Possible gun malfunctions and their elimination

It should be borne in mind that the instrument must be constantly flushed with regular use, as well as when processing a significant amount of space. Its cleaning must be carried out after spraying every 3-4 containers. When performing this process, the first thing to do is to pass the solution through the entire device of the pistol by pressing the trigger, after which it must be postponed for 1-2 hours so that, under the influence of acetone, all the foam inside is removed. After this time and repeated rinsing of the instrument for 5-10 seconds, it can be used again.

The main malfunctions of the pistol are as follows:

During the connection of the container, a characteristic sound is not generated and the mixture is not supplied. This is because the inlet ball valve is sticking. Basically, this malfunction occurs during the removal of the cylinder from the tool, therefore, during storage, it is necessary that it be present on the gun. To repair it, you need to unscrew the container adapter, and release the valve ball. In some cases, this may require a solvent designed to remove the foam, which must be poured over this element of the device and wait a little. When removing the ball, extreme care should be taken to avoid damaging its surface. In addition, the loss of the valve spring must be avoided. After cleaning the assembly, the tool will work as before in most cases.

Arbitrary outflow of the mixture from the nozzle of the tool. This mainly occurs when the element itself or the needle of the regulating device are clogged. To fix the breakage, you need to make an almost complete analysis of the pistol. In the process, you need to unscrew the regulator, disconnect the tool barrel, unscrew the nozzle (in a number of non-separable devices, actions can be carried out differently, but the task remains the same - dismantling the assembly that supplies the polyurethane foam). The needle and nozzle must be handled as carefully as possible, since if any damage occurs to any of them, it will be necessary to replace with a similar component. Then, all the elements should be treated with an appropriate rinsing solution, in which the barrel can even be soaked. After processing, all components must be wiped off with a soft cloth. After the tool is reassembled, the self-flowing polyurethane foam is often suspended.

Impossibility of unscrewing an empty bottle. Sometimes there is such a problem, which in most cases occurs when the pistol is not used for a long time. In such a situation, unscrewing the container together with the adapter can help, thereby reducing the increased pressure. After this action, the cylinder begins to unscrew, but the above element will need to be held with a key

In the most difficult cases, you even have to cut the balloon with a grinder, observing the utmost care in the process. Unscrewing the head of the container should only be done after pre-wetting in a solvent.

To avoid this, when changing the cylinder, it is necessary to remove the remaining polyurethane foam from the adapter.

With proper operation and adherence to certain rules, these malfunctions can be avoided or significantly reduced their likelihood of occurrence.

How to use a foam gun

- For the most productive use of canned polyurethane foam, several simple rules must be followed, mainly related to the methods of working with a pistol and the condition of the cylinders themselves:

- before starting work and periodically during its implementation, the balloon needs to be vigorously shaken for some time (about half a minute) so that the foam components having different densities are mixed with each other;

- during operation at low ambient temperatures, foam cylinders should be slightly heated or kept in a warm room, the normal temperature for foam is 20-25 ° C;

- foaming places need to be slightly moistened with a spray bottle, but not strongly, for better adhesion;

- while foaming, carry out circular movements with the nozzle of the gun for better styling of the foam;

- when foaming, try to keep the balloon in the maximum vertical position, but in places where this is impossible, try to foaming first of all - on a fresh bottle or alternate with places where this condition is fully satisfied;

- fill vertical seams from bottom to top;

- it is better to under-froth than over-froth, because after hardening, a crust forms on the surface of the foam, closing its pores, so it is better to add the missing foam than cut off the excess.

Finally, I would like to share the advice of folk craftsmen. If you have unused foam or flushing fluid left in the cylinder, you can remove it by pressurizing the cylinder using a compressor and a blower gun, or better yet, a tire inflation gun with a pressure gauge. Bring the pressure in the cylinder to 7 - 8 atmospheres and you will be able to use the rest of the material to the end. Checked - it works!

Peculiarities

The gun can help in the following situations:

- when squeezing out the required amount of foam, which contributes to the application of an error-free portion of the substance;

- in saving material consumption: thanks to the gun, 3 times less foam is required than with a conventional nozzle on the cylinder;

- in adjusting the supply of material depending on the size of the cavity to be filled;

- in adjusting the required foam flow: after releasing the lever, the foam supply stops, while no surplus remains;

- in the preservation of the remaining material: after the termination of work, the foam substance in the pistol does not freeze;

- in maneuvers when working at height: the tool can be used with one hand, which is very convenient if the builder is standing on a stool, step-ladder or holding something in the other hand.

