How to unscrew a screw

Wood screws

Unscrewing broken screws from metal structures is quite simple, since the head almost never sinks into the metal due to its hardness. In case of breakage, any screw or self-tapping screw can be unscrewed from the metal profile using ordinary pliers.

With a tree, the situation can be much more serious. Since the wood is soft, it does not offer much resistance to the screw head during tightening, and it can sink to a sufficiently large depth without any problems.

Therefore, it is quite problematic to unscrew such a screw in the usual way (using pliers). There are several techniques for removing a broken wood screw. Let's consider them in more detail.

Method number 1 Twisting with removal of the tree surrounding the head

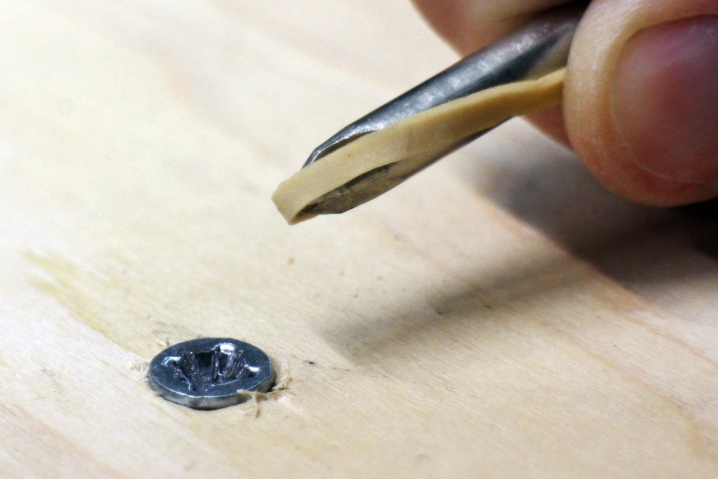

Using a chisel or chisel, a wooden surface is processed, located in the area of the screw head

This method is used if it is not a pity to spoil the appearance of the board into which the screw was screwed. This is the most reliable method, the essence of which is to remove wood fibers from the location of the screw head, followed by its extraction in any convenient way.

After that, chips are removed from the surface.

The sequence of actions in this case looks like this:

Then the screw is unscrewed in any convenient way, for example, with pliers

1

Processing is carried out until the moment, until a space in a diameter of 20 to 30 mm from the center of the screw is freed. The depth to which the ditch is made should correspond to the immersion depth of the screw head.

With this method of unscrewing, the probability of breaking the screw is significantly lower.

2

At the same time, at the initial stage of unscrewing, the pliers are held at an angle of 45 °, when the cap appears from the surface of the wood, you can unscrew the screw holding on to its thread.

Method number 2 Removing a screw with a torn slot

Broken splines are one of the most common screw breakages.

1

Usually, it is caused by poor quality material, the use of the wrong nozzles or excessive force.

It is very difficult, if not impossible, to unscrew such a screw with an ordinary screwdriver.

2

To solve the problem of the torn slot, it is necessary to "fill" it again. To do this, you need to use an insert screwdriver, colloquially referred to as a "bat". You can use a regular or double-sided bat.

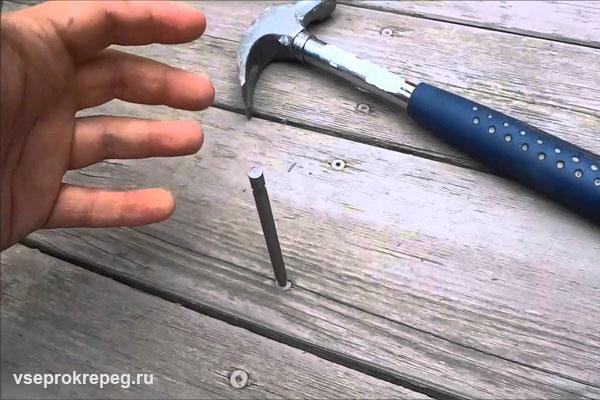

One end of the bit is inserted into the damaged slot, on the other, several blows are made with a hammer

3

Then you can use a regular screwdriver.

After the slot is "updated", the screw can be unscrewed without any problems with an ordinary Phillips screwdriver

Method number 3 If the screw is difficult to turn

First, the screw head is warmed up with a soldering iron.

