Self-assembly of polycarbonate - how to lay it correctly

To follow the manufacturer's instructions on how to properly lay polycarbonate on a canopy or other objects, you need to prepare:

- roofing material;

- profiles;

- drill;

- self-tapping screws;

- screwdriver;

- protective goggles and gloves.

The work is performed in stages:

- The laying of polycarbonate on the roof begins with the fact that the sheets are placed relative to the parameters of the lathing and mark the places of their attachment.

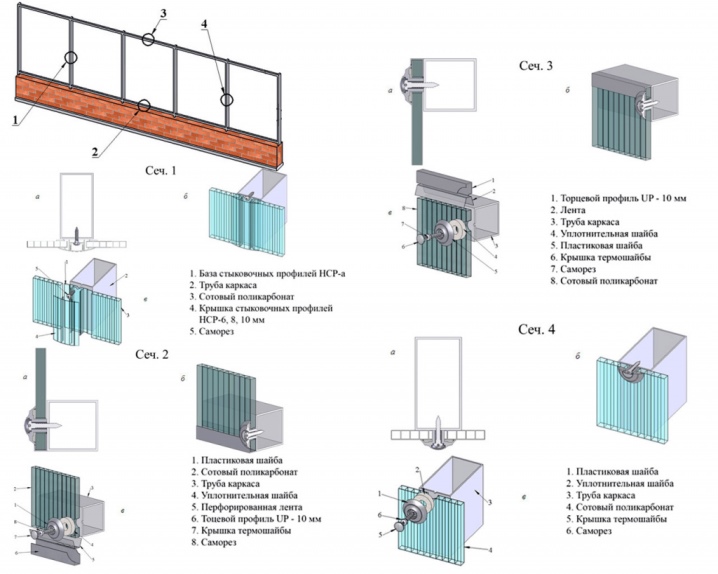

- For self-tapping screws and thermal washers, holes are drilled. They should be located at a distance of 40 millimeters or more from the edge of the panels. The hole diameter is made 5 millimeters larger than that of the thermal washer.

- The material is cleaned from shavings.

- The end part of the panels is sealed so that water and dirt do not collect in the polycarbonate honeycombs. It is impossible to seal the sections with tape. For this purpose, aluminum or polycarbonate profiles are used. The upper cut is closed completely, and a place is left in the lower cut for the drainage of moisture and condensate, for which holes with a diameter of 1.5-3 millimeters are drilled along the edge with an interval of 25-30 centimeters.

- The manufacturer's instructions describe how to properly install the polycarbonate. This must be done taking into account the thermal expansion of this material. If you ignore this recommendation, then at subzero temperatures it will begin to fall out of the mountings, and in hot weather it will deform and then burst. To prevent this, gaps are left between the panels.

- Polycarbonate is laid and fixed with self-tapping screws. To ensure a secure fit, fasteners should be used in conjunction with special thermal washers. Their gaskets seal the holes in the material and strengthen the joint. The diameter of the thermal washer must exceed this parameter for the self-tapping screw.

- Before placing polycarbonate on a canopy or other object, the panels must be correctly oriented. The side with the UV protective film must be on the outside of the roof.

- When the material is joined at right angles, corner profiles are used. If the panels are adjacent to the wall, a wall profile is used. For mounting the ridge on the roof, a ridge element is used.

Why is it important to fix polycarbonate correctly?

The honeycomb product was named for the visual similarity of the structure in the context of the honeycomb. Cellular polycarbonate in the slab consists of several polymer layers connected by longitudinal reinforcing bridges. The minimum number of sheets is two, the maximum is four.

The luminous flux passes through polycarbonate by 90% or more, besides, the strength of the synthetic material is a hundred times higher than that of glass. Polycarbonate bends well, remaining resistant to mechanical damage, for which it is often chosen for the construction of arched canopies. When struck, cracks do not go on it, so even a hail attack is not afraid of it.