It should be noted that the tool may fall during operation. But thanks to the metal base of the gun, the container with the foam will not break. In addition, it should be noted that a regular cylinder freezes in the open air, unlike a pistol.

4 Using a pistol - how to properly use it to carry out construction work?

The operation of such a device is simple and does not have any complicated moments. Before use, it should be charged with construction foam in a cylinder. To do this, the adapter ring is turned up to the stop and the sealant package is screwed in. Then the ring is returned to its original position. If you hear a short hissing sound, the connection is correct.

After connecting the cylinder, you can start working. To do this, you need to place the tip of the structure in the slot and pull the trigger. In order for the foam to lay down neatly, the gun must be smoothly moved along the treated area. Turn the adjusting screw to decrease or increase the release of sealant.

In the gun, unused foam can be stored for a long time without losing its qualities, and it can be used later during repairs. But the balloon must not be removed.If the can is removed, the remaining polyurethane will dry in the feed tube and inside the structure, ruining the gun. After work, the device should be treated with acetone or a new foam pack should be installed on it.

The use of polyurethane foam requires compliance with several simple rules:

- work must be carried out at appropriate air humidity;

- proper preparation of surfaces is needed.

Many people rarely pay attention to air humidity when starting repairs. Mounting mortar is capable of polymerizing only in the presence of moisture in the ambient air

Hot and dry summer weather is not suitable for sealing crevices. In order for the repairs to be carried out efficiently, in the summer heat, work should be done in the morning or evening. Before proceeding with sealing, you should prepare in advance all the necessary equipment: a spray bottle with water, cylinders with foam and cleaner, as well as rags.

Foaming technology:

- 1. Clean the surface to be treated from dirt (dust, debris).

- 2. Spray water on walls, slopes or other defective areas.

- 3. Install the cylinder into the gun and shake the structure (repeat this several times during operation).

- 4. First of all, work is carried out on the ceiling and in the depth of the cracks using an additional extension nozzle.

- 5. The seam should be filled with 30–40% foam. It is impossible to seal the entire space with sealant, as the volume of the solution will increase.

- 6. Polyurethane from the gun must be released continuously, without interruption, and the tool must be moved along the treated area smoothly, without jerking.

- 7. After foaming, the layer of polyurethane foam should be moistened from the sprayer and interrupted for several hours to dry. Then, if necessary, you can apply a second layer of the solution.

It should be borne in mind that the surface treated with polyurethane must not be left unprotected from the effects of sun, wind and precipitation. For protection, paint, plaster and other building materials are used.

What is the risk of improper use of foam?

The main properties of this material are an increase in volume, reliability of fixation and inertness to most influences. But they are the ones that turn into a problem if the foam is used carelessly. After all, polyurethane foam has specific properties:

- can expand uncontrollably, turning mounted slopes or other interior elements into a pile of garbage;

- adheres to the skin and hair in such a way that it is almost impossible to clean them;

- hitting furniture or other surfaces can hopelessly ruin them;

- dangerous if swallowed and in eyes.

If the foam has dried, it can only be removed mechanically. True, the real effect is given by the use of the medicinal antiseptic "Dimexide" or battery acid. But these products will dissolve not only the polyurethane foam, but also the coating on the surfaces to be cleaned.

Compliance with these simple rules will extend the life of the equipment, save expensive materials and save the interior. To protect your health, it is advisable to work with gloves and goggles, ventilating the room.

Polyurethane foam properties

The main property of the substance, which ensures its widespread use, is a high degree of filling and excellent adhesion. The expansion coefficient in this case varies from 10 to 60%. Curing occurs due to the interaction of the material with moisture and air. Gas is also added to the cylinder, with the help of which pressure is created to displace the substance. The main components are methylene diphenyldiisocyanate (MDI), polyol, blowing agent, and catalyst.