1

A situation that is also encountered quite often. The reason may be wetting (or vice versa, drying out of the wood), the use of too hard material, the absence of a hole for tightening the screw. In this case, it is necessary to use the heating of the screw and the place of its tightening.

Then the tree in the area of the cap is warmed up with an iron.

2

Such actions lead to the fact that the tree dries out severely. Locally, its structure at the location of the screw changes.

After that, the screw is easily unscrewed with a regular screwdriver.

Method number 4 When the hat is missing

A broken hat is also quite common.

1

The main reasons are still poor quality material or excessive tightening force.

A new slot is made using a triangular file

2

In this situation, you can try to unscrew the remnants of the screw with pliers. If this does not work (for example, most of the thread is in the wood), you can make a new spline.

Next, the screw is unscrewed using an ordinary screwdriver.

Method # 5 Using an extractor

The shape of the working surface of the extractor allows it to be used for unscrewing screws in a variety of situations

1

In most cases, you can generally use a special insert - an extractor.

It is enough just to use an extractor insert with a screwdriver to unscrew the problematic screw

2

Using the extractor allows you to unscrew all previously considered "problem" screws: deeply screwed, with "lapped" slots, "tight", etc.

VIDEO: HOW TO REMOVE THE SCREW WITH RIPPED EDGES how to unscrew the licked off screw

How to unscrew a screw with torn edges

How to unscrew a screw with torn edges

9.2

Total Score

How to unscrew a broken screw

Relevance of information

9

Availability of application

9

Disclosure of the topic

9.5

|

Bolt unscrewing methods

Below are the most effective ways to remove damaged bolts and screws.

With tainted edges

When deciding how to unscrew a bolt with torn edges, you need to consider whether you have access to it, its location, and what tool you can use. Based on these factors, you can apply one of the following methods:

- Using a chisel. This method is suitable for large bolts that are easily accessible. All you need is a hammer and chisel. The chisel is applied tangentially to the head and sharp blows are applied to it. The method is simple, but it rarely achieves the desired result. It should only be used when there is no other tool at hand.

- If there is easy access to the location of the fasteners, you can use the universal adjustable wrench. Even a round head can be clamped securely with this tool. If you use small cobra wrenches, which have sharp notches on the working surfaces, you can unscrew the smallest bolts. Such a tool can help out in many cases, but it must be new. With a worn tool, the notches can no longer provide reliable adhesion to the metal, and the key will slip.

-

If the edges are not severely damaged, then the heads for the spanner wrench can help out. For these purposes, the profile of the spanner wrench must have 12 edges (there is an asterisk inside the head, not a hexagon). Unscrewing is performed as follows. Choose a head one size smaller than the size of the bolt, and press it onto the torn edges with a hammer, then unscrew it in the usual way.

- This method consists in using a hacksaw for metal, with which a cut is made on the head of the bolt for a flat screwdriver. The cutting depth should not be more than 75% of the bolt head height; at greater depth, one of the halves may break off.

- If you have a file or a grinder at your disposal, then you can restore the turnkey edges of a smaller size. If you have an open-end wrench, it is not necessary to cut out the hexagon; it is enough to make two parallel faces.

- If welding can be used at the location of the attachment, then this will greatly facilitate the task. In this case, you can put a nut of a suitable diameter on the head and weld them together, and then use ordinary keys.

With a torn off head

Very often, disassembling old threaded connections, you can not only damage the edges of the bolt, but also tear off the head. Then the question arises: how to unscrew the torn off bolt. If you have disconnected the parts, and the stripped bolt protrudes from the body of the part, then you can use all of the above methods.

But how to unscrew a bolt with a torn off head if the bolt body does not protrude from the part? There are several options for solving this problem.

- It is best to use a special tool - an extractor. The extractor is made of a cylindrical metal rod, at one end of which there is a tapered thread of the opposite thread, and at the other end there is a square shank. To use it, a hole must be drilled in the center of the bolt. The hole diameter is 2-3 mm less than the thread diameter. After that, you need to take an extractor of a suitable size and hammer it into the hole with a light blow. Turning the extractor by the shank, unscrew the rest of the bolt.

- If there is a left-hand thread tap, you can successfully use it as an extractor. The only difference is that the hole diameter must be the same as for threading. The exact value can be found in the corresponding tables.

