How to unscrew a stuck bolt

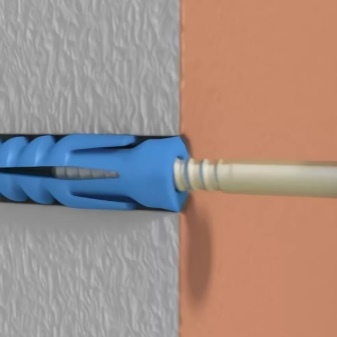

Repair of various body elements and main components of a car is not complete without solving the problem of corrosion, oxidation of bolts. As a rule, in factories, craftsmen carefully process all fasteners. High-quality lubricant is present on the threads of all seats. With further repairs, such compositions are not applied. After water gets on the surface of the threads, the joints stick together, and sour bolts become too difficult to dismantle.

Wizards use three effective methods to solve this problem. The choice of the appropriate option should be based on the capabilities of the car owner.

Unscrew rusted bolt or nut by tapping

Tapping helps to gradually break down limescale and rust. To properly dismantle the fastening materials, you need to take a small hammer and strike, trying to crank the hardware. This method helps to quickly unscrew the connection.

Unscrewing effort should be moderate so that you do not have to drill additional holes. If the process is performed correctly, the bolts must be thoroughly cleaned from rust and treated with graphite grease.

Using solvents

High quality anti-rust and anti-scale compounds are expensive and the most effective. However, on the market you can find many budget options for domestic production.

The most popular is the WD 40 aerosol composition. The substance quickly penetrates micro-gaps and gradually dissolves corrosion. In addition, the hardened bolts are unscrewed with brake fluid, kerosene and white spirit. To achieve the maximum effect, you should wet any fabric with a substance and wrap the hardware for a while.

Thermal method

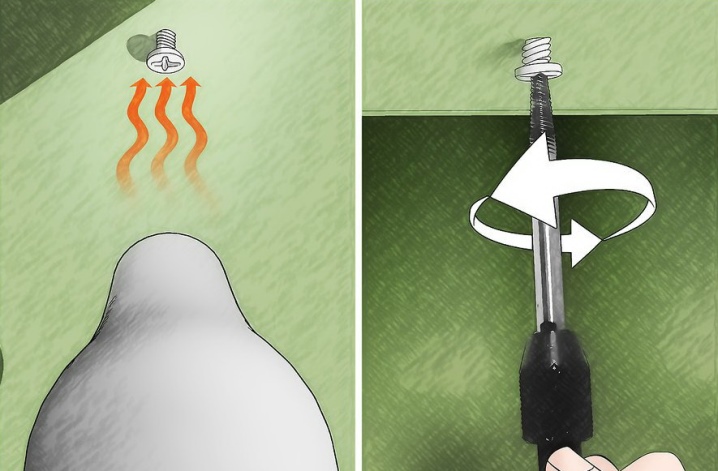

If the above methods do not give the desired result, there is only one way out - fire. Heating the elements and instant cooling allows you to quickly release the screw connection from scale. After heating with a gas burner or other device, the hardware must be cooled with machine oil.

In almost any situation, the bolts can be loosened with improvised means. All you need is a flat or Phillips screwdriver, open-end wrenches, heads, lubricant, and some effort.

Previous Post How to disassemble a mouse without bolts

Next post High strength bolts

Recommendations

A tool useful for unscrewing different types of screws is best purchased in advance and kept close at hand. This moment is especially relevant for owners of garages and personal vehicles. Here, an extractor for unscrewing broken hardware will be most useful - it is better to choose a universal type of construction, with a shortened working part. With it, it will be possible to unscrew the problematic fasteners even in hard-to-reach places.

There are some simple tips to help you reduce the chances of edges or splines breaking off.

- Select exceptionally high quality fasteners with a hardened head.

- Securely fix the tool tip in the slots. When a screwdriver or bits slip, the protruding edges are erased - it will be more difficult to turn out such a hardware.