Varieties

The material can be divided into one-component and two-component, as well as household and professional. The quality does not have a strong difference from this, but the way the foam comes out of the cylinder is different.When using professional cylinders, an assembly gun is required: a device that controls the flow of the substance. While household ones are equipped with PVC guide tubes, which are sprayers. In addition, the material has differences in application temperature:

- winter;

- summer;

- demi-season.

The disadvantages include sensitivity to ultraviolet rays, under the influence of which it is destroyed and a long solidification time. The setting time of a substance is characterized by the duration of polymerization and depends on the volume. The hardening period is from 8 to 12 hours.

Correct use

A cylinder with household polyurethane foam is intended for single use, so you should think about its effective use, since unused material will be lost. Polyurethane foam is usually produced in cylinders, tubes, on the surface of which information is applied about the conditions of use and preparation for use.

The capacity is 600-800 milliliters. A non-professional balloon comes with a disposable PVC tube with special notches. Thanks to the notches, the length of the tube can be shortened, and in the case of hard-to-reach places, an extension adapter in the form of a flexible hose is put on it.

Before starting work, the cylinder is shaken vigorously and the cap is removed, which serves as a kind of safety lock. Then it remains only to screw the plastic tube, which is supplied with it and has an internal thread, onto the threaded part of the cylinder.

It is important to note that the straw can be used several times. It has a collapsible design and Lego is cleaned with a ramrod or a piece of thick wire from the foam frozen in it

To improve the degree of expansion of the solution and its hardening, the required amount of moisture contained in the air may be insufficient, therefore additional wetting is applied.

How to use polyurethane foam without a gun? Consider the recommendations:

- The inner surface of the seam, on which the substance is applied, is thoroughly cleaned and moistened.

- When filling a deep seam, several passes are made. At the same time, they are waiting for the hardening of the previous one.

- When working with the balloon, before applying a new suture, it must be shaken vigorously to mix the components.

- During operation, the cylinder is positioned strictly upside down.

- For vertical work, the seam is filled from the bottom up.

The process itself is as follows. The end of the tube is positioned about five centimeters from the place you want to fill

I would like to draw your attention to the fact that about half of the required volume is filled due to the expansion of the substance. The material is extruded in a wavy motion

As the substance increases in size, surpluses are formed, which are cut off with a sharp knife after hardening.

