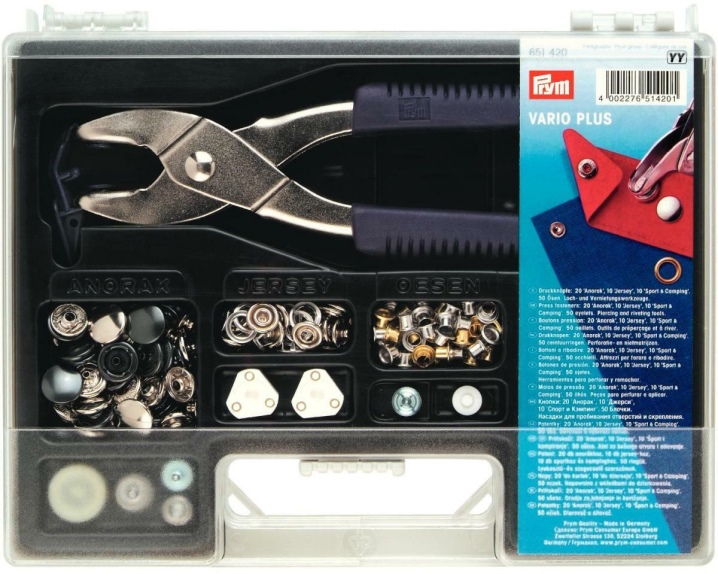

Types of fittings

Garment accessories include the following parts:

- Buttons.

- Hooks.

- Hinges.

- Lightning.

- Blocks.

- Velcro textile fasteners.

- Holniten are metal rivets. Most often used in denim clothing to secure stitching.

- Buckles.

- Eyelets. Strong metal or plastic fasteners are mainly used in leather goods.

- Rivets. There are utilitarian rivets - those that are used for clips, fastening and fastening, and decorative. Very often sewing accessories in clothes combine both roles.

The most popular materials for making fasteners and fasteners:

- Metal.

- Ceramics.

- Plastic.

If the part is not correctly selected, that is, without taking into account the peculiarities of the fabric or leather, then the accessories simply will not cope with their functions. Then you will have to change the details on the clothes yourself, so as not to throw expensive things into the far corners of the wardrobe.

