Tips & Tricks

Working with putty is not difficult, you just need to follow some rules and recommendations:

- It is better to immediately buy the required amount of the mixture.

- When leveling corners, it is advisable to start leveling the walls right away. This speeds up the process and prevents the formation of transitions.

- To return to interrupted work with putty, simply moisten it with water.

- The mixture should be of a pasty consistency, in case of lumps or crust formation, work with it is no longer possible.

Puttying corners is not difficult, but laborious and requires training and experience. You will always need a lot of plaster, especially for leveling, you need to be prepared for this. How to putty the ceiling with your own hands video for a beginner for painting?

A room with even corners always looks beautiful, and it is much easier to decorate them.

Additional Information: How to properly putty corners for painting

Advice! You can often hear that you need to chamfer a corner. Yes, this is a justified procedure to avoid its destruction.

But the appearance is lost. This can be avoided if the final coating is wallpaper. Or additionally strengthen the corner with PVA glue added to the putty.

- First you need to determine how obtuse or sharp the angle is, ideally it should be 90⁰. If it is too round, then plastering will be necessary.

- Before puttingty on drywall, it is necessary to glue it with a serpentine mesh for a reliable connection.

- Align the surfaces joint to joint.

- Place the mixture in the resulting gaps, level the surface again and remove excess mortar. You can use an angled spatula here to make the job easier.

- Check the building level for the degree. If necessary, putty to a correct right angle.

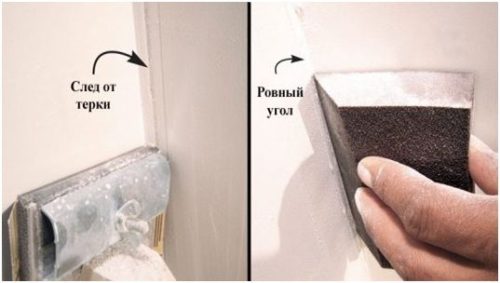

- It is impossible to make an ideal corner with putty, it always turns out to be rounded. Therefore, it is necessary to grind the surface with a float.

Interior corner trim

Filling is a preparatory procedure for surfaces before their final finishing. Such cladding allows you to align the walls and make them smoother. What kind of putty is better to putty drywall for painting?

But not many people know how to putty the corners. Corner processing has its own characteristics and nuances. This article will discuss how to properly putty the corners of the walls and what materials and tools you need for this.

It is necessary that the corners are even and strong so that they do not crack or crumble when the building shrinks. Aligning them with putty increases the adhesion of the wall with paint or wallpaper. Also, when planning the subsequent pasting of walls with thin wallpaper, you need to make everything as even as possible, otherwise all defects and flaws will be clearly visible.

The question of how to putty the corners so that they are neat and even worries many home craftsmen. After all, if applying putty on a flat wall is not difficult, then irregularities or ugly influxes are obtained in the corners. But is it possible to achieve ideal wall angles, or is it only professionals can do it?

When choosing the right composition that will be used when aligning the corners, you need to pay attention to the number of grains in the solution. This indicator affects the quality of the future facing coating: the lower the indicator, the thinner and better the finishing layer will be.

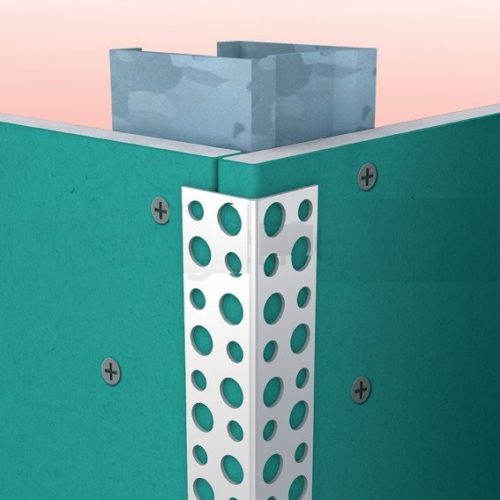

Experts recommend not to try to show miracles of dexterity, trying to get the perfect edge with just a spatula, but to use special perforated corners. The corner not only greatly facilitates the filling process, but also increases the strength of the edge of the outer corner of the wall.

When renovating an apartment, after leveling the walls, it is the turn of the corners putty. After all, perfectly flat walls are not all. Putty on the outer and inner corners is necessary to make them even and neat, while strong and durable.

Without skills and understanding of the process, the preparation of walls and ceilings for finishing will not take place. We will figure out how to putty the corners of the walls correctly, and what tools will be needed to successfully complete the work.

