Are you here

How to change a button on your jeans yourself.

A typical case. On jeans with a broken button on a broken leg. The property of this type of buttons is to jump off the rod under increased load. Removing the remains of a button. We remove with a side cutter in one motion. Then the process of installing the button, according to your desire.

Remove the unnecessary denim button.

A) On a broken leg:

If you disassemble the button on the seamy side of the product, you can damage the fabric, so we bite off the button on the front side.

B) On a stable leg: First, bite off the leg of the button, then what is left. With this method, the tissue is not damaged at all.

Peculiarities

Riveting is one of the options for non-collapsible assembly of parts. The advantage of this method is its low cost. Consumable material - rivets - are relatively inexpensive. You can buy them at any store that sells fasteners.

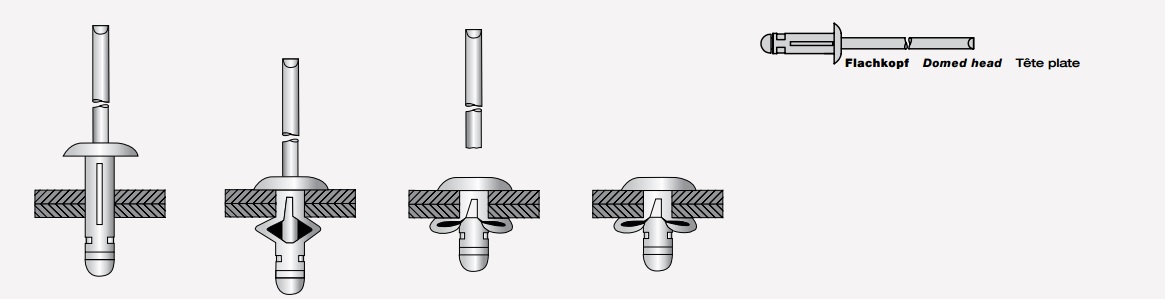

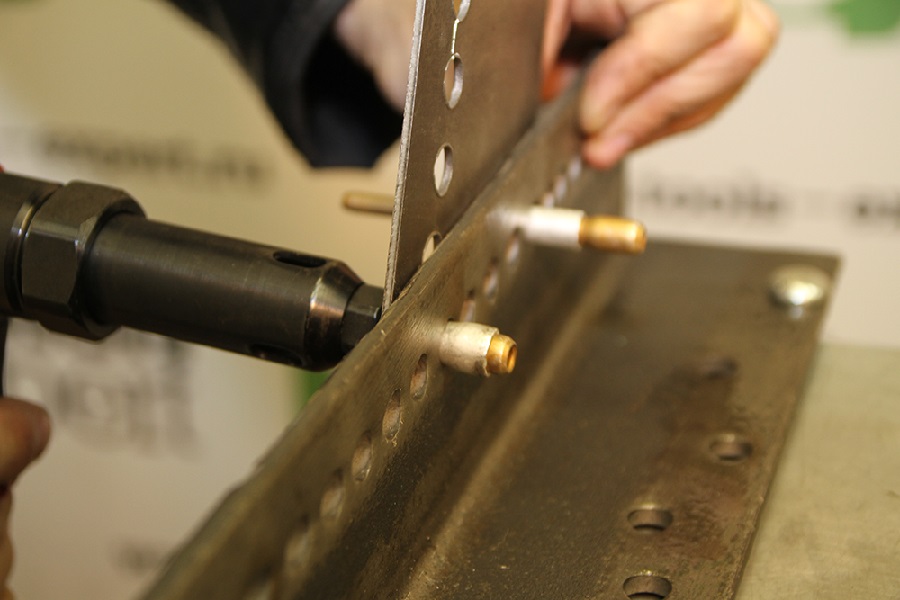

Modern materials are divided into two main types: threaded and exhaust. Both are essentially hollow tubes with a cap at one end. In the first case, a thread is cut inside the tube, and in the second, a rod with a thickening at the end is inserted into it.

Usually, to install a large number of standard rivets, a special tool is required - a riveter. It can be electric, pneumatic, or manual. The use of this equipment allows to reduce the physical efforts associated with crushing a metal rivet. These tools are not cheap at all, this is what becomes the main reason for refusing to use rivets in everyday life or for small repairs. Indeed, the purchase of an expensive tool for the sake of one or two rivets is hardly justified.

Below we will consider how to install a rivet without special equipment.

What do you need?

So let's get started!

Given: parts that need to be connected, but at the same time cannot be welded, for example, so as not to spoil the painting.

Objective: Install no more than 4 rivets.

The task: to rivet without a riveter, since it is not available, but it is quite expensive, and the purchase for the sake of 4 rivets is completely unjustified.

Given: threaded rivets and ... what is in the garage, plus the notorious ingenuity, without which in this case there is nothing at all.