- If you still can't unscrew the chip, you can try to remove it in this way. Drill a hole in the bolt with the largest possible diameter, taking care not to damage the threaded connection. Then take the appropriate tap and cut a thread in the hole. During this process, the threads are cleaned and the remnants of the bolt are removed.

Option one

If part of the screw or self-tapping screw protrudes above the surface, you can try to grab this tip with pliers. Experts advise using thin pliers known as platypuses. Then, by turning counterclockwise, pull out the fasteners.

However, if a screw or self-tapping screw is screwed in deeply, there is simply nothing to grab onto. In this case, you will have to touch the surface into which the fastener is screwed. Yes, it will be damaged and it will have to be fixed later. But sometimes there is simply no other way out.

If a self-tapping screw or shurpa is screwed into a tree, you can get to them with a chisel. In the case of a concrete surface, you can drill a shallow surface nearby or make cuts with a grinder in order to be able to grab the fastener with pliers, pliers.

If a self-tapping screw was used for metal, then it remains only to make additional holes nearby in order to get close to it with platypuses.

Suppose that the cap on the self-tapping screw or screw remains, but the slot is torn off, as many craftsmen say - "lapped", seamed. A screwdriver or drill simply breaks off such a fastener. The easiest way to deal with this problem is to use a piece of rubber or any rubberized material. For example, a medical harness or a bicycle camera will do. We cut out a small rectangular or square piece from the material and put it on the head of the fastener with a torn off thread. Then we rest with a screwdriver and begin to carefully unscrew. Rubber creates additional grip, the metal screwdriver no longer breaks off the slippery metal head and does its job. If the rubber is damaged or torn during operation, just take a new piece and continue twisting.

Why are the edges of the screw torn off?

There are several negative factors explaining why the head does not unscrew:

- corrosion of the metal, as a result, the structure of the material is disturbed, it loses its properties, becomes less durable, crumbles, this leads to the fact that the master cannot dismantle during the repair by unscrewing the rusty fasteners;

- the screw tends to rotate if it was installed in a structure made of the wrong material.

The problem of how to unscrew the screw arises when the rules for using the tool are violated.

The problem arises when the rules for using the tool are violated

The problem arises when the rules for using the tool are violated

crosshead screwdriver

Possible causes of damage to fasteners:

- poor quality of the tool: the metal is too soft, which contributes to the constant slipping of the screwdriver, sharp edges are dull due to wear, this also does not allow the screw to be firmly fixed in the slot, in addition, the tool may be incorrectly selected for such work (does not correspond to the size of the head);

- weak efforts in the process of unscrewing the fasteners, while the screwdriver is not held in the slot, constantly slides off, as a result the head is deformed, for this reason it is called "licked";

- at the installation stage, the fasteners were installed in a structure made of material that does not correspond to the screws, because of this it scrolls, with a screwdriver it will not be possible to pull out such hardware.

The tool may be incorrectly selected for the job.

The tool may be incorrectly selected for the job.

Screwdriver bit

A common problem with power tools is the wrong speed. Moderate force is used to drill out the fasteners. The operating time of the screwdriver should be short. If you drill a screw vigorously, the slot will deform. As a result, it will be necessary to additionally solve the question of how to unscrew a screw with a damaged head, which will increase the duration of the work.

If you drill a screw intensively, the slot will deform.

If you drill a screw intensively, the slot will deform.

When the fastener bolt turns

It rarely happens when a bolt turns in a threaded hole, how to unscrew it, we will consider in more detail.

First you need to pry the product with a nail puller and try to pull it out as high as possible. Leaving the connection in tension, slowly turn it out with a key. If a nailer is not available, you can use a screwdriver. If the bolt is small, you can remove it with pliers.

The head is clamped and pulled upward with force. If it was not possible to remove the bolt immediately, then start rotating the head clamped by the pliers counterclockwise, without loosening the upward force.

These lubricants are designed for rubbing parts. If you lubricate a bolt or nut with them, over time the grease will harden and will be more difficult to unscrew than a rusty bolt. It is better to lubricate the bolts and nuts when tightening them with graphite grease.

You can buy it at any car dealership.

I hope that the article was useful and helped you find a way out of a difficult situation.

Ways to unscrew bolts, screws, screws with lapped edges

If in the usual way it was not possible to unscrew the fasteners whose edges were licked off, you can use one of several proven options.