After the drywall is fixed to the frame or glued to the surface, it is time for finishing work. And if everything is more or less clear with even bases, then few know how to putty the corners of the walls. As a result, in these areas, cracks often come out later, or even whole pieces of decoration fall off.

Forming a corner

There are two types of corners: external and internal. They differ in shaping technique.

Particular attention has to be paid to the first

Outer

Making the outside corner perfect is not an easy task. Therefore, it is better to use special corner pads, which make the work much easier and faster.

Outside corner trims

Outside corner trims

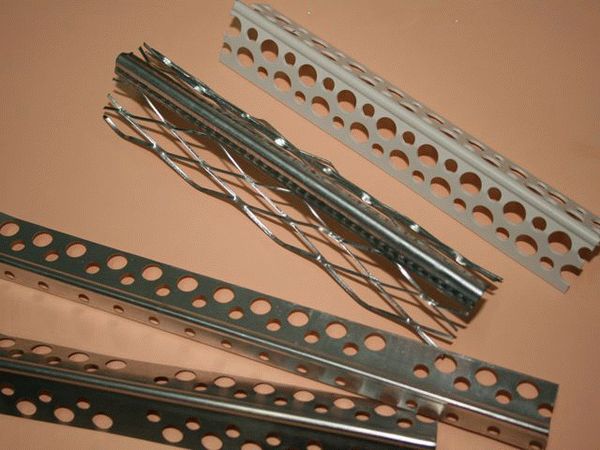

There are several types of overlays:

- Metal For production, an aluminum alloy or thin steel is used. All products are perforated. This reduces weight and also allows it to be “sunk” much deeper into the wall. Unfortunately, corrosion is common and can show through to the surface.

- Plastic Almost identical to metal, but do not undergo degradation processes. They are used only when applying a fairly thick layer, several layers. This is due to their significant thickness of the sides.

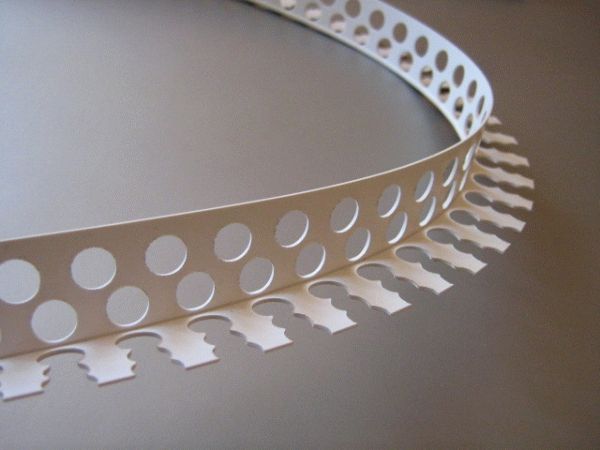

- Flexible parts These products are used to work on curved surfaces. They can align the edges of the arches. They do not break and easily take the desired shape.

Arched corner

Arched corner

Work technology

Working with corner elements requires adherence to a certain technology. It consists in the following:

- The putty is applied to the wall - along the entire height of the corner.

- A corner piece is applied and well pressed into the previously applied solution.

- Now you need to use the level. They measure the correct fit, align if necessary. To do this, add the solution in small portions.

You need to wait a little, the solution should set. It is advisable to measure it again by level. Often the solution gives a slight shrinkage, it must be compensated for.

Puttying the outer corner using a metal perforated corner

Puttying the outer corner using a metal perforated corner

The work does not end there:

- Now you need to apply the solution to the patch itself. To do this, in turn, it is thoroughly coated on both sides. This is easy to do with any medium trowel for wall putty.

- All excess solution is removed. After that, you can finally align the walls.

We are waiting for the complete drying of the surfaces. After that, we proceed to a thorough sanding. This must be done carefully. Excessive efforts in the places where the corner is installed lead to its bleed-through, which means that the work will have to be repeated again.

Further, everything should be well impregnated with a primer. And a decorative layer can be applied. The corners will be even, and it turned out to be not so difficult to make them.

Interior

Aligning the interior corners is not always as easy as it might seem. Although it is believed that they can be given a little less effort.

- Before you putty the corners, you need to decide how much they are curved. Perfectly even corners are almost impossible to meet. They can often be sharp or rounded.

- You need to understand that large differences can only be corrected by applying plaster. To do this exclusively with putty, and even a finishing layer, will not work.

- Before filling the corners of drywall, they should be glued with special paper or serpentine mesh, thus ensuring a reliable connection of the two sheets at the junction.

Plastering the wall should always start from the corner.

Plastering the wall should always start from the corner.