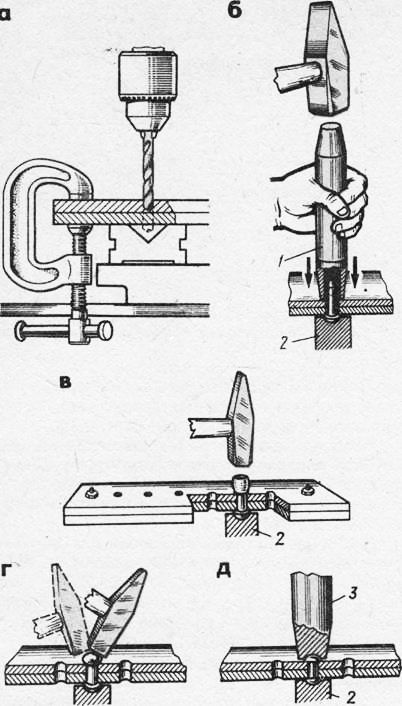

Having rummaged in the deposits of any iron trash accumulated over the centuries, you need to find a long bolt that matches the diameter and thread pitch of the existing rivets, or, conversely, purchase rivets of the corresponding parameters, if such a bolt already exists.

Next, you need to build the simplest riveter, with which you can roll the rivet. To do this, you should select:

- a steel sleeve, for example, made of a nut of a slightly larger diameter than the already mentioned bolt;

- at least 2 washers with a hole diameter corresponding to the diameter of the bolt;

- a small bearing (some craftsmen consider the bearing to be superfluous);

- a nut that matches the size of the thread to the already indicated bolt.

A homemade riveter is mounted as follows:

- screw the nut onto the bolt;

- install the washer;

- install the bearing;

- put the puck back on;

- put on a sleeve that can be covered with another washer.

To make a homemade rivet installation device, you will need the following materials and tools:

- steel pipe with a diameter of 5 cm;

- long bolt with a diameter of 8 mm;

- a nut for the previously indicated bolt;

- welding machine;

- grinder, drilling machine, drills.

Besides the need installation of a threaded or blind rivetfastening metal or other parts and structural elements, there may be a need to install rivets as an accessory on clothes or shoes. Tools for such an operation do not have to be made from scrap materials, they can come in handy:

- screwdrivers: Phillips and slotted;

- pliers;

- hammer;

- a bolt or piece of steel bar with a flat-grinded end;

- a piece of steel tube, similar in diameter to a rivet.

The various accessories used for clothing are made of relatively soft metal and have a small thickness; it does not require much effort to rivet it.

Using a chisel

The method described above is good in cases where the work needs to be done as accurately as possible, and there is a drill and a set of drills at hand. But sometimes, if the aesthetic component is not too important, or when there are no power tools at hand, you can use another method, for example, knocking down the rivet head with a metal chisel.

Blind rivets are made from alloys of non-ferrous metals or mild steel, so it is not at all difficult to “cut down” its head with a chisel. To remove fasteners, the cutting edge of the tool is inserted under the edge of the head and then hammered until the top of the hardware is removed. Remnants of the rivet can be knocked out with a suitable punch. It should be said that this method is not sparing for the elements to be joined and, if the metal around the rivet has been painted, the coating will inevitably be damaged.

Procedure

Cylinder mechanism

As already noted, there is no need to remove this lock from the door. Only a few simple manipulations are performed:

- Dismantling the armor plate (not always installed).

- Turning the key until it stops (the tongue must be completely recessed).

- Removing the protective strip (attached to the end of the door leaf).

- Unscrewing the locking screw.

- Removing the larva. If it does not pull out, it should be slightly turned with a wrench so that the tongue aligns with the hole in the hole.

- After installing a new larva, all actions are performed in reverse order.

Lever mechanism

Here we are already talking not about a partial repair of constipation, but about its complete replacement. There are options though. If the product is imported, then it is quite possible to change the core with re-coding of the levers (internal pins ensuring the level of secrecy). Some manufacturers supply the market with spare parts with a set of keys "for them".

The algorithm of actions is the same, but there are some differences:

- the locking mechanism will have to be removed completely. The order of its disassembly is indicated in the attached instructions;

- in order to remove the lock, you must first dismantle the handles.

Crossbar mechanisms

In this case, the knowledge of how to change the lock in a metal door of a simpler design is clearly not enough. Depending on the model, there are several stops, and they can come out of the canvas in different places - both from the side and below, above. It is their presence that significantly complicates the work; if possible, it is better to remove the sash.

- The canvas is laid on the floor.

- It is partially disassembled to provide access to the internal mechanisms. By the way, in Chinese doors it is not always possible to do this on your own, and therefore you will have to contact a specialist.

- The traction of the crossbars is weakened.

- They are disconnected from the lock device.

Further, everything is similar to the procedure for dismantling / installing the lever mechanism or cylinder.