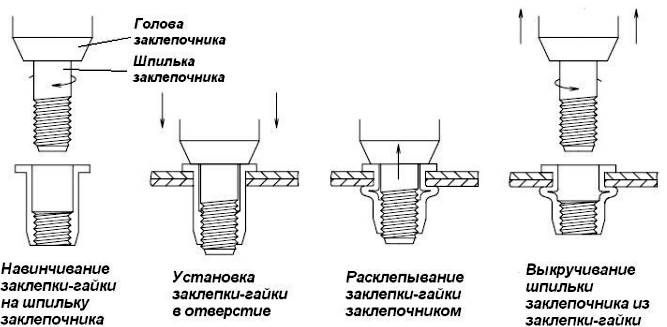

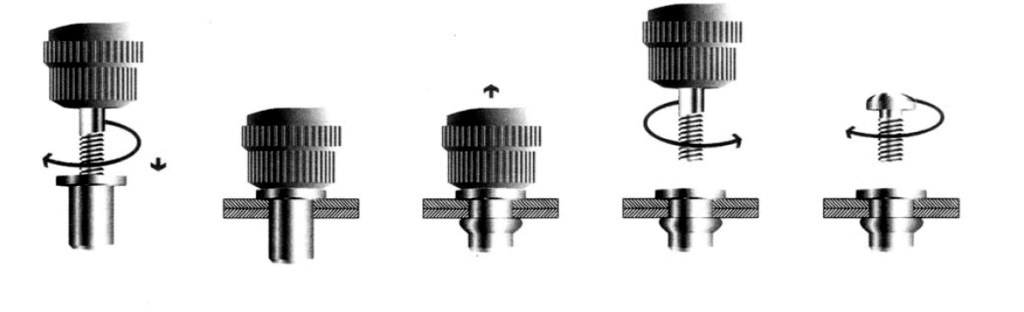

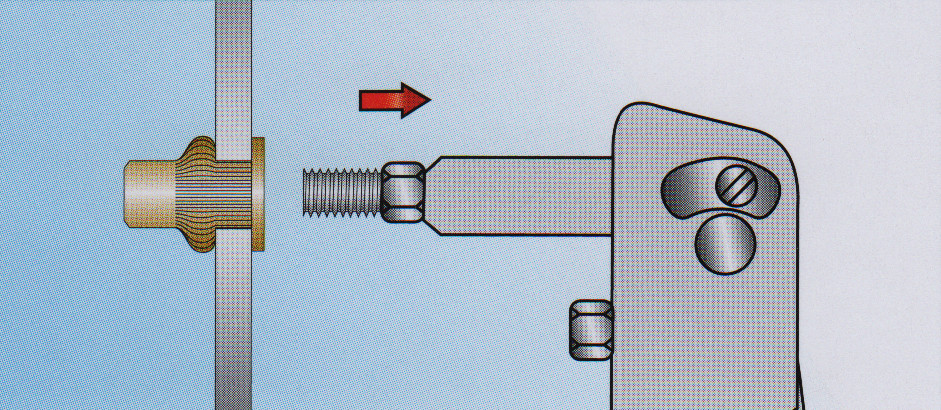

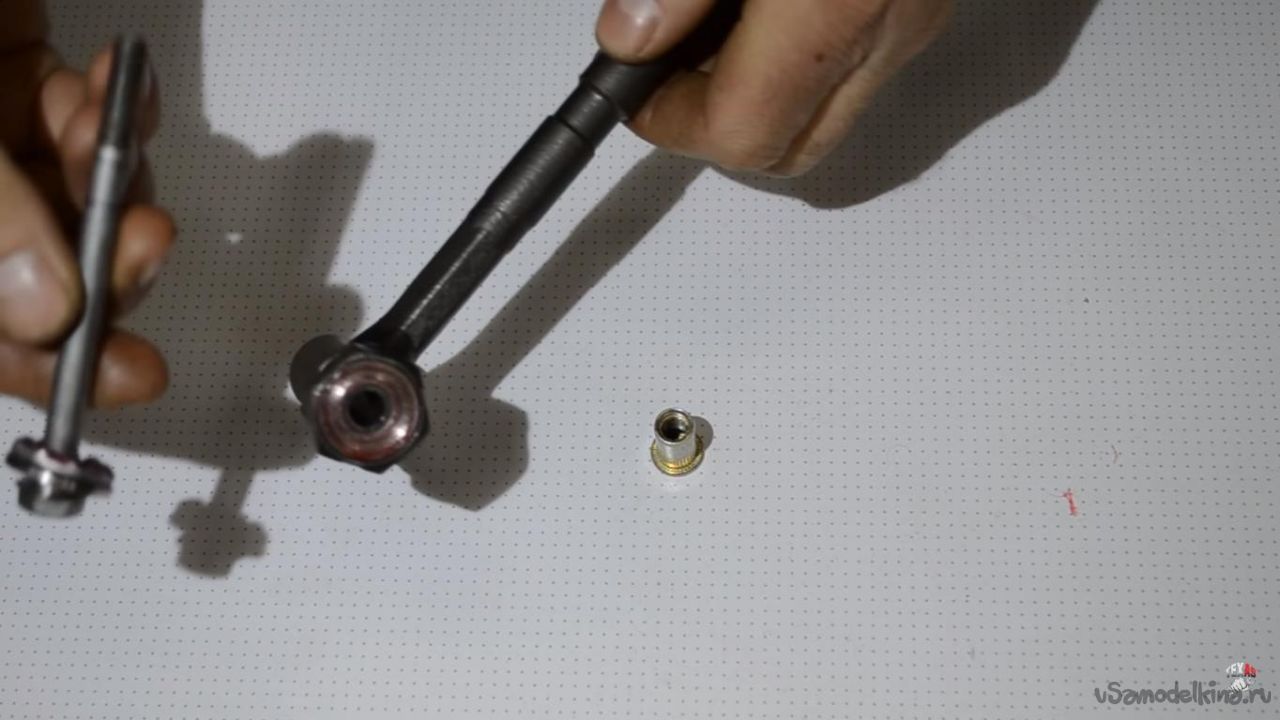

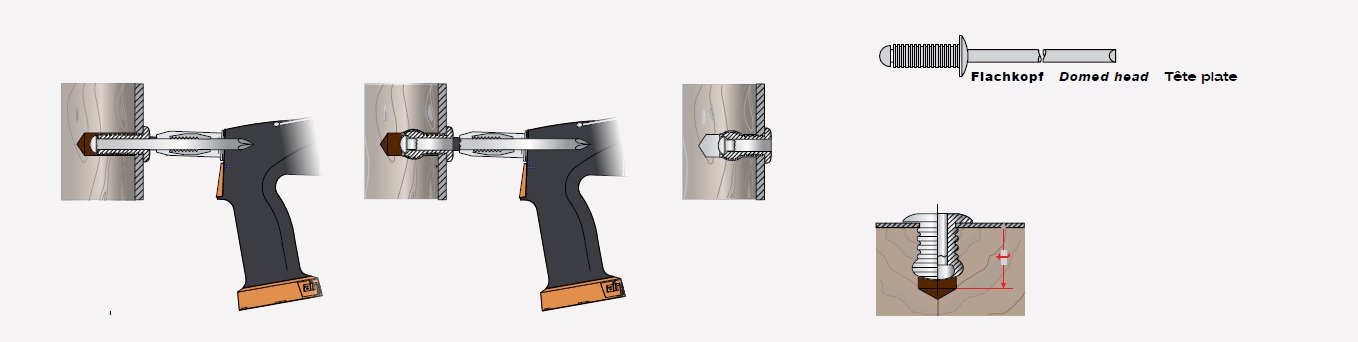

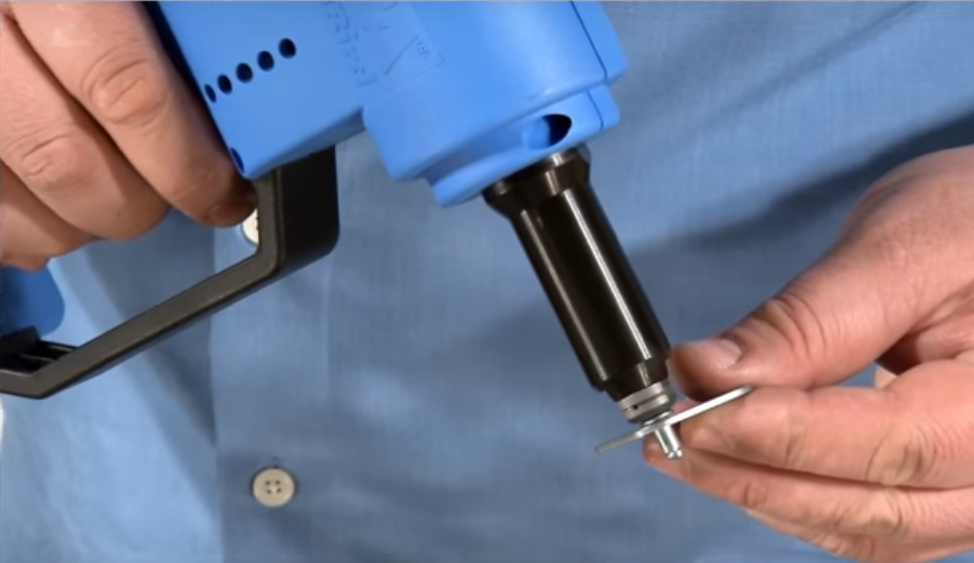

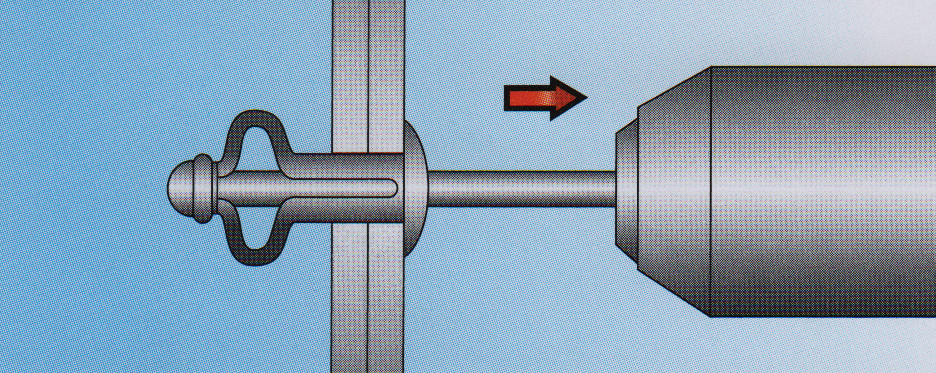

Installation of threaded rivets without rivet

An expensive professional tool is not always available. In addition, if it is necessary to perform one-time operations, its purchase is impractical. In such cases, work is performed without the use of a special tool. There are several ways to rivet a threaded rivet without a rivet. The easiest way is to install threaded rivets without a rivet using a screwdriver. For this, a special nozzle is used, in the body of which a bolt with a collapsible thrust bearing is located. The bolt, through a notched end nut, is screwed into a rivet, which is then installed in the mounting hole. After that, the screwdriver is turned on and, due to the rotation of the bolt, a force is created that forms a bead and fixes the rivet. Rotation of the rivet is prevented by a knurled nut and a thrust bearing. After installation, it remains only to unscrew the bolt from the fastener, transferring the screwdriver to the reverse rotation mode. This method makes it possible to use a conventional screwdriver as an electric riveter. In the absence of a special attachment, such a design can be assembled by hand.

In general, the listed methods make it possible to carry out the installation of threaded rivets without a riveter with sufficient quality. The speed and complexity of installation depends on whether you are using the power tool.

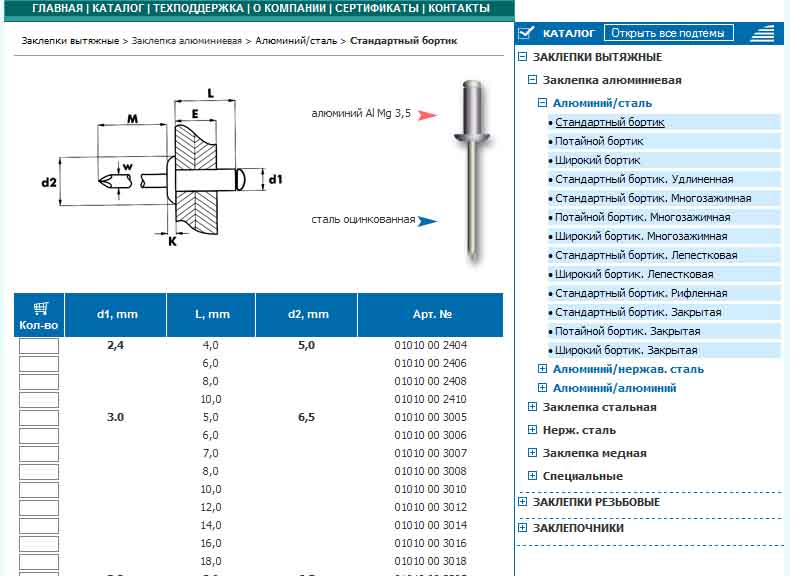

Types of rivets

For each type of riveting tool, only the same types of rivet fasteners are suitable.