Leveling technique

Each master has his own technology for leveling with putty. The following is often used:

- Work begins precisely from the corner. The fact is that in this way it is possible to bring the walls out as evenly as possible. If you start with the walls, you will have to put in a lot more effort.

- Walls can be piled up to the top or bottom. Therefore, the angle is constantly checked.

- The solution is first applied to one wall, then to the other. Better to immediately capture a significant section of the wall. A small rule comes to the rescue.

- It is required to constantly monitor the process.

It is almost impossible to form a perfect angle; a slight rounding is obtained. It is removed by grinding. This is done in several stages:

A hand grater works well. Sandpaper is attached to it

It is important that it overlaps the edge of the tool.

Sanding starts from one of the walls. Alternately, you need to go to the next

Grouting is carried out with the side on which the sandpaper is wrapped.

By making quick and energetic movements, it is possible to achieve an even angle.

The final stage of filling corners is sanding

The final stage of filling corners is sanding

Plasterboard corners

It is not necessary to putty the corners, it depends on whether you want the corners of your rooms to be symmetrical and you can save on this. well, very rarely). And also, if in the future you use thick vinyl or non-woven wallpaper for decoration, because small errors under them will not be so noticeable.

The use of paint will emphasize them. Also, if sanding under paint is done on all surfaces, and under wallpaper - in places where roughness is revealed. To apply putty on the inner corners, a special spatula with a 90º angle is used. Such corners are much more difficult to align than outside corners, because there is little room for maneuver.

In addition, if the corner is plasterboard, it takes a day. When the start dries up, you can proceed to the finishing layer, again using a regular spatula. Roll the finish around the perimeter as thin as possible.

When it dries up a little, gaining plasticity, we level it with a special angled spatula. The type of putty depends on the purpose of the room, which is being finished. For the kitchen and bathroom, cement is suitable, which is not damaged by high humidity.

Dries 1-2 hours. Gypsum is used in interior decoration, except for the bathroom, because there it will lag behind the wall over time. Gypsum dries for 2 hours. There is also a mixture of lime and cement for facade finishing that can withstand all weather conditions.

It also dries for 1-2 hours. We take a small spatula, apply the composition to the places where the screws are installed, remove the excess. There should be just enough putty in this place so that the surface is even. Thus, we go through all the screws. They can be sealed in parallel with the seams, or you can - first of all.

The first layer is applied with a starting putty. It is laid in a layer of about 5 mm (the maximum should be seen in the instructions for a particular putty) and hides all the irregularities.

Dilute it with water to a thick sour cream, stir thoroughly so that there are no lumps.

- Serpyanka.

- Fiberglass tape.

- Perforated paper. Some firms offer fiberglass paper tape, which is considered the most modern type.

- Not expensive paper tape.

If canvases in the form of PVC panels, MDF and similar building materials are used on drywall, the base does not need to be putty, it will be enough to treat it with antiseptic solutions or soil, especially in rooms with a high humidity threshold.In order for the plastering of drywall corners to pass without problems, use the following materials that will help you in your work: By clearly following the instructions, you will simply achieve the desired results, or rather, strong and even corners that are already ready for further upcoming finishing. First you need to prepare the putty in full accordance with the instructions, if it was purchased in the form of a dry powder. To do this, putty is slowly poured into a container with clean water and stirred with a construction mixer for about 10 minutes. After that, let it stand for another 10 minutes and stir again.

Some craftsmen prefer to make additional fastening of the semicircular corner using a construction stapler, but without applying a preliminary layer of putty.

Features and Benefits

Dry putty has a number of advantages over other finishing materials. The first, and perhaps most importantly, is the low price. It is not difficult to make a solution on your own, but it will cost a penny.

The second advantage is that it well bridges all kinds of cracks and irregularities. If the wall is damaged, there are faults on it, then plaster will help correct the situation. Under a layer of this material, all imperfections will be invisible, and you can safely paint or cover it with wallpaper.

Finally, it is easy to apply. Even if you have absolutely no experience in repair work, you are still able to level surfaces of slight curvature yourself using quality material.

Create a corner by level

How to properly putty the corners of drywall under the wallpaper? The work is very painstaking, without skills, which is impossible to complete. If you have never dealt with this process, then it is worth practicing a little in one area, and only after you understand the principle of this process, perform further actions.

Outside corners

To make the outer corner even, beautiful, the work is done according to the following technology:

- The outer edge of the intersections is a place of constant impact. It is often damaged by mechanical stress.

- To protect such places, a galvanized perforated corner is installed. A small amount of putty mixture is applied on both sides of this profile.

- Until the composition is dry, the perforated element is put in place and pressed into the solution. This should be done carefully so as not to "crush" the aluminum corner. The work is checked by the level.