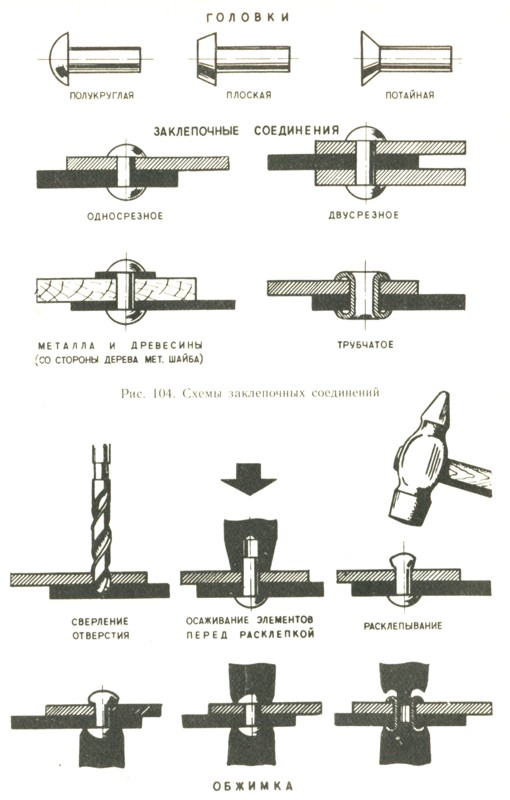

Brief description of the rivet

Many experts remember that until recently, the principle of joining metal with rivets was distinguished by many shortcomings and technical nuances. That is why it was almost impossible to carry out this procedure at home.Initially, it should be noted that the riveting process itself was accompanied by a huge number of various technological complexities, which made it very difficult to perform a high-quality connection.

To install the rivet in the right place, the craftsmen had to make a titanic effort. In addition, it was not always possible to securely fasten on both sides of the material to be processed. That is why specialists were often interested in the question of how to fix a rivet without a rivet, having only the tools at hand. But in practice, this procedure was particularly difficult, since flaring takes a lot of time and effort.

Against the background of these disadvantages, numerous experts from different countries have worked to create a high-quality and easy-to-use tool for solving such problems. Thanks to this, a manual type of riveter appeared on the mass market, which is distinguished by its compactness and versatility. The main advantage of this tool is that it guarantees a reliable connection of metal workpieces with minimal effort on the part of the master.

A quality riveting tool is distinguished by its versatility and simplicity, it is very easy to use it. It allows you to provide unhindered access to the connection, without any accessories. Separately, it should be taken into account that to work with the riveting device, it is necessary to pre-drill a small hole in the metal blank to install the rivet. The fixation will be performed by the main tool.

Experts say that the specifics of this work are notable for their simplicity, thanks to which even a beginner can now cope with it. It is also important that you can buy a rivet riveting tool at a very affordable price.

Dismantling the construction rivet

It is difficult to call this action dismantling as such. This is deletion. To remove the rivet, you will need the usual riveter with which it was installed. But since it is not at hand, it is worth figuring out how to rivet a rivet without a riveter.

Rivets with a cap or bent part sticking out above the plane of riveted parts can be torn off with a sharp chisel and hammer:

- Place the tip of the chisel exactly under the head (or folded part).

- Hit the chisel with a hammer. Some large rivets may take several blows to break.

- When the cap (or folded part) is torn off, all that remains is to remove the rivet from the hole. This can be done by pushing it out with a nail or other thin object (such as a screwdriver).

But more often you cannot get to the hats and bent parts, since they are, as it were, in the body of the parts being fastened. Special grooves are drilled in the parts under the caps and expanding parts at the factory, and then the rivets sit in the metal as if they were cast. How to rivet rivets in such a "tricky" case?

