centimeters of a brick wall.

How dense are the slabs

This criterion depends on the thermal conductivity coefficient. If we take Rocklight or Technolight as an example, then their density is 30-40 kilograms per cubic meter. At the same time, the density of Technoflore, which is used to insulate the floor under the screed, is 81-185 kilograms per meter ³.

Vapor permeability index

This criterion is also very important: the lighter the board, the higher the vapor permeability. As a result, the climate in the apartment will be much more favorable. In addition, insulation with high vapor permeability lasts much longer. This is due to the fact that water molecules do not retain steam for a long time. Since TechnoNicol is almost 98 percent air, it does not trap steam. In numbers, this is equal to 0.3-0.6 mg / (ppm Pa).

Water absorption and fire resistance

Since the specialists used various additives when creating stone wool, in the end it is very resistant to moisture. Water absorption is equal to several percent.

Since Technonikol cotton wool practically does not burn, it is advisable to use it in houses with a high risk of fire. Cotton slabs do not burn and begin to melt only under the influence of a temperature of 1000 degrees.

If a fire breaks out, TechnoNIKOL will be able to prevent the spread of fire for some time. At the same time, it will protect from fire any materials that are less resistant to high temperatures.

How long will it last

Experts say that Technonikol cotton wool, even under poor conditions, can last for about 50 years. The impressive length of the service life is due to the high quality characteristics of the cotton wool.Basalt fibers are resistant to purulent and corrosive processes. In addition, they are not afraid of rodents. In order for the insulation to last as long as possible, it must be properly installed. During installation work, it is imperative to use steam and waterproofing.

Material calculation

Differences in the dimensions of mineral wool elements can mislead you. Professionals try to save working time. The price of a mistake is the same for everyone - budget overruns and wasted time.

Use the online calculator to make calculations. It will take into account all the necessary values, parameters and conditions.

A quick guide to using the calculator:

Please note that the list of cities does not include all the settlements of Russia

Therefore, try to choose options that are minimally remote from the location of your home.

This is important because this parameter determines the average winter temperatures;

all numerical values (thickness) are displayed in millimeters

Just in case: in 1 m 100 cm or 1000 mm;

We recommend looking at the detailed characteristics of heaters on the manufacturers' websites. There you will also find the recommended prices for this type of product;

all calculations are approximate, so it will not be superfluous to add 10% to the results

Having received as a result of calculations the thickness of the insulation and knowing the area of the walls, it is easy to calculate the volume of the insulation. We hope this will be helpful.

Recommendations

When buying mineral wool, pay attention to the integrity of the package. Packaging insulation must be completely sealed, partially compressed, no scratches or torn film

Only in this way there will be no moisture in the insulation before installation. If there are defects, through holes and slots in the material that absorbs water and water vapor, the insulation becomes ineffective and changes geometry.

Rocklight insulation is placed between the steering rods. After installation, it is necessary to protect the mineral wool with a vapor-tight membrane from atmospheric moisture. Further on top of the vapor barrier are wooden blocks 20–30 mm thick.

For thermal insulation of vertical structures, it is necessary to build a frame. When installing Rocklight slabs, make sure there are no holes. To exclude cold bridges, the insulation is placed in two layers so that the second one overlaps the joints on the first layer.

Above the layer of thermal insulation, the damping of the rolling water spreads with an overlap between the rolls of at least 150 mm. The vapor barrier is attached by a small body to the roof rails for condensate drainage. When installing a water seal, you should know on which side to correctly install the vapor barrier on the insulation.

When consumers buy Rocklight, they are especially interested in compressive strength as well as vapor permeability. The first parameter is equal to the limit of 30 kPa, and the other is 0.3 mg / (m × h, Pa).

Basalt insulation "Rocklight" allows you to save on installation. Any homeowner will be able to complete the installation work on their own. The material can be glued or screwed on, filling the joints with construction foam, pre-treating the surface with a primer as an alternative solution.

If it is a sloping roof, it is important to leave a ventilation gap between the insulation and the structure itself. For this "Rocklight" is mounted directly on the frame, which is reinforced from the inside at a distance of 30 centimeters between the slats

Installation work is quick and easy, as the plates are easily installed in the right place.