Gas wrench

This method is used when loosening bolts, since they have a head protruding from which you can grab. For this:

- Clean the head of the bolt.

- Lubricate the junction with kerosene or diesel fuel, a liquid like WD-40 helps well, and leave for 15–20 minutes.

- Unscrew the bolt. This is done with a gas wrench. With its help, a large force is created and even a round head can be well gripped.

The disadvantage of this method is that it is not always possible to get close to the desired bolt with a gas wrench.

Slicing new faces

If the bolt is large, then with the help of a grinder, new faces can be cut on it. It is enough to make only 4 of them and use a smaller wrench to unscrew the bolt. It is possible to cut new faces on the bolt with a file, but this is more difficult and takes longer. On the head of a screw or screw, you can make a cut with a hacksaw for metal or a grinder.

Hammer and chisel or impact screwdriver

This option is more suitable for lapped nuts or large enough screws. The chisel rests on the head of the fastener and, hitting it with a hammer, gradually turn the screw or nut. Small screws or screws can be removed with an impact screwdriver and hammer. After loosening the fastening, the work is done with an ordinary screwdriver.

A tourniquet or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of dense rubber.The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

Extractor

An extractor is a special tool that is used to loosen screws, bolts or screws with lapped or broken heads.

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the lapped screw slot.

- An extractor of the required diameter is selected. Drive or screw it into the prepared hole. It depends on whether a conventional or a screw tool is used.

- Unscrew the bolt.

Video: unscrewing the licked screw with an extractor

Conventional or left hand drill

Left hand drills with counterclockwise rotation are available. They improve the centering of the tool and reduce the stress on the drill, which results in higher productivity and accuracy of drilling. By inserting such a tool into the drill, you can unscrew the screw or licked screw head. If a left-hand drill is not available, you can try drilling out the jammed fasteners with a regular drill. In this case, you need to take a drill, the diameter of which is less than the diameter of the bolt or screw.

It is necessary to act carefully so that you do not have to cut the threads for the new fastener later.

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called "cold welding". After the glue securely fixes it, turn the nut with a wrench and unscrew the screw or screw with it.

Welding

If there is a welding machine nearby, then you can fix a new nut on the head of a bolt or screw by welding it. After that, it can be unscrewed immediately.

Solder and soldering iron

If you need to unscrew a small screw or screw, use a soldering iron and solder:

- The heated solder is dripped onto the head of the fastener with lapped edges.

- Until the tin has solidified, a screwdriver is inserted into it and wait a few minutes.

Ways to unscrew bolts, screws, screws with lapped edges

If in the usual way it was not possible to unscrew the fasteners whose edges were licked off, you can use one of several proven options.

Gas wrench

This method is used when loosening bolts, since they have a head protruding from which you can grab. For this:

- Clean the head of the bolt.

- Lubricate the junction with kerosene or diesel fuel, a liquid like WD-40 helps well, and leave for 15–20 minutes.

-

Unscrew the bolt. This is done with a gas wrench. With its help, a large force is created and even a round head can be well gripped.

The disadvantage of this method is that it is not always possible to get close to the desired bolt with a gas wrench.

Slicing new faces

If the bolt is large, then with the help of a grinder, new faces can be cut on it. It is enough to make only 4 of them and use a smaller wrench to unscrew the bolt. It is possible to cut new faces on the bolt with a file, but this is more difficult and takes longer. On the head of a screw or screw, you can make a cut with a hacksaw for metal or a grinder.

A deeper cut can be made on the head of a screw or screw for a screwdriver

Hammer and chisel or impact screwdriver

This option is more suitable for lapped nuts or large enough screws. The chisel rests on the head of the fastener and, hitting it with a hammer, gradually turn the screw or nut. Small screws or screws can be removed with an impact screwdriver and hammer. After loosening the fastening, the work is done with an ordinary screwdriver.

An impact screwdriver can be used to unscrew small or lapped screws

A tourniquet or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of dense rubber.The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is laid between the screwdriver and the head of the screw or screw

Extractor

An extractor is a special tool that is used to loosen screws, bolts or screws with lapped or broken heads.

Extractor - a tool for loosening screws, bolts or screws with lapped or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the lapped screw slot.