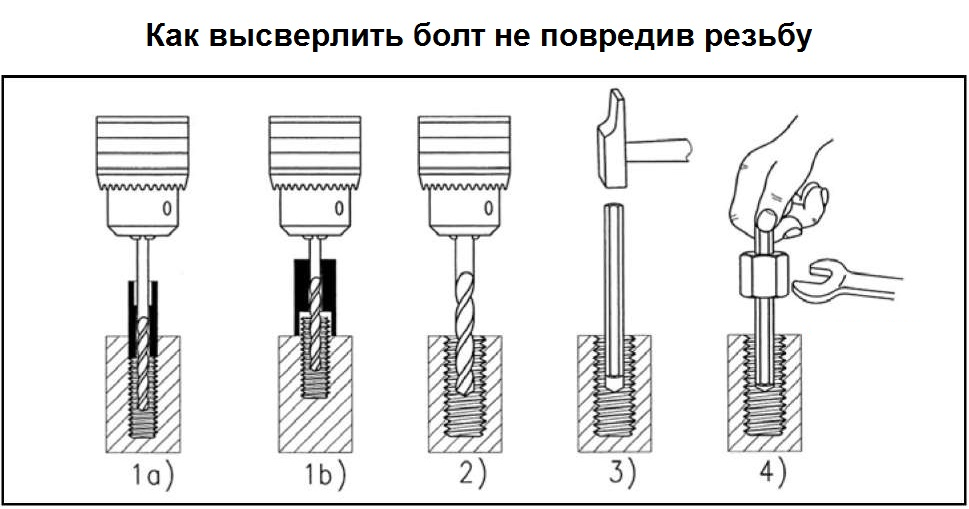

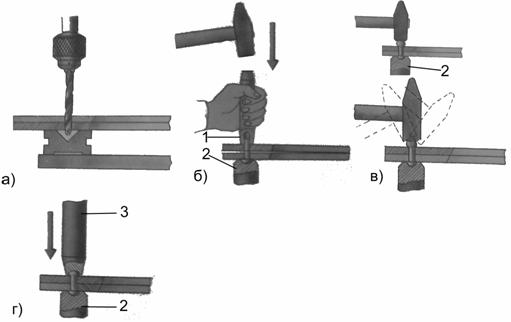

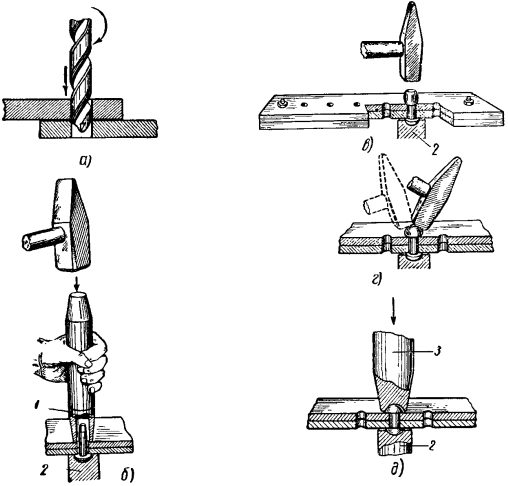

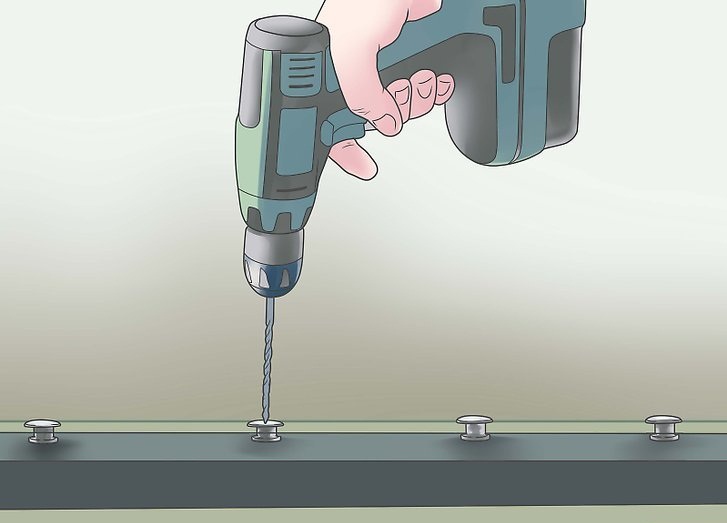

Here a screwdriver (or drill) with a metal drill selected for the diameter of the rivet will come to the rescue. Proceed as follows:

- Use a punch to make a serif on the head of the rivet so that the drill does not walk, although some are used to doing without serifs.

- Place the screwdriver's bit on the head and drill out the insides of the rivet.

- When the drill goes through, the remnants of the cap and flared part fall out on their own.

How to remove a rivet

Rivets are one of the most primitive types of fasteners. They are used to join sheet steel and tin, as well as plastic and even leather. The connections that are made with rivets are very strong and riveting is extremely difficult. In fact, in order to remove the rivet, you need to cut off its head, otherwise nothing will work. And to apply this rivet later, of course, will not work. It will only be allowed to throw it away.

You will need

file, chisel, pliers

Instructions

1. The difficulty in removing rivets also lies in the fact that you need to be extremely careful and tidy, so as not to damage the surface from which you remove it. Rivets are made from different materials with different properties and strengths. Therefore, choose the disposal method according to the material first.

2. Rather, you will need a lot of each time to work, therefore, be patient and have the right tools. From the tools, prepare a file, a chisel, pliers, perhaps even a drill with a thin drill. In short, get hold of virtually every selection of tools, as you may need any of those tools.

3. If you are removing a rivet from a metal or similar surface, use a file to get started. This will be fine if the head of your rivet itself is above the surface it connects. If the file does not give the expected results, use a chisel. But be careful, try to scratch the surface as little as possible and not injure your fingers.

4. Because rivets are not only made from different materials, but also come in different types, the approach to removing different types will also be different. So, if the head is not at ease above the surface for which it serves to connect, but has a countersunk head, use a drill instead of a file and a chisel.

5. The drill must be thin, but it must be carefully selected in diameter. First, carefully drill out the countersunk head of the rivet, and then select a rod or a similar tool, the main one, so that it fits correctly in diameter, and try to knock out the head.

6. Later, after you have aligned with the head, carefully bend the teeth with pliers and pull out the rivet shank. Cut the edges of the hole that remain after the rivet using the appropriate material method.

7. If the rivet needs to be removed from the leather product, everything will be more difficult if it is significant for you to damage the surface of the material as much as possible. In this case, only pliers will work. Gently squeeze the head in several places, and then try to loosen it.

8. If possible, carefully bend the teeth of the rivet and pull out the shank. If the rivet does not lend itself, pulling its head slightly upward from the material with pliers, file it with a file. Then follow the same pattern.

Varieties of hand tools

Today there are two types of manual rivets: pull-out and threaded, their price difference is not big.

To answer the questions: how to choose a manual, pull-out or threaded riveter, which of the tools is better, you need to understand their principles of work.

When using a rivet rivet to secure the rivet, a certain pulling force is generated.

In metal workpieces that will subsequently be connected to each other, you need to drill a hole, the diameter of which is equal to the diameter of the rivet. After that, fix the rivet on the device, insert it into the hole and squeeze the tool handle.