Although polycarbonate is one of the strongest and most reliable polymers, it can degrade in sunlight. It so happens that polymer plastic used as a cladding for a greenhouse, greenhouse, outdoor gazebo, veranda and similar open-type buildings quickly wears out.

It takes only a couple of years from the moment of installation, and the cladding completely loses its original physical characteristics and declared qualities.

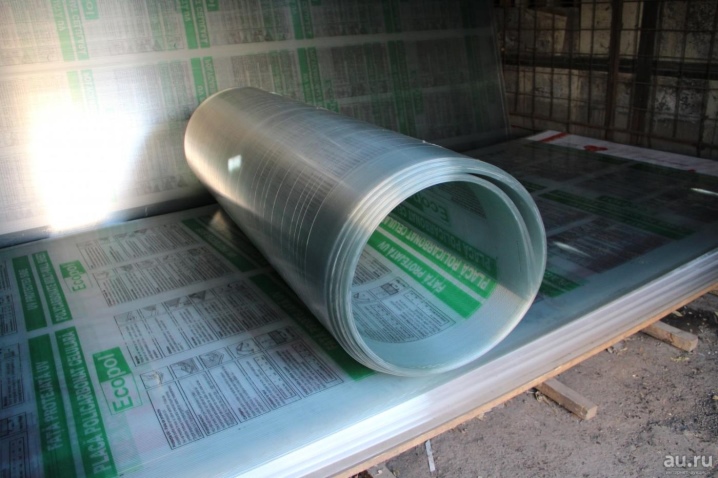

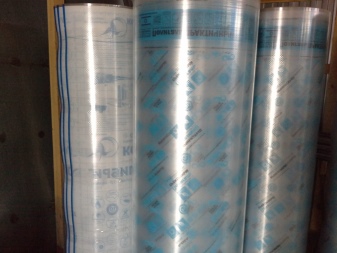

The presence of a protective layer against ultraviolet radiation is the most important quality of polycarbonate.If you attach the sheet with the treated layer inward, you can immediately reduce its service life by a whole decade. Determining the right side with resistance to the damaging effects of the sun is not difficult: it is covered with a packaging film with a list of product data and its parameters. There will be no markings on the back of the film.

There are several ways to apply UV protection.

- Spraying. A thin layer of a solution is applied to polymer plastic, which looks similar to industrial paint. The considered method has significant drawbacks. During transportation and installation of the polycarbonate sheet, the protective layer is damaged, which makes the polymer unsuitable for efficient operation. Spraying as UV protection demonstrates instability to various atmospheric conditions and does not tolerate mechanical stress from the outside.

- Extrusion protection method. At one of the stages of production, a special layer is applied to the canvas to prevent the destruction of the polymer. It penetrates the surface of the polycarbonate material. The canvas receives resistance to damage of various kinds, including mechanical stress. The difference with the previous method also lies in the service life of polycarbonate - at least 20 years.

The polycarbonate sheet is delivered to the customer in a packing film (on both sides). It must be removed upon completion of installation, otherwise, under the rays of the sun, the packaging will firmly adhere to the sheet and cause it to turn yellow. It so happens that the master removes the film, forgetting to mark the UV-protected surface, which should be directed outward. Determining the right side is easy in this case too. You need to take a polycarbonate sheet by the end and look through it at the sun. Purple reflections will appear on the UV coated side. In principle, such a test may or may not be carried out, replacing it with a call to the supplier.

A competent specialist will help you figure out which side should be laid out, and which side should "look" inward. Sellers probably know the technical characteristics of their product. Cellular polycarbonate sheets have a film that prevents the destructive effects of ultraviolet radiation. Moreover, the outside of the canvas has a coating that transmits a certain part of the light spectrum. The maximum luminous flux gets through the coating with polarized mica particles, and harmful infrared radiation is reflected. In rooms glazed with polycarbonate, under intense light, the air heats up slightly, which improves the microclimate in hot weather. Such polycarbonate sheets are distinguished by a pearlescent, pearl or golden hue.