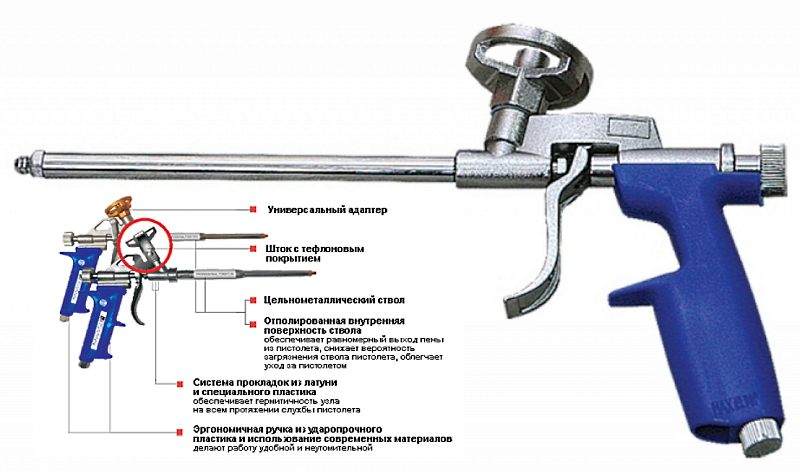

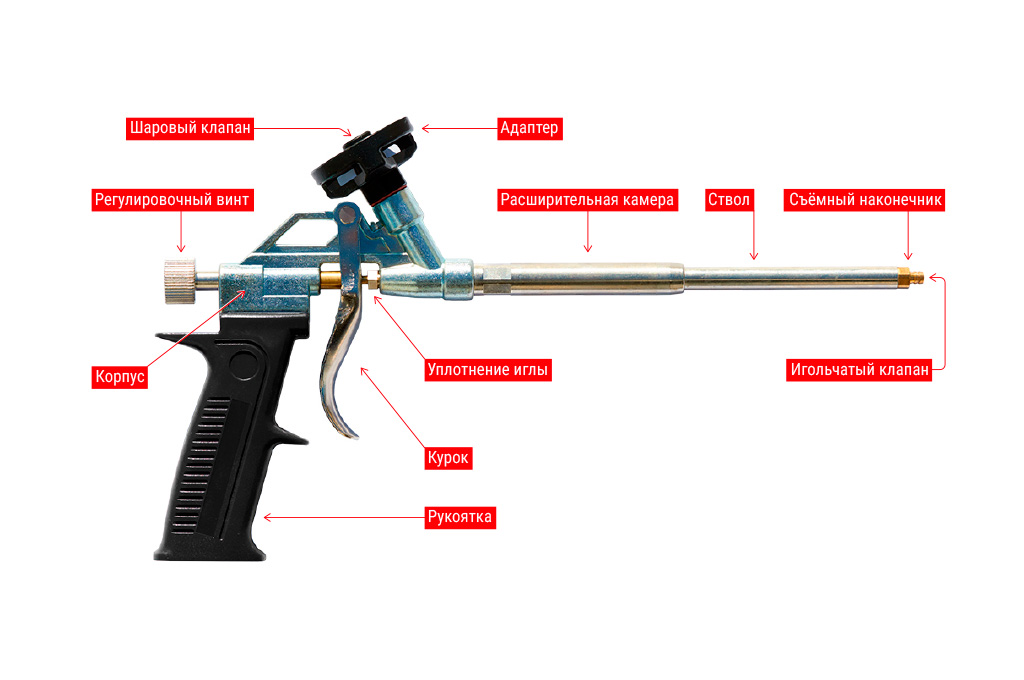

Foam gun device

The assembly gun has a robust housing made of durable materials. The quality of the foam gun depends on the foam control mechanism. The design of the pistols is simple and they consist of the following elements:

- A metal tube 190 mm long, at the ends of which valves are placed.

- At one end, a tip is screwed in with a 2 mm hole and a metering outlet valve. Removable tips or flexible extension can be attached to the tip of the handpiece.

- Attached to the other end is a pistol-like handle with a trigger to open the outlet valve through a stem located in the tube.

- Above the handle, a ball valve and a fitting (adapter) are attached to the tube for screwing on a bottle with foam or flushing.

- There is an adjusting screw at the end of the tube on the side of the handle. It limits the trigger travel and thus reduces or increases the amount of foam released.

Constructional features of a gun for polyurethane foam

Regardless of the manufacturer, the general structure of the tool is the same and quite simple:

- Unlike polyurethane foam for household use, which is sprayed by means of a plastic tube, in the gun it is supplied through a tube made of metal, which is equipped with a special nozzle at the edge. The diameter of the hole of this nozzle has a cross-section five times smaller than that of the feed tube, which makes it possible to create a high working pressure of the composition.

- The cylinder is connected by means of an adapter, which is fixed on the tool body.

-

The gun for polyurethane foam is equipped with an adjusting screw that allows you to change the speed of the mixture discharging.

- Its handle can be made of plastic or aluminum. It is fixed to the barrel with a nut. Thanks to the collapsible design, it is possible to easily clean the tool from all solidified material residues.

- The trigger, which is located at the handle of the pistol, is also one of the important elements, making it possible to more conveniently spray foam from a cylinder.

After familiarizing yourself with the design of the tool, you can try to install a tube into it and perform a test application of the mixture to any of the recesses required for processing.

Right choice

When choosing a mounting gun, it is important to consider some design features that you should decide on before buying. First of all - think, do you need a gun for a single occasion, or are you going to use it all the time? The main purpose of the purchase will help you with the following selection criteria

Material

Modern guns, specialized for the use of polyurethane foam, are made from different materials, each of which has its own positive and negative sides. But in order to be sure of the long service life of the tool, it is advisable to carefully examine it before purchasing. Currently, there are three main materials from which this tool can be made:

- Powder mold - light weight and low strength. The only positive quality is the low price. It is better to use one-time only if minor repairs are to be done. Not suitable for long-term use;

- Cast metal - high reliability, but rather heavy, which makes working with it somewhat inconvenient. A good gun that significantly outperforms powder-mold guns;

- Plastic is a lightweight and reliable material that can last for many years (if you buy a tool from a serious company). It loses somewhat in quality and strength to pistols made of cast metal, but wins due to a more comfortable mass.

Disassembly possibility

There are models with the possibility of disassembly and without this privilege. It is more expedient to choose the first type, since after the completion of the repair work it will be more convenient to clean it, and, therefore, such pistols should serve their owners longer. In addition, the possibility of repair and ease of use will be obvious advantages.

Video: how to disassemble the assembly gun

Coating

There are several types of foam gun covers:

- uncoated - the most budgetary models, distinguished by their low price and durability;

- zinc coated - good durability, but it is difficult to clean the tool after use;

- Teflon coated - a modern type of coating, used most often in tools manufactured by reputable companies. It is the most optimal because it has good wear resistance and presentable appearance. Popular with professionals.

Barrel length

The choice of pistol barrel length is limited to three standard ranges:

- from 10 to 15 cm - used for working with easily accessible surfaces;

- from 15 to 20 cm - a universal gun for all types of work;

- over 20 cm - a purely specialized tool for sealing hard-to-reach surfaces.

It is desirable that this indicator tends to 20 cm, since shorter or, conversely, long trunks will not be so useful in work. They will not allow the builder to properly apply sealant to hard-to-reach surfaces. According to experts and manufacturers, 20 cm is the length of the barrel, which corresponds to almost any work related to sealing surfaces, cracks and joints.

Flow regulator

Flow controllers are an important part of a quality foam gun. The main types of pistols on this basis are as follows:

- Guns without a regulator are cheap models that do not allow you to save polyurethane foam by regulating the thickness of the sealant layer;

- Pistols with a plastic regulator - suitable for short-term work, the plastic ball (with long and almost continuous use) easily breaks down;

- Tools with a Teflon or metal ball are the most reliable models with a large margin of safety.

The flow control should be able to apply foam in thin and thick layers. The optimum in the regulator is the use of a Teflon or metal ball. When buying a tool, it is better to ask what material the regulator is made of, and whether it is available at all.

Features of spray foam

To apply this mixture, you do not need to have any special skills. To do this, it is only necessary to fill any space with polyurethane foam several times, after which the spraying of the material will occur easily and without flaws, but in order for the process to be carried out as correctly and efficiently as possible, you should still adhere to a certain sequence and take into account a number of subtleties:

- The level of fixation of polyurethane foam with a damp surface is much higher. Moisture leads to an increase in volume and a more significant expansion of the material, giving its structure more uniformity. With this in mind, before applying the mixture to the surface that is being treated, it should be moistened with water using any spray.

- The supply of polyurethane foam must be made to the previously prepared space by lightly pressing the trigger with the tool nozzle directed at it in advance.

It is required to take into account that filling of vertical slots must be carried out from the bottom up. If its dimensions are quite extensive, then spraying should be performed in zigzag movements.

- The surface to be treated with the presence of different dimensions requires the application of a specific volume of material, for which the adjusting screw is responsible. The device must be properly adjusted according to the required amount of the mixture to be applied.

- Even with continuous operation, the components of the polyurethane foam begin to settle at the bottom of the container over time. To avoid this, the gun needs to be shaken periodically so that they can be returned to their optimum condition.

- Upon contact with air, a significant expansion of the mixture occurs when it leaves the container. It is recommended to fill the site with it by no more than a third of the volume. If necessary, it is better to additionally process the remaining empty space after the previously applied layer has hardened. The process of removing significant excess polyurethane foam will cause unnecessary costs and take more time.

- Even if the pistol has a rather elongated barrel, it is far from always possible to get to all hard-to-reach areas with its help.In such a situation, the solution is an extension adapter in the form of a flexible hose, which is put on this component of the tool.

Gun device for work

Now we will consider what parts this tool consists of. The design of the product is quite light, and there are no complex knots in it. The nozzle itself is five times smaller in diameter than the tube.

Now we will consider what parts this tool consists of. The design of the product is quite light, and there are no complex knots in it. The nozzle itself is five times smaller in diameter than the tube.

This is necessary to ensure normal pressure and the ability to apply a small layer of foam. There is also just a pipe, often called a barrel. A very important detail is an adapter, it is also called an adapter. It works as a connector between the gun and the cylinder. The design also includes an adjusting screw that helps control the release of the substance.