During the operation of the rivet rivet, the rivet is expanded with a special ball, which, when the handle is pressed, enters the tube.

Thus, the outer side of the rivet is flattened, which makes it possible to firmly fix the parts to be joined together.

A hand-held threaded riveter is also suitable for household work. Its principle of operation is practically the same as that of the previous mechanism. The only difference is that in the threaded rivet, the ball is drawn in due to the fact that the cut thread rotates.

Such a connection is more optimal for thin-walled parts, where it is rather difficult to cut a thread, but this connection is needed.

When a threaded manual rivet is used, there is the possibility of screwing a screw or bolt into the rivet.

In most cases, manual-type riveting rivets are purchased for home use, they are still more functional and versatile, while being slightly cheaper than threaded tools.

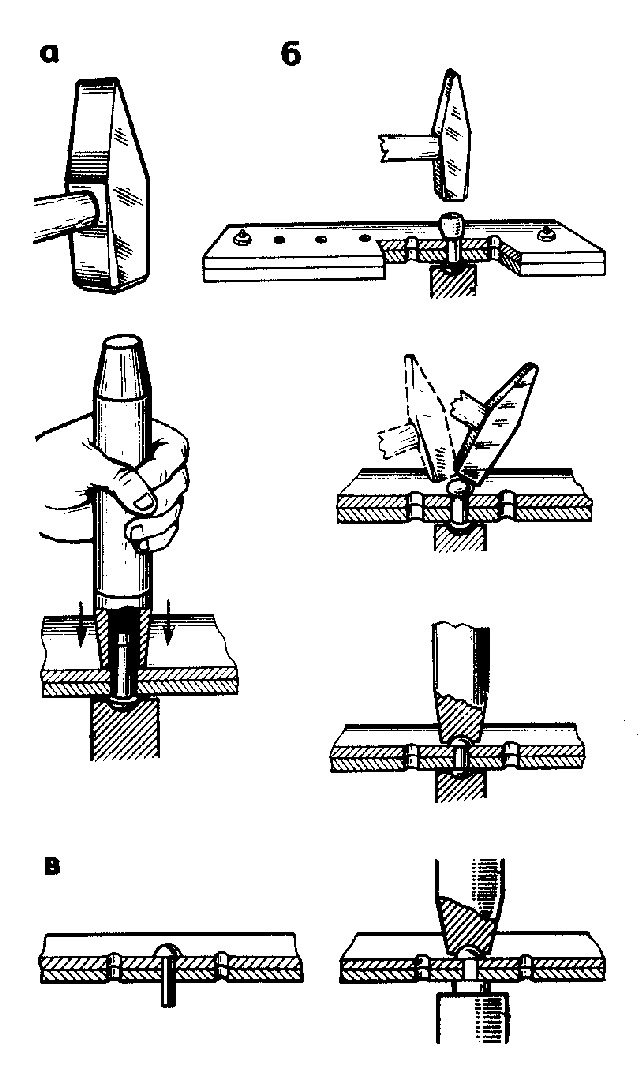

Removing the rivet with tools at hand

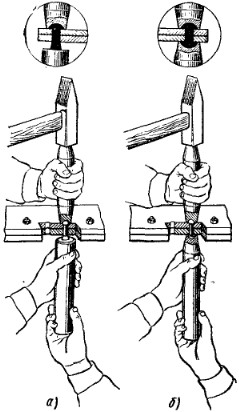

As we have already said, at the heart of dismantling any POP rivet is machining the hollow section of its head until it comes off the shank. This simple but very precise operation can be performed using a thin chisel or flat head screwdriver and a hammer. The sequence of this work is as follows:

- First of all, it is necessary to determine the thickness and material properties of sheets connected by blind rivets. Knowing the parameters of the metal, you can accurately select the tools and approximately calculate the maximum allowable force during dismantling. When working with very thin sheet material, our method can hardly be called optimal and it can be used only at your own peril and risk.

- To remove the rivet, place a screwdriver chisel or tip between the side of its head and the sheet and, gently tapping with a hammer, bend it. The thinner the material connected by fasteners, the more delicate you need to treat your work. It is also worth considering the choice of the tool carefully - it must be thin enough so that it can be neatly hammered under the side.

- If the removal of the fixing part of the hardware was successful, you need to carefully remove the fastener from the through hole. For this purpose, it is best to use a thin screwdriver or a thin metal rod of the correct diameter. Your task in this case is simply to push the tail of the rivet out of the hole. Most often, this can be done without much effort, but sometimes a hammer may be needed again - one or two blows to the screwdriver or the rod aimed at the rivet leg will help push it out of its "familiar" place.

This method is good because it can be used even where it is impossible to connect electrical tools - it is often used when working in the field.