Another type of polycarbonate is more suitable for greenhouse applications. It lets in enough light for optimal vegetation growth while keeping the damaging radiation outside. The important thing here is which side to mount the polycarbonate on the greenhouse. When a leaf does not lie down correctly, climatic conditions are formed in the greenhouse, which have a detrimental effect on vegetation.

Another type of cellular polycarbonate is a material with high reflective qualities. The aluminum-sprayed coating resists greenhouse effects and provides a cool shade. Plates are produced in several color variations: silver, green and blue.

Therefore, it is so important to know the front side!

And it's very easy to do it! In 100% of cases, modern manufacturers with a worldwide reputation on the top side of the panel will glue instructions on a protective film, where they will describe in detail the installation process, pay special attention to which face is the front, and also advise to glue the edges with special adhesive tape so that it does not get into the honeycomb dust or insects (which can sometimes be seen in the photo). Plus, the general rule always says: the line that has markings, instructions, logos, etc.

etc.- and is front (as in the photo), and the other, where there is absolutely nothing but the protective film itself, will be the opposite. Therefore, if you buy polycarbonate from a well-known manufacturer, then you definitely will not have problems with its correct installation.

Plus, the general rule always says: the line that has markings, instructions, logos, etc. etc. - and is front (as in the photo), and the other, where there is absolutely nothing but the protective film itself, will be the opposite. Therefore, if you buy polycarbonate from a well-known manufacturer, then you will definitely not have any problems with its correct installation.

And if the manufacturer hasn't left any tips on the polycarbonate?

This also sometimes happens that apart from multi-colored films from different sides there is nothing, or even both protective films are transparent. But there is a way out here too:

Option 1: ask the seller. Why not, because the seller must know exactly where this model has a front edge. Consult, it will not be superfluous!

- Option 2: if the seller shrugs his shoulders and shrugs his shoulders, then the World Wide Web will come to our aid. On the Internet, you will certainly find people on the forums who already know about such problems and will tell you how to find out the correct location of the sides.

- Option 3: and even if there is no answer anywhere at all, look for clues on the polycarbonate itself. On the upper part, at a distance of about 70-80 cm, the manufacturer himself often makes laser notches so that during installation customers can navigate where is the top and where is the bottom, even if all the films have already been removed. Look for notches or other markings that will tell you where the top is. Better yet, when removing the films, mark for yourself where the top side is, and where is the bottom. And you won't have any problems!

As you can see, there is nothing difficult in determining the front face of polycarbonate. Either the answer will already be detailed in the instructions, which itself will be on the upper part, or there will be hints on the protective film like the inscriptions "Top side". And even if everything is even more difficult, sellers, the Internet, and in extreme cases, simple marking and laser notches will always come to the rescue.

And do not forget that it is important not only to correctly determine the front face, but also not to lose it during the installation process. Otherwise, you will cut off a piece of the panel, and then you will wonder where is which edge

To avoid this, mark and remember in advance where is the top and where is the bottom. Or buy polycarbonate with symmetrical UV protection. Yes, its cost will be higher, but the probability of incorrect installation will simply disappear!

Happy installation and remember: determining the right side of the carb is not as difficult as it sounds!

Fasteners

Installation of polycarbonate can be carried out using various elements: self-tapping screws, washers, special designs. They are chosen based on the purpose of the future structure and materials for creating the frame.

Washers and screws

How to fix polycarbonate - different fasteners can be used for this. The most popular are carpentry or galvanized self-tapping screws from 19 to 50 mm. Their choice depends on the following factors:

- washer size - decorative models with a thickness of 3-15 mm, silicone standard with a thickness of up to 5 mm;

- installation diagram - for wooden lathing fasteners 50 mm, self-tapping screws 19 mm are used in the fastening without overlap, with an overlap - 25 mm;

- thickness of slabs - when using a window structure, the thickness of the side slabs is 6-8 mm, for the roof 10 mm, for a standard frame, the thickness of the material is not more than 10 mm.