The main types of mineral wool on a basalt basis TechnoNIKOL

As you can see from the above list, the scope of this thermal insulation material is quite extensive, this is due to the fact that the manufacturer produces a wide range of products for each specific task. Let's consider in more detail each of the types of products.

Insulation Technolight

Mineral insulation Technolight is used for sound and heat insulation of various structures that are not subject to constant stress. These include roof coverings assembled from rafter legs, battens, counter battens and hydro and vapor barriers.

It is also permissible to use this type of material for internal wall insulation on a balcony or in an apartment during the preliminary assembly of the supporting frame, or as the main sound-insulating and heat-insulating layer of the floor on the logs.

Main advantages:

- High fire safety (category NG).

- Low thermal conductivity (0.033 units).

- Excellent vapor permeability (0.3 units).

- Does not interact with concrete and metal structures.

- Prevents mold and rodents.

Insulation Technoblok

Technoblock from Technonikol is a type of material for insulating various structures of industrial, semi-industrial and domestic buildings and structures, which serves as an intermediate insulating layer between the supporting structures and the decorative facing of the facade of the building.

This material is not intended for permanent exposure to static loads, and demonstrates high efficiency in sound insulation or thermal insulation of load-bearing structures of buildings.

Main advantages:

- Excellent energy savings when heating or air conditioning rooms.

- High degree of resistance to high room temperatures (up to 700-800 C).

- High density (up to 45 kg / m3).

- Optimal compression ratio (up to 10%).

- Easy to assemble and cut with a regular utility knife.