- An extractor of the required diameter is selected. Drive or screw it into the prepared hole. It depends on whether a conventional or a screw tool is used.

-

Unscrew the bolt.

Video: unscrewing the licked screw with an extractor

Conventional or left hand drill

Left hand drills with counterclockwise rotation are available. They improve the centering of the tool and reduce the stress on the drill, which results in higher productivity and accuracy of drilling. By inserting such a tool into a drill, you can unscrew the screw or screw with a licked head. If a left-hand drill is not available, you can try drilling out the jammed fasteners with a regular drill. In this case, you need to take a drill, the diameter of which is less than the diameter of the bolt or screw.

It is necessary to act carefully so that you do not have to cut the threads for the new fastener later.

The drill should have a smaller diameter than the problematic bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called "cold welding". After the glue securely fixes it, turn the nut with a wrench and unscrew the screw or screw with it.

With the help of glue, the nut is fixed to the licked head, and then the screw is unscrewed with it

Welding

If there is a welding machine nearby, then you can fix a new nut on the head of a bolt or screw by welding it. After that, it can be unscrewed immediately.

A new nut can be welded to the problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or screw, use a soldering iron and solder:

- The heated solder is dripped onto the head of the fastener with lapped edges.

-

Until the tin has solidified, a screwdriver is inserted into it and wait a few minutes.

- Unscrew the problem screw and clean the tip of the screwdriver from the solder.

Technique for unscrewing a screw with torn edges

If a trouble with the screw still occurred (a screwdriver or a bit began to turn, jumping over the edges), you do not need to despair and try your best to turn the "stubborn" or even worse hammer him in, but simply stop and take all possible actions to remove the fasteners from the body of the material. Moreover, depending on the circumstances, you can use one of the following methods to solve this problem.

Removing the screw

The first step is to try to remove the deformed screw using the standard method, by unscrewing it. However, this operation should be done only with a high-quality tool, which may require the purchase of additional equipment (bits, screwdrivers).

If the above action did not give the desired result, and the edges of the screw "licked" even more, then you will have to apply more radical methods.

So, if the screw is not screwed into the body of the material for its entire length and the head protrudes slightly above the plane of the material, then it can be unscrewed using pliers, round-nose pliers or a gas wrench. For this, it is enough to squeeze the screw head with the sponges of the locksmith tool and unscrew the fasteners counterclockwise.

When the screw is completely screwed into the body of the material, then it is unlikely that it will be possible to unscrew the fasteners without damaging the above method. Alternatively, it is advisable to use the following techniques.

Sawing edges

Allows you to provide a screw with a recess of 2-3 mm, with which (using a flat screwdriver with a sharp tip) you can unscrew the product. And it is quite simple to make such a slot using an ordinary metal sheet.

Threading

On a professional level, a stuck screw can be unscrewed using a special tool (left-hand thread tap). For this, a hole with a diameter smaller than the diameter of the screw should be drilled in the body of the fastener, and after that, an extractor should be screwed into the resulting hole (counterclockwise) and when it stops, unscrew the fastener.

If all the above methods did not lead to the desired result, then the screw with the torn off edges is simply drilled with a drill with a drill for metal.

Where to begin

Assess the degree of complexity of the problem: if a torn off screw is sunk into the structure of the material, complex methods are considered; to remove fasteners at the screw-in stage, use pliers - they grip the head and unscrew it.

Before starting the procedure for removing the product, check that the correct screwdriver is selected. For this, all types of tools are checked. If initially the screwdriver is incorrectly selected, then there is no need to perform complex procedures for removing the fasteners. The problem will be solved by replacing the tool.

Precautionary measures

When a method is selected on how to unscrew a screw with torn off edges, it is necessary to adhere to the recommendations:

- when using an auxiliary tool, the intensity of the applied forces should be controlled: sometimes, in order to quickly remove the fastener, you have to press harder on it, but the situation will worsen in this case and, conversely, too careful actions with weak pressure will lead to an even faster erasure of the slot edges;

- when the fasteners are unscrewed too intensively, or an auxiliary tool is used, during work with which metal shavings are formed (hacksaw for metal, etc.), it is necessary to periodically remove it, since the presence of foreign particles causes insufficient tightness of the tool to the edges of the slot, what will slow down the work;

- it is recommended to wear protective goggles when removing a screw without a cap, since metal chips may form during the procedure when using a power tool;

- you need to know which way to unscrew the screw, so, in most cases, hardware is made with a right-hand thread, which makes it possible to install fasteners by screwing in a clockwise direction, and it is removed, on the contrary, when the screwdriver moves in the opposite direction.

When using an auxiliary tool, the intensity of the applied forces should be monitored.

When using an auxiliary tool, the intensity of the applied forces should be monitored.

Rusty screw

Before dealing with the question of how to unscrew a self-tapping screw that is prone to corrosion, all available methods should be considered:

- a blow to the fasteners, in this case there is a violation of the integrity of the shell of rust, thanks to the vibration generated by this, it will be easier to unscrew the rusted screw;

- use of a percussion instrument: the effect obtained is the same as in the first case, a manual or mechanical impact screwdriver is suitable;

- if the question is being decided how to unscrew a broken screw, which scrolls when trying to remove it, and in addition is covered with rust, the heating method should be used, while the metal expands, after cooling the product will decrease to its original size, as a result, the integrity of the shell of rust is violated, which allows you to quickly remove fasteners;

- an alternative method is the use of the chemical WD-40, a rust converter is used, which destroys the formed shell, but a positive result can be obtained only if the entire surface of the screw is processed, this condition is often difficult to fulfill.

If corrosion occurs, all available methods should be considered.

If corrosion occurs, all available methods should be considered.

Precautionary measures

The process of unscrewing faulty fasteners may seem simple and harmless, but in inexperienced hands there is a risk of accidents.

To ensure safe removal of fasteners, it is important to adhere to certain safety measures.

- Use protective equipment such as goggles and gloves to keep your face and hands safe in the event of unexpected breakage of the tools used. Inexperienced craftsmen must always use protective equipment until their skill reaches the required level.

- Use only proven and high-quality tools. Before any work, you need to make sure that the tool is in good working order and corresponds to the occupation. And only after that, get down to business.

- Prepare fastening materials in advance, which will replace the problematic screws. If the use of these fasteners has shown its ineffectiveness, then they should be replaced with nuts and bolts.

- Before starting to unscrew the deformed fastener, it is necessary to determine in which direction the thread is directed, so as not to complicate the already difficult task of removing it.

- Selection of the optimal pressure on the tools. If you press too hard on the screwdriver or screwdriver, then you can completely ruin the head of the screw, after which it will become even more difficult to unscrew it. With an increased load, there is a high risk of breaking the cross or even splitting the fasteners.

When planning measures to extract a self-tapping screw that does not lend itself to standard unscrewing options, you need to find not only an effective option, but also one that will be within your power. The choice of a too complex technology for performing a task by a beginner can cause unpleasant consequences in the form of injuries and a disappointing final result of the work.

Each master should have in his arsenal several options for action in such situations, which have already been tested more than once. The success of a business depends on a number of factors, but an inexperienced individual may not be aware of them.

Cautions

- Welding is very dangerous and should only be performed by specialists.

- If you are using a bolt extractor, it can get stuck in a frayed bolt and be difficult to remove. You can try using it again, and then at least you will remove the bolt.

- Make sure that the object you are removing the bolt from is well secured and under control so that if it slips out, you will not be hurt. You may need to put a little effort into this.

- Metal shavings from the bolt can cause injury or mechanical damage.

- Electrical tools can be dangerous and should only be used under adult supervision. Follow instructions and wear safety glasses.

Finally

Torn off slots on the head of a self-tapping screw or screw, this, of course, is unpleasant, but not fatal. In such cases, do not immediately give up your hands, reaming the surface around the screw. You can find a way out of any situation, which means it is better to try to use the options described in the article. That being said, it is best to start with the simplest ones, such as leather and rubber. If there is an extractor in the home tool kit, then you can forget about the other methods - this way will be the easiest.

The main thing to remember is that a correctly sized bit significantly reduces the risk of splines breaking.

The main thing to remember is that a correctly sized bit significantly reduces the risk of splines breaking.

Finally, we bring to your attention a short video on today's topic, from which you can glean a lot of useful information about extractors.

Previous DIY HomiusAmazing Side by Side: 9 Ways to Use Old Forks and Spoons

The next DIY Homius18 best life hacks for a gardener without investment