For the main methods, a universal hexagon self-tapping screw with a drill at the end is used. Designed for aluminum structures. It can also be used for wood, but the strength characteristics are lost. On the opposite side, ordinary carpentry screws can be used.

Washers for fastening

The only type of fastener for all types of polycarbonate is a screw with a large washer made of durable plastic or a self-tapping screw. Washer screws are used to create decorative designs. Not suitable for greenhouses due to centering sleeve. The simplest version of tight fastening of sheets is provided by a snap-on split profile. The boards are placed on the assembled profile and snapped into place with an overlay foil. Bolts with nuts can also be used, but they are not very convenient to use - the work takes more time and you can destroy the plate by overtightening the nut.

How to attach polycarbonate to a metal frame:

- Experts recommend using fasteners with washers and plugs that have an O-ring and bulged washers.

- They are recessed in the holes with a leg.

- The panel is pressed tightly, harmonious appearance, moisture does not get inside.

Self-tapping screws or other similar items must be purchased separately. Polycarbonate washers are produced in different colors, stronger, thermal washers are transparent.

Washers with plugs

Polypropylene washers consist of a plug, a cover (different colors) and a seal. They have no UV protection, quickly fade and lose strength. Not recommended for indoor use and on shaded roofs. Their main advantage is the price.

Metal washers are mainly used for metal frames and large areas. They do not loosen, provide high-quality fastening. They are concave, a gasket is placed in the mold, fastened with bolts or self-tapping screws. Washers with gaskets provide maximum tightness, prevent moisture from penetrating into the canvas.

Metal washers

For fastening plastic under a canopy or indoors, you can use self-tapping screws with a gasket or a thin washer. In the most optimal cases, the washers can be completely abandoned. It is imperative to put on an additional gasket under the washer for outdoor structures.

Profile

The connecting profile allows you to attach sheets with a frame and between themselves.

The profile is made of identical sheet material and can be 4-16 mm thick.

A thermal gap of 3 mm is left inside between the profile and the sheet.

During installation, a perforated or sealing tape is used, which is attached to the ends.

Then the plastic is installed directly in the profile.

The profile itself is of several types:

- connecting;

- one-piece;

- end;

- detachable.

All options have their own characteristics and characteristics that must be taken into account when choosing a type of construction.

Plates can be mounted in aluminum, plastic or polycarbonate profiles. The profile itself has a different cross-section and is marked with Latin letters. Plates installed in the grid can be fixed with a sealant. But in strong winds it will be a weak connection

It is important to choose a quality sealant that will retain its elasticity and strength for several years.

To know how to properly attach polycarbonate to a greenhouse, you need to remember several important rules:

- the sealant is used only on the upper slopes;

- avoid any curvature of the sheets when using thermal washers - this leads to the appearance of holes and loss of tightness of the structure;

- arched structures from below are fastened with perforated tape, which will protect against air release, breaks and damage to the sheets themselves;

- metal profile is used only for structures larger than 2 m;

- aluminum is a good hermetic agent and is a base, rubber seals.

Master Class. How to check if polycarbonate is installed on the right side of the greenhouse?

Imagine that installers have fixed polycarbonate to a greenhouse, and you want to check if the polycarbonate is installed with a protective coating that should reflect ultraviolet rays to the sun or into the greenhouse.If the polycarbonate is installed facing the inside of the greenhouse, then ultraviolet light will destroy the material twice: first, passing through the polycarbonate to a protective coating, then it will be reflected from it and pass through the material a second time. If the polycarbonate is installed correctly, then the UV rays will be reflected and will not harm the sheets. The thicker the spray, the longer the sheets will remain transparent.

Polycarbonate sheets are glued on both sides with transport films to preserve their presentation. The outer side has logos and has many warnings "this front must be set to the sun", the other film is transparent. To tear off the films, you have to turn the polycarbonate over. When the films are peeled off the carbonate, the sheets are absolutely transparent and the beginner will be confused as to which side was the front.