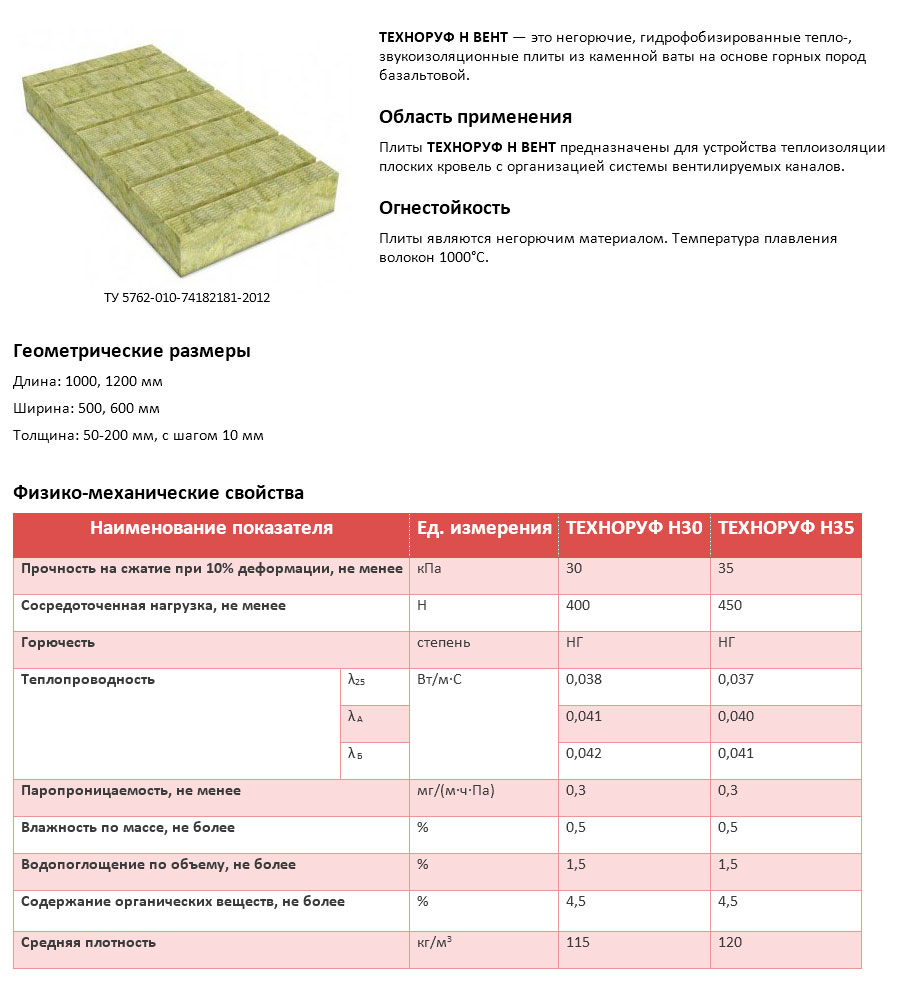

Mineral slabs Technoruf

Technoruf is the main insulation material for sound and heat insulation of industrial, semi-industrial or household structures, which is used in new construction or reconstruction of buildings and structures.

The main advantage of this particular brand is the ability to equip any type of roofing without preliminary preparation of the base using a screed. This is possible due to the high density of mineral slabs, which is 140 kg / m3.

The main technical advantages of Technoruf:

- High density, which, according to the manufacturer's information, is 140 kg per cubic meter.

- High organic matter content (up to 4.5%).

- Low thermal conductivity (from 0.036 to 0.042 depending on operating conditions).

- High strength of the material for delamination (at least 15 kPa).

- It is not subject to combustion and can withstand high temperatures (up to 1000 C).

Mineral slabs for facades Technofas

Technofas is a modern insulation for building facades with a density of 145 kg / m3, manufactured with dimensions of 1000 × 500mm or 1200 × 600mm.

This heat-insulating material has a low level of thermal conductivity (from 0.036 to 0.042) and allows the subsequent plastering of the surface of mineral plates with preliminary pasting with a plaster mesh.

Main advantages:

- Effective protection of buildings and structures from the negative impact of the environment.

- High thermal insulation properties.

- Resistance to combustion due to the use as the main component of basalt rocks that can withstand temperatures up to 1000 C.

- Excellent resistance to static and dynamic loads (due to high density).

- Technofas does not interact with metal structures and concrete base.

Characteristics and varieties of mineral wool Technoblock

Experienced builders know very well that when choosing a heater, specific technical characteristics of the material play an especially important role. They will seriously affect the future quality of thermal insulation.

Mineral wool Technoblok has a thermal conductivity of 0.035-0.37 W / m. And this indicator is considered good.This building material will perfectly retain heat, therefore, when insulating even the outer walls, it will be enough to use one layer of 6-9 cm thick slabs.

The density of the Technoblock is 46-60 kg / m³. This high density is due to the need to use the material as a facade insulation. In this case, high strength is the most important indicator, since the effect of various loads on the facade itself is possible. In addition, high density significantly reduces water absorption.

But the compression ratio of the Technoblock is 8%, this indicator affects the possible deformation of the material. A plate with high compression can be deformed with a little effort; immediately after the pressure is released, the material returns to its original position. The high compression ratio allows more products to be packaged at the same time. Upon opening the package, the Technoblock instantly returns to its original appearance.

The following models belong to specific varieties of the Technoblock:

- Optima;

- Prof;

- Standard.

Minvata Master Technoblock is distinguished by its high density indicators, as mentioned above. For example, Technoblok Prof has a density of 50-60 kg / m³, while for Optima mineral wool this figure reaches 70.

The Tehnoblok thermal insulation is packed in special high-strength polyethylene. The package can contain 5-10 such plates. The material is made in various configurations, the average size of the plates is 1000x1200x600 mm, there are other sizes, for example, 1200x600x50 mm.

Choosing TechnoNikol technoblocks, you can provide your home with reliable thermal insulation and for a long time not think about the costs of repair and restoration of the thermal insulation layer.

For advice on insulating a frame house with technoblocks from TechnoNIKOL specialists, see below.

Where is it applied?

Stone wool has a fairly wide range of applications. A wide range of products allows you to choose the right material. Performing the function of heat and sound insulation, insulation can protect structures from destructive influences.

Cotton wool is produced in rolls and slabs, it can be of different densities, therefore it can be used both on external and internal areas of objects. The choice of material depends on:

- places where it will be installed;

- climatic features of the area;

- heat losses of the object.