- Excess putty is removed with a spatula, the work is left to set the composition.

- Then a layer of putty is applied, which evens out the corner and the surface of the wall.

Corner profile on putty

Corner profile on putty

After everything is dry, you need to sand the surface well and repeat the putty process.

Corner of plasterboard construction with PU and putty

Corner of plasterboard construction with PU and putty

Internal corners

It is much easier to work with the internal elements of the surface, this is the joint of drywall sheets, which is often even. How to putty inside drywall corners:

- Pick up a small amount of the mixture on the spatula.

- Treat with the composition first one side of the corner, then the other, this will help to bring the walls and partitions out of the gypsum board in level.

- If there is a gap between the plates, then it is well clogged with putty. Excess composition is removed with a spatula, which is set at 30 degrees.

- As soon as the mixture dries, the surface should be well sanded; at the end of the process, dust is removed with a rag.

- Stick on the reinforced tape, which is already prepared and has a certain shape. It is good to buy self-adhesive material for this purpose.

- Irregularities are determined by level or long rule.

- The second layer removes irregularities from the corner and putty everything, while the reinforced tape is hidden. Then the surface is sanded.

- After complete drying, the surface is sanded with sandpaper. For convenience, a special bar is taken.

Laying in the corner of the reinforcing tape

Laying in the corner of the reinforcing tape

Grouting drywall corners

Grouting drywall corners

As you can see, there is nothing difficult in arranging the corners, both internal and external. It is worth a little practice before large-scale work, then there will be fewer mistakes, and the work will be of high quality the first time. You do not have to spend the solution to correct irregularities.

Watch the video: the process of filling the inner corners.

Corner filling technology

In appearance, external (external), internal and curved angles are distinguished. Each type has its own shaping and finishing technology. Particularly you should consider the option of how to putty the corner of the wall at the points of abutment to the ceiling.

Outdoor

To simplify the process of do-it-yourself puttying of an external right angle, it is convenient to use special corner strips with perforated shelves. They are made of galvanized steel or plastic. Plastic corners are more practical because are not subject to corrosion, traces of which can eventually appear on the surface of the wall if metal is used.

The order of work is as follows:

- apply a thin layer of putty all over the corner;

- attach the perforated corner to the surface and press it into the solution;

- using the building level, check the vertical and general correct fit;

- in case of deviations, align the position of the corner, lubricating putty under it;

- wait until the mortar sets and then apply the putty mortar to the wall surface on both sides of the corner.

After the putty has dried, treat the surface with an abrasive mesh and saturate it with primer 2 times. Cement mortars can exhibit slight shrinkage, which can be compensated for by applying a thin layer of the mixture and re-sanding.

Internal corners

Putty on the inner corners is a little more difficult. Especially in cases where their size is different from 90 °. When performing the work, it should be remembered that the layer of putty should not be more than 2-3 mm. Large differences are leveled only by classical plastering.

Putty is applied from the corner towards the plane of the wall. Very often, the angular vertical is heaped up or down. Therefore, during finishing, the surface must be constantly checked for this parameter. In this case, each of the walls is putty separately.

It is very difficult to obtain the ideal angle by applying mortar and leveling with a trowel. The desired result is achieved as a result of finishing sanding of each wall separately. Grouting should be done with plaster abrasive mesh No. 100-120.

Curved corners of arches

Manufacturers of building materials produce flexible plaster corners especially for arched sections. They have one of the shelves with cuts across the entire width, and provides the ability to bend a straight line. The rest of the technology for puttingty curved surfaces is no different from finishing the outer corners.

Places of abutment of walls to the ceiling

The corners between the walls and the ceiling are also internal. The peculiarity of their finishing is that the putty is made only after the plastering of the walls is finished and perforated plaster corners are not used. The application of the solution to the ceiling should be done with a minimum layer.

The leveling process is mainly aimed at obtaining an even surface of the wall, since floor slabs are usually even so. If the slabs do not match in terms of installation height, then it is best to consider the option of a stretch or false ceiling, and in this case, filling is not required.

What are and when to use

Putty is the preparation of surfaces for final finishing. With its help, they ensure that the wall is (or looks) perfectly flat. It is applied on relatively flat surfaces. If you need to level the walls, bring out the corners at 90 °, do this with plaster or drywall. The putty is not intended for this.