- Maintain the tool in working order. On a key or screwdriver, the edges also often turn out to be licked, which greatly interferes with the normal unscrewing of the fasteners.

Considering these tips, you can avoid the occurrence of problems with unscrewing screws for various purposes from the parts fastened by them.

In the next video, you will learn how to remove any screw.

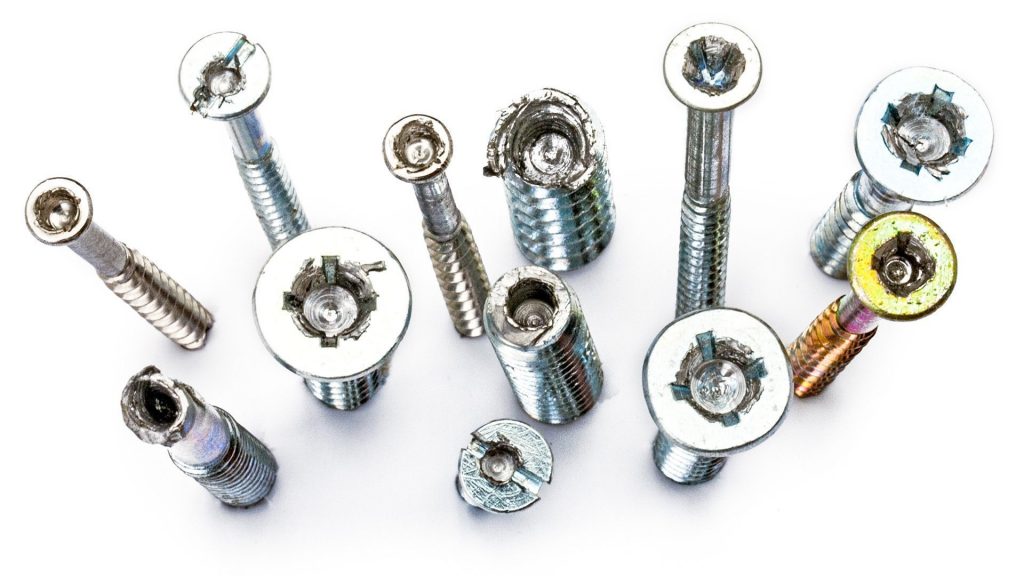

Ways to pull out a screw with a torn cross

If the edges of the fastener are torn off or licked, then there are several ways to unscrew such a screw or self-tapping screw.

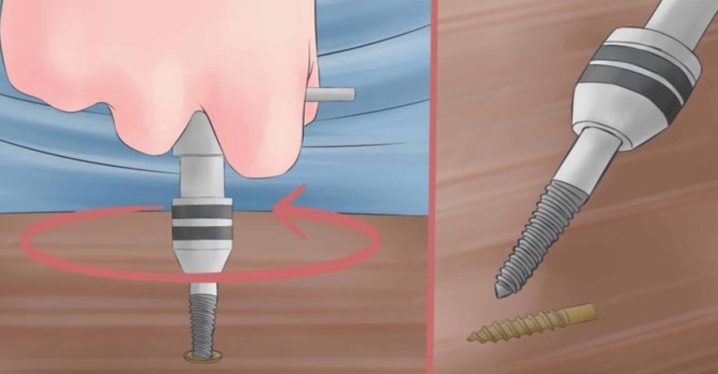

Crimping protruding thread head

In the event that a part of the self-tapping screw protrudes above the surface, you can unscrew it by squeezing the head with pliers. For this, it is best to use thin pliers (platypuses). With their help, they clamp the tip of the screw and begin to rotate it counterclockwise. Instead of pliers, you can use a drill chuck. They squeeze the head and unscrew the self-tapping screw.

With a drill chuck, crimp the head of the self-tapping screw and unscrew it

With a drill chuck, crimp the head of the self-tapping screw and unscrew it

Restoration of splines

If you cannot grab the head with pliers, and the screw rises slightly above the surface, then the slots can be restored. To do this, use a grinder or a hand saw for metal. With their help, a cut is made on the head, it should not be deeper than 2 mm, otherwise the head will weaken and break. After that, unscrew the screw with a flat screwdriver.

The cut on the head should not be deeper than 2 mm, otherwise it will weaken and break

The cut on the head should not be deeper than 2 mm, otherwise it will weaken and break

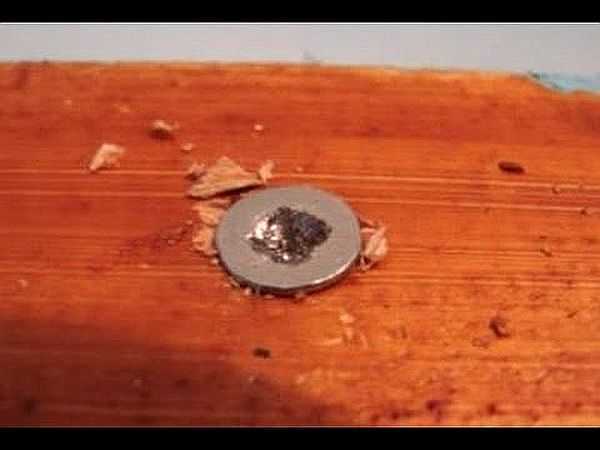

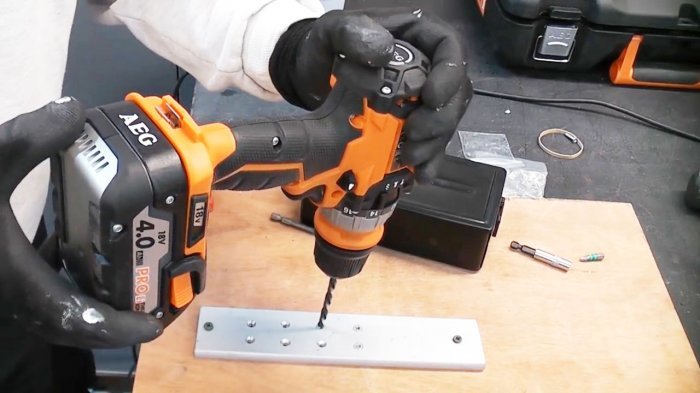

Drilling a hole in the head

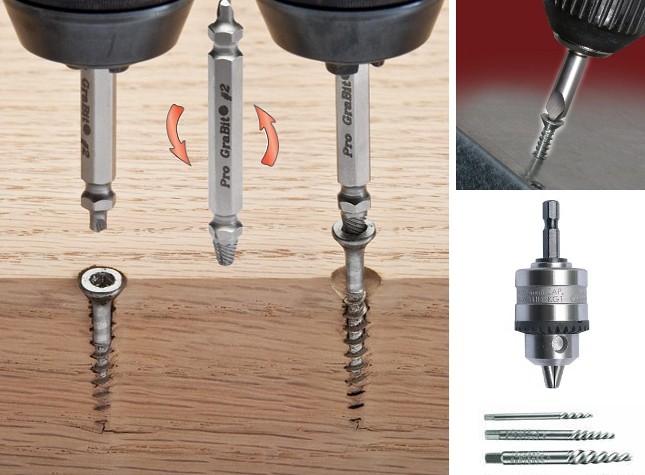

A left hand drill can be used. In the store, in addition to the usual drills, there are those with a spiral stroke from left to right. Using such a tool, a hole is made in the head of the screw. When the drill reaches a certain depth, it gets jammed and the self-tapping screw begins to unscrew with it.

When the drill reaches a certain depth, it gets jammed and the self-tapping screw begins to unscrew along with it.

When the drill reaches a certain depth, it gets jammed and the self-tapping screw begins to unscrew along with it.

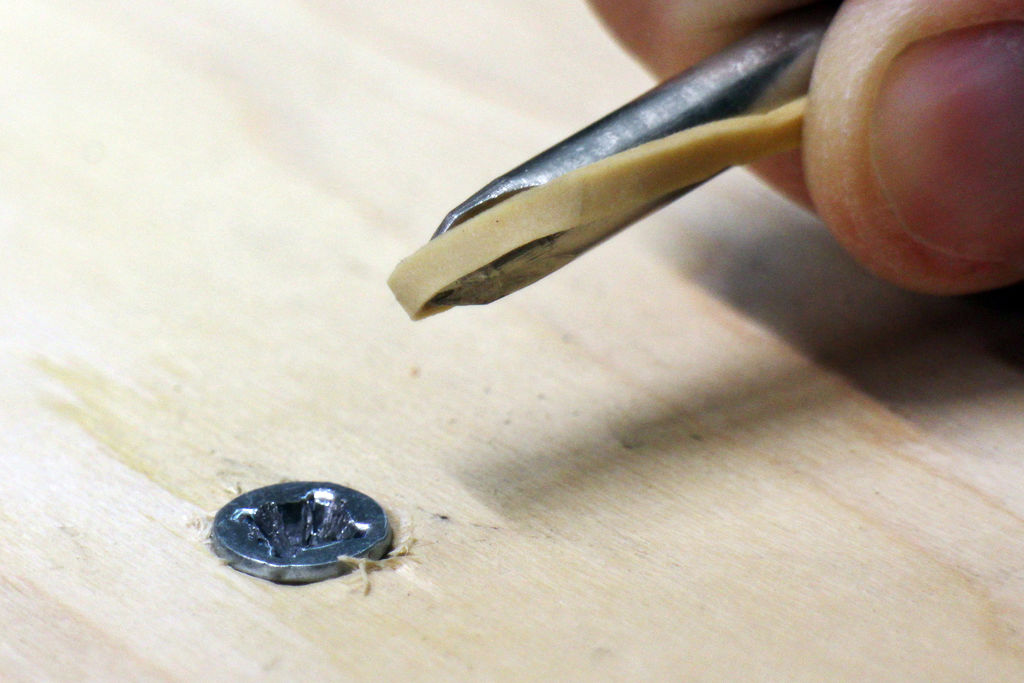

Use of rubber

For this method, you need to find a piece of medical harness or dense rubber, for example, a camera from a motorcycle. A screwdriver is selected that fully matches the slots on the head of the self-tapping screw. A piece of rubber is placed between it and the head and, pressing hard on the screwdriver, unscrew the problematic fasteners. Rubber helps to increase the coefficient of friction, and the tip fits snugly into the slots on the head, so the screwdriver does not slip.

A piece of rubber is placed between the tip of the screwdriver and the head of the self-tapping screw and, pressing hard on the screwdriver, unscrew the problematic fasteners

A piece of rubber is placed between the tip of the screwdriver and the head of the self-tapping screw and, pressing hard on the screwdriver, unscrew the problematic fasteners

Heating fasteners

This option works well when the fastener is screwed into plastic. Using a soldering iron, heat the screw head. The high temperature softens the plastic and weakens the fasteners. After that, you need to quickly, until the surface has cooled down, unscrew the self-tapping screw. If the screw is in wood, then it is heated and waited until it cools down. This allows the fastener to be slightly loosened, after which it is easier to unscrew the fastener.

Extractor application

An extractor is a tool designed to unscrew screws, bolts and self-tapping screws with broken heads. First, using a drill, the diameter of which is less than the diameter of the head, a recess is made in it. After that, take a conical extractor of the appropriate diameter, screw it into the recess and unscrew the fasteners. You can use the extractor immediately if the depth of the slots is sufficient for screwing it in.

Usually self-tapping screws and screws are right-handed, and the extractor is left-handed.

Usually self-tapping screws and screws are right-handed, and the extractor is left-handed.

There are slotted extractors. They are made in the form of a nut, to which there is a slot instead of an internal thread. A slotted extractor is put on the screw head, and then the slot is screwed into it.

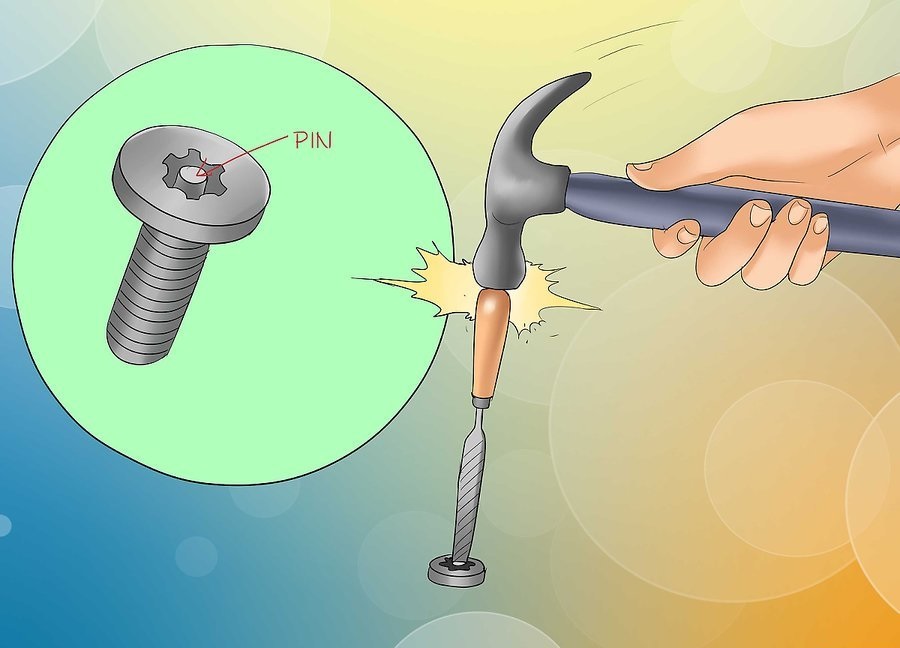

With a core and a hammer

The core has a sharp end, therefore it provides reliable engagement with screw head or screw. In order to unscrew the problematic fasteners, the core is abutted against the head at an angle of 45o, after which it is gently hit with a hammer in the direction opposite to screwing. As soon as the fastener is loose, the screw is unscrewed with a screwdriver.

Using an impact screwdriver

The peculiarity of the impact screwdriver is that it has a strong handle that can be hit with a hammer. Take such a tool so that its tip matches the slots on the screw. They insert the sting into the slot and make several blows on the handle, after which they try to turn the fasteners.Such actions allow you to loosen the fastening, after which the screw or self-tapping screw is simply unscrewed.

Using glue

For this, epoxy glue is usually used, as it provides a very reliable connection. After the screw head has been greased with glue, a nut is placed on it and wait until it adheres well. After that, using a key, turn the nut and at the same time unscrew the problematic fasteners.

How to remove problem screws?

Unscrewing a screw if its crosspiece is torn off is not an easy task. The licked hardware can be on a laptop or hold a car wheel, but there are still stuck and rusted bolts, options with a torn off head and with a left-hand thread. All of them are quite amenable to twisting, if you approach the matter correctly.

Tool change

If we are talking about a conventional screwdriver, its edges can be ground off in the course of previously performed work. If the contact is clearly poor, you should try changing the instrument. The one that fits snugly in the slot is selected

It is worth paying attention to the marking: for PH and PZ you need screwdrivers with different types of tips, they are not interchangeable

Using pliers

The method is relevant only if the screw head is located on the surface of the material, not sunk into it. The side parts of the cap are captured with pliers, counterclockwise rotation is performed. If the screw gives in, there is no need to rush - it is better to act slowly and carefully.

Power tool

If you cannot manually remove the stuck screw, you can try dismantling with a screwdriver or electric drill. To do this, the cartridge is freed from bits, the hat is opened and fixed in it.

It is important to remember that the power tool must have a reverse mode - it is in it that the work takes place. If there is a cap on the outside, this is the easiest way to remove the problem screw

pad

With weak contact with a hat recessed deep into the material, it becomes too difficult to unscrew the problematic fasteners. Sometimes the use of an additional layer between materials helps to solve the problem. For example, a piece of thin rubber, leather, or an abrasive part of a household sponge can be used for these purposes. The gasket is fixed over the head, improving grip; a screwdriver or screwdriver bit is inserted from above.

Notch formation

If the slot is torn off, you can unscrew the screw by making a notch on it with a grinder or a hand tool. After that, using a screwdriver of a suitable size with a flat tip, the fasteners are unscrewed. The short-term heating of the hardware will help to further facilitate unscrewing. Thermal expansion will help to slightly increase the diameter of the hole, making it a looser fit.

Slicing faces

With an external type of a torn slot, a simple solution can be cutting new faces on it. Processing is done with a file or grinder, a hacksaw for metal. Even 4 edges will allow you to use a wrench of a suitable diameter to get rid of a tightly seated screw.

Using a special tool

When other methods do not help, you can use the extractor by screwing it into the body of the fastener - this works even if the cap is blown off. Some of these tools require a hole to be pre-drilled. The extractor must be jammed in the screw, and then unscrew it along with the problematic hardware. At the same time, the material is not damaged, this technology can be used on all types of fasteners, except for self-tapping screws made of hardened steel.

Cold and hot welding

A torn cap or lapped splines often do not solve the problem of removing the interfering screw. To regain control of the threaded connection, you can weld or cold-weld the nut to its surface. In this case, the screw can be removed using a box or ordinary wrench.

Drilling

It allows you to completely remove a screw that is too deeply recessed. This method works with wooden surfaces. You can simply drill out the hardware itself, later replacing it with a new one. In addition, a good solution may be to use a cork nozzle that can pull out a solid section of the wooden surface along with its contents.

Soldering

A small screw or screw with torn off slots (most often cross-shaped) can be tightly connected to the screwdriver using soldering. To do this, hot tin is applied to the head of the fastener, and the tool tip is immersed in it. Let the compound cool and adhere well. Then you can easily unscrew the screw, which has become a continuation of the screwdriver, clean the tool from traces of solder.

Stuck and rusted screw

Here we also have to deal with the consequences of exploiting the connection. You can remove rust with the help of special compounds, a few drops will be enough. Then an impact screwdriver is used (can be replaced with a chisel) and a hammer. Under shock loading, the stuck and rusted parts of the screw become movable. Once they give in, you can change the tool and unscrew the problematic threaded element in the traditional way.

Recommendations

In many cases, the success of the entire enterprise is determined not so much by obvious decisions and applied force as by creativity and cunning.

At the same time, it is important not to outwit yourself and think in advance whether the result will become even worse. For example, if a bolt is likely to get stuck due to some deformation of the surrounding material, you can try to resolve the issue by heating the head.

This is especially true for plastic products - they are made of a material that reacts fairly quickly to heat. The screw expands slightly during heating and, as it were, pushes the base that has clamped it, now a little softened.

Please note that the “melted” plastic can “grab” the fasteners even more tightly, so the latter should be unscrewed while still noticeably warm. The difficulty here lies in correctly calculating the heating and in no case overdoing it, since the plastic base for the screw is the most typical for technology, and excessive overheating of the plastic case can lead not only to noticeable deformation of the product, but also to disruption of its functions

A similar situation with heating is especially relevant if the manufacturer, immediately before screwing in the bolt, smeared its thread with paint - this is often done so that the fastening is reliable, completely forgetting that there may be a need for untwisting. In this case, heating is required quite strong - a soldering iron with a thin tip is used for it. At the same time, with this approach, the hardware not only should not be directly screwed into the plastic base - there should not be any plastic next to it at all! Remember also that as a result of heating, the bolt itself also became a little less durable, and any excessive efforts may well end in the breaking of the thread or head.