4

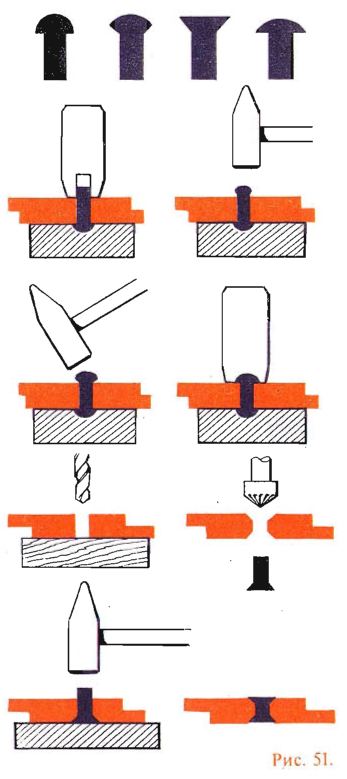

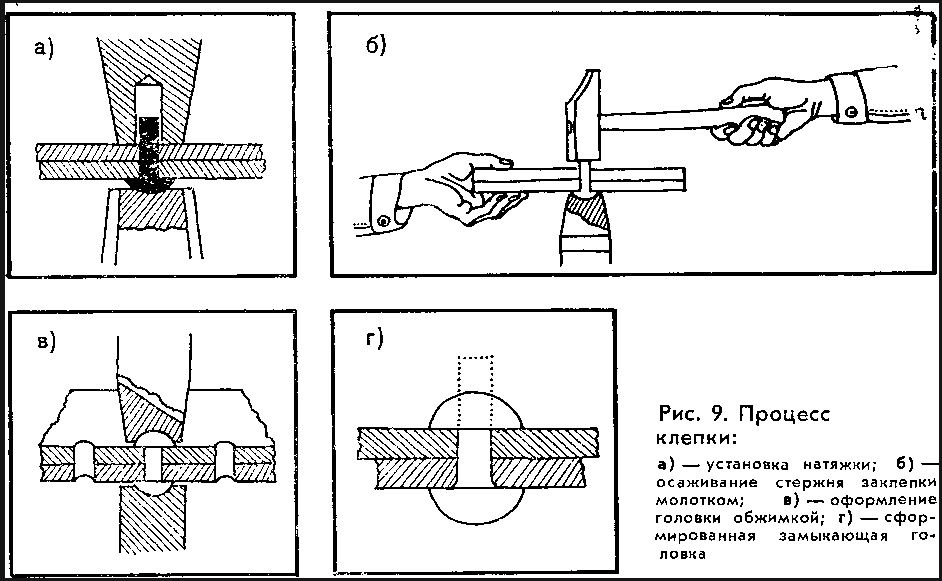

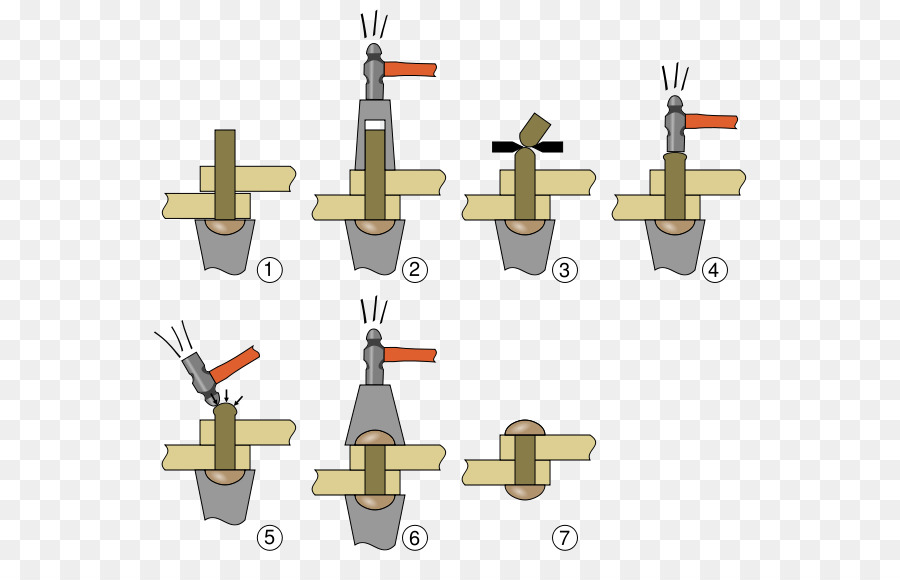

In contrast to pull-out, conventional cast or stamped riveting elements must be installed using certain forces applied to the closing end. This can be pressing or targeted impacts to flatten the end of the rod emerging from the hole. The second option most resembles forging, especially since it is performed cold or hot. If the thickness of the riveting does not exceed 1 centimeter, a cold forging of the closing head can be used. If the diameter is more than 10 millimeters, then it is necessary to heat the fastener to facilitate the flattening of its end.

Rivet tool

As a rule, before hot riveting a rivet, it is heated in a forge, after which it is installed in the hole and a flat end cap is made with several strong blows. In this case, an anvil with a hole under the mortgage head should be located below. For the cold method, a special tool is used - a striker with a semicircular hole, with the help of which an even hemisphere is formed by deforming the end coming out of the hole within the notch. Sitting with a conventional hammer gives the same result if you hit the end, directing the blows slightly casual, from the center to the edges, but such a head will be less accurate.

Where to start

Going straight to the store, as they say now, is counterproductive. First of all, you need to figure out what is really necessary - to change the lock in the iron door or its larva. In the latter case, everything will come down to a small cost, both in terms of money and time.