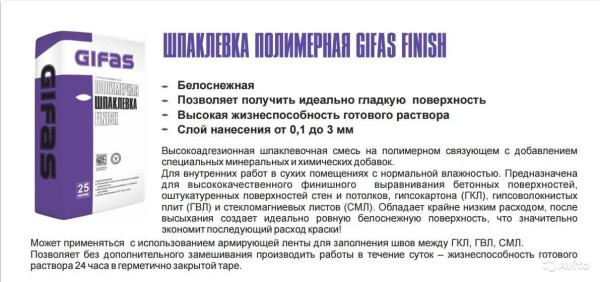

Putty is sold in a wide range

Like plasters, putties are composed of a binder, filler and additives that give them special properties. They are distinguished from plasters by the use of aggregates - sand - fine fractions. Binder is used of two types - cement or gypsum, sometimes lime and polymer additives are added to them. Accordingly, there are gypsum and cement putties.

There are also polymer putties - acrylic and latex. They are based on synthetic substances, the properties of which change depending on the additives. They are not natural, but have a longer service life, and also withstand more freeze / thaw cycles. For facade work, it is better to choose them. Indoors, they are not the best choice, as they have low vapor permeability, which can cause dampness of the walls, the appearance of fungus and mold. They are convenient because they can be used on wooden and metal surfaces.

Brief description of the properties of polymer plasters

According to the type of application, all putties are divided into two types: starting and finishing. In the starting ones, grains of sand of a larger size are used - 0.3-0.8 mm. As a result, the surface is slightly rough. They are used at the first stage to seal cavities and cracks. In finishing compositions, sand is practically dust with a very fine grain of 0.1-0.3 mm. This results in a smooth surface.

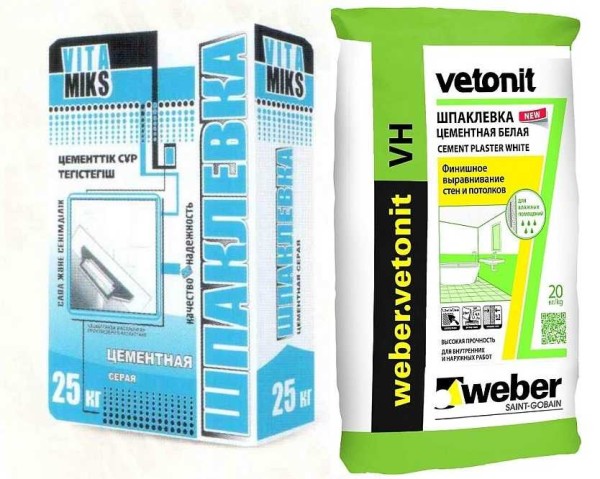

Cement plasters - scope, advantages and disadvantages

Cement plasters are cheaper than gypsum plasters, they can be applied in a thicker layer - some compositions are up to 10 mm. After mixing (stirring with water) can be used for about 3 hours. The plasticity of the composition is influenced by temperature and humidity. Usually it is indicated for + 20 ° C and humidity 60-65%.

Cement plasters are versatile. They are used both for interior and exterior decoration. Moreover, most of the facade compositions are made on the basis of cement, as they withstand more defrost / freeze cycles and create a more durable surface. They also do better in damp rooms. If you need to plaster a bathroom or kitchen, it is better to use a cement-based compound.

Cement plaster can be white or gray

Cement renders can be gray, white and ultra-white in color. It depends on the type of cement used. White compositions are more expensive, since more expensive brands are used, therefore finishing compositions are more often made white.

The disadvantage of cement plasters is a long setting time - several days for complete drying - this is the norm. Several hours should pass before applying the next layer. From 2-3 hours at a layer of 1 mm, up to 24 at a thickness of 6 mm. Since it is rarely possible to achieve an even surface in one layer - there can be three or more of them - then the filling with cement plasters takes a long time. For this reason, their popularity is rather low.

Gypsum putties, their features

The layer of plaster putty is 0.5-10 mm, depending on the type. They dry much faster, which has a positive effect on the speed of finishing work. On the other hand, the mixed composition must be used within 30-60 minutes, so such putties are kneaded in small portions. This is not very convenient. If you are going to putty the walls with your own hands for the first time, start with small batches. Gradually figure out how much you can work out at a time. Also note that the consumption of the starting plaster is greater than that of the finishing plaster - the thickness of the layer is different and do not be mistaken in the volume.

Gypsum plasters without modifying additives are intended for dry rooms. There are compositions for wet ones, but this must be indicated on the packaging, since they contain hydrophobic additives.

Gypsum plasters are easy to apply

Despite the higher price and short shelf life of the mixed batch, gypsum-based plasters are now more popular.They are more plastic, with their use it is easier to achieve the required surface smoothness, it is easier for beginners and professionals to work with them. If the putty of the walls is still unfamiliar to you, use gypsum compounds.