In other areas, basalt wool with a lower density is used.

Distinguishes between technical and industrial insulation. The first is needed when there is a possibility of very high temperatures - above 900 ° C.

Basalt insulation is used for:

- insulation on any structure or building - it can be installed horizontally, vertically, obliquely;

- insulation on plaster;

- thermal insulation of the hinged ventilated facade;

- internal insulation of protective structures;

- in sandwich panel systems, concrete panels;

- thermal insulation of the lower layer of roofing structures;

- insulation of attics, attic floors, frame walls;

- thermal insulation in the ceilings of walls and ceilings of baths and saunas;

- insulation in plumbing and chimney structures, steam and ventilation devices, in ovens.

Thermal insulation material Technoflor

Technoflor is a mineral insulation based on basalt rocks, which will serve as the main insulation layer for any type of floor.

The manufacturer Technonikol produces 3 main varieties of this material:

- soil (density 90 kg / m3) - for laying on the ground, floating or warm floors;

- standard (density 110 kg / m3) - for installation as the main insulation with subsequent filling with a screed or concrete mortar;

- prof (density 170 kg / m3) - for the construction of floors with increased load (industry, warehouses, gyms, etc.), which will subsequently be strengthened with a concrete base.

This type of sound and heat insulation withstands colossal compressive loads, which range from 12 kPa (type "Ground") to 50 kPa (type "Prof").

Advantages:

- Effective heat and sound insulation at increased loads.

- Possibility of subsequent finishing of the mineral coating with a rough or fine screed based on a cement-sand mixture or concrete.

- High density.

- Effective resistance to high temperatures (up to 1000 C).

- Low water absorption.

Varieties

In the modern construction market, there are several types of Technonikol cotton wool, so specialists have the opportunity to choose the most suitable option for certain operating conditions. Let's consider in detail each of the types.

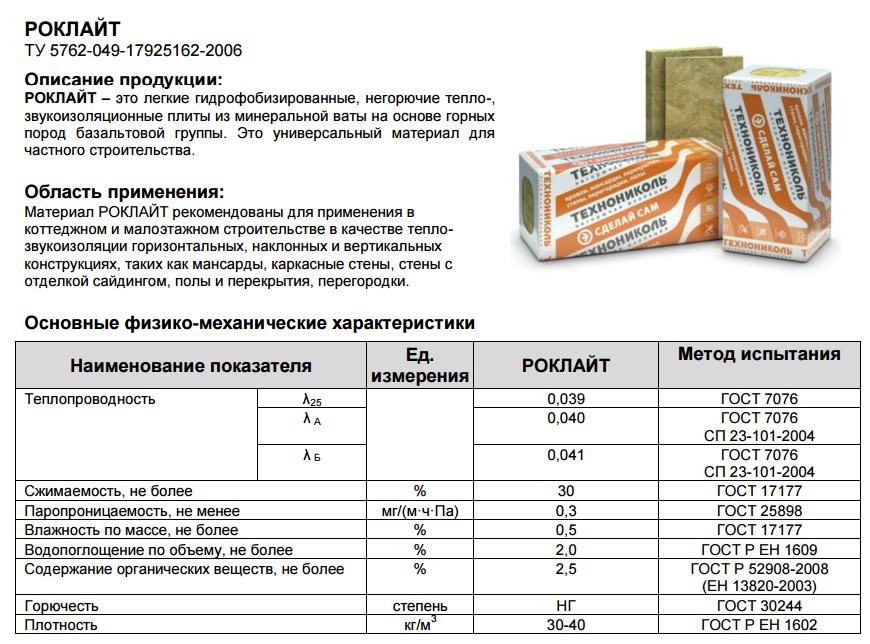

Rocklight

This insulation is a lightweight hydrophobized basalt slabs. The fibers were bonded by specialists using a resin. Rocklite is not afraid of high temperatures and water. It is rational to use it for sound and heat insulation of buildings concentrated at different angles.