Lever locks or cylinder locks are mainly installed in steel doors.The keys to the first represent a rod, at the end of which there is a plate with notches. Here you will have to think about how to replace the lock in the metal door, since the usual lock insert is absent in it.

If the model is cylindrical, then in most cases it is enough to install a new larva. Locking devices of this type are supplied with a flat key with teeth along the entire length of the working part. This is an easier repair option.

Removing the blind rivet

Everyone knows that a rivet is a disposable fastener that is used to securely hold two or more elements together. For a number of reasons, situations may arise when a rivet needs to be riveted. In this case, only the tools at hand will come to the rescue, since there is no specialized device.

You need to start riveting by removing the ring, which was formed at the time of fixing the fastener. If the master has such an opportunity, at the time of compression of the construction material, it is necessary to insert a saw blade for metal. In this case, the fasteners can be cut off, and the spire can be removed by pulling it out by the rod. If it is not possible to cut or saw down, then you can use a method proven over the years - a drill.

As practice shows, the countersunk ring can only be removed by drilling, and the heads can be gently knocked down with a hammer. It is worth considering that this method is applicable only if the strength of the bonded material is greater than that of the fasteners themselves. In addition, the procedure itself is considered traumatic, since there is a high risk of injuring the fingers.

Originally posted 2018-04-18 12:28:24.

Watch the video

Novice radio amateur power supply

Site headings

- Aviation

- Auto and Moto

- Army and navy

- Archeology

- Animals

- Health

- Celebrities

- Games

- Interesting

- Internet and computers

- History

- Space

- Crime

- Cooking

- Culture and art

- Fashion & Style

- Music

- Science and technology

- news

- Society

- Hunting and fishing

- Politics

- Nature

- Psychology

- Travel and Leisure

- Entertainment

- Religion

- Rodnoverie

- Needlework

- Garden

- Homemade

- Sport

- Construction and design

- Secrets and myths

- Economy

- Humor, jokes

- Sandbox

When I play Topigr, I wish we were completely problem free, and not free.

Now in the world there are so many unexplainable things that mom do not grieve.

Pindos, admit that you have not been to the moon and we will lag behind you.

Basque is the same banderlog as Rotaru! Basque, why don't you go to perform in Crimea and Donbass.

The so-called "truly great star" sponsored the genocide of Donbass! Let ne speak.

Another pig returned to its pigsty. Donbass has become cleaner.

90% agree with the opinion of the author. Here is the opinion of a.filipovic. I still do not understand who it is.

This is not a sandstorm. The sea receded in the wind and the wind lifted the sand.

Do-it-yourself chaise lounge chair

Information and entertainment site "Labuda" is daily, operative, relevant, interesting news and useful information from different spheres of life.

Full or partial copying of materials from the labuda.blog site is permitted only with an active and indexed hyperlink to the publication source.

legal information

Dear authors, remember that the publications you post must not violate the laws of the Russian Federation and the copyrights of third-party resources.

* Extremist and terrorist organizations banned in the Russian Federation and the Republics of Novorossia: Right Sector, Ukrainian Insurgent Army (UPA), ISIS, Jabhat Fatkh ash-Sham (formerly Jabhat al-Nusra, Jabhat al-Nusra "), National Bolshevik Party (NBP), Al-Qaeda, UNA-UNSO, Taliban, Mejlis of the Crimean Tatar people, Jehovah's Witnesses, Misanthropic Division, Brotherhood "Korchinsky," Artillery preparation "," Trident them. Stepan Bandera ”,“ NSO ”,“ Slavic Union ”,“ Format-18 ”,“ Hizb ut-Tahrir ”.

Manual riveter: how to use

Hand tools are easy to use, and you don't need to acquire any special skills. A correctly purchased mechanism will do this work efficiently and quickly. When buying a tool, the price should not play a big role, the main thing is to choose a model of good quality. This will allow you not to worry about the tightness of the connection and the failure of the instrument.

You just need to properly drill the holes so that the diameter exactly matches the diameter of the rivet itself. We have already described the work of the riveter in detail above. After work, it remains only to process the reverse flattened side of the rivet, that is, remove the excess formed with pliers.

What to focus on

Riveting material

If it's aluminum, it's easy to work with, so it doesn't matter which riveter you choose. It is more difficult with steel, therefore, the device should be selected more powerful

Ease of use

First, the tool can be one- or two-handed. Naturally, the latter can create more pressure, so it allows you to work with fasteners from any material, of different sizes. Although in some cases (for example, limited space), you can only use one-handed.

Secondly, the design of the head. If it is swivel, then this creates additional convenience. Sometimes it is necessary to rivet in difficult areas (in "inconvenient" places), and this feature of the tool is very helpful.

Third, are there replaceable attachments for different sizes of fasteners? This need not be commented on.

Gadgets

Some models have a special "container" where "waste" is dumped. For example, when you have to rivet the roof or build a fence made of profiled sheet, small pieces of metal are scattered to the sides. If they find themselves in the grass (sand, on the ground) around the place of work, then problems cannot be avoided, especially with children - they like to run barefoot in the summer.

