Ways to unscrew bolts, screws, screws with lapped edges

If in the usual way it was not possible to unscrew the fasteners whose edges were licked off, you can use one of several proven options.

Gas wrench

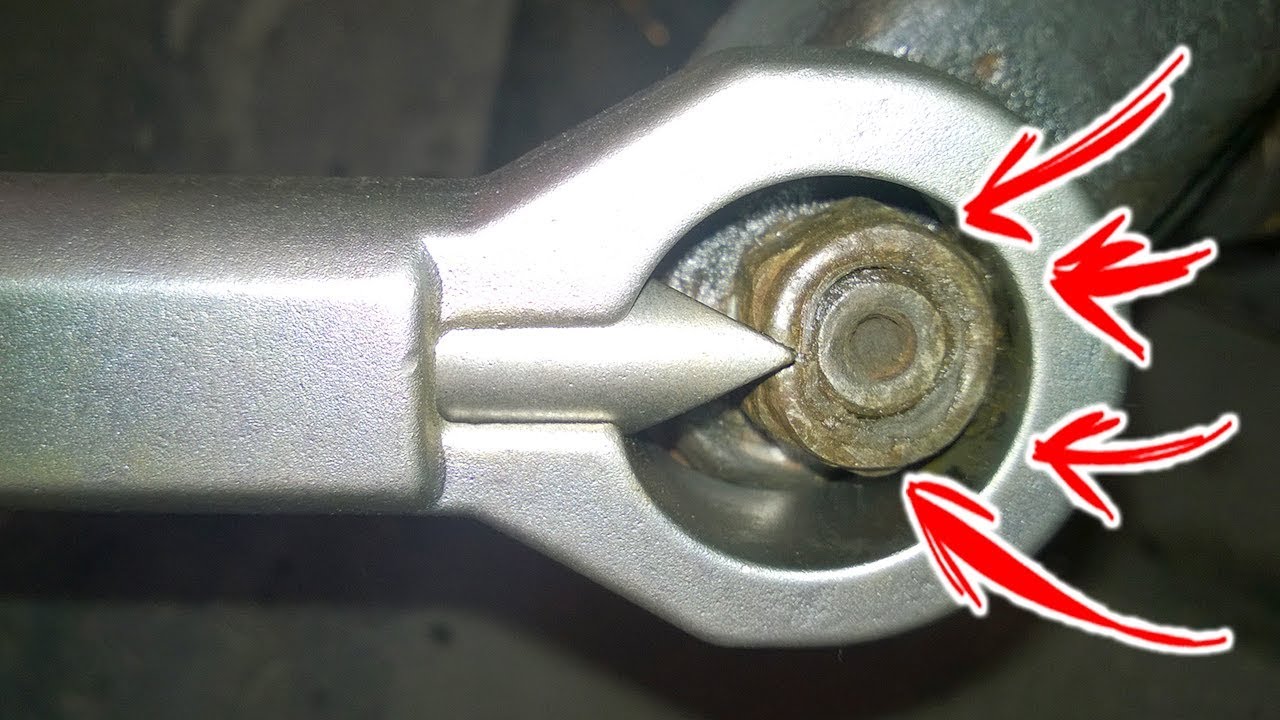

This method is used when loosening bolts, since they have a head protruding from which you can grab. For this:

- Clean the head of the bolt.

- Lubricate the junction with kerosene or diesel fuel, a liquid like WD-40 helps well, and leave for 15–20 minutes.

-

Unscrew the bolt. This is done with a gas wrench. With its help, a large force is created and even a round head can be well gripped.

The disadvantage of this method is that it is not always possible to get close to the desired bolt with a gas wrench.

Slicing new faces

If the bolt is large, then with the help of a grinder, new faces can be cut on it. It is enough to make only 4 of them and use a smaller wrench to unscrew the bolt. It is possible to cut new faces on the bolt with a file, but this is more difficult and takes longer. On the head of a screw or screw, you can make a cut with a hacksaw for metal or a grinder.