If the cross on the head has worn out so much that it no longer lends itself to an adequate description from the point of view of geometry, you can try to solve the issue with the help of a thin rubber gasket. It must be attached to the place of the damaged cross, and then press it firmly from above with a slightly smaller Phillips screwdriver. You still need to get used to this method, but the point of the trick is that the rubber does not slip, it adheres tightly to the hardware and clogs into all its cracks, yielding to the onslaught of a screwdriver. As a result, a kind of temporary slot is formed, allowing you to unscrew the fasteners.

A similar method involves using super glue or solder (less effective). The selected mass must be dropped into the torn slot, and then immediately insert a screwdriver there to form a new slot.The subtlety of the task lies in the fact that the tool in no case should change its position while the glue dries, otherwise you will again create unnecessary problems for yourself. It remains to wait as long as, according to the instructions (or experience), this type of glue dries, after which you can try to unscrew the mount a little.

If you are sure that you have spare fasteners of the same size, but cannot remove the stuck old copy, you can use the method that is often used in technical repair shops to remove small fasteners. First you need to choose a drill, whose diameter is exactly equal to the diameter of the hardware head

After that, the hat is drilled out with extreme caution, doing everything possible so as not to touch either the surrounding plastic or the lower, threaded part of the mount. As a result, it does not interfere with removing the cover after all the other bolts have been unscrewed.

After removing the cover, it will appear that the threaded part now protrudes slightly above the inner part. Next, you need to carefully pick up the piece with pliers and unscrew it - this time the displacement of the fragments to be connected will no longer interfere with it, and it is not screwed in at all so deep as to strongly resist. Accordingly, during assembly, the finally disassembled bolt is replaced with a new one.

For information on how to unscrew any bolt, see the next video.

Rust Prevention Tips

Prevention is the best way to fight rust. Always tighten the fasteners according to the torque of similar threaded connections, use quality bolts, nuts and screws, and lubricate the part before tightening. Even if the part is new, it is better to clean it again. All this will allow you to avoid the moment when you have to resort to shock methods.

All the methods described above are quite effective, so you can safely use any of them. They have been tested by different craftsmen and have always given a positive result. By following these tips, you can easily overcome stuck screws, bolts or nuts.

And by taking preventive measures into account, you can avoid recurrence of the problem.

«>

Ways to unscrew rusted parts at home

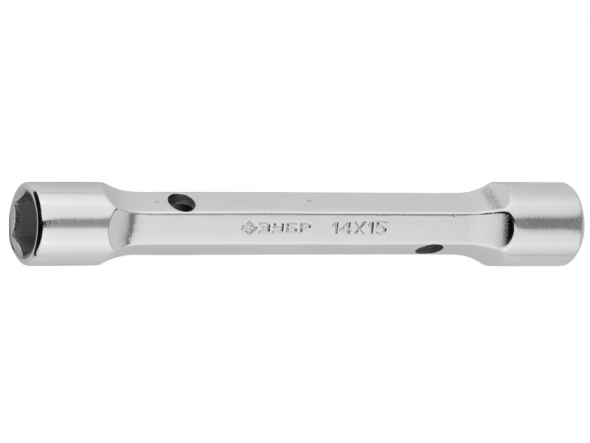

Dismantling with socket head or spanner

If the rust layer is not too thick, use a socket or box wrench. In this case, the tool must have 6 or 12 points of contact. Next, you need to alternately tighten and loosen the thread with sufficiently sharp movements. If that doesn't work, brush the surface with a wire brush and then apply one of the greases mentioned above. Once the product has started to work, take a hammer and lightly tap on the mount to knock off the top layer. Then use the key again, the clamp should loosen. To enhance the effect, you can use a pipe on the wrench or use a non-ratchet tool with a long handle. But be careful in your work, bad and old tools can break right in your hands.

Use muscle power and this tool

Exposure of nuts and bolts to high temperatures

Alternatively, heat can be used to remove the part. Take a blowtorch and use it to warm up the mount

It is important to heat only one side of the bolt or nut so that it expands from the heat and damages the rust layer. If such a tool is not at hand, you can use an ordinary candle.

After heating, pour cold water over the part, and then pick up the key again. The only drawback of such methods is that they spoil the hardening of the metal.

Do not use this method near flammable objects and rubber gaskets

How to unscrew with a screwdriver using a mixture of gearbox oil and acetone

A mixture prepared with your own hands is effective. It consists of 50% automatic transmission oil and 50% acetone.It is necessary to use the lubricant several times over several hours, each time leaving it for at least 40 minutes. Sometimes the bolt is for a screwdriver, in which case use the same tool or chisel and hammer. Then, with the help of blows, try to loosen the fasteners. If you are not afraid of extreme methods, use zinc or sulfuric acid. Initially, you need to make a small side of plasticine or wax around the fasteners. Then put a piece of zinc into the formed recess, pour a chemical element on top. The problem will be resolved in a day. In the same way, you can unscrew the stuck screw on the mixer.

Twisting until it stops

An important method is the so-called "contradictory method": in order to loosen the fastening of a stuck part, you should not unscrew it, but, on the contrary, try to tighten it tighter, to the end. This will allow the bolt or nut to travel more freely, which ultimately helps in removing the rusty mount.

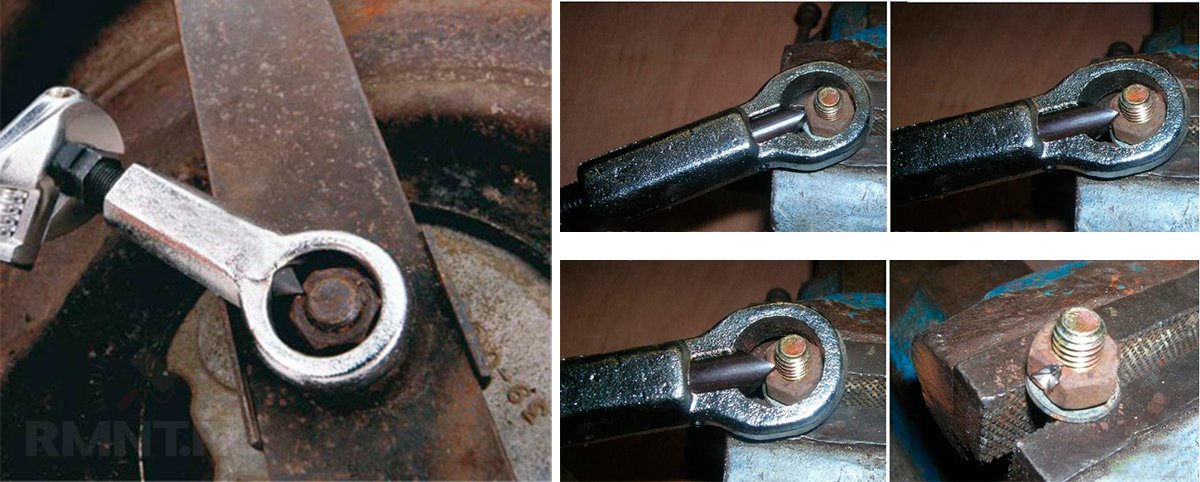

Complete dismantling

If all these methods were unsuccessful, then the mount will need to be destroyed. This can be done in several ways. If you are working with a bolt, you need to drill it out and cut a new thread. You can also use a special tool such as a nut puller. It tightens the part, it cracks under pressure, so that the nut can be removed with an ordinary wrench. The most radical way is to use a grinder. It is enough just to saw the bolt lengthwise using a metal disc.