Decent factories on the edge of the sheet with a laser burn out the name of the polycarbonate, the number of the factory (Carboglass has three factories in different regions) and the number of the shift, the day and time of manufacture of the sheet. With the information, you can define the ingredients of the "test" and the settings for the equipment. You understood that if the inscription is readable from outside the greenhouse, then the sheets are laid correctly - with the front side facing the sun. The photo has the inscription "Carboglass US Premium 360 09/14/2017 13:05".

Details: You need to know that Karboglass in the fall of 2017, sheets "specially for greenhouses" have a dusting of 25 microns, which is enough for 4-5 years; sheets "Agro" have a protective coating of 40 microns, the plant assures that this will be enough for 10 years of street use; and Premium sheets are sprayed with 50 microns and sun protection for 20 years. Other factories spray a maximum of 25-30 microns, at least in the summer of 2017 a number of factories gave us these numbers when calling. At the same time, other factories have premium polycarbonates with a density of 600-630 grams / square meter, while Karboglass has an average Agro with a density of 600 grams, and Premium has a density of 700 grams / meter - you understand, Karboglass is cooler. At the same time, in the whole country, only Karboglass has a "reinforced" polycarbonate with an additional diagonal partition, there is no doubt that it is 25-30% warmer than the hollow polycarbonate honeycomb and is stronger than materials from other factories. At the same time, Karboglass asks for money for the sheet least of all, so Karboglass is still champions.

Plants that write that they have UV protection not outside the sheet, but inside the sheet or inside the granules, or "the protective layer is produced by extrusion," are deceiving you. This is a muddy way of saying - polycarbonate is for indoor use only and not for greenhouses.

Look, let's say you installed the polycarbonate incorrectly - one sheet costs 2350 rubles, you need to request a rework, for this you need to have a contract not only for the sale and purchase of a greenhouse, but also a contract for the assembly of greenhouses. And you also need to have a receipt for payment.

Buy from the Plumbing Store. Call 3412 / 56-50-60

Which side to attach polycarbonate to the greenhouse

Polycarbonate is widely used in the greenhouse business and in personal greenhouse buildings. It is lightweight, durable and can be installed by yourself

But at the same time it is important to know which side to fix the sheets on the greenhouse.

Tips on how to determine the right side when attaching material:

- The color of the protective film and the inner layer may differ;

- The instructions may indicate the manufacturer's advice on how he will designate the protective surface;

- The seller or other specialist can help.

The protective coating is only on one side of the material. But it is not always possible to correctly determine with which one. But you need to figure it out, because the quality of the building and the protection of plants from UV radiation depend on this.

The easiest way to determine the right side is to distinguish between the colors of the coating. Usually the protective film is colored. The inner layer remains transparent.

The protective film may be highlighted in color or other characters.It is also possible to purchase polycarbonate with double protection on both sides. Such a purchase will cost more, but will be more durable.

The right side can be easily determined by a specialist. It can be a seller or a person who installs polycarbonate. The right sides can be easily confused. To prevent this from happening, it is necessary to perform the work especially carefully.

Aluminum fastening systems

An aluminum profile is ideal in terms of waterproofing, and along the way can act as a load-bearing base if the shape allows. Thanks to rubber seals, aluminum systems provide excellent protection against condensation and moisture. They have excellent thermal insulation, are very reliable, durable and look aesthetically pleasing.

Since any type of polycarbonate requires maintenance, remember to do seasonal maintenance to prolong the life of your greenhouse. Do not use abrasive or other strong cleaning agents; clean water and a rag will suffice. Well, remove the snow carefully so as not to damage the top layer of polycarbonate, which is responsible for UV protection. If you follow these simple rules, the greenhouse will serve you for many years.

Which side to lay polycarbonate on the greenhouse

To understand which side of the polycarbonate is best attached to the sun, elementary - by marking the protective film. It is the marked side that provides maximum protection against UV radiation

What is very important - the microclimate in it directly depends on which side to lay polycarbonate on the greenhouse. This means that the amount of the resulting crop

What rules should be followed when laying polycarbonate in a greenhouse?

