Reasons for tearing off edges

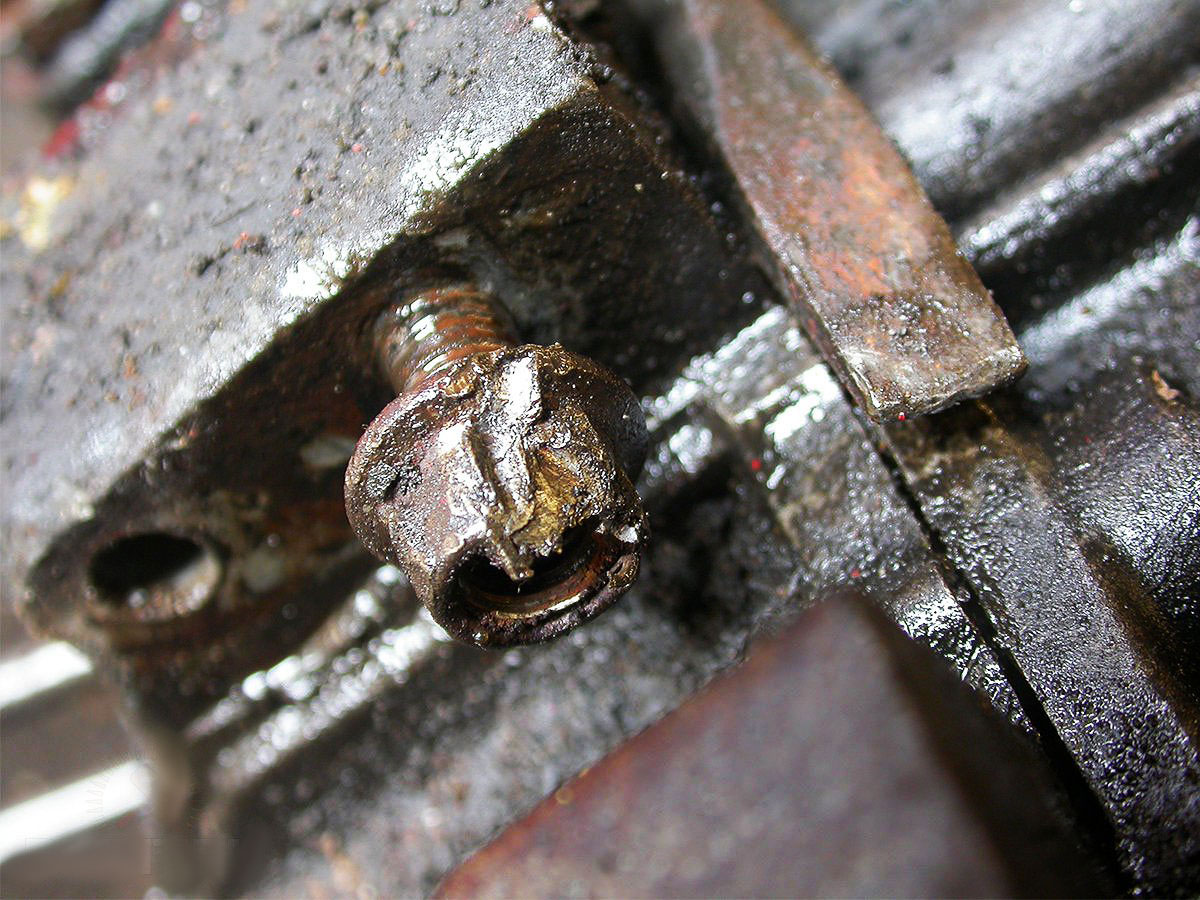

The desire to quickly replace failed parts fixed with a threaded connection is not always feasible. Sometimes, trying to unscrew the bolt from the unit body, the key starts to spin.