Rocklight

Rocklight

This type of cotton wool Technonikol is actively used for insulating low-rise structures. The average cost varies within 1350 rubles per cubic meter.

Teploroll

Long slabs rolled into rolls. In addition to the standard advantages of mineral wool, Teploroll is excellent sound insulation. Teploroll is most often used to insulate the roof, attic and floor in residential buildings. The average price is 1650 rubles per meter³.

Teploroll

Teploroll

Technoacoustic

This type of TechnoNIKOL has a high fire and moisture resistance. Technoacoustic is popular among specialists due to its good soundproofing quality. You can equip residential and non-residential premises with cotton wool.

It is often used for soundproofing in the construction of cafeterias, restaurants and nightclubs. The price starts from 3,000 rubles per meter³.

Technoacoustic

Technoacoustic

Technoblock

The technical block is resistant to combustion, performs well the function of sound and heat insulator. It is based on basalt wool with a low concentration of phenol. They equip the middle layer in layered walls. The price starts at 1,790 rubles per cubic meter.

Warming effect

Warming effect

Technofas

Another non-combustible type of Technonikol stone wool. They carry out thermal insulation of the facade of the house, which will then be finished with plaster. It absorbs well the materials used for finishing. Technofas is the most expensive type of TechnoNicol cotton wool. You will have to pay more than 59,000 rubles for a cubic meter.

Meet TechnoNIKOL products

This company, currently on a par with the largest European manufacturers (more precisely, one of the five largest of them), produces not only thermal insulation. She makes the following products.

Roofing materials:

- Roof tiles;

- roofing material;

- membranes made of polymeric materials;

- primers;

- mastics.

Heaters:

- Expanded polystyrene made by extrusion;

- mineral (basalt) wool, made in the form of slabs.

Basalt wool: composition and features

The finest stone fibers of this material consist of processed gabbro-basalt rocks. There are a lot of air spaces between these fibers. As a result, the level of thermal insulation of the material is simply excellent. After all, it is no secret that it is air, being motionless, that has great resistance to heat transfer.

But this is not all the advantages of the insulation - it is good not only in frost, but also with a critical increase in temperature. Such characteristic of Technonikol mineral wool as fire resistance is very impressive. This material does not burn, calmly withstanding temperatures of even 1000 degrees Celsius. However, it does not even melt! Even if, unfortunately, there is a fire, basalt wool will protect your home, preventing walls and ceilings from collapsing. It will block the path of fire, without emitting a single drop of harmful substances in case of fire.

You can familiarize yourself with the characteristics of basalt wool insulation in more detail in the article: Technical characteristics of basalt insulation, advantages, disadvantages and scope.

Extruded polystyrene foam Technonikol

This type of material is increasingly used for the insulation of houses both in our country and abroad. After all, it keeps warm very well. For example, to achieve an equivalent effect, you need to take a layer of wood 10 times thicker than expanded polystyrene (twenty centimeters versus two). So the EPS is cheaper. And it is much lighter than other heaters, and this reduces transportation costs and facilitates installation. Its strength and rigidity allow it to be used where softer heat insulators cannot cope. But this material is afraid of fire - it not only burns, but also releases toxic substances. So it is necessary to comply with fire regulations, providing adequate protection.

Where is used

Builders use the material to perform heat and sound insulation works. This substance minimizes the penetration of cold and heat loss. Experts prefer to use stone wool in frame buildings and for thermal insulation of residential buildings.

In what works they use:

- KV process metal, concrete, stone and wooden walls from the outside and inside.

- For insulation of small architectural forms (balcony, loggia) and small outbuildings.

- For floor insulation.

- On ceilings, ceilings and walls.

- For the purpose of insulating pipelines, chimneys, stoves and ventilated facades.

Specifications

The main factors for the selection of heaters are the coefficient of thermal conductivity, moisture resistance, fire resistance and environmental friendliness. Thermal conductivity refers to the ability of a material to transfer heat. The lower, the better the material retains it. The fire resistance of the material should be maximized.