A deeper cut can be made on the head of a screw or screw for a screwdriver

Hammer and chisel or impact screwdriver

This option is more suitable for lapped nuts or large enough screws. The chisel rests on the head of the fastener and, hitting it with a hammer, gradually turn the screw or nut. Small screws or screws can be removed with an impact screwdriver and hammer. After loosening the fastening, the work is done with an ordinary screwdriver.

An impact screwdriver can be used to unscrew small or lapped screws

A tourniquet or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of dense rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is laid between the screwdriver and the head of the screw or screw

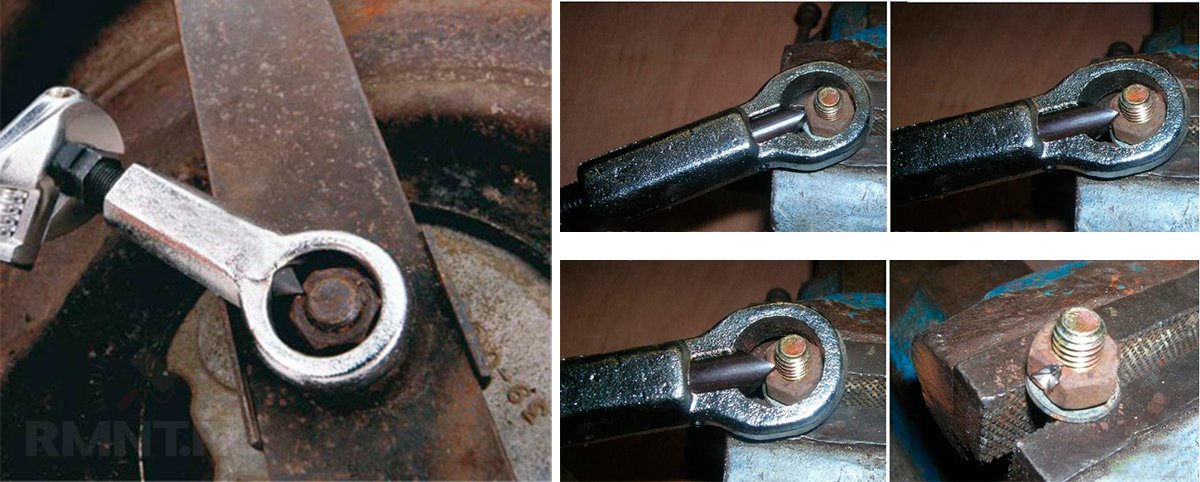

Extractor

An extractor is a special tool that is used to loosen screws, bolts or screws with lapped or broken heads.

Extractor - a tool for loosening screws, bolts or screws with lapped or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the lapped screw slot.

- An extractor of the required diameter is selected. Drive or screw it into the prepared hole. It depends on whether a conventional or a screw tool is used.

-

Unscrew the bolt.

Video: unscrewing the licked screw with an extractor

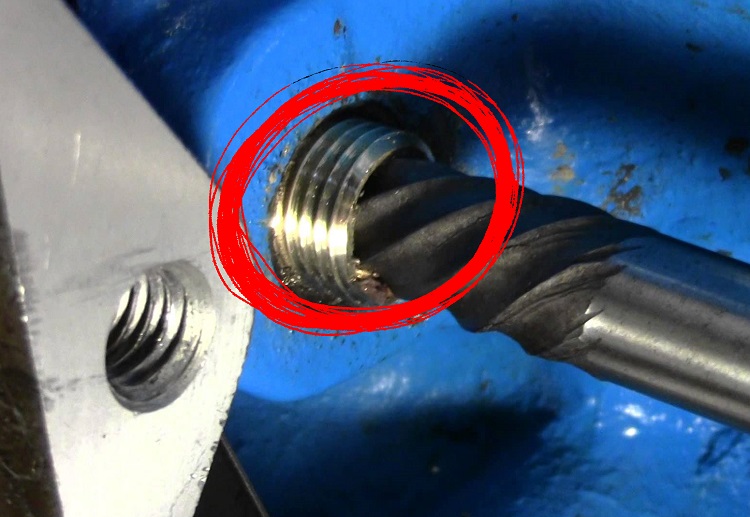

Conventional or left hand drill

Left hand drills with counterclockwise rotation are available. They improve the centering of the tool and reduce the stress on the drill, which results in higher productivity and accuracy of drilling. By inserting such a tool into a drill, you can unscrew the screw or screw with a licked head. If a left-hand drill is not available, you can try drilling out the jammed fasteners with a regular drill. In this case, you need to take a drill, the diameter of which is less than the diameter of the bolt or screw.

It is necessary to act carefully so that you do not have to cut the threads for the new fastener later.

The drill should have a smaller diameter than the problematic bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called "cold welding". After the glue securely fixes it, turn the nut with a wrench and unscrew the screw or screw with it.

With the help of glue, the nut is fixed to the licked head, and then the screw is unscrewed with it

Welding

If there is a welding machine nearby, then you can fix a new nut on the head of a bolt or screw by welding it.After that, it can be unscrewed immediately.

A new nut can be welded to the problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or screw, use a soldering iron and solder:

- The heated solder is dripped onto the head of the fastener with lapped edges.

-

Until the tin has solidified, a screwdriver is inserted into it and wait a few minutes.

- Unscrew the problem screw and clean the tip of the screwdriver from the solder.

Effective ways to unscrew a rusted bolt or nut?

If we consider more effective ways to deal with rust, it is worth highlighting the following methods.

Heat.

From the physics course, we know that metal tends to expand against the background of an increase in temperature. This feature can be used to solve the problem at hand.

To unscrew a rusted nut, warm it up well, then immediately try to unscrew it.

It is important here to act quickly so that the metal product does not have time to cool down. The essence of the manipulation is that due to uneven heating, rust is deformed and has less restraining force.

Heating can be carried out in any available way. This could be a gas torch, candle, lighter, or even a soldering iron.

You can also use a blowtorch or other device.

When using this technique, be careful and remember about contraindications. In particular, heating is not recommended if wood or paintwork products are located in the connection area.

In this case, the part will be damaged, and you will have to spend money on its replacement.

Tapping.

Unscrew rusty nut or the bolt can be done using the folk method - by tapping around the perimeter of the part.

Mechanical action on each side allows to achieve greater deformation, contributing to the crumbling of rust.

Be careful not to damage the edges of the nut when tapping. Otherwise, the unscrewing task will become more difficult.

Twist.

You can also go the other way. First, tighten the nut (bolt) with maximum effort, and then try to swing the joint and displace the rust layer in this way.

If the manipulation is successful, it will not be difficult to unscrew the nut or bolt.

Wax cup (difficult, not practical, but possible).

This technique cannot be called popular, but in terms of efficiency it does not lag behind "competitors".

The algorithm of actions is simple. Blind a cup-shaped form of plasticine or wax so that its sides are above the level of the nut (about 2-3 mm).

After diluting the sulfuric acid, pour the liquid into the prepared cup and add a little zinc. This chemical combination provides a galvanic effect and the ability to unscrew the part.

Destruction.

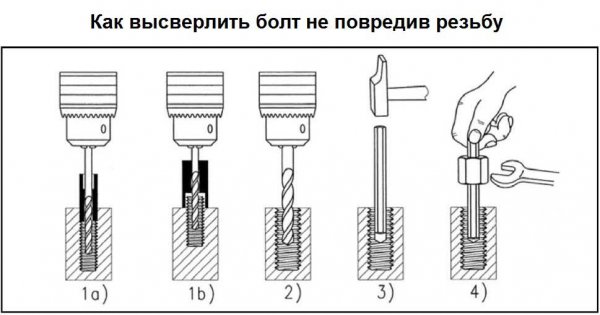

If none of the above methods gave results, and the upper part broke or was severely deformed, there remains one more solution - the destruction of the bolt and its drilling out of the vehicle part.

Here, to complete the work, you will need a hand or electric tool, as well as a set of drills of a suitable diameter.

Before drilling, place the drill bit in the center of the bolt and hit it with a hammer. This is necessary to deepen the product in the central part to a certain depth.

At first, work in small steps and make sure that the drill goes exactly in the central part (tilting to the left and right side is prohibited).

Start with a small diameter drill, and then take a larger piece.

When choosing a drill, pay attention to two criteria - price and country of origin. Please note that high quality products cannot be cheap, because hardened steel is used in their manufacture, and sharpening is done in a certain way

Please note that high quality products cannot be cheap, because hardened steel is used in their manufacture, and sharpening is done in a certain way.

At the same time, special drills do an excellent job with aluminum, cast iron and other materials (including fragile ones).

To ensure correct drilling, use special lubricants, thanks to which it is possible to solve several problems at once - to protect the drill from strong heat, cool the metal and lubricate the drilling elements. As a result, the whole process is facilitated.

Khimichim

Now we will consider ways for those who do not rely on the help of physics, but want to solve the problem with the help of chemistry. Your laboratory should have: kerosene, white spirit, acidified sulfuric acid, zinc, plasticine, hammer, water, sandpaper, wrench, chisel.

Attributes of the chemical method for loosening the nut

Process.

With kerosene (experienced people recommend making a mixture of White Spirit and kerosene) we moisten the nut and bolt, applying a tampon to them, no matter what, cotton or gauze. After some time - from an hour to a day, and with repeated attempts, you may find that the hub nut can be easily unscrewed. But even here you can't do without strength: at least, you will probably have to work with sandpaper to clean the parts from rust. If, after that, the matter does not go well, you should help with a hammer: knock it on the edges of the hub nut.

If in this case you did not succeed, make a small container of plasticine, fix the hub nut on top, pour water with sulfuric acid there, put zinc in the container. A chemical reaction starts that does a very good job with rust. Usually a day is enough for even running corrosion to release the part. Finish the job with the wrench. But this method is valid only if the reason is that the nut is firmly stuck and / or rusted, and if it is simply overtightened, neglecting the required tightening torque (in order "for sure"), then you just need to chick it.

What is the bottom line ..

As you can see, unscrewing the hub nut is not an easy task, but it can be solved.

Note that to begin with, try to preserve the hub nut by using penetrating fluids such as a pedestal. Physical efforts to twist the hub should be moderate.

And, of course, it is worth refraining from strong blows and burning with a burner, as ways that can damage not only the nut, but also the bearing.

Cases when it is difficult to unscrew the bolt

Threaded connections have the unpleasant property of losing their mobility over time. To avoid this, the fasteners to be connected are made of different metals, for example, steel and brass. Or the mating pair is made of stainless steel. But that rarely happens.

Basically, steel fasteners are used in mechanisms, assemblies and metal structures. If it is in a humid environment, then over time, corrosive processes begin, which significantly complicate dismantling when the need arises. There may be several reasons why hardware (metal products) do not want to be unscrewed.

The edges are torn off

Each fastener must be tightened with a certain amount of force during assembly - sufficient to ensure the strength of the connection. By applying excessive force, it is possible to break the threads of small products - from M3 to M12.

For larger fasteners, this is no longer scary, so many men tighten bolts and nuts with maximum effort. This is bad for any hardware. When the time comes to disassemble the connection, parts damaged during assembly can greatly complicate the task: with a rolled slot - a screw or screw, with torn edges - a bolt or nut.

Most often, a hexagon turns an open-end wrench that has only two working planes. Therefore, if possible, you should always use a spanner, head or special tool.

But if the edges are already "lapped", they do not always help. The tool rotates and the fasteners remain in place.

Rusty nut

Corrosion processes always lead to the appearance of rust, which tends to swell and grow in size. As a result, the thread is jammed. Unscrewing a rusty nut becomes problematic. Auto mechanics, locksmiths, and craftsmen who work at home are all faced with this.

In addition, the nut can rust not only in the area of the thread, but also in the place of contact with the product. Sometimes the puck doesn't help either. The connection becomes monolithic over time. To disassemble it, you have to work hard.

The bolt got stuck from time to time

Often there is a situation when fasteners cost years before disassembly on mechanisms. During this time, it manages to stick to the body of the structure so strongly that the strength of the connection can be compared to that of a welded one. The most difficult to unscrew in these situations are hardware that is subject to thermal effects.

Car enthusiasts and service mechanics know how difficult it is to unscrew the exhaust system fasteners on a muffler or resonator. Sometimes any way to move a stuck bolt out of place is powerless. It remains only to destroy the connection using one of the mechanical methods.

How to remove a hex head bolt or sprocket

In the automotive industry, other equipment often uses hex bolts. How to turn out a torn off hat that has its edges torn off:

- Make a horizontal notch with a grinder or a file on the head. In this case, a strong screwdriver is used to unscrew the torn off screw.

- Using a special TORX sprocket, which is hammered into the cap. The nozzle is selected in size, slightly larger than the torn off cap, for a strong connection between the walls.

- Extractor set available from hardware store. Before using the extractor, a hole is drilled with a drill in the base of the bolt, then the extractor is inserted, the screw is removed with pliers or a special clamp.

- Use a counterclockwise drill with a slightly smaller hole diameter. The tool works in reverse mode, with this method it is possible to damage the thread.

How to unscrew a torn-off bolt manually

Torn off nuts are more difficult to unscrew, since there is a possibility of damage to the threads during work. The easiest way is to use chemicals, the surface treatment is cleaned and treated with a product for 15 minutes. If the edges are torn off, it is impossible to use a key or a head. In such cases, a chisel is used, which destroys the main part of the nut, then it is removed and replaced with a new nut.

How to remove a bolt if the head breaks off

A broken head of a structure can cause a lot of hassle when working. How to deal with such a difficult situation without resorting to the use of a serious tool. With the small size of the element, it is possible to make a cut with a grinder, the recess of which will allow the use of a screwdriver with sharp edges. For more complex work, you will need an extractor, drill and reamer. The base of the threaded connection is drilled exactly in the middle, after making the hole, the tool is screwed in counterclockwise.

When performing sequential actions, it will not be difficult to unscrew the damaged structural element even for those who first encounter this problem. It is necessary to correctly assess the situation, use a good quality tool for a productive result.

How to drill out a broken bolt

For work, a drill is used from high-quality material. The size must be selected in accordance with the cut edges, the diameter of the drill must not be larger than the hole. A high-quality drill has a higher price, but its use excludes rapid wear and the possibility of breakage during operation.

It is worth using the tool slowly, before completing the task, correctly assess the situation. It is necessary to monitor the position of the tool during work, drilling is carried out strictly in the center, without deviations in different directions.

Self-tapping screws with torn off splines (asterisk)

If the overheated self-tapping screws are twisted / twisted a couple of times, their edges lose their sharpness, the screwdriver scrolls, and the screw itself remains in place. If it "sits" in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band under the screwdriver (for example, for hair). Due to the elastic force, they achieve a tighter fit to the remaining edges, which helps to move the screw out of place. The rest of the methods are more "traumatic":

- Cut grooves inside the "lapped" funnel using a flat screwdriver and unscrew. This method is quite dangerous: if the walls of the "funnel" are too thin, there is a possibility that the screw head will simply crumble from the effort. All that remains is the screw, which cannot be unscrewed in any way.

It's already difficult to unscrew such a self-tapping screw - Drill out and unscrew with a small diameter extractor.

- Take a chisel, grind it to the size of the cap. Put it on the hat, hitting it well with a hammer a couple of times. A new cap is formed and, at the same time, existing rust may crumble (if the self-tapping screw is stuck in the iron). Using the same chisel, try to move the stubborn screw from its place. To facilitate the process, you can drop oil on wood or WD40 grease on metal.

- Drill out the material around the cap, take a tube with an inner diameter slightly larger than the diameter of the cap, put it on the cap. Pour glue inside. When the glue hardens, unscrew by the tube.

We unscrew the self-tapping screw with the torn off edges (cross)

The remnants of a bolt or a stud without a head can be unscrewed as follows: cut the left thread in the remaining body, drip a moment with glue, screw in the left tap, leave for an hour. Drop oil on the main thread and also leave for an hour. Unscrew when the glue has set. If the remnants of a self-tapping screw are stuck in the wood, it is easier to close this hole and install other fasteners nearby.

How to unscrew a hexagon without a key

Other ways to unscrew the non-hex bolt are as follows:

- If the bolt dimensions are not too small, you can use a chisel or an ordinary hammer: they strike at an angle in the direction of unscrewing the fasteners.

- Method using a ring or gas wrench.

- If there is a problem, how to unscrew the "licked" hexagon, you can use a nutrunner with a nozzle. The bolted connection is unscrewed using an impact mechanism.

- Method of application of welding: a small amount of metal with a nut or any piece of reinforcement is welded to the fastener, with which it is then unscrewed.

- An extreme measure for unscrewing a hexagonal hardware with an internal axis is to completely dismantle the fastener, when the cuts are made with a hammer and the fasteners are disassembled.

Ways to unscrew bolts, screws, screws with lapped edges

If in the usual way it was not possible to unscrew the fasteners whose edges were licked off, you can use one of several proven options.

Gas wrench

This method is used when loosening bolts, since they have a head protruding from which you can grab. For this:

- Clean the head of the bolt.

- Lubricate the junction with kerosene or diesel fuel, a liquid like WD-40 helps well, and leave for 15–20 minutes.

- Unscrew the bolt. This is done with a gas wrench. With its help, a large force is created and even a round head can be well gripped.

The disadvantage of this method is that it is not always possible to get close to the desired bolt with a gas wrench.

Slicing new faces

If the bolt is large, then with the help of a grinder, new faces can be cut on it.It is enough to make only 4 of them and use a smaller wrench to unscrew the bolt. It is possible to cut new faces on the bolt with a file, but this is more difficult and takes longer. On the head of a screw or screw, you can make a cut with a hacksaw for metal or a grinder.

Hammer and chisel or impact screwdriver

This option is more suitable for lapped nuts or large enough screws. The chisel rests on the head of the fastener and, hitting it with a hammer, gradually turn the screw or nut. Small screws or screws can be removed with an impact screwdriver and hammer. After loosening the fastening, the work is done with an ordinary screwdriver.

A tourniquet or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of dense rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

Extractor

An extractor is a special tool that is used to loosen screws, bolts or screws with lapped or broken heads.

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the lapped screw slot.

- An extractor of the required diameter is selected. Drive or screw it into the prepared hole. It depends on whether a conventional or a screw tool is used.

- Unscrew the bolt.

Video: unscrewing the licked screw with an extractor

Conventional or left hand drill

Left hand drills with counterclockwise rotation are available. They improve the centering of the tool and reduce the stress on the drill, which results in higher productivity and accuracy of drilling. By inserting such a tool into a drill, you can unscrew the screw or screw with a licked head. If a left-hand drill is not available, you can try drilling out the jammed fasteners with a regular drill. In this case, you need to take a drill, the diameter of which is less than the diameter of the bolt or screw.

It is necessary to act carefully so that you do not have to cut the threads for the new fastener later.

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called "cold welding". After the glue securely fixes it, turn the nut with a wrench and unscrew the screw or screw with it.

Welding

If there is a welding machine nearby, then you can fix a new nut on the head of a bolt or screw by welding it. After that, it can be unscrewed immediately.

Solder and soldering iron

If you need to unscrew a small screw or screw, use a soldering iron and solder:

- The heated solder is dripped onto the head of the fastener with lapped edges.

- Until the tin has solidified, a screwdriver is inserted into it and wait a few minutes.

Step-by-step instructions for unscrewing the bolt

The techniques presented below will help to solve the problem of unscrewing fasteners with various types of damage.

With tainted edges

The experience of specialists will tell you how to unscrew bolts with stripped edges. For this, several effective methods are used at once. The speed of work is affected by the location of the fasteners, the availability of the necessary tools and the availability of hardware. It is recommended to apply each of the following methods in turn until the damaged hardware is completely dismantled:

- Engaging a sharp chisel. This method is only applicable if a large bolt is broken. Access to fasteners will be a weighty argument. You will need a chisel and hammer to remove a part with a broken edge. A chisel must be applied to the head of the bolt tangentially and hit with a hammer. This approach can be called the simplest. But such actions are not suitable in all cases.

- A more efficient way is to use a flip key.If there is free access to the hardware, the universal key will most likely be able to rip the item from its place. The principle of operation lies in the use of special notches, which are located on the working surface. The wrench securely grips the head and allows you to unscrew the smallest bolts. A prerequisite is that the flip key must be new.

- A spanner may also be a necessary tool. Stripped-off bolt heads are often used to tackle the most challenging applications. The key profile should consist of 12 edges, and inside there is an asterisk socket. The head should be one size smaller than the bolt. The part is carefully put on the fasteners with a hammer and the hardware begins to twist.

- Hacksaw for metal. The device allows you to cut a recess for further unscrewing the hardware with a flat screwdriver. In this case, the depth should be 25% less than the height of the hardware head.

- With the help of a grinder or a file, you can make new faces for a smaller key size. With an open-end wrench, you can make only 2 faces parallel to each other.

- A fallback is to use a welding machine. In this case, an additional nut must be welded to the bolt.

Damaged threads

Thread damage is a common problem. As a result, the bolt scrolls in the seat and is not pulled out. There is a proven way to remove a stripped thread bolt. Use a flat screwdriver to lift the fasteners. To do this, a screwdriver is placed between the head of the hardware and the base, after which the fastening element is pulled up with effort. Then you need to start unscrewing until it is completely removed from the seat.

Experts also recommend pushing the fastener from the back, provided that the hole is a through sample. If it is not possible to dismantle the nut due to the stripped thread, this place is cut off with a grinder.

Under the sprocket and hexagon

Fastening materials with sprocket heads and a hexagon are widely used. Such hardware is reliable and easy to use. However, such parts can also fail.

If the edges are damaged, proceed in the same way as in the case of simple bolts. The only difference is that the dismantling is carried out using special keys with characteristic faces - a hexagon or an asterisk.

For a screwdriver

With limited access, you can make a notch in the bolt. A chisel or grinder will come to the rescue. Having made a cut, they try to unscrew the hardware with a screwdriver. If this method does not bring the desired result, the screwdriver is placed at an angle and hammer blows are applied to the handle. It is recommended to apply a lubricant before unscrewing the torn off bolts. The applied force must be in a counterclockwise direction.

A detailed video on how to unscrew damaged bolts:

Why is a rusty bolt or nut difficult to loosen

Any metal fasteners inevitably corrode and rust over time. The process is accelerated if bolts, nuts are often exposed to an aggressive environment:

- contact with water;

- interaction with chemicals, including detergents;

- street dirt, dust, corrosive salts - they accelerate the corrosion processes.

Despite the special protective coatings against rust, if the surface of the fastener was even slightly damaged, then over time the process of destruction is inevitable.

After some time, the rusted bolt must be removed and replaced, but a problem often arises - it does not loosen. Due to the oxidizing processes of the metal, rust builds up on the fasteners and parts and the surfaces "seize" to each other. If this process develops at the location of the bolt thread, then the situation becomes even more difficult.