This is due to the tearing off of the edges on the head of the hardware when exposed to an increased load. And the reason for this may be the following factors:

- sticking, which is caused by the diffusion of atoms with a long connection;

- displacement of the connected parts relative to the axis of the holes, which leads to jamming of the screw;

- overtightening during installation (increased load);

- the use of an inappropriate tool during assembly (for example, to tighten a bolt with a head size of 14 mm, a 17 key is used, and a screwdriver is inserted to eliminate the gap);

- corrosion pitting the surface of the head.

How to remove a hex head bolt or sprocket

In the automotive industry, other equipment often uses hex bolts. How to turn out a torn off hat that has its edges torn off:

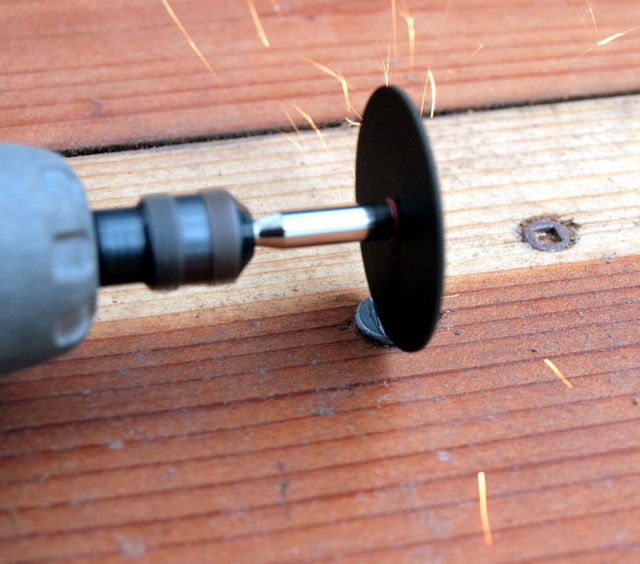

- Make a horizontal notch with a grinder or a file on the head. In this case, a strong screwdriver is used to unscrew the torn off screw.

- Using a special TORX sprocket that is hammered into the cap. The nozzle is selected in size, slightly larger than the torn off cap, for a strong connection between the walls.

- Extractor set available from hardware store. Before using the extractor, a hole is drilled with a drill in the base of the bolt, then the extractor is inserted, the screw is removed with pliers or a special clamp.

- Use a counterclockwise drill with a slightly smaller hole diameter. The tool works in reverse mode, with this method it is possible to damage the thread.

How to unscrew a torn-off bolt manually

Torn off nuts are more difficult to unscrew, since there is a possibility of damage to the threads during work. The easiest way is to use chemicals, the surface treatment is cleaned and treated with a product for 15 minutes. If the edges are torn off, it is impossible to use a key or a head. In such cases, a chisel is used, which destroys the main part of the nut, then it is removed and replaced with a new nut.

How to remove a bolt if the head breaks off

A broken head of a structure can cause a lot of hassle when working. How to deal with such a difficult situation without resorting to the use of a serious tool. With a small element, it is possible to make a cut with a grinder, the recess of which will allow the use of a screwdriver with sharp edges. For more complex work, you will need an extractor, drill and reamer. The base of the threaded connection is drilled exactly in the middle, after making the hole, the tool is screwed in counterclockwise.

When performing sequential actions, it will not be difficult to unscrew the damaged structural element even for those who first encounter this problem. It is necessary to correctly assess the situation, use a good quality tool for a productive result.

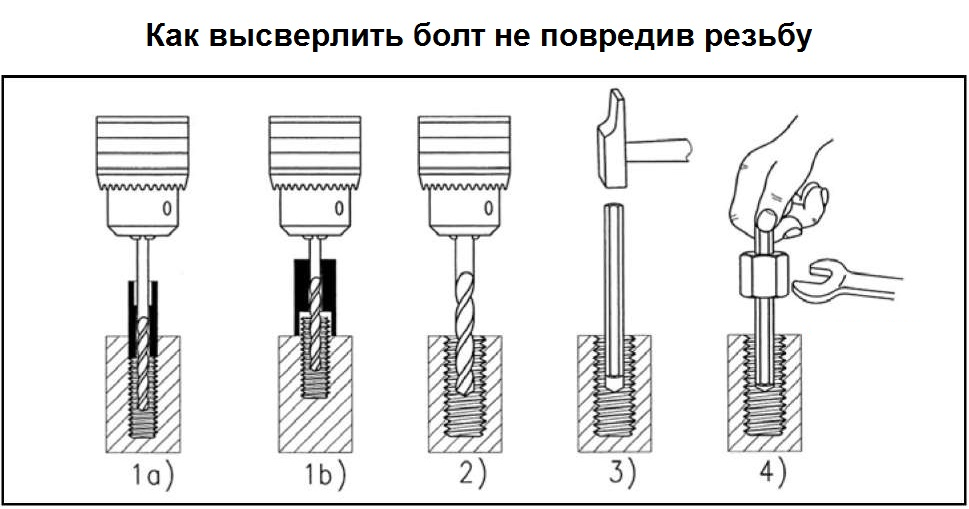

How to drill out a broken bolt

For work, a drill is used from high-quality material. The size must be selected in accordance with the cut edges, the diameter of the drill must not be larger than the hole. A high-quality drill has a higher price, but its use excludes quick wear and the possibility of breakage during operation.

It is worth using the tool slowly, before completing the task, correctly assess the situation. It is necessary to monitor the position of the tool during work, drilling is carried out strictly in the center, without deviations in different directions.

Flush break

This type of breakage is considered the most difficult to repair, as it is very difficult to determine the diameter of the hole, especially when shearing fasteners. Therefore, in order to drill out a certain kind of broken bolt, it is necessary to clean the surface. This will allow us to determine the gaps we need.

This type of breakage is considered the most difficult to repair, as it is very difficult to determine the diameter of the hole, especially when shearing fasteners. Therefore, in order to drill out a certain kind of broken bolt, it is necessary to clean the surface. This will allow us to determine the gaps we need.

Often the following unpleasant situation occurs: the place of the break has curved shapes that are very difficult to process and straighten. And it is categorically not recommended to drill a product in such a state, because there is a risk of finally ditching the structure. Therefore, you first need to apply the core, which prepares the place in the center of the drill.

The further procedure for drilling a bolt that has broken in one way or another is similar to the option for a surface break. After the hole has been created, the thread residues are removed with a hook.

Ways to unscrew bolts, screws, screws with lapped edges

If in the usual way it was not possible to unscrew the fasteners whose edges were licked off, you can use one of several proven options.

Gas wrench

This method is used when loosening bolts, since they have a head protruding from which you can grab. For this:

- Clean the head of the bolt.

- Lubricate the junction with kerosene or diesel fuel, a liquid like WD-40 helps well, and leave for 15–20 minutes.

-

Unscrew the bolt. This is done with a gas wrench. With its help, a large force is created and even a round head can be well gripped.

The disadvantage of this method is that it is not always possible to get close to the desired bolt with a gas wrench.

Slicing new faces

If the bolt is large, then with the help of a grinder, new faces can be cut on it. It is enough to make only 4 of them and use a smaller wrench to unscrew the bolt. It is possible to cut new faces on the bolt with a file, but this is more difficult and takes longer. On the head of a screw or screw, you can make a cut with a hacksaw for metal or a grinder.

A deeper cut can be made on the head of a screw or screw for a screwdriver

Hammer and chisel or impact screwdriver

This option is more suitable for lapped nuts or large enough screws. The chisel rests on the head of the fastener and, hitting it with a hammer, gradually turn the screw or nut. Small screws or screws can be removed with an impact screwdriver and hammer. After loosening the fastening, the work is done with an ordinary screwdriver.

An impact screwdriver can be used to unscrew small or lapped screws

A tourniquet or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of dense rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is laid between the screwdriver and the head of the screw or screw

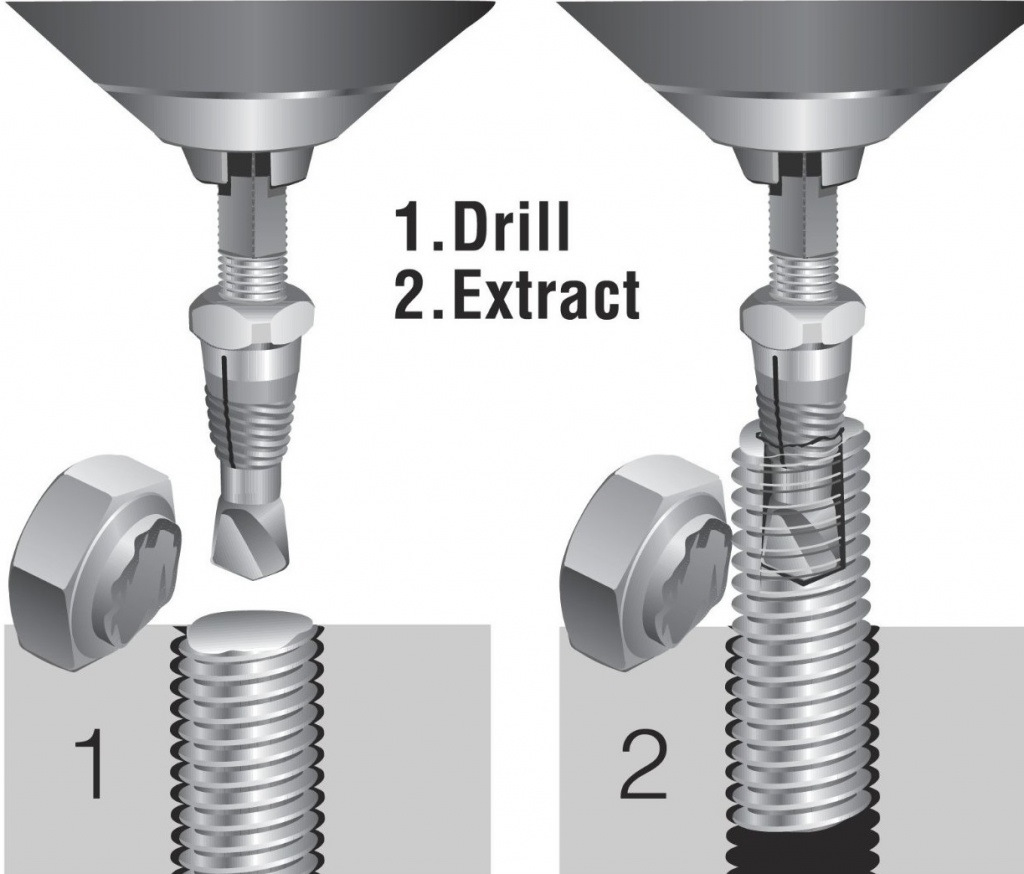

Extractor

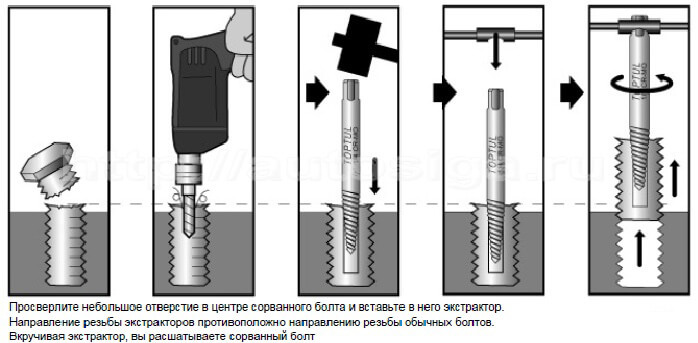

An extractor is a special tool that is used to loosen screws, bolts or screws with lapped or broken heads.

Extractor - a tool for loosening screws, bolts or screws with lapped or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the lapped screw slot.

- An extractor of the required diameter is selected. Drive or screw it into the prepared hole. It depends on whether a conventional or a screw tool is used.

-

Unscrew the bolt.

Video: unscrewing the licked screw with an extractor

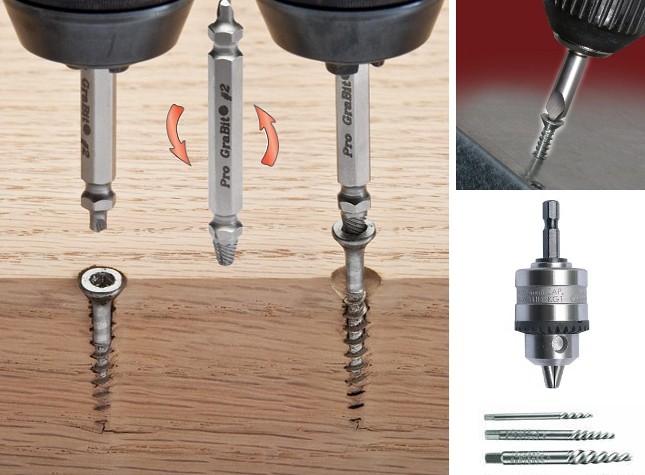

Conventional or left hand drill

Left hand drills with counterclockwise rotation are available. They improve the centering of the tool and reduce the stress on the drill, which results in higher productivity and accuracy of drilling. By inserting such a tool into a drill, you can unscrew the screw or screw with a licked head. If a left-hand drill is not available, you can try drilling out the jammed fasteners with a regular drill. In this case, you need to take a drill, the diameter of which is less than the diameter bolt or screw

It is necessary to act carefully so that you do not have to cut the threads for the new fastener later.

The drill should have a smaller diameter than the problematic bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called "cold welding". After the glue securely fixes it, turn the nut with a wrench and unscrew the screw or screw with it.

With the help of glue, the nut is fixed to the licked head, and then the screw is unscrewed with it

Welding

If there is a welding machine nearby, then you can fix a new nut on the head of a bolt or screw by welding it. After that, it can be unscrewed immediately.

A new nut can be welded to the problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or screw, use a soldering iron and solder:

- The heated solder is dripped onto the head of the fastener with lapped edges.

-

Until the tin has solidified, a screwdriver is inserted into it and wait a few minutes.

- Unscrew the problem screw and clean the tip of the screwdriver from the solder.

Drilling

One of the methods that allows you to remove rusty and welded bolts, destroying them completely. It is used in cases where the bolt is twisted. This method is especially convenient if, during the operation of the mechanism, the edges of the head were violated (licked off).

After selecting the drill, it is necessary to eliminate the effect of the drill drift to the side during the drilling process. To solve this problem, devices called conductors are used. Structurally, this is a plate with holes into which sleeves equal to the diameter of the drill are inserted. They do not allow the drill to go to the side during operation.

If fasteners with a large diameter drill two holes from the side of the center to a depth of ten millimeters. Insert metal pins (nails, pins of a suitable diameter) and try to turn the old bolt.

If the thread gives in, the problem is solved. If not, the hole should be drilled all the way through or through. Then remove the remaining metal.

Bolt breakage below surface

Complex malfunction, especially for a soft metal part

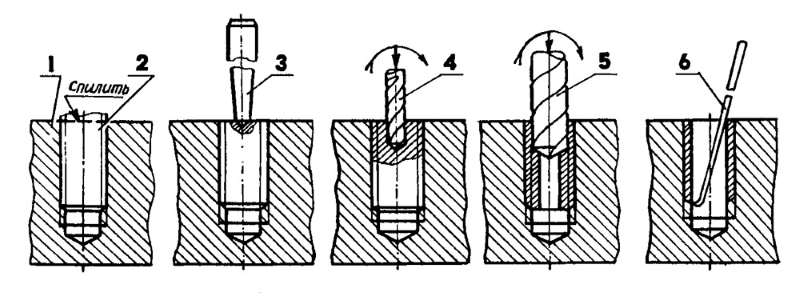

Therefore, it is very important to unscrew the broken bolt without damaging the thread in the hole. The procedure is as follows:

- The center of the hardware is outlined using a core. It is best to use a thin and durable metal tool, it will not damage the product;

- Then a tap is purchased that has a reverse thread. Its diameter should be smaller in comparison with the diameter of the bolt;

- A not very deep hole is drilled for the tap;

- A tool is installed to cut the threads. It turns in a circle and then the element can be unscrewed.

If the last point failed, then the tool can become directly a bolt. However, it is not worth making unnecessary efforts, as there is a possibility of breaking it. As a result, you can remove the old broken part and tighten the new elements.

With a drill

You can try drilling out the rest of the bolt with a drill that is close to the size of the bolt. After drilling, remove the remnants of the bolt with a screwdriver.

It should be remembered that for this type of drilling, a certain skill is required so as not to damage the thread of the hole.

If the described instructions on how to properly unscrew a broken bolt did not help you, then you can use another method.

If the design of the part allows, then you can drill the place of the broken bolt with a large drill, then cut a new large diameter thread and tighten a suitable bolt.

If you do not have the opportunity to tighten a large bolt, then you will have to look in the store or find a locksmith or turner who will make you a sleeve with a large outer diameter for a new hole. Cuts a smaller female thread on the sleeve to suit your design.

On the Internet, you can find various photos of broken bolts and advice from various professionals who describe the whole process of working to unscrew one or another broken bolt.

This article describes the simplest options you can use to remove a broken bolt. But sometimes bolts or studs break in the most inappropriate places.

To eliminate this problem, you will most likely have to contact certain specialists who, due to their professional activities, have a lot of ideas on how to unscrew a broken bolt from any of the most difficult-to-reach places.

How to prevent edges from ripping off

So that a problem such as torn off edges of a bolt or splines of a screw, a screw does not take you by surprise, you must adhere to simple rules:

- you need to buy only high-quality fasteners that have high strength and reliability;

- when tightening and unscrewing screws or screws, the screwdriver must not be allowed to slip in the slots. This leads to their erasure and it will already be difficult to unscrew such fasteners;

- you should always monitor the condition of the instrument. If the screwdriver or wrench has licked edges, then with their help it will be difficult to unscrew the screw, bolt or screw.

It is much easier to prevent the edges from licking on bolts, screws and screws than to unscrew the damaged fasteners later.

Do not panic when a problem such as a licked bolt head or slots on the head of a screw or screw appears. There are many ways to solve it. It is necessary to adequately assess the situation that has arisen, and choose one of the available options.

How to unscrew a torn bolt

If there is not enough gripping area for the tongs, attempts to use the tool in this situation are practically useless. It is necessary to use a file to make edges on a torn off product of a smaller diameter. After successful processing, a key or a head of the required diameter is selected, the torn element is smoothly unscrewed.

Loosening a torn bolt

Using a hammer in conjunction with a chisel can facilitate work, it is necessary to make a notch and unscrew it with a tool with precise blows. This method is considered effective, since the impact force is exerted in the right direction. As soon as it can be visually determined that the process has moved, a suitable spanner or socket can be used.

If you have a welding machine at hand, it is necessary to weld the nut onto the cap, then with a sharp movement it is possible to unscrew the torn off part. In cases where the nut cannot be welded on due to lack of space, a piece of metal is welded on for further processing of the edges.

Experienced craftsmen will tell you how the connection element with the torn edges is twisted, some just start drilling without wasting time. An effective way is to eliminate the washer between the bolt and the clamping area. The hammer hits the chisel mounted on the nut.

Ways in which you can unscrew the bolts

Broken bolt extractors

There are several ways to remove a broken bolt. Let's consider them in more detail.

With the top of the cap head bolt

When deformed, a kind of "antennae" are formed on it, which can be hooked on the rest of the bolt in the hole

The easiest way to unscrew a broken but well lubricated bolt when tightening is to use its already broken off top.

The probability of success when using this method is small, but it is worth trying, especially if the bolt breakdown occurred at the initial stage of tightening.

Using a small screwdriver or chisel

Removing damaged bolts

You can try to unscrew the remnants of the bolt using a screwdriver or small chisel. In this case, there are two options for action: either simply unscrew the broken part, using irregularities at the place of the gap, or make some kind of a small slot on the upper side of the broken part, clinging to the edges of which and twisting.

The latter method is realizable only if the material from which the chisel or screwdriver is made has a higher strength than the material from which the bolt was made.

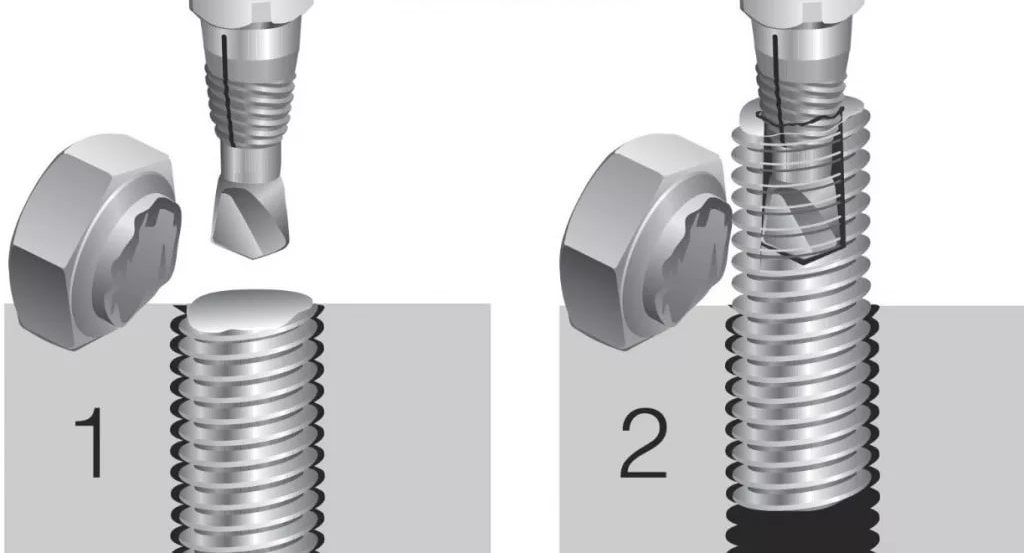

Using the extractor

The extractor is a drill with a long tapered tip

This is the most effective way, since it almost always succeeds in achieving results. The peculiarities of the device of extractors are that they are screwed into a hole located in the central part of the screw to be unscrewed. In this case, the thread present on the extractor has the opposite direction to the bolt thread (so-called "left-hand thread").

Usually, the kits sold include several drills of different diameters.

They all have the same shape, while on the other side of the tapered thread there is a rectangular mount for a drill or tap.

In the process of screwing it into the bolt, the extractor wedges it and at some point it stops. Further rotary motion is transmitted through the extractor to the bolt and unscrews it.

Consider the sequence of actions that need to be done in order to unscrew the torn off bolt using an extractor.

No. 1 Reaming the remnants of the bolt

It is recommended to make a bushing of small length, from the outer part of which you cut a thread with a pitch equal to the thread of the hole into which the stripped bolt was screwed

1

First, you need to make a hole in the remnants of the broken bolt. This is a very difficult operation because the bolt diameter is relatively small. Also, be very careful when drilling to avoid damaging the threads.

In this case, two drills with a different tip shape are used - with an obtuse and an acute angle

2

In the center of the sleeve, you need to make a hole large enough to pass the drill, which will ream the rest of the bolt.

Unfortunately, this method is not always applicable, since for its implementation it is necessary to have a lathe on hand. Therefore, a different method is applied.