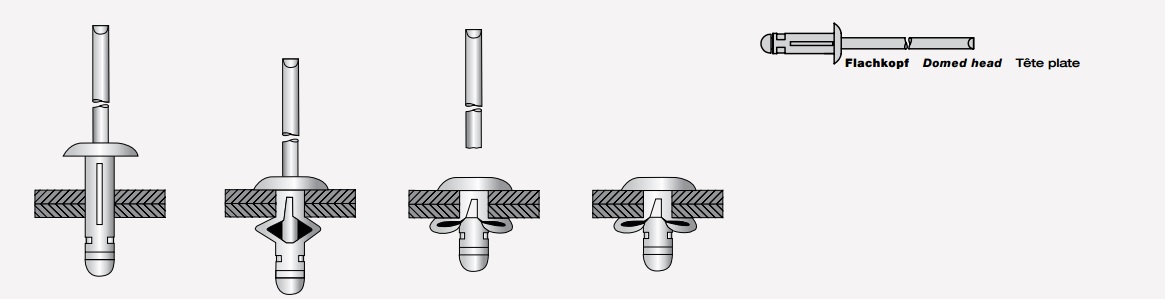

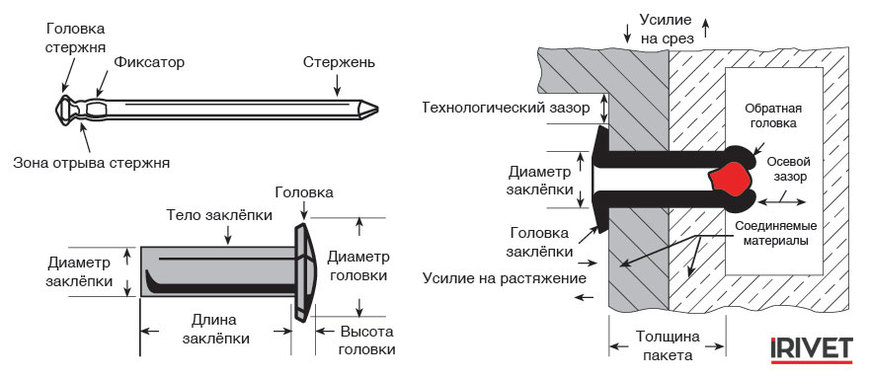

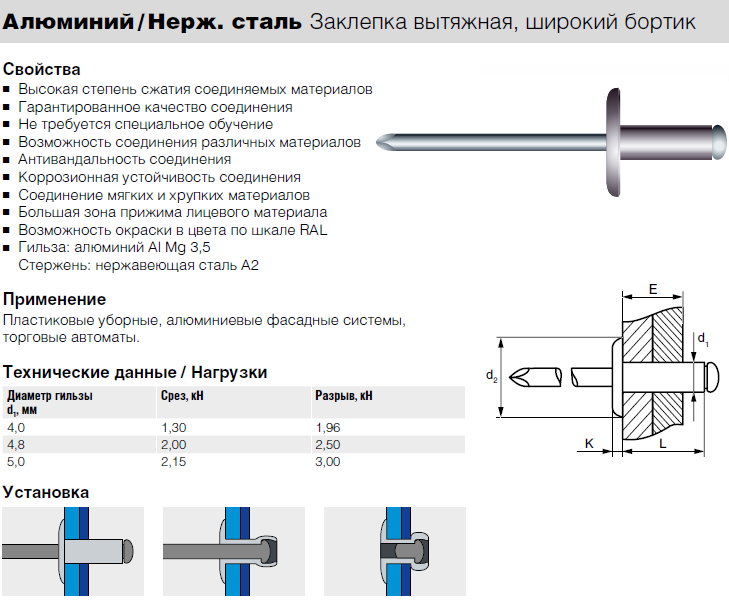

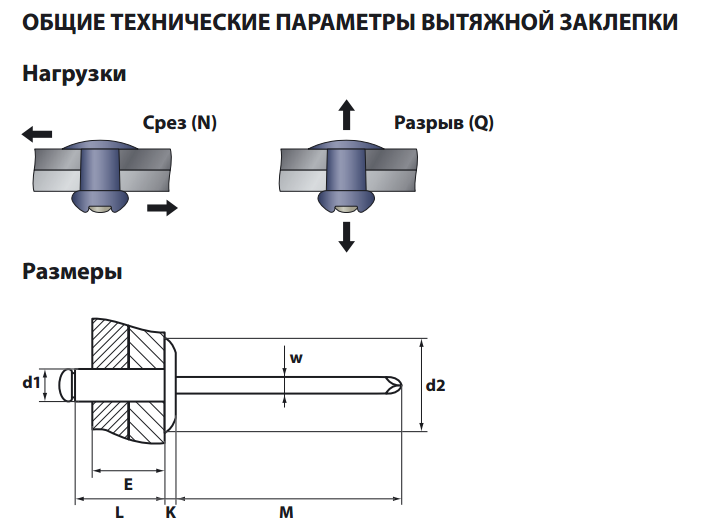

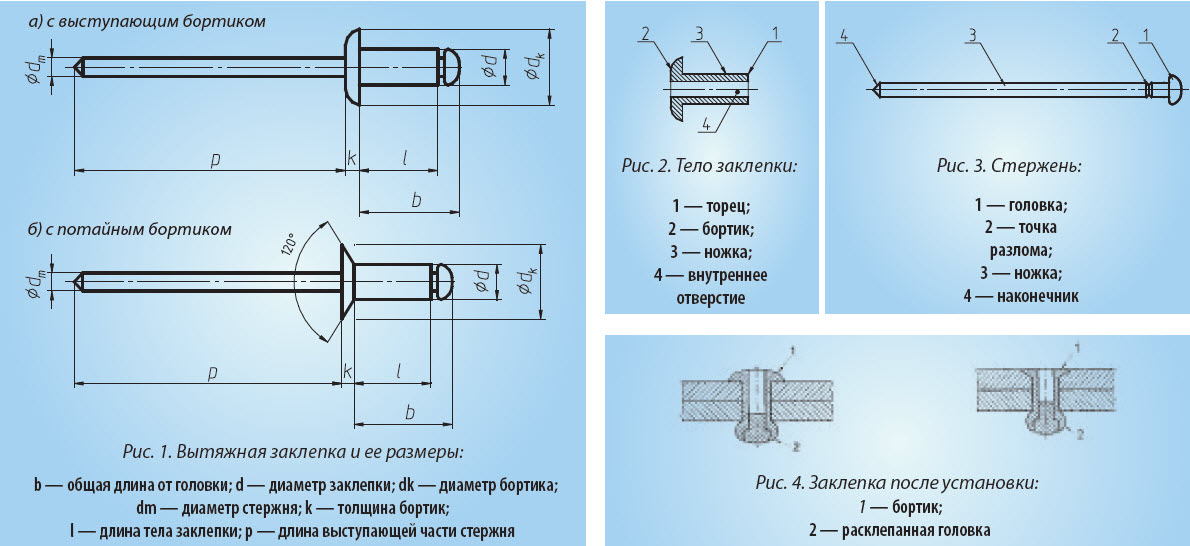

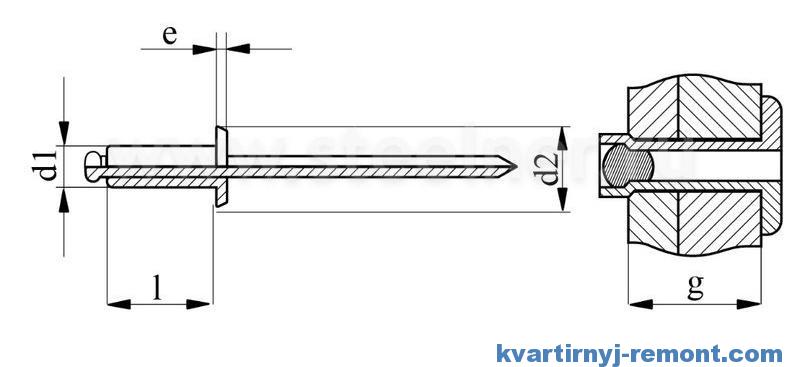

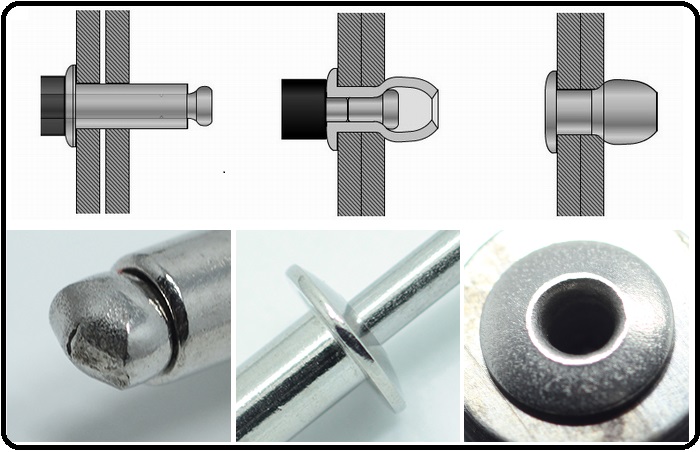

Exhaust

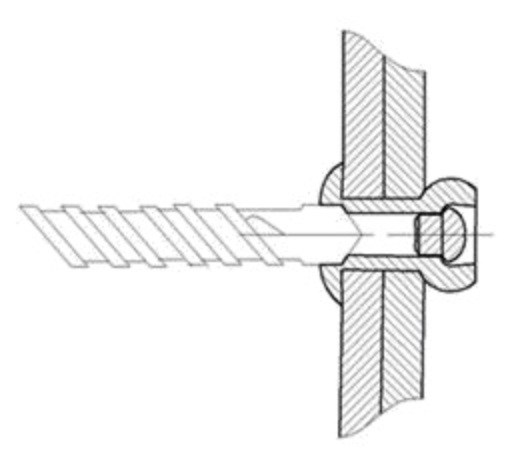

A fastener that consists of two main parts. The first part is a hollow cylinder (rivet body) with through holes on both sides, and a collar (rivet head) on one side.

The body of the rivet is made of metal that is easily deformable. The cylinder diameter is the size of the fastening material. The second part is the rod (rivet core), twice as long as the rivet body itself. Made from high strength steel. The core passes through the entire body of the rivet and has a seal at one end, which is called the head of the shank. The diameter of the rod head is slightly larger than the diameter of the rivet body. In appearance, the rivet shank resembles a nail.

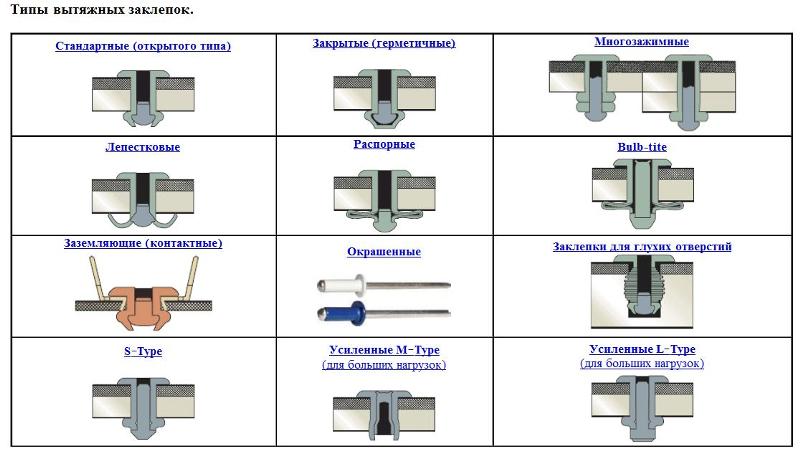

Blind rivet fasteners, depending on their purpose, are of the following types:

- Secret - the junction has a flat surface;

- Regular with collar - standard and most commonly used;

- Conventional ones with a large shoulder are used when joining two materials of different softness.

- The increased collar allows a more even distribution of the pressing force on the joint surface and does not cause deformation of the material;

- Hermetically sealed rivets with a gas-tight body. The name speaks for itself - used for airtight and waterproof connections.

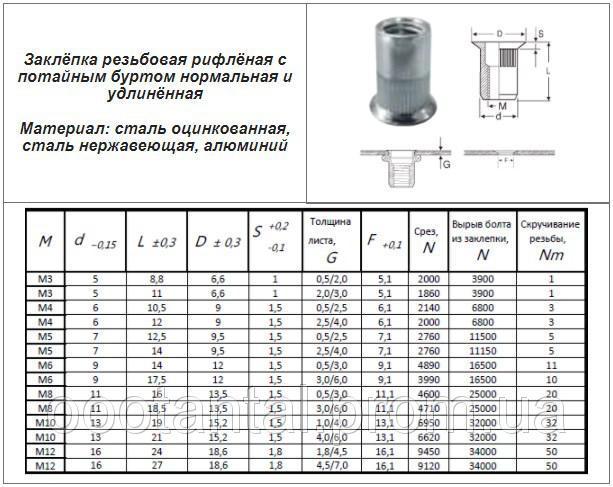

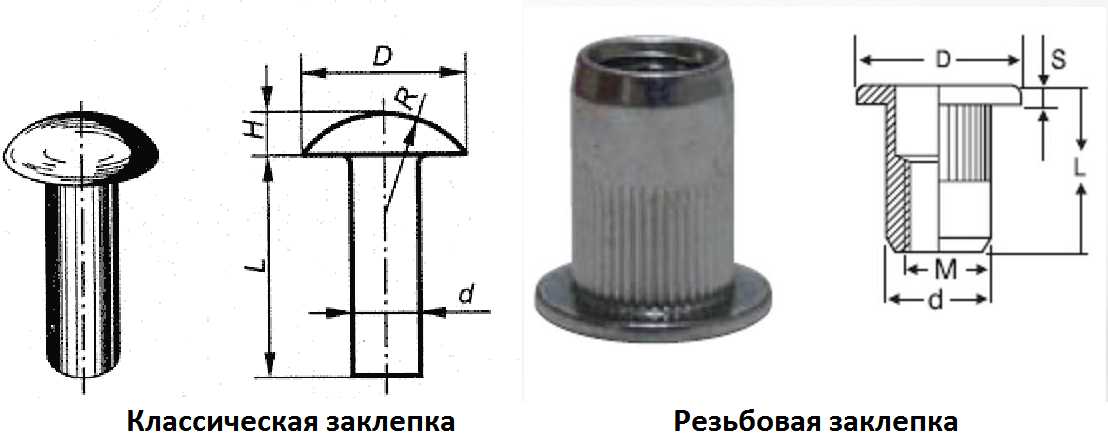

Threaded

However, like the exhaust, it consists of a hollow cylinder made of soft metal. There is a metric thread inside the body. Some species have a grooved surface on the outside and on the shoulder. According to the shape of the body, rivet fasteners are divided into: round, hexagonal, grooved.

The threaded rivet connects very thin materials where the pull fastening material will not provide a strong connection and vibration resistance. This type of riveting is also used in places that are hard to connect to - ventilation and air conditioning systems, medical furniture, car parts and racks.

The body of pull-out and threaded rivets is made of soft metals - copper, aluminum, aluminum-silicon alloy. The rods of the pull-out fastening material are made only of steel. The rivets are coated with zinc as corrosion protection. If the parts are supposed to be used in an aggressive environment, then the rivets are made of stainless steel.

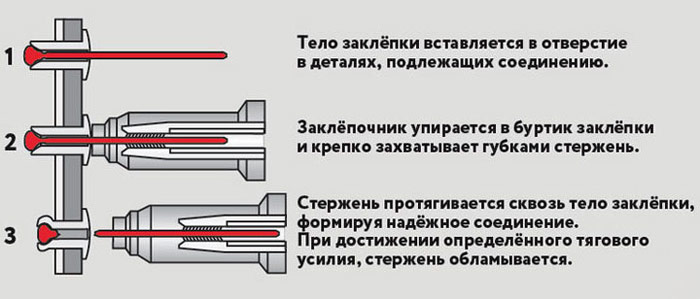

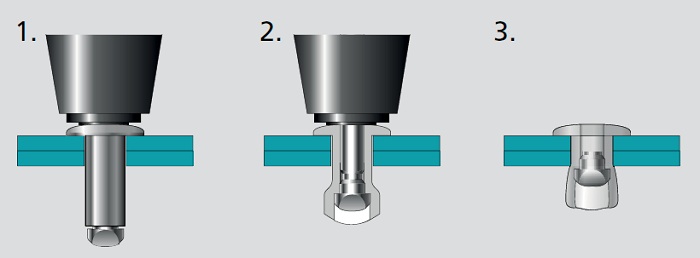

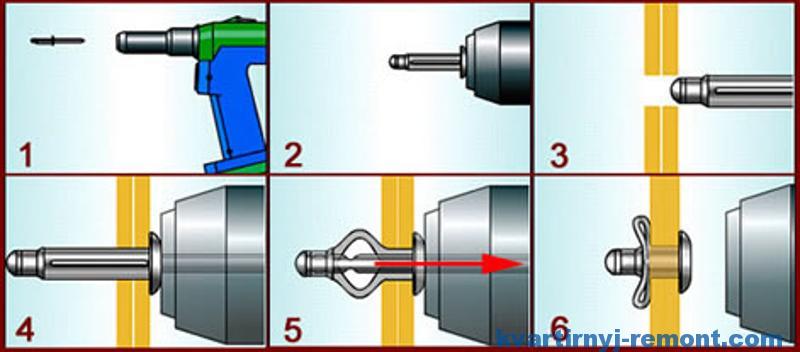

Principle of operation

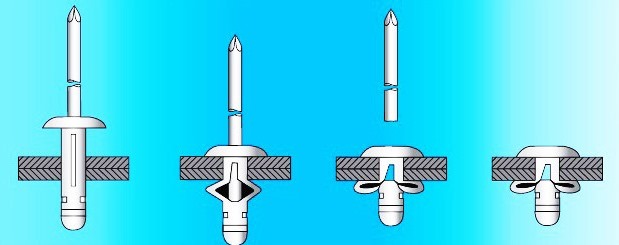

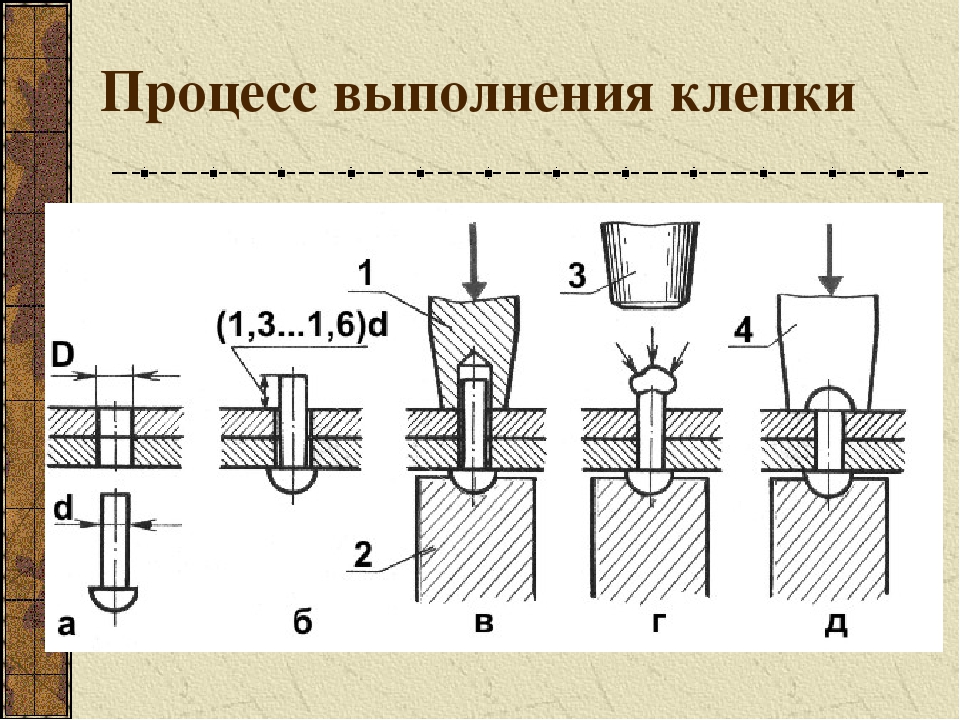

The riveting process is very simple. It is necessary to drill through holes in the materials to be fastened. About one tenth of a millimeter larger than the diameter of the rivet being used. The rivet mechanism grips the rivet shank (wire) up to the working part, after which the pulling mechanism is applied, which, through the wire, pulls the rivet head to the base and breaks the wire (when the rivet joint is ready).

2 Application Methods - How to connect 2 plates?

Before using rivets, you need to know how to rivet certain parts correctly. There are many connection methods, but they are usually divided into 3 types. Strong fasteners are used exclusively where certain loads are present. Sealed, as the name implies, are needed in order to ensure tightness at the joints of sheets or any parts. Finally, the permanently sealed ones perform both functions. It should be noted that for the second type, that is, for sealed rivets, the insert heads are made reinforced.

Blind rivets

Blind rivets

The most common method of connection is overlap, while it is applied not only to sheet metal, but also to parts of complex shape. This option is also called single cut. Under the influence of multidirectional loads, for example, when stretching, such a seam can easily deform. The butt joint is more durable, using one or two (on both sides of the seam) overlays, but this option, also called multi-cut, greatly heavier the structure and leads to a greater consumption of material. Installation of rivets for fasteners can be chain or staggered, the second is more reliable, but very laborious.

Problems that may arise with the rivet

After the extraction part is removed with the tool, it should fall out through the hole. However, after some time of constant use, you may find that the exhaust part will get stuck inside the tool.

If blocking occurs, it is most likely that the jaws inside the instrument are misaligned. You will have to completely disassemble the tool and set the jaws in the correct position. After this procedure, the performance of the equipment will be fully restored.

In the video, the home craftsman clearly demonstrates how to quickly and easily fix the problem with the "biting" of the rivet's drawing part:

We all know what a great thing threaded rivets are.

In some cases, there is no alternative to them. Until a certain time, I somehow managed without them. But one fine day one wonderful car came to me, on which it was necessary to install window protection. Here's one:

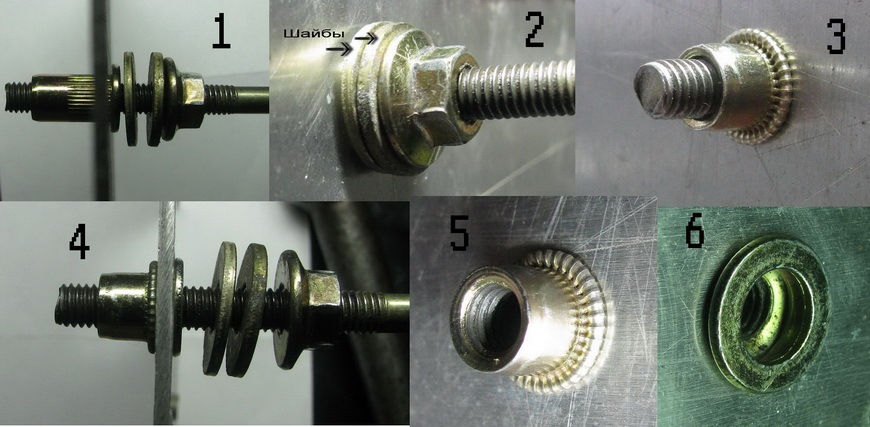

Then I began to work on collective farms, and in the end it turned out, although not presentable in appearance, it was adaptable, but very functional, and with its help I put more than a dozen rivets. The base is an M6 bolt, strength 8.8

This is what it looks like assembled, with rivets installed

Main parts: Bolt M6. A piece of M12 bolt. More precisely, there was no bolt, studs. A nut is welded on one side, turning it into a bolt. The hairpin is drilled through D = 6.5mm. Then comes the nut from the UAZ stepladder. Strong. Further - the thrust bearing, the dimensions are not critical. Further - a washer with a fitting from the brake pipe. Also not important. What was, then he put it.

I think the principle of operation is clear. We drill a hole, under the M6 riveting seems to be 9mm. We insert the adapt. We hold nut 1 with one wrench, while unscrewing nut 2 with the second wrench.

As the effort has increased, it means the riveting is over. We twist everything back until loosening, unscrew the M6 bolt, and put the next one.

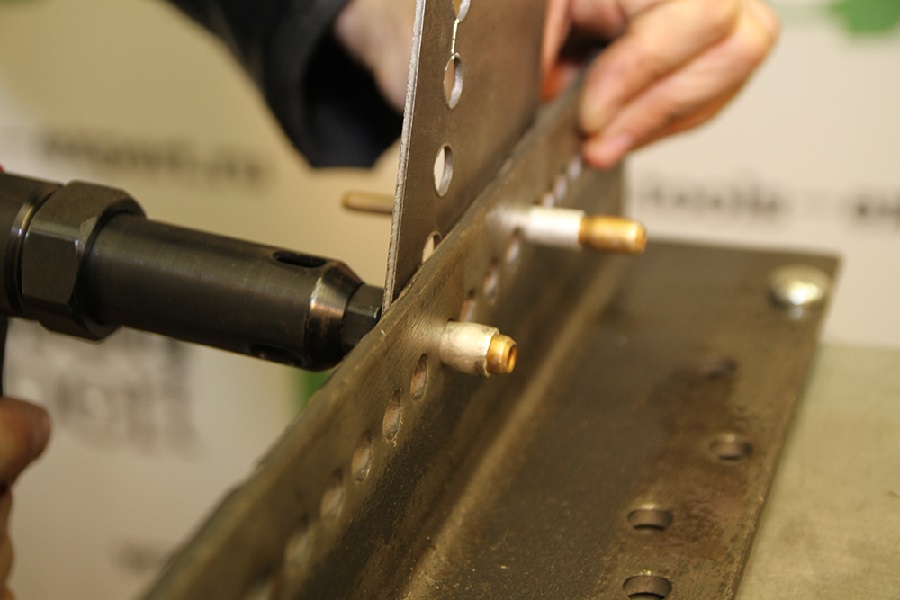

A practical and easy-to-use semi-automatic manual riveter for blind rivets, if desired, you can do it yourself. Moreover, most of the components for it can be found without any problems in the workshop or in the garage.

A distinctive feature of this design is that it does not have a power lever, as on factory models - here a screwdriver acts as a drive. An electric drill is also suitable.

To make a homemade riveter, you will need a work bushing with collet cams, a taper bushing and a spring, which can be borrowed from an old rivet gun. You will also need a head where the rivet shank is inserted.

How to assemble an antennae button for clothes?

In much the same way as a denim button, a button is installed on a mustache-type clothing. The only difference is that all manipulations need to be carried out only for the upper part of the button.

The lower part of the part is much easier to assemble:

- To install it, you can buy a special tool from the store with a recess inside.

- If you do not have such a tool, you can use a metal plate with a hole similar to the size of the "bump". Insert the bottom of the button into the hole of the metal plate, and “slam” the leg with a hammer from the back of the garment.

Advice:

If for some reason the buttons are not installed correctly, then remove them and put new ones. Do not use damaged buttons, as they will not hold securely, they need to be replaced.

To install the button on clothes at home, you can also use the tools at hand: a Phillips screwdriver, a bolt, a thick nail, a dowel

To expand the cylindrical part of the button, you can use any cone-shaped device, and then, using a bolt (cylindrical rod) of a suitable diameter, flare (attach) the button rod completely.

Install the button on a smooth wooden surface, but be very careful not to break the button or destroy it.

A piece of wood can be used to install the bottom of the button if there is no suitable metal object with the desired hole. Make a recess in a wooden block with a drill (the diameter and depth should correspond to the “male” part)

Collect the bottom of the button and place a block on top. Tap the part with a hammer.

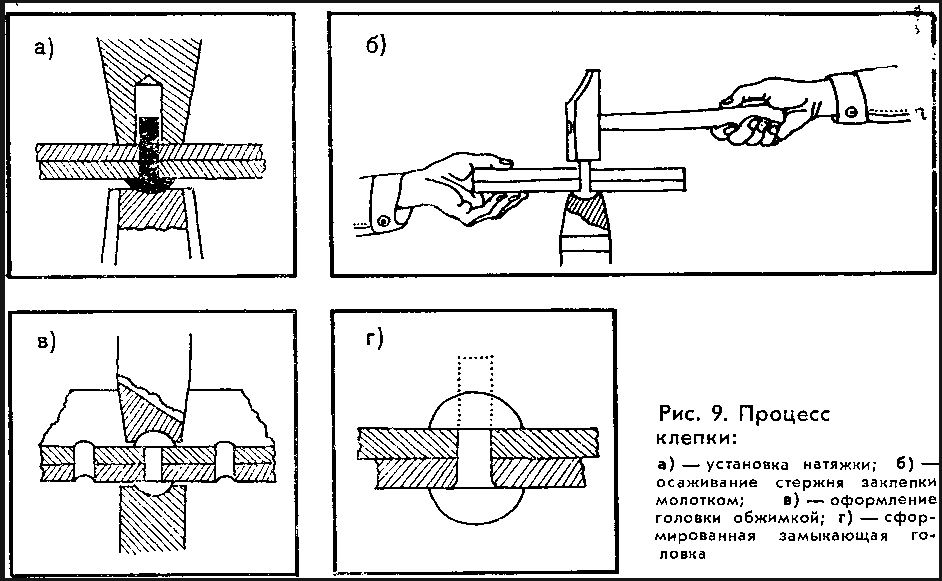

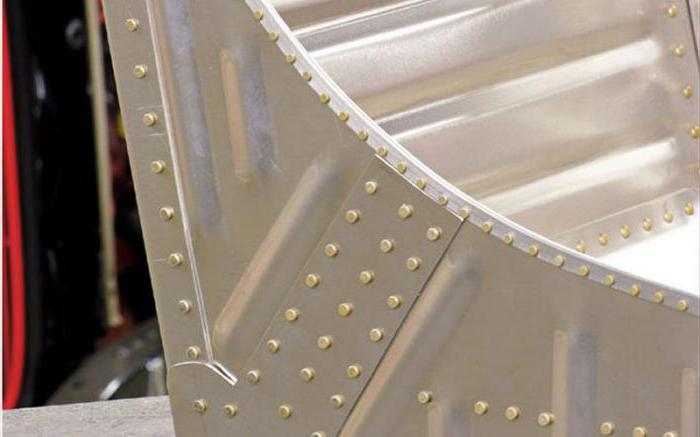

What is riveting

The mechanical connection of parts using a series of rivets is called a riveting, and the connection itself is a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are connected. Not only metals are riveted, thus they connect parts in clothes, accessories, etc.But there it is more of a finish than a loaded connection. So further we will talk about riveting in construction or home improvement. In principle, instead of riveting, you can use a screw connection, but bolts and nuts are more expensive, and their installation takes more time.

This is what a riveted joint looks like

If we talk about installing fences made of profiled sheet, rivets are more reliable, since they can only be removed by reaming the fasteners. When installing screws or self-tapping screws, they can be unscrewed and carried away both metal and hardware. In some cases, riveting is more convenient when installing a roof from corrugated board or metal. On the roof, the installation of screw connections is problematic and time-consuming. And with rivets, and with a good tool, you can do it in an hour or even less.

The most common use in the personal household

How are parts connected with rivets? The rivet is inserted into the prepared through hole. It has a head that rests against the material and the rod. During the riveting process, the end of the rod is flattened, changing its shape under the influence of force. Therefore, plastic metals are used for these hardware.

What do you need?

In order to manufacture the body of the future rivet, various materials are required. For the production of rods, only hard metal is used - steel.

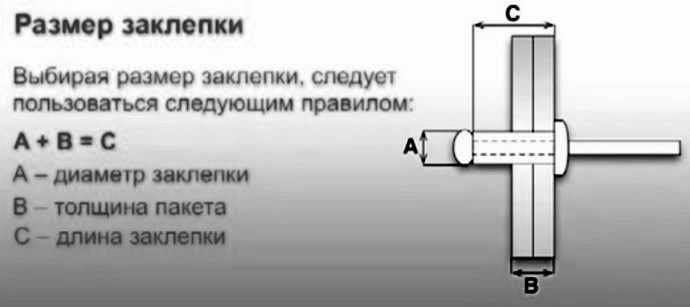

When choosing rivets, attention is usually paid to their characteristics. Should be interested in strength, and how one part affects another

For durability, it is recommended to select rivets in such a way that their type and material match each other.

Experts additionally advise to take a closer look at the rivet length. If the part turns out to be less than the thickness of the elements to be connected, then there may simply not be enough material to create the closing head.

There are a variety of rivets on the market. Each of them has its own advantages.

- Classic ones are usually used for most types of fastening.

- With the help of threaded connections, reliable connections are created. This is especially true for parts that have thin walls. Usually such a part is characterized by a countersunk or wide flange. The thread is located on the inside. On the outside there is a corrugation, it affects the increase in the strength of the fit.

- Piston ones are distinguished by the fact that at the end of the rivet there is a stamped conical recess. For the manufacture of the part itself, it is recommended to use exclusively soft metals. When the elements are connected, two hats are obtained.

- The rod contains a solid rod. It helps to withstand strong physical activity.

- If traction is used, then when riveting, they will not need to be held.

- Tubular ones have a kind of cavity inside the part. This type is most often used at low loads.

The riveter is a special tool, in another way it is called "pincers". It works by analogy with a pistol and is necessary in order to connect structural elements, as well as individual parts. The main condition is that the thickness of the product should not exceed 10 mm.

The power gun helps to fix the parts from their inside. The hand riveter has 2 parts. The first is the spring mechanism. Its main task boils down to the fact that it helps to pull such a rivet inside. The second is a leverage system that requires additional effort to apply.

If a rivet is to be secured, pulling force must be applied. The most suitable option is a pull-out type of a hand riveter. The rivet shank is pulled in by applying force against the lever. The head of the rod seems to expand. In order for the parts to be firmly fixed, the elements from the outside must be flattened.

The work of the threaded riveter is practically the same.It is necessary to remember the main rule - the ball is drawn into the working part, after which such a part is twisted properly. No extra effort is needed here. It is worth resorting to twisting the handle only if there is a need to fix a part that is small in its thickness.

Additionally, nozzles can be found in specialized stores complete with a gun. They mainly differ in diameter and tail length.

Peculiarities

Riveting is one of the options for non-collapsible assembly of parts. The advantage of this method is its low cost. Consumable material - rivets - are relatively inexpensive. You can buy them at any store that sells fasteners.

Modern materials are divided into two main types: threaded and exhaust. Both are essentially hollow tubes with a cap at one end. In the first case, a thread is cut inside the tube, and in the second, a stem with a thickening at the end is inserted into it.

Usually, to install a large number of standard rivets, a special tool is required - a riveter. It can be electric, pneumatic or manual. The use of this equipment allows to reduce the physical efforts associated with crushing a metal rivet. These tools are not cheap at all, this is what becomes the main reason for refusing to use rivets in everyday life or for small repairs. Indeed, the purchase of an expensive tool for the sake of one or two rivets is hardly justified.

Below we will consider how to install a rivet without special equipment.

What do you need?

So let's get started!

Given: parts that need to be connected, but at the same time cannot be welded, for example, so as not to spoil the painting.

Objective: Install no more than 4 rivets.

The task: to rivet without a riveter, since it is not available, but it is quite expensive, and the purchase for the sake of 4 rivets is completely unjustified.

Given: threaded rivets and ... what is in the garage, plus the notorious ingenuity, without which in this case there is nothing at all.

Having rummaged in the deposits of all iron junk accumulated over the centuries, you need to find a long bolt corresponding to diameter and pitch existing rivets, or, conversely, purchase rivets of the corresponding parameters, if such a bolt is already available.

Next, you need to build the simplest riveter, with which you can roll the rivet. To do this, you should select:

- a steel sleeve, for example, made of a nut of slightly larger diameter than the already mentioned bolt;

- at least 2 washers with a hole diameter corresponding to the diameter of the bolt;

- small bearing (some craftsmen consider the bearing to be superfluous);

- a nut that matches the size of the thread to the already indicated bolt.

A homemade riveter is mounted as follows:

- screw the nut onto the bolt;

- install the washer;

- install the bearing;

- put the puck back on;

- put on a sleeve that can be covered with another washer.

To make a homemade rivet installation device, you will need the following materials and tools:

- steel pipe with a diameter of 5 cm;

- long bolt with a diameter of 8 mm;

- a nut for the previously indicated bolt;

- welding machine;

- grinder, drilling machine, drills.

In addition to the need to install a threaded or blind rivet fastening metal or other parts and structural elements, there may be a need to install the rivet as an accessory on clothes or shoes. Tools for such an operation do not have to be made from scrap materials, they can come in handy:

- screwdrivers: Phillips and slotted;

- pliers;

- hammer;

- a bolt or piece of steel bar with a flat-grinded end;

- a piece of steel tube, similar in diameter to a rivet.

The various accessories used for clothing are made of relatively soft metal and have a small thickness; it does not require much effort to rivet it.

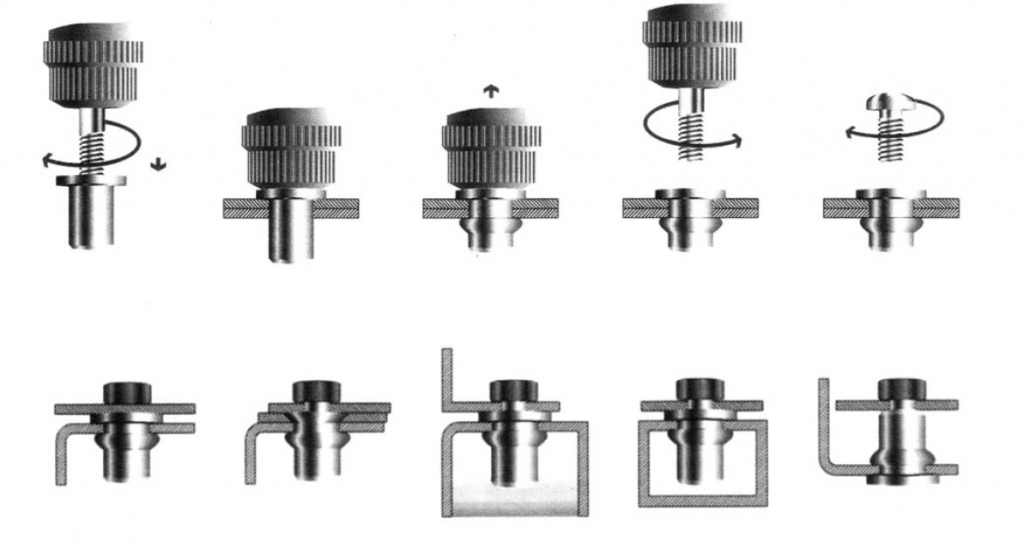

General procedure for installing threaded rivets

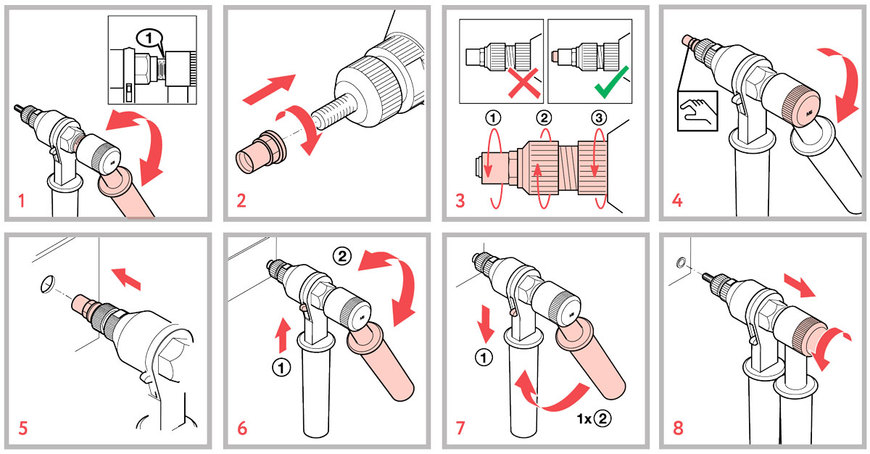

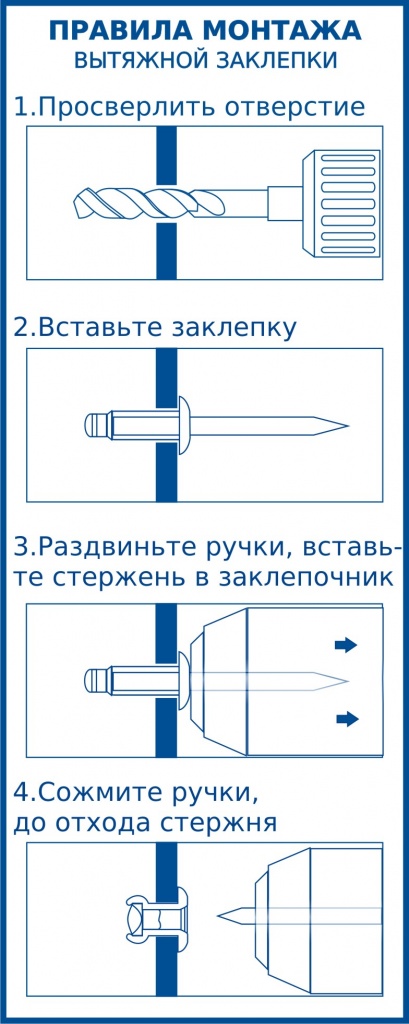

Before riveting the threaded rivet, preparatory work is performed. It is necessary to select a drill, the diameter of which should be 0.1 mm larger than the outer diameter of the rivet, which will make it easy to install it in the hole. After that, a hole is drilled in the place where the fasteners are installed. In addition to threaded rivets of round cross-section, similar hardware with a hexagon-shaped cross section is also produced. This shape makes it possible to exclude the possibility of turning the part during installation. To make holes for such rivets, special hexagonal punches are used. However, they are only suitable for working with sheet metal, which somewhat limits the scope of application of hardware of this shape. Manufacturers recommend using a special tool for mounting fasteners - a riveter. Therefore, the installer must have the appropriate skills and understand how to install the threaded rivet with the rivet driver. Such tools can be mechanical (hand), electrical and pneumatic. The mechanical riveter design consists of a working part and two handles. The working part contains a movable screw mechanism, at the end of which there is a thread. To make a threaded rivet with a rivet, perform the following sequence of actions:

- The rivet is screwed onto the thread of the screw mechanism of the tool.

- The working part of the riveter with the rivet installed is placed in a prepared hole in the metal base.

- The handles of the tool are compressed. This creates a force due to which a bead is formed in the inner part of the rivet. As a result, the fastener is tightly fixed with the formation of a reliable and strong connection with the mounting hole for the screw or bolt.

- The working part is removed from the rivet by unscrewing it.

The advantage of the mechanical riveter is its simple and reliable design, as well as its low price. However, to install threaded rivets with it, it is necessary to apply a significant amount of force. If it is necessary to carry out a large amount of installation work, it is advisable to use riveters with an electric or pneumatic drive. These are professional tools that ensure the installation of threaded rivets by tightening the set screw. This creates a force sufficient to form a shoulder, after which the screw is unscrewed from the hole. The tools are simple and easy to use, so there is no problem in understanding how to use the rivet rivet.

Installation features

To install a rivet, you need to follow a simple instruction. Let's take a closer look at the steps.

- Parts must have pre-drilled holes. They are connected to each other, the rivet body in the form of a cylinder is placed there.

- The rod is located throughout the body, it must be grasped with sponges (sometimes a riveting head at a riveting tool is suitable for this purpose). It should be borne in mind that the seizure takes place near the base of the cylinder head.

- Next, you need to make a little effort and pull the rod through the rivet body. The process is accompanied by the expansion of the cap or head. By changing the end of the cylinder, it is possible to form the opposite wide part of the rivet (it is located on the surface of the previously connected parts).

- After we have managed to install the parts, the remnants of the extended rod should be broken off exactly at the moment when the riveter's force is at its limit. It is advisable to immediately check if the connection is strong enough.

After the action is completed, on one side of the connection it will be possible to find the head from the rivet body, and on the other side there will be a flattened end from the cylinder, which should resemble petals in appearance.

How to rivet?

Before using the manual riveter, it is recommended that you understand the fastener arrangement. It is for this method of fastening that rivets are intended.

The cylinder has a hole, it runs along the entire body, while also capturing the head area. Externally, the metal rod bears resemblance to a nail that has a rounded head. To insert into a cylindrical hole, we need a retainer. Then the head is retracted until it stops.