It is better to purchase models that have a barrel-to-handle nut. If you remove it, then there will be access to the stem, so its cleaning can be done without much difficulty. There is also a trigger and a handle. The last detail should be aluminum and very strong. As you can see, the structure of the foam gun is pretty simple.

Instructions for changing the cylinder

This is a very simple action that does not require any special preliminary preparation. Naturally, during the change, the amount of foam in the product will decrease. When the resource has been completely spent, you need to replace the cylinder with another. This is done in the following way:

- The barrel of the device is directed into the trash can. By pressing the trigger, you need to remove unnecessary foam from the product. Then the product is turned upside down with the handle, and the cylinder must be screwed in with rotational movements.

- The attachment point must be cleaned with a cleaner and quickly install another cylinder. The gun is now ready for use. So you roughly learned how to disassemble the foam gun and how to clean it correctly.

Flushing the gun

Many people may forget about flushing the foam gun as a waste of time. But this is not at all the case. The fact is that if such foam hardens or clogs all over the trunk, then it will be difficult to remove the frozen foam from there, and it will take many days. That is why the device must be cleaned immediately after completion of work. How exactly to do this:

- For cleaning, the barrel outlet is turned over to the "away" position. Then the foam balloon is unscrewed, and the cleaning agent is inserted into the holder. Next, you need to press the lever until the barrel is completely filled with a special agent.

- You need to wait about ten minutes, after which the liquid is removed, and the barrel will have to be rinsed again. When you begin to remove the cleaning mixture canister, pull the trigger to remove any remaining cleaning agent and dissolved foam.

- Tighten the special screw as far as it will go.

Basically, this is all that can be said about how to use the foam device. Now let's take a look at a tool from the most popular manufacturer.

Gun for work

Hilti The company is engaged in the creation and distribution of new professional models. For example, the Hilti CF-DS 1 is extremely popular with both professionals and amateurs. This pistol costs about 2,500 rubles. By purchasing it, you can get an interesting design, a sturdy product and a high build quality in general.

Hilti The company is engaged in the creation and distribution of new professional models. For example, the Hilti CF-DS 1 is extremely popular with both professionals and amateurs. This pistol costs about 2,500 rubles. By purchasing it, you can get an interesting design, a sturdy product and a high build quality in general.

The anatomical handle has a special coating and fits perfectly in the hand. The trigger is huge and designed for two fingers, which increases the speed of work. In addition, the Hilti CF-DS 1 polyurethane foam tool can be supplied with a safety lock. The device can block the trigger from being accidentally pressed during transportation or dropping the device. The weight of the product is only 480 grams, therefore, working with it, the operator will not be able to get tired. It is better to buy such a device than to use a homemade one.

How to use polyurethane foam

Sometimes special polyurethane foam can be used without a gun.How to use a balloon? In such a situation, it is necessary to choose the tube for the waste of the substance and figure out how to press the valve. Such an action can be represented in the following way: it is necessary to release air from a special chamber so that it can completely get into a certain place without catching your hands. In this case, take a tube of three parts: 1 and 3 - flexible, and 2 - solid. The valve is pressed with the middle part, the first will prevent the substance from splashing, and the third already brings everything to the place of processing.

Sometimes special polyurethane foam can be used without a gun.How to use a balloon? In such a situation, it is necessary to choose the tube for the waste of the substance and figure out how to press the valve. Such an action can be represented in the following way: it is necessary to release air from a special chamber so that it can completely get into a certain place without catching your hands. In this case, take a tube of three parts: 1 and 3 - flexible, and 2 - solid. The valve is pressed with the middle part, the first will prevent the substance from splashing, and the third already brings everything to the place of processing.

Cleaning the gun after using it

At the end of work or with a planned long-term inactivity (more than a month), you need to rinse the instrument with a special rinsing solution. During this process, the gun should be turned with the nozzle away from you and the cylinder with polyurethane foam should be replaced with the same container, but only filled with the specified composition.

Next, you need to press the trigger to fill the barrel with a solution and leave the tool with it for 15 minutes, during which the remaining mixture will dissolve. After the specified time has elapsed, press the trigger again to release the composition with the remaining polyurethane foam. Next, you need to rinse the barrel again with a clean solution, and then twist the cylinder. After bleeding the remains from the barrel of the gun, you can hide it in a convenient place in which it will be kept until the next use.