Environmental friendliness means that it does not emit harmful substances and does not cause an allergic reaction. Stone wool, including basalt insulation, is one of the best insulation materials from this perspective. All types can be divided into plate and bulk material. All this is mineral wool, but presented in a different form.

The material must not be flammable, absorb moisture, because then it loses its ability to maintain heat. It is desirable that the plates or insulating sheets are large.

Density

The thickness of the layer depends on the climatic conditions: the colder, the thicker it should be. It is advisable to choose heat insulators with high density and low weight, such as Master. Heavy insulation adds stress to the rafters. The material should not change shape with sudden changes in temperature, for example, in heat or cold.

The compressibility of the plates does not exceed 30%, the moisture content in the mass corresponds to 0.5%. The material may contain organic substances, but their volume is not higher than 2.5%. The thickness usually changes in 10 mm increments, with a minimum of 50 mm and a maximum of 100 mm.

Dimensions (edit)

Thermal insulation with mineral or basalt wool is carried out in several stages:

- cleaning the surface from debris and pollution;

- installation of guide profiles that are tied at a height of 60 cm;

- use of fixing plates with dowels;

- reinforcement of the plate with special glue.

Roof insulation starts with planning and preparing:

- installation of windows;

- connection;

- internal insulation of the roof structure.

The following actions are performed if it is necessary to eliminate roof defects:

- a layer of waterproofing is created; when using conventional membrane materials, ventilation is required;

- laying material insulation in the space between the rafters;

- waterproofing can be stapled.

Summary

Fundamental differences in mineral insulation are insignificant. The emphasis on properties is justified only in product advertising:

- Paroc - all elastic;

- Izovol for a bath - with a reinforced heat-reflecting layer;

- blown cotton wool Isover - penetrates into any nooks;

- Ursa Pureone - thanks to a natural binder, environmentally friendly.

But the cost may differ significantly. Complicating the situation and different sizes of measures in the price lists.

In this overview, prices are reduced to a single indicator (RUB / m³). Therefore, just choose the most profitable option for the current period.

And remember: in the case of mineral wool, it is not the price that heats, but the volume.

Isover (Yegoryevsk, Chelyabinsk)

More than 20 years ago, the French concern Saint Gobain officially discovered the Russian building materials market. Over the past 10 years, the company's management has abandoned the import of mineral wool to Russia and opened its own production facility under the Isover brand in the Moscow region. Today, there are two full-cycle production sites in the Russian Federation - in Yegoryevsk and Chelyabinsk.

Mineral wool Isover is suitable for ventilated facades and under plaster; for pitched and flat roofs; into internal partitions and doors. Materials are designed in accordance with the operational features and the specifics of installation for each specified case. There are four main groups in the company's catalog:

- Isover warm - thermal insulation;

- Isover is quiet - Shumka;

- Isover professional - universal insulation;

- Isover for house / apartment - mineral wool with a compromise combination of cost and performance.

The list offers 24 insulating material options.

All slab, roll versions and blown wool are packed in heat-shrinkable polyethylene. This allows 3-5 times to reduce the volume of insulation ready for shipment (important for more efficient transportation).

The positive aspects of Isover are the variety of options. Manufacturing according to your sizes is possible. Among the existing advantages, the convenience of working when filling hard-to-reach areas with blown wool stands out.

Of the minuses - the need to use highly specialized equipment (only valid for the blown version of mineral wool).

| Isover Warm Roof | Isover Blow-out Cotton | Isover Sound Protection | |

|---|---|---|---|

| Purpose | Insulation of roofing systems | Thermal insulation of hard-to-reach places | Sound insulation of premises |

| Dimensions, mm | 5,000x1 220x50 | 1,000x440x400 | 1 170х610х50 |

| Density, kg / m³ | 16 | 30-50 | 14 |

| Thermal conductivity, W / (m K) | 0.037 | 0.032-0.038 | 0.038 |

| Package quantity (pieces / m² / m³) | 2 / 12 / 0.61 | — / — / 0.176 | 14 / 10 / 0.5 |

| Price, rub / m³ | 1 178 | 1 200 | 1 617 |

Video instruction from Isover for clearing structures: