Causes of occurrence

Diagram of the causes of cracks in concrete.

Of course, a crack cannot just appear from scratch; there is a reason for its formation, which will need to be clarified first of all before eliminating it. After all, patching up the crack, as we found out earlier, is not so difficult. But if the cause is not eliminated, it will appear again and again. Before you build a wall of foam blocks, you need to know the reasons why the shortcomings of this material may come to light.

A crack can appear due to displacement of the soil or foundation, with temperature changes, due to high humidity or improper mixing technology. It turns out that it is possible to erect walls from foam blocks only on a reliable foundation, without fail using reinforcement in the walls, and so on. That is, construction using this material must be carried out in strict observance of all the rules of the technology for performing construction and masonry.

Of course, if the wall is ready and it has cracked, it is no longer possible to disassemble it. Therefore, you have to resort to various methods of embedding. Above, we have already considered one way to seal a crack in the wall. Obviously, this is not the only way that you can use it, there are other options. Here, for example, is another option for how you can repair a crack in a wall made of aerated concrete:

- The plane on which the crack has formed must be cleaned of the destroyed layer of building material.

- After cleaning, dust is washed with water, you can also use a dry dedusting method using a hairdryer or vacuum cleaner.

- When the wall is clean and free of dust, a primer is applied to the surface.

- Now you can start sealing, choosing the right material depending on the size. You can fill up a small crack using absolutely any solution. Large cracks must be repaired using an adhesive. A large one is closed up with a mixture of glue or cement with the addition of crushed stone. For the convenience of work, you need to use a spatula and grout.

- The selected solution is used to fill a seam or crack and stabilize for a while with a sheet of plywood, which can be fixed using self-tapping screws.

- When not cracks have appeared, but a large hole has formed, concrete reinforcement with nails or an iron mesh will be required. In this case, the aerated concrete must be cleaned, the resulting hole must be metallized with nails, and a metal mesh must be put on them. And only after that, the cavity is filled with a solution of glue and pieces of aerated concrete.

In the case of the chosen method of restoration and repair, the following materials and tools will be needed:

- Water (or aqueous solution);

- Vacuum cleaner (or hair dryer);

- Glue;

- Cement;

- Crushed stone;

- Grout;

- Putty knife;

- Plywood sheets;

- Self-tapping screws;

- Nails;

- Iron mesh.

All these materials must be prepared in advance, even before carrying out repair work.

From all of the above, we can conclude that cracks arise due to non-compliance with the technology of laying the wall, with the wrong type of foundation, with incorrect consideration of the ratio of the advantages and disadvantages of this material.

If a person is not confident in his abilities, then it is better to entrust the execution of this work to masters or specialists who can both perform the work and independently eliminate the shortcomings obtained in the course of the work.

What to do if a crack in your home is widening

This situation means only one thing - it is urgent to take drastic measures to eliminate such a problem.If you ignore all the recommendations of specialists, limit yourself only to the above repair options, then the result will be the collapse of the whole house. But a beginner can also cope with the work of eliminating such complex active cracks - the main thing is to strictly adhere to the following instructions:

- All the plaster from the wall at the location of the crack is knocked off - be sure to maintain a distance of 50 cm on each side of the crack.

- The crack is cleaned of mortar and dirt - this can be done with a metal spatula.

- The cleaned crack is filled with polyurethane foam.

- Fastening metal plates that will tighten the crack, preventing it from spreading further. In this case, the following points must be taken into account:

- the plate must be chosen from thick, high-quality metal;

- to obtain an optimal result, you will need to tighten the crack with at least 3 plates, and if the crack is long, then you may need both 4 and 5 metal plates;

- plates are attached with self-tapping screws, but using dowels.

After applying the fastening metal plates, you can continue to work according to the usual algorithm - priming / fixing the reinforcing mesh / applying new plaster.

But keep in mind - such measures serve as a temporary measure, since without a specific education it will not be possible to determine the cause of the appearance of active cracks. Most often, in the future, it will be necessary to carry out correction work on the foundation - it is either strengthened / strengthened, or the walls / roof of the house are raised and the base is completely replaced.

How much does a screed cost?

Every year, new types of construction work appear. For example,…

Armature

Reinforcement is a collection of interconnected particles and elements, which, together with a material such as concrete, in reinforced concrete structures are perceived as beams that stretch stress. Reinforcement bars are also used to reinforce concrete in columns.

Reinforcement elements are divided into rigid (angles, channels, rolled I-beams) and flexible (rods of periodic and smooth profiles, as well as knitted or welded frames and meshes).

Consider the classification of types of reinforcement.

Depending on the purpose, fittings are:

- working (the section is assigned by calculation, the forces in the particles of the main load are perceived);

- structural (distribution fittings, perceiving shrinkage / expansion, exposure temperature);

- assembly (installed to combine the structural and working parts);

- anchor (embedded parts).

Depending on the orientation in the structure:

- transverse reinforcement, which actively prevents the formation of cracks from the arising stresses near the supports and connects concrete to the reinforcement from the compressed zone in the tension zone;

- longitudinal reinforcement, which completely and completely perceives tensile stresses, preventing the formation of cracks in the tensioned zones of the structure.

Depending on the conditions of use, the fittings are:

- unstrained;

- strained.

In pre-stressed reinforced concrete structures, prestressed reinforcement is exclusively working.

There are five options for reinforcement and concrete contacts:

- contact with concrete structures by friction;

- connection on shear bonds;

- adhesion (the process of joining when concreting a steel reinforcing element);

- interaction of cement mortar and steel reinforcement at the electrochemical level;

- compression of reinforcement with concrete after shrinkage.

If it so happens that a crack has started along the load-bearing wall or foundation, this is not yet a sentence, it’s just time to apply “global” (radical) measures to strengthen the entire structure. We will talk about the most simple and popular methods of preserving the integrity of a building in this article.

Note.

The article uses conditional terminology.

When purchasing a ready-made house, the new owner in all cases deals with a pig in a poke

And it doesn't matter if it is a new building or a renovated old one. Builders build and repair cottages and private houses in a fantastically short time, which always affects their stability and durability

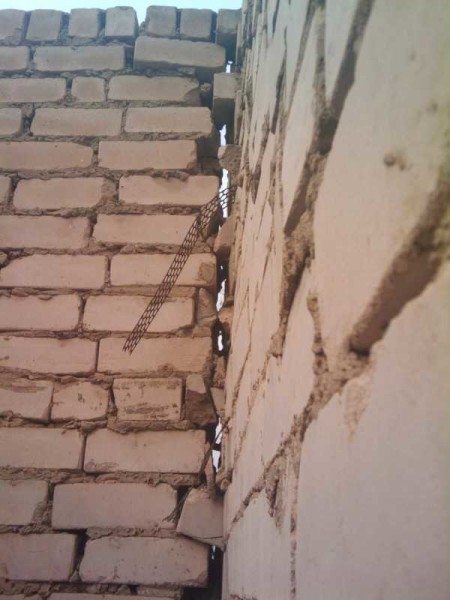

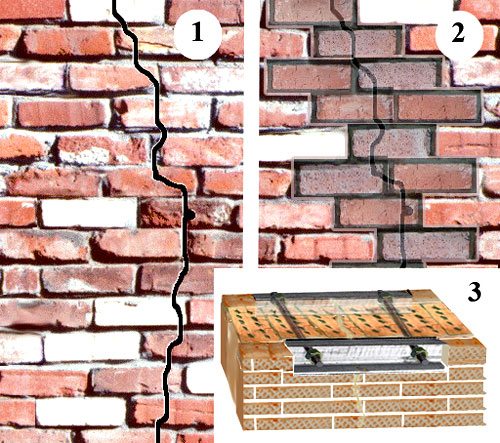

Regardless of the reasons for its appearance, a crack is a frequent and faithful companion of stone buildings and structures. We will talk about the most difficult cases of these unpleasant and dangerous defects - structural cracks, which serve as signals of the appearance of the mobility of the bearing elements. To stop the crack propagation, the movement should be stopped and the elements fixed, and then repaired and "masked".

Note.

A crack in the finish does not always mean the presence of defects in the wall material. Make sure that it is the carrier material that is damaged by removing some of the trim and exposing the defective area for observation.

Let's leave the theory and consider the three most common cases of the appearance of element mobility: collapse, blockage and separation of the extension.

Basic rules for screed houses

Steel corners

Steel corners

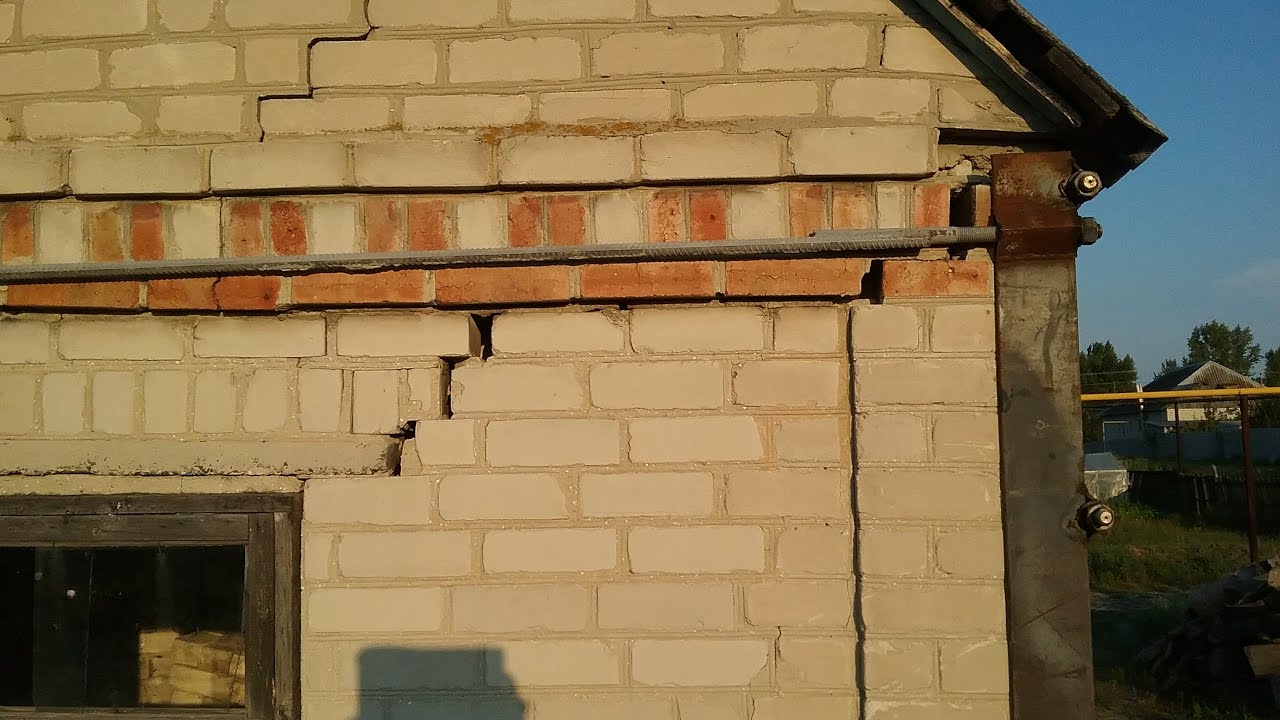

In an already finished building, a screed is necessary to prevent the appearance of new cracks, and also so that damage that has already appeared does not increase. The technology has proven itself to date. To screed a house with dimensions of 6x6 meters and a height of 3 meters, the following materials will be needed:

- Steel corners 10x10 cm - 4 pcs. by 3 m.

- Rods in diameter from 16 mm - 48 m.

- Thick-walled pipe, diameter similar to rods - 1.5 meters long.

- Studs with thread for rods - 16 pcs.

- Nuts and washers - 16 pcs.

Studs with thread

Studs with thread

To pull the house down, you need to install metal corners at the corners of the building. Sections of thick-walled pipes are pre-welded on them. Studs are fixed to the rods, and after that the whole structure is tightened with nuts. For the reliability of the entire structure, some rules should be taken into account:

- After a year of such a screed, you need to check and tighten the nuts. This procedure is recommended to be repeated every summer.

- Before installing the rods, you will need to make the correct miscalculations. This will allow the entrance doors to open normally.

- Sequential tightening of all nuts will allow to avoid distortions of the structure.

- The thicker and wider the metal of the corners, the more reliable the screed of the house from cracks in the walls will turn out. Don't skimp on corners.

- If the house is decorated with various decorations and other decorations, then before installing the structure, you should prepare a place for the corners so that they fit snugly against the wall.

- For self-installation, it is recommended to fix the corners with self-tapping screws directly to the wall. This allows the corners to be locked and the nuts securely tightened.

For clarity, it is worth looking at the house screed from cracks in the walls in the photo. This will allow you to understand the mountings and the structure as a whole:

After completing the work, the house can be refined with finishing materials, for example, siding, but leave access to the nuts to tighten them.

Crack repair

Sealing and elimination of cracks can be done only after the cause has been eliminated and it has stopped expanding - otherwise all work will be done in vain. To determine how to repair the cracks, it is necessary to take into account a number of existing circumstances.

There are several restoration technologies - the use of one or another reconstruction method depends on the type, width, duration of the crack and some other factors.

Normal repair

Cracks in walls of a brick house of small width (up to 5 mm) are sealed with a mortar on a cement or gypsum base (the second option is appropriate only if the work is carried out indoors). (See also the article Brick in the interior: features.)

There is also the possibility of using various types of sealants that are specifically designed for this purpose.

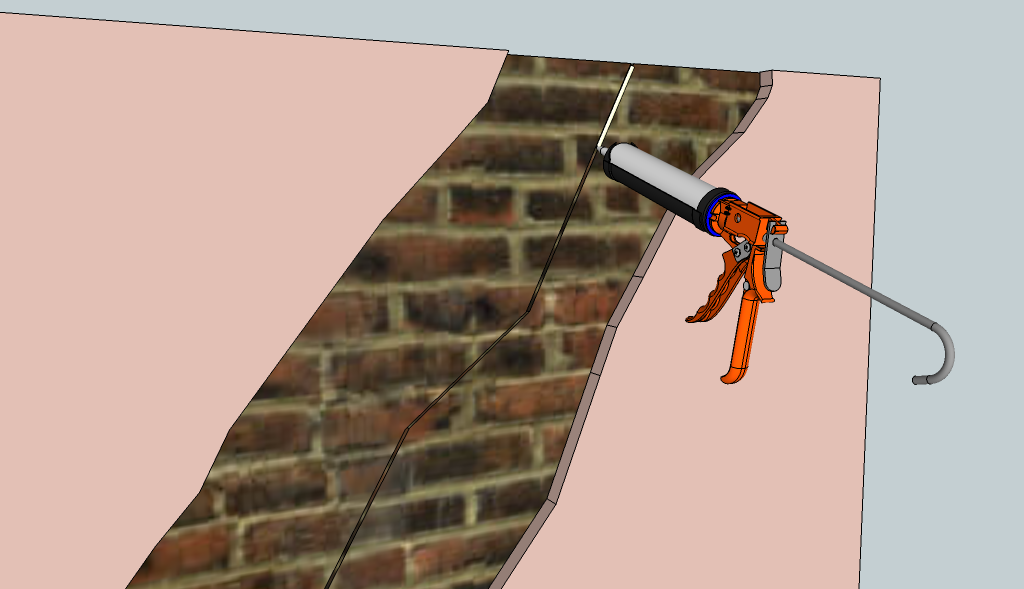

- The crack must be “opened” along its entire length, i.e. embroider its outer part, making it more accessible for applying repair mass. For this purpose, you can use a chisel, by means of which the edges of the crack are knocked down along its entire length;

- The cavity is cleaned of dust, crumbs, sand and other construction debris, then it is abundantly moistened with water and allowed to dry;

Reconstruction area

- The crack is filled with the repair compound - first of all, it is necessary to push the solution as deep as possible and only then the entire cavity should be filled. You should not carry out the embedding “with a slide”, but you will not be able to create a perfectly flat surface that will be on a par with the common plane, since the solution will shrink in any case after moisture loss;

- A crack in the wall of a brick house is most often closed up almost on a par with the general plane, and after shrinkage it is masked by means of finishing materials - putties, etc .;

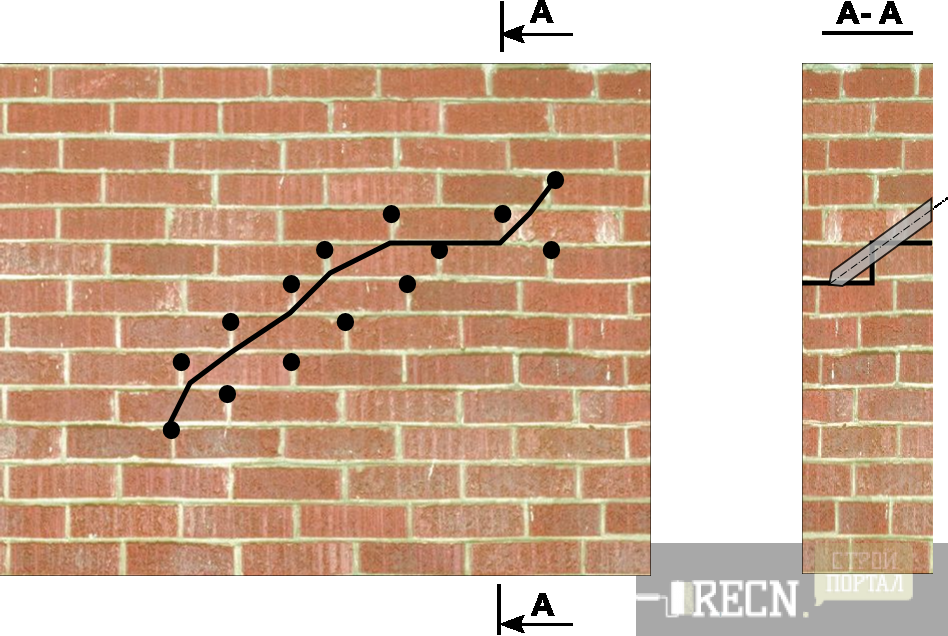

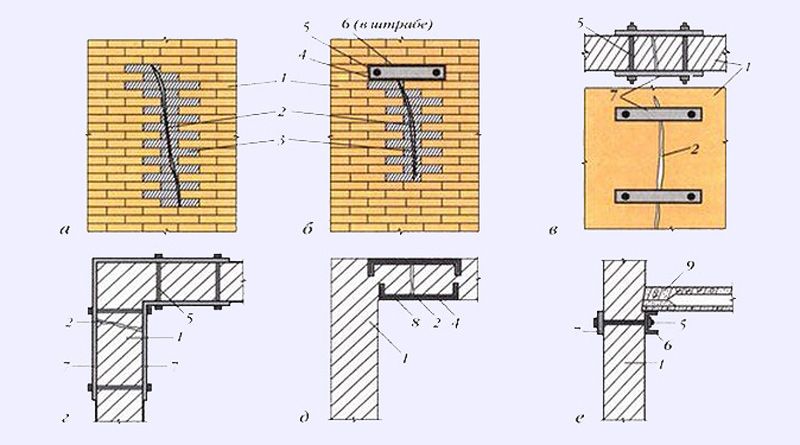

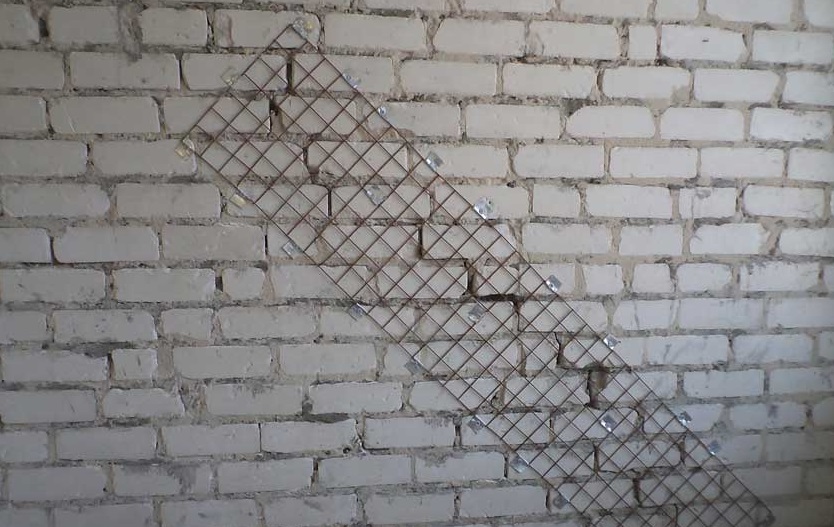

Large cracks, in addition to the usual filling with mortar, also need additional reinforcement by means of metal plates, which should cover the cavity across. They are fastened by means of anchor bolts, which are screwed into pre-drilled holes.

In some cases, if the cracks have a through intersecting structure, it becomes necessary to disassemble a separate section of the wall in order to create interlocking masonry in the area of the crack with additional internal reinforcement in the form of reinforcement. Despite the fact that in this case the cost of reconstruction increases significantly, the use of other methods is ineffective.

Cementation

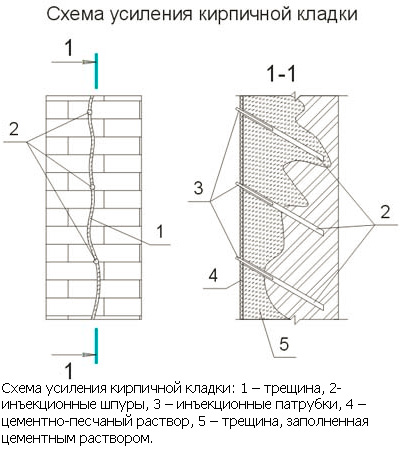

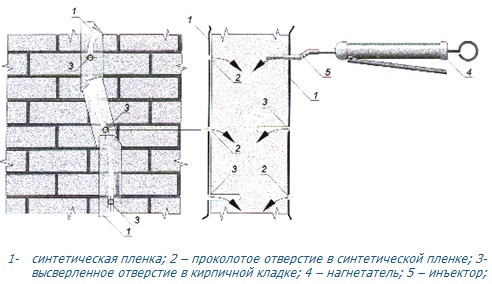

The scheme according to which the injection of brickwork is carried out

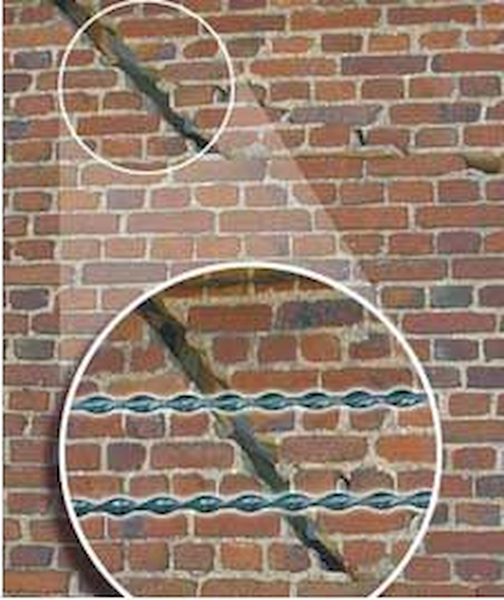

Large or, conversely, numerous hairline cracks can be removed by cementation. This technology is the injection of cracks in masonry with cement mortar through specially drilled wells.

By means of a special pump, a repair mixture is supplied to them, which fills all existing cavities. Tubes with a diameter of 1-2 cm are used as an injector.

Injection of cracks in brickwork is carried out not only to fill the existing voids, but also to create cross-reinforcement - the wells are drilled in such a way that, after filling them, a reinforcing structure is created that will prevent further creeping.

Cementation of masonry: photo

However, the injection of brickwork has one serious drawback - this process is almost impossible to carry out without the proper skills, training and equipment, and therefore, the mandatory presence of specialists is required. You can try carburizing yourself, but the efficiency of the process is likely to be poor.

Cracks in a brick wall and their repair is a serious problem that most often requires an immediate solution if you want to preserve the integrity of the building as a whole and its individual parts in particular. Timely measures taken will save you from serious problems in the future. In more detail, you can get this information by watching the video in this article, where the process is described more clearly.

Sealing and treatment of cracks in foam concrete

We knock down the plaster. The depth of the embossing must be equal to the thickness of the metal.

- Choosing the type of fastener. These can be anchor bolts, dowels or long bolts with nuts.

- We clean the splits and grooves and fill them with polyurethane foam. We insert the channel into the opening and fasten it. We mount a reinforcing mesh on top and plaster the emergency area.

- We iron, reinforce, putty.

Additionally, you can use staples.For their preparation, you will need reinforcement, which is shaped into a bracket by bending. To install it on the walls, it is necessary to make strobes of the required size for a normal fit and holes of the required diameter.

To determine the progressiveness of cracks, it is enough to cut paper strips and stick them on the crack in different places. A tear in the paper is a sign of an increase in the split.

Consider how you can repair cracks in a concrete wall:

- We widen the gap in the plaster onto concrete using a spatula, cutting it by no more than 5 mm, and remove the old edge. If this cannot be done with a spatula, a hammer and chisel can be used.

- Thoroughly lubricate the crack with water.

- Using the DSP, we carefully cover it, pressing the solution strongly (the solution used should be of medium density).

- Smooth the surface with a damp sponge.

To increase reliability, you can use a serpyanka (reinforcement). It must be laid over the entire surface of the crack. First, the gap is putty with a layer of up to 2 mm, after which a reinforced tape is laid in it, which is carefully putty.

Consider how to repair small cracks in a concrete wall:

- We make plaster dough with the addition of chalk.

- Fill the cracks with plaster dough.

- We carefully prime the surface in two layers.

- We smooth the surface, rubbing against the old plaster.

Quite often, gypsum is used instead of plaster. It is necessary to know an important point - unlike ordinary plaster, gypsum, in the presence of vibration, can easily fall off, because has the property of only a mechanical connection. Therefore, we recommend that you do not use the plaster mass near the doors, because due to constant popping, it will simply fall off. Gypsum dough is best used on drywall partitions. We also recommend making notches on smooth concrete slabs before applying the plaster with a chisel.

Consider how the cracks in the walls of the foam block are repaired:

- We open the cracks with a spatula or a knife.

- Put putty on the wall in one layer.

- Using special glue, we glue the fiberglass to the surface.

- > Finishing putty we putty the fiberglass.

- We make a neat grout of the finishing putty.

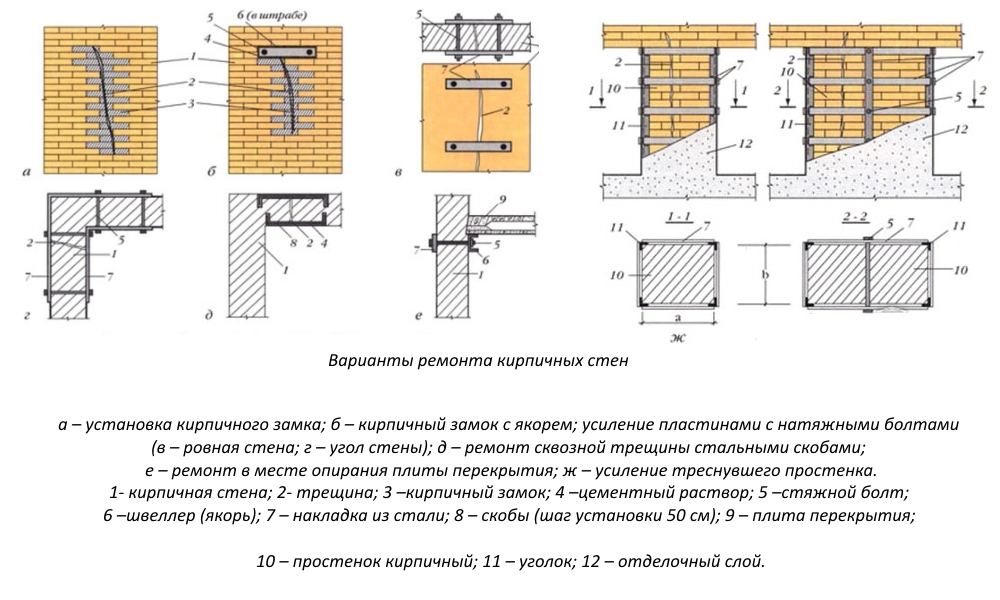

Methods for fixing cracks and strengthening walls

A common mistake is to strengthen load-bearing structures with an exclusively metal reinforcement mesh.

It is important to understand that the formation of wide vertical splits (from 10 mm) in itself is a sign of wall destruction; it is not enough to seal such a crack with a mortar without a reliable metal screed. Recommended reinforcement options include:

- Driving T-shaped metal anchors into dowels located along the edges of the gap.

- Placement of longitudinal steel brackets with folded corners in pre-drilled holes in the walls, followed by cement coating. This method is considered optimal when repairing through cracks from the outside.

- Strengthening the brickwork from the inside with special locks.

Truly working legal way to save money. Everyone needs to know this!

When the mounts enter the wall, their depth should be at least half of the total thickness. Combination of fixing elements is allowed and encouraged. Ideally, the filling of cracks in brick walls is carried out after the installation of at least three reinforcing structures: top, bottom and center.

The use of a reinforcing mesh is advisable, if desired, to strengthen the entire wall area. Such cases include preparation before plastering the facade (even a correctly calculated foundation does not exclude the risk of shrinkage) and the reinforcement of old masonry. When choosing a method and material for filling the gaps, the future external finish must be taken into account. All metal elements are treated with anti-corrosion compounds and hidden under plaster or painted.

What is the best way to close up defects in brickwork?

The composition for filling cracks depends on its location: outside or inside the house. The internal ones can be repaired with a gypsum-based solution or a limestone-cement mixture; for non-critical defects, this method is no different from ordinary cosmetic repairs. For external work, it is better to choose more moisture-resistant materials, otherwise the effect of eliminating a crack on the wall of the house will not last long. Recommended options include:

- For thin, shallow gaps with a width of no more than 5 mm - filling with pure cement mortar after preliminary cleaning and thorough wetting. A special case is microscopic shrinkage formations up to 1 mm; it is better to seal them with epoxy resin.

- For cracks from 5 to 10 mm - covering with a cement-sand mixture for repair in a ratio of 1: 2 or 1: 3 (water is added to the state of a plastic mass - a little more than ½ of the binder).

- For wide and deep gaps in brick walls and structures with an air gap, polyurethane foam is well suited. This material needs mandatory protection from ultraviolet radiation, therefore, at the end of solidification, all excess is cut off (and not flush with the wall, but deeper by 2-3 mm) and covered with the same solution or plaster.

- For crevices of any type - polymer-cement composition of Portland cement M400, sifted fine sand, PVA and water. In this case, a lot of glue is added - from 1 liter per bucket, this component is introduced last.

- For internal and external cracks in masonry, use silicone sealants. The advantages of this option include the elasticity and durability of the material, resistance to temperature extremes and moisture, and the convenience of filling gaps with a construction gun. The disadvantages are its high cost; it is not suitable for bulk cracks.

- If it is necessary to repair the outside of the site with old masonry mortar, mixtures with a slight addition of brick chips are used.

Regardless of the selected composition, the work on its application is carried out after clearing the cracks, tightening with metal (if necessary), removing debris and priming. At the end of the repair, the condition of the walls in a brick house is closely monitored for at least 2 months.

Classification and causes of cracking

The advent of durable and technologically advanced Portland cement revolutionized the construction industry. However, from the point of view of the risk of cracking, the new binder has one significant drawback - a high hardening rate.

As you know, after construction, a building does not immediately take a stable place in the soil mass. The natural shrinkage process takes several years. A cement-based mortar, on the other hand, gains strength very quickly. Such a big difference between the time of decay of sedimentary deformations and the active set of strength by Portland cement leads to the appearance of cracks that break the masonry massif.

With a lime mortar, things are easier. It hardens slowly, therefore, when the foundation settles, through voids in the walls, as a rule, arise. That is why we see much fewer cracks in buildings that have stood for centuries than in modern high-speed new buildings.

Experts classify cracks in masonry according to the following criteria:

- The reason for the formation: structural, deformation, shrinkage, temperature, wear;

- Destruction type: rupture, crushing, cut;

- Direction: horizontal, vertical, oblique;

- Outline: curved, straight, closed (do not reach the edge of the wall).

- Depth: through, surface;

- Hazard level: not dangerous, dangerous;

- Time: stabilized, not stabilized.

- The size of the opening: hairy (up to 0.1 mm), small (up to 0.3 mm), developed (0.4-0.8 mm), large (1 mm or more).

There are many reasons why the house is cracking:

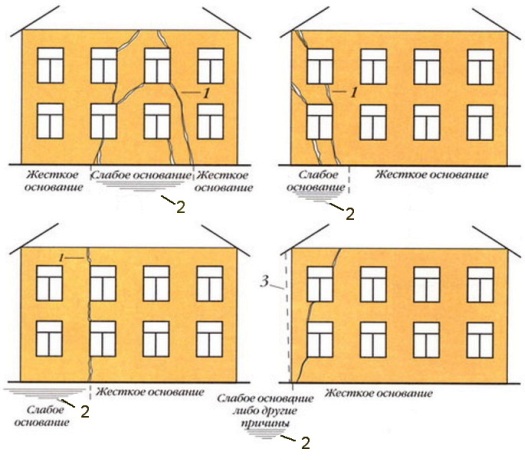

1. Sediment of the soil.It can be caused by uneven compressibility of the soil (dense and weak areas), uneven loading of the foundation, leakage of tap and sewage water into the ground. It leads to the appearance of inclined splits reaching the edge of the wall or the development of vertical (inclined) cracks in the middle of the facade.

1 - sedimentary cracks; 2 - sediment funnel; 3 - deviation of the wall from the vertical.

1 - sedimentary cracks; 2 - sediment funnel; 3 - deviation of the wall from the vertical.

2. Freezing and thawing of soil. Freezing of heaving soils causes an uneven rise of the foundation (if its base is located above the freezing point of the soil). This process is especially dangerous for a building under construction, the weight of the walls of which is small (low bending stiffness). In this case, many cracks form on the walls. During the spring thawing of the soil, the reverse process occurs - the foundation settlement. Walls receive new damage.

3. Repair of a crack in the wall may be necessary after the addition of a new building. From this, additional compressive stresses develop in the foundation soil, leading to foundation settlement. As a result, inclined cracks appear in the adjoining walls of the existing building (open upwards).

4. Uneven foundation loads within the same building. In modern homes, long glazed walls are often interspersed with blind areas. The difference in load results in uneven settlement of the foundation.

5. Digging a foundation pit next to the building. If the house stands on the slope of the excavation or close to it, then the creep of the soil affects the foundation and inclined cracks appear in the brick walls from the side of the excavation.

6. Influence of adjacent foundations. Stress zones overlap, increasing soil compression and settlement.

7. Surface loads. When storing a large amount of building materials next to a building under construction, additional stresses appear in the ground. They can cause significant settlement of the foundation and the appearance of cracks.

8. Dynamic influences. As a result of pile driving, constant movement of heavy vehicles, operation of compressors, sandy soils are compacted and clayey soils are softened. As a result, the foundation gets sediment, and the walls - cracks.

9. Thermal deformation. Cause the formation of cracks in the middle of the walls (vertical direction). Filling cracks in brick walls is most often required for long buildings that do not have expansion joints.

10. Overloading of masonry. Appear in walls and on pillars. A characteristic feature of crush cracks is closedness and vertical direction. They are very dangerous as they can cause a sudden collapse of one wall, followed by a chain reaction of the fall of all the others.

11. Shrinkage deformations (non-hazardous). Observed on plastered walls (cracks are small, randomly scattered, closed, do not reach the edge of the wall). The reason for their appearance is the shrinkage of too greasy plaster mortar.

The non-hazardous category also includes vertical rectilinear cracks with a constant opening along the length. They are localized at the junction of the walls (old and new).

How to choose the right aerated concrete block

Compliance with documents and acts, as well as timely work and support of highly qualified specialists - these are all the necessary conditions that must be met for aerated concrete production.

What blocks and where are used

- First of all, you need to choose a foam block according to the type of structure. After all, they eat differently and each is suitable exclusively for their work. The photo above shows a table on this matter.

- The main indicators in this process are strength, density, size and, of course, frost resistance. These indicators are basic, therefore they are all indicated in the data of the passport for checking the quality of the aerated concrete product.

- Also, the certificate or passport must have a specialized blue seal, which must be supplied by the manufacturer.In some cases, quite frequent, an additional mark of the organization that conducts the tests is required. Quality indicators must be fully consistent with the requirements of the project.

Separately, you should pay attention to the fact that a block of good quality is distinguished by a light color shade, even corners and edges, as well as a homogeneous structure. Therefore, if there are spots, streaks or oily films on the surface of the block, you must refuse to purchase.

If all the rules of the technological operation were observed, then the pores of the block will always be only closed, round and even

They will be evenly distributed over the block area.

Also, when purchasing, you should pay special attention to the cut of each block. If there are pores that are very different in size and do not have a round shape, this indicates that the rules and parameters of thermal conductivity were not followed. It can also be a sign that the block has poor sound insulation properties.

If a monolithic aerated concrete block will be used, special attention should be paid to the surface level of the mixture. If there are watery compartments, this indicates that the required recipe was not followed when creating the block.

How to strengthen brick walls

Brick wall dressing scheme

Advice: In the absence of results after carrying out repair work on the walls, it is necessary to partially re-lay them.

To guarantee the strength of a cracked brick wall, it is advisable to strengthen it from the inside of the building.

This means:

- Sealing the crack.

- The imposition of a lock on it, or a metal profile.

- The lock is fastened to the wall with anchors, and the gap is bridged across it, which will prevent it from enlarging in the future.

- The repair can be done with metal staples, their ends should go into the wall to a depth of at least 1/2 the thickness of this wall, in which holes for the staples should be drilled in advance.

- In a day, such a repaired wall can be put into operation. But in any case, it cannot be heavily loaded - the wall will acquire full strength only in a month.

If cracks appeared due to an incorrectly poured foundation, the best solution would be to strengthen the foundation with an auxiliary concrete belt.

- A trench is dug along the entire perimeter of the house with a depth, greater than the depth of the foundation.

- An auxiliary belt will fit in it.

- In order to prevent the formation of further cracks in the masonry, the base is poured according to the appropriate technology.

What cracks in brick walls can be, their cause, and how to fix it, you can learn from the video in this article. Cracks in masonry are very common. The cost of solving this problem is different, but it is worth getting rid of it immediately in order to avoid violating the integrity of the structure of a residential building.

Graduated from the Faculty of Architecture of the Penza State Institute of Architecture and Construction. For the past ten years, he has been a leading specialist in a large construction company in Penza, engaged in the construction of multi-storey residential buildings. The total work experience in the specialty is 18 years. Consults on design issues, choice of materials for interior and exterior decoration, finishing technology.

How to repair cracks yourself - step by step instructions

You can cope with the repair of small cracks on your own without involving a construction team and additional costs. Having previously studied the intricacies of technology, as well as correctly choosing the tools and materials necessary for the work.

On a brick wall

The most common material for masonry walls is brick. If the damage is minor or medium, then the repair should be carried out according to the following instructions:

-

To make the jointing with a hammer and a screwdriver, as a result the gap will slightly increase.

-

Completely clean the joint from dust and moisten the surface. Using a trowel or mortar trowel, apply the cement mortar, carefully filling the depth of the crack and leveling the joint surface.

For large and through slots, the operating procedure will be different:

-

Expand and clean the surface of the crack, as in the previous instructions, knock out the remnants of the old solution.

-

Drill holes for dowels on both sides of the slot, insert dowels.

-

Treat the surface with a penetrating primer to increase the adhesion of the materials.

-

Fill the cavity with the solution, pushing it into the depth and filling the voids.

-

Lay the seam on top with a reinforcing mesh, screw the screws into the dowels.

-

In more serious situations, tighten the crack with metal rails fixed with anchors or embedded elements.

- Plaster the mesh. It may be necessary to partially dismantle the old damaged masonry, and then new bricks are inserted into the fresh mortar, thus the masonry is restored and the wall is strengthened.

On a plasterboard partition wall

Usually, the joints of drywall sheets crack, and if the crack has gone along the sheet itself, there is damage to the frame or deformation during installation.

Steps for sealing GKL cracks:

-

Clean and embroider sheet joints or cracks.

-

Coat the edges of the sheets with a primer.

-

Apply a small layer of putty.

-

Press down the reinforcement mesh or tape and press it into the seam surface.

-

Level the entire layer and sand thoroughly.

On a plastered surface

Cracks in the plaster are superficial and do not pose a threat to the structure, however, they spoil the appearance of the interior very much and spread out in the form of a grid.

Stages of repairing small cracks:

-

With a hammer, knock the entire area of damage without sparing and knock off the exfoliated parts, remove the remains of plaster and dust with a spatula.

-

Go over the groove with a penetrating primer that will strengthen the edges and improve adhesion or wet it with water.

- Fill the entire cavity with a solution or a special ready-made mixture, if necessary, lay a reinforcing mesh, fixing it on nails or small screws.

-

After the plaster layer has dried, apply a finishing putty, narrow cracks can be reinforced with a special tape.

On concrete

With the development of monolithic construction, concrete is becoming more and more popular, and more and more often the question of repairing concrete surfaces arises.

How to grind:

-

Sift sand and cement to separate the finest fraction. The finer the particles are, the smoother and more reliable the coating will be. Knead the liquid solution.

- Prepare a half-grater, fixing a piece of fur on it, collect a bucket of clean water.

-

Dip a half-grater in water, then apply a small portion of the solution to it with a spatula. Press the tool against the wall and rub the solution into the crack area in a circular motion, constantly wetting it.

With the help of grinding, builders not only remove cracks, but also grind all the grooves and irregularities on the monolith or ordinary concrete to a perfectly even state. Large chips and cavities are perfectly bonded by epoxy resin paired with a hardener and reinforcing mesh or tape.

Even well-erected walls are subject to gradual destruction over time, so the dream of building once and for all in practice is unattainable. The house will stand for a long time if the owners monitor the condition of the structural elements and identify defects in time. You can cope with a small repair to seal the formed cracks on your own, thereby preventing further damage creep.