The rivet helps to fasten. It consists of a metal rod and a cylindrical tube - these are 2 main elements. There is always a head at the end of the tube.

Threaded rivets are relevant for the pull-out hand riveter

It is important to take into account that the rod has its own thread. It scrolls exactly to the point that the cylinder is inserted.

Next, we will figure out step by step how to properly fix aluminum and tubular parts with our own hands and carry out their installation. In order to attach rivets at home, a special tool is required. He is called a riveter.

There are 2 types of riveters - amateur and professional. Each of the tools has interchangeable heads. They are needed when working with elements of different sizes that are used during fastening. The main difference is the price and the force required to push.

To rivet parts correctly, you need to adhere to the following algorithm:

- we apply markings to the parts that we plan to connect;

- we drill the necessary holes with a drill;

- then you need to insert a rivet;

- the riveter's handles move apart, a rod is inserted into it;

- then the handles must be squeezed until the rod breaks off;

- we loosen the handles and check if the rod has completely entered.

Almost any metal can be used to make a fume product. It is necessary to approach the choice of material in such a way that there is no subsequent corrosion process.

When creating a rod, it is customary to use a steel base. It is characterized by high strength. Various options are allowed in the size and length of the cylinder, it all depends on what is the ultimate purpose of such a product. Before making a purchase, it is recommended to think over exactly what characteristics will be required.

How to install a rivet, see below.

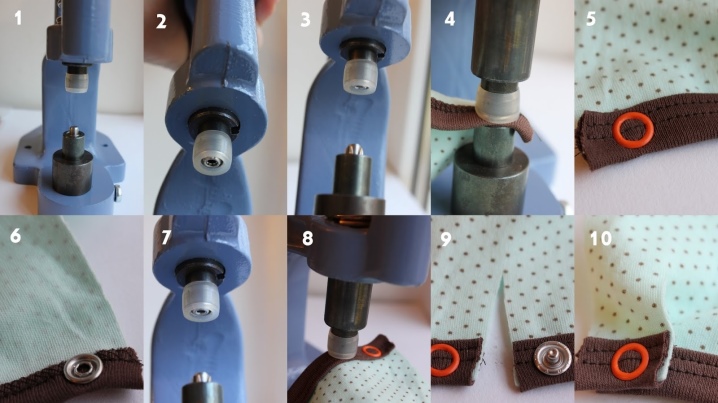

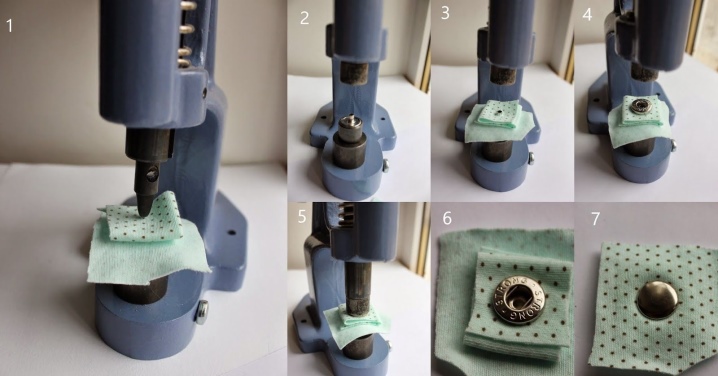

How to install a button on clothes at home?

Of course, if you have the opportunity, then entrust the installation of accessories to a master who has a special press, various devices, a set of tools, and most importantly - experience, thanks to which such work will not take him much time. If you do not have such an opportunity, or you want to find out for yourself how to install a button on clothes, then prepare the following tools:

- Awl.

- Hammer.

- Forceps.

- Punch. This tool will have to be purchased. It is necessary so that the hole turns out to be even, and the edges of the fabric do not crumble.

Advice:

- Do not cut a hole under the block with scissors, as over time the button or block will surely "fall out" from it. The hole for the button should be minimal, it is advisable to even slightly pull the fabric over the leg, since the tighter the fabric is pressed against the part, the more securely it will be fixed.

- Punch a hole in leather or fabric on a wooden (not metal) anvil to avoid damaging the punch point. The tree should be very dense (not loose). An area with a knot will do. Other dense materials can also be used as anvils that will not damage the punch.

- Areas on knitted and loose materials where holes will be punched can be glued with an adhesive cloth so that the edges of the hole do not crumble. You can also process the edges of the hole with silicone glue.

Rivet installation process

It is necessary to work with the tools carefully, slowly and without making any sudden movements. Otherwise, the fabric, accessories or tools may be damaged.

The most common type of fittings installation is the installation of a block on clothing. In workshops and ateliers, forceps are used for this procedure. However, such a tool should be bought of good quality so that the handles do not bend and the “cheeks” do not move.

Do not despair if you do not have special forceps at hand, you can do without them at home. Use the following step-by-step instructions:

- Punch a hole of the required diameter in the textile or leather.

- Pass the leg-block, put a ring on it.

- Place the patch of clothing with the sequin on the anvil.

- Use a punch to split the leg of the block into petals. If all steps are done correctly, then the petals should bend themselves on the block ring.

- Walk over the block with a little hammer to secure it to the fabric.

When working, lay the ring with the convex side away from you so that it repeats the convex shape of the edge of the block.

How to attach buttons to clothes?

The most difficult process is installing rivets on the rough fabric, from which outerwear is often made. Difficulties also accompany the installation of rivets on jeans. But if you use a good tool and follow all the technological steps, then you will probably be able to fix the button on the clothes.

You will need the same tool as when installing the block. Sometimes, for this type of buttons, special punches are included in the kit, but they are ineffective to use. It is much more convenient to use a punch that splits the leg into petals.

To make a rivet on a jacket or other outer garment, proceed as follows:

- Unfold the leg of the four-part button at the top and bottom.

- Follow the standard riveting process (described above).

Removing rivets from clothing

This is done in two ways. One - with the help of side cutters, the other - with a knife and a pair of pliers. The choice of methods depends on whether your rivet is alpha (inner) or beta (outer). The corners and edges of the stitching are mostly riveted with alpha varieties, otherwise known as eyelets. Beta is used in cases of buttons that fasten clothes. One part there is alpha, and beta is riveted on it. Despite the fact that such rivets hold the material perfectly, they are afraid of mechanical stress.

How to rivet alpha rivets with a knife and two pliers?

- Carefully so as not to damage the fabric, insert a sharp knife blade under the edge of the wide part of the rivet on one side and bend it back so that you can grab the edge with pliers.

- Do the same for the opposite side of the rivet. Insert the knife blade and peel back the edge.

- Grasp the edges of some of the pliers on the outer folded part of the rivet, and with the other on the edge of the seamy folded part.

- Pull in opposite directions and the inside will pop out from the outside.

It is done.

How to rivet a beta rivet on your clothes? It's even easier here. The procedure is as follows:

- Take the garment with the flared (folded) part of the rivet protruding from the inside of the pressure washer facing you.

- Take side cutters (preferably with those on the pliers), set them under the very bottom of the extended part and squeeze.

- Twist and squeeze again.

- At some point, the top element will jump off the bottom one by itself. Or, when there is enough space between it and the lower element, the inner part that goes into the pressure washer can simply be snipped without harm to the material.

It is done.

Peculiarities

Rivets are fasteners in the form of a sleeve or a rod with a embedded head at one end and a head that closes in the process of riveting at the other. Threaded rivets differ from blind rivets by the presence of a thread. That is, they are hexagonal or cylindrical bushings with a support flange in the upper part and a thread in the lower one. The upper part is made in the form of a thin-walled tube without threads and often has a longitudinal outer notch. During the installation process, it is deformed. The vertical notch on the top ensures uniform deformation and prevents material tearing.

The advantages of threaded rivets include:

- ease of use;

- strong fastening of elements made of fragile and thin materials such as sheet metal without deformation;

- the possibility of one-sided fixation in the event that the total thickness of the parts to be joined exceeds the length of the fastening element without loss of strength;

- maintaining the strength of the connection over time;

- mechanical and chemical non-aggressiveness;

- maintaining the integrity of the surface and paintwork;

- the ability to connect elements from different materials;

- lack of mechanical stress in the structure;

- possibility of dismantling and re-installation.

Despite the fact that at present, in most cases, instead of rivets, welded or glued joints are used, the fasteners under consideration have a number of advantages in comparison with them, which determine their indispensability in some nodes. First, threaded rivets are thermally stable. Secondly, they do not cause structural changes in elements during installation, unlike welding, which is especially important when joining parts made of different materials, the behavior of which can be unpredictable. Thirdly, threaded rivets ensure movement retention.

However, these fasteners have several disadvantages:

- installation is complicated by the need for pre-making holes;

- most threaded rivets do not seal the seams;

- installation is associated with high noise levels.