Some "home craftsmen" prefer not to think for a long time what tool to buy. If the amount of work is insignificant, they buy a couple of cheap models at once. In the event of a breakdown, there is always a spare at hand. And 150-200 rubles is not so much money to go around and ask the price. Although this point of view is not suitable for everyone, it also has a right to exist.

There is also another opinion. It is better to buy a professional model for 700 rubles, and this will be a guarantee that it will last long enough. Moreover, the riveter may be needed more than once.

It is necessary to take into account such a factor as the accuracy of the owner. We do not pretend to be the authorship of the thought, but, nevertheless, let's say - you can break anything, no matter how much "it" is worth. Therefore, you should not too much trust the reviews of people about a particular model, especially strangers.

Considering the above, one should not be surprised at the opinion of professionals that the choice of a manual "riveter" is akin to a lottery - not guessing whether you are lucky or not.

Many industrial products use rivets as a way to securely and quickly fasten a knot that will not be disassembled in the future. Thin sheet metals are often bonded in this way. If you need to remove the riveting and not damage the surface of the product, then I will offer all three available ways to achieve the desired result.

Main areas of application

Many will agree that no repair work can do without a riveter. The versatility of this hand-held tool is considered to be the most demanded in those cases when it is necessary to connect several workpieces, and the use of other fastening methods is impractical. As practice shows, with the help of this device, various fasteners are most often connected.

As for the lever rivet, the working mechanism itself is presented in the form of a pistol and consists of two parts. The main work is performed by the spring mechanism, which draws the rivet into the inside of the tool.Then the lever system flattens it evenly. The unique structure of the manual lever riveter allows you to connect together those parts, the thickness of which can exceed the 10 mm mark.

The fixing of various workpieces with rivets is of high quality due to the fact that this tool contains the following technical characteristics:

- High degree of reliability. Under the action of a manual riveter, a non-separable connection is created, due to which the highest degree of strength is achieved. It should be noted that the versatility of the riveted connection was used in the construction of the well-known Shukhov Tower in Moscow, as well as the Eiffel Tower in Paris. But these architectural beauties have existed for more than one decade. This once again proves the effectiveness and reliability of the use of rivets.

- Good vibration resistance.

- Preparation for the installation of rivets is carried out as quickly as possible. Hand tool operation lasts only a few seconds, which significantly speeds up the pace of riveting.

- Unlike welded seams, rivets do not burst or crack. When an unfavorable factor affects the connecting element, it begins to stretch, so that existing faults can be seen in a timely manner and quickly eliminated.

- Unlike a screw connection, rivets are much cheaper, since they are small pieces of metal of a cylindrical shape.

It is worth noting that today several types of riveting mechanisms are produced, which can have both simple and complex shapes. For example, on sale you can find universal swivel heads that can be used in the most difficult-to-reach places. As for the installation of rivets, this process takes only a few seconds.

How to remove a rivet from a metal structure

A rivet is a disposable fastener designed for fastening 2 or more parts. A riveter is used to install this fastener. How to remove a rivet will have to proceed from the availability of available tools, because there is no universal tool. In addition, the selection of materials for the metal structure is made in accordance with the technical specifications.

Aluminum, copper, steel differ in hardness, they are subject to different degrees of diffusion, oxidation rate and other physicochemical processes. The only way that can be called almost universal is drilling. This process can be carried out in 3 ways, which in most cases depends on how close the fastening metal is to the fastened elements.

Drilling rivets

-

The tight fit of the fastening rod to the hole suggests that it will not be possible to knock it out. In this case, dismantling will have to be carried out by the method of complete destruction of the rod. It is necessary to accurately determine the diameter of the drill with which the hole was made in the metal structure. The same diameter of the drill will be required to remove, or rather, drill out the rivet along with the rim. It is better to start work on removing the rivet at low speeds so that the drill does not damage the fastened parts. Nevertheless, this method is not the most reliable for dismantling the structure, which will need to be reassembled.

There is always a risk that the drill of a hand tool will move to the side, enlarging the hole. In this case, it will be difficult to re-fasten the parts using the old marks.

- Dismantling of aluminum rivets can be carried out according to the principle of a corkscrew with a drill of a smaller diameter than the rivet itself, a self-tapping screw, a screwdriver and pliers. Despite the large list of instruments, the operation will take less time.A hole is drilled in the middle of the rivet, a self-tapping screw is screwed in, the resulting part is removed with pliers. Steel, tight-fitting, in this way is almost impossible to remove due to the fact that the drill is very hot.

- Steel can be removed in a combined way. To begin with, it is drilled along the rim on both sides so that the clip rings separate from the rivet rod. Further, in accordance with popular wisdom, a wedge is knocked out by a wedge. This requires a screwdriver with a handle that cannot be destroyed with a hammer blow. It is set in the middle of the rod and with gentle hammer blows on the end of the handle force is given to remove the rod from the hole, this is the only way it can be removed without damaging the metal being fastened. If the rivet fastened the thick structure, and it comes out hard, then, if the end is large enough to grip with pliers, it can be pulled out. A poorly yielding rivet can be rotated, but pulling out the rivet is not recommended if the hole is needed to reattach the structure.