In addition to the fact that it is important to consider which side to put polycarbonate on the greenhouse, a number of factors should be taken into account:

- choose the right thickness of the material;

- choose the right light transmission. It is optimal to use transparent plastic and correctly determine which side of the cellular polycarbonate should lie to the sun;

- orient the sheet correctly: the channels should be parallel to the bend.

The procedure for installing sheets for a greenhouse on a frame

This procedure is simple:

- Decide which side to attach the polycarbonate to the greenhouse.

- Mark and cut the sheets.

- Make holes in the places where the thermal washers are installed with a step of 40-50 mm.

- Secure the roofing material with self-tapping screws.

- Screw the self-tapping screws strictly perpendicular to the sheet.

- Close the ends and connections with a profile.

But the basis of the entire installation is to correctly understand which side to lay polycarbonate on the roof. Otherwise, all the work will have to be redone, spending a lot of time and money.

What needs to be considered for perfect sheet attachment to the greenhouse?

It will help you get an answer on how best to lay polycarbonate with which side to the sun video from professional installers of structures based on this polymer canvas.

Strict adherence to all the rules will save you from mistakes during installation work and will help you understand how to properly lay polycarbonate on a greenhouse, canopy, canopy or roof of a house.

In December 2018. plant "Polygal Vostok" passed all tests to confirm compliance with the requirements of the Technical Regulations "On ...

Cellular polycarbonate POLIGAL produced by the Polygal Vostok plant has passed all checks and tests in the BODY ...

Today, polycarbonate is a popular material that is often used in the construction / arrangement of various objects: Home ownership. ...

Polycarbonate is used for a wide variety of purposes. Many structures can be made from it, ranging from agricultural ...

With the development of building technologies, more and more practical novelties appear on the market, allowing you to completely transform the external ...

The production company "Polygal" produces high quality cellular polycarbonate building material. These products are in demand on the market ...

Polycarbonate is used for a wide variety of purposes.Many structures can be made from it, ranging from agricultural ...

"Polygal" - the best polycarbonate for greenhouses and greenhouses High quality polycarbonate for greenhouses makes it ...

Cellular polycarbonate is an effective solution for creating translucent structures Since its inception, cellular polycarbonate ...

Each owner of a private house and summer cottage tries to equip housing with maximum comfort and coziness. At…

How and with what to attach polycarbonate to metal and wood?

When all the preparatory work is completed, you need to start the process of installing the structure, which is a competent fastening of polycarbonate.

When all the preparatory work is completed, you need to start the process of installing the structure, which is a competent fastening of polycarbonate.

There are 2 common ways of attaching polycarbonate sheets:

- With thermal washers

- Using profiles

Fastening polycarbonate with thermal washers

For thermal washers, you need to make holes in the polycarbonate sheets a couple of millimeters wider than the diameter of each thermal washer. The plastic structure on the short leg should fit snugly into the hole and snap into place. Its length is equal to the thickness of the panel.

For thermal washers, you need to make holes in the polycarbonate sheets a couple of millimeters wider than the diameter of each thermal washer. The plastic structure on the short leg should fit snugly into the hole and snap into place. Its length is equal to the thickness of the panel.

The thermal washer must have a rubber seal, which makes it possible for additional fixation and does not allow moisture and dust to pass through. This method of installation can ensure tight retention of polycarbonate with washers, which will expand under thermal loads and prevent the sheets from changing their shape. This method of fastening is called point.

Fastening polycarbonate with metal profiles

Such an installation assumes that polycarbonate sheets will be inserted into a metal profile, and then the finished structure will be installed where necessary. This method is convenient when the panels are stacked in several rows and need to be joined together.

Such an installation assumes that polycarbonate sheets will be inserted into a metal profile, and then the finished structure will be installed where necessary. This method is convenient when the panels are stacked in several rows and need to be joined together.

The edges of the panels in the profile must be fixed with self-tapping screws or the same thermal washers. Most often, with the help of profiles, panels can be fixed, which should become the edges of the structure, and the middle can be mounted using a point fixing.

The profile can be:

- Detachable

- Non-detachable

- Docking

- Special (it is necessary to connect panels where the configuration of the frame changes)

- Angular

- Stenov

In all cases, the polycarbonate sheets in the profile should "go" no more than 20 millimeters.

All the above methods of fixing polycarbonate are also called dry. But the "wet" method assumes that the sheets must be attached to the frames or to each other using polymer putty. After that, all joints on the inside are treated with a sealant.

The method of fixing polycarbonate should be chosen based on what tasks are assigned to the structure and how easy it will be to mount it. And if all the rules are followed, it should turn out to be strong and beautiful.

Video on how to fix cellular polycarbonate

Detailed video instructions for installing cellular polycarbonate.

How to properly attach polycarbonate to the greenhouse frame so that the coating does not crack, buckle or burst. How to choose mounts for polycarbonate.

Features of cutting and preparation for installation

Lay polycarbonate on a flat roof with a slope of 5-7 degrees. This will ensure good water drainage and easy cleaning.

Since the material tends to expand and contract when exposed to high or low temperatures (on average, plus or minus 5 mm per 1 m2 of area), this must be taken into account during installation.

For this, the diameter of the holes in the polycarbonate is made 3-4 mm larger than the dimensions of the screw. Thus, by leaving a margin of 1.5–2 mm near each fastener, you will prevent warping of the material in summer and cracking in winter.

Use silicone, teflon, polyethylene and neoprene as a seal.

Use a band saw, circular saw or grinder to cut polycarbonate. Work on hard and level surfaces to avoid material deterioration.

Remove the protective film last - it will protect from scratches, chips or other particles on the front side and ends of the sheets.

How to fix it correctly?

After purchasing polycarbonate, the buyer is often puzzled by the question of whether it is necessary to clean the plastic sheet from the film. The correct answer is the recommendation to remove the film immediately after installation in order to avoid problems in the future. This is a shipping film that covers the sheets during transport and storage, so it must be removed when no further shipment is planned.

Some summer residents take the transport film as a protective layer from UV. Leaving it on the panels, they expose the material to the destructive influence of the sun. It is worth knowing that the UV layer is invisible - it will not be possible to peel it off on an unspecified basis. Therefore, there is no need to be afraid to accidentally remove the excess due to inexperience. If the film on the outside of the sheet remains unremoved, it will firmly stick to the top of the material with the dark areas of the inscriptions, and after that it will be simply unrealistic to remove it. Moreover, the film on the outside of the canvas threatens the safety of the layer that protects against ultraviolet radiation. In winter, the film that has not been removed will trap the snow.

When installing, it is also important to take into account the ability of polycarbonate to respond to temperature changes. In hot weather and in cold weather, standard polycarbonate demonstrates deviations from the original width by 1 cm or more

If at the same time the sheet is tightly fixed on the frame, the appearance of cracks with the subsequent destruction of the material is inevitable. To prevent this from happening, the holes for the screws should be 3-4 mm larger in diameter than the screws themselves. This will prevent possible deterioration of the material when it changes during thermal expansion. It is important not to over-tighten the bolts, otherwise the sheet may be deformed.

Also, you can not bend the material more than the prescribed norm. Each type of polycarbonate is characterized by a certain flexibility and specific indicators of the minimum bending radius. If the sheet is bent more than permissible, folding during transportation or laying out on arched structures, the polycarbonate will burst during the first thermal expansion, and the tightness will be broken. Water will ooze through the break when it rains. This part of the structure will be unsuitable for further operation, and it will have to be replaced. The maximum radius is determined by the thickness of the polycarbonate - the thinner, the more it is allowed to bend the sheet. For reliability, you need to check with the seller about such qualities.

With proper installation and adherence to the installation procedure, the constructed structure made of cellular polycarbonate will serve for many years without problems.

How to properly lay polycarbonate, see the next video.