The first is used to level the top of the remnants of the bolt, and the second is used directly to drill the hole for the extractor. In this case, the diameter of the drill with the tip having an obtuse angle should be slightly less than the diameter of the threaded hole. The diameter of the second drill should be equal to the diameter of the extractor.

No. 2 Twisting the extractor

It is undesirable to use pliers, as they lead to "licking" of the rectangular end of the extractor

1

Then everything is simple - an extractor of the appropriate diameter is twisted into the resulting hole

This should also be done with caution, as low as possible. It is necessary to use the correct tool for screwing the extractor (a tap or a special nozzle for a square drill) so as not to spoil its attachment from the opposite side

As a last resort, you can weld a nut of the appropriate size to the end of the extractor in order to unscrew the bolt using a conventional wrench

2

Next, the extractor is screwed into a bolt and rotates in it until it stops.

Further rotation of the extractor leads to the unscrewing of the remaining bolt

BEST WAY to unscrew the RIPPED BOLT or BROKEN HAIRPIN with your own hands in the garage !?

How to Unscrew a Broken Bolt: 100% Working Way

5.9

Total Score

How to remove a broken bolt

9.2 Average score

Disclosure of the topic

9

Availability of application

9

Relevance of information

9.5

2.6 User rating

Disclosure of the topic

8

Availability of application

Relevance of information

|

Preventive measures when screwing bolts into a part

In order not to face such problems, it is best to prevent them. It is not difficult to do this and such work will not cause any special problems.

WD-40 is a versatile formulation suitable for a variety of applications, from lubrication to rust cleaning

WD-40 is a versatile formulation suitable for a variety of applications, from lubrication to rust cleaning

Before "tightly" tightening the bolt, the hole must be generously lubricated with "WD-40" or diesel fuel. After a while, it is required to screw in and unscrew the bolt several times. It remains to lubricate its thread, after which you can stretch it.

Another good preventive measure is candle paraffin. They need to rub the thread of the bolt before screwing it in. After a full broach, it will be nice to slightly heat the hardware with an ordinary gas burner. At the same time, the paraffin will melt and fill in all the smallest voids. After these steps, corrosion simply has no chance.

It makes sense to keep a couple of candles in the garage - it is not known what they can be useful for

It makes sense to keep a couple of candles in the garage - it is not known what they can be useful for

Should I use soap for thread lubrication?

The answer to this the question is clear - by no means. The fact is that in the manufacture of both laundry and toilet soaps, alkali is used. Its amount is negligible, but it is enough to initiate the oxidation of metals. As a result, shells appear on the bolt, as well as on the part itself. They are connected in the process of corrosion, and after some six months it will no longer be possible to turn the hardware out even with the help of an extractor. A similar process in the common people is called sticking.

But soap for lubricating bolts when tightening is not worth using PHOTO: bash.news

But soap for lubricating bolts when tightening is not worth using PHOTO: bash.news

Self-tapping screws with torn off splines (asterisk)

If the overheated self-tapping screws are twisted / twisted a couple of times, their edges lose their sharpness, the screwdriver scrolls, and the screw itself remains in place. If it "sits" in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band under the screwdriver (for example, for hair). Due to the elastic force, they achieve a tighter fit to the remaining edges, which helps to move the screw out of place. The rest of the methods are more "traumatic":

-

Cut grooves inside the "lapped" funnel using a flat screwdriver and unscrew. This method is quite dangerous: if the walls of the "funnel" are too thin, there is a possibility that the screw head will simply crumble from the effort. All that remains is the screw, which cannot be unscrewed in any way.

- Drill out and unscrew with a small diameter extractor.

- Take a chisel, grind it to the size of the cap. Put it on the hat, hitting it well with a hammer a couple of times. A new cap is formed and, at the same time, existing rust may crumble (if the self-tapping screw is stuck in the iron). Using the same chisel, try to move the stubborn screw from its place. To facilitate the process, you can drop oil on wood or WD40 grease on metal.

-

Drill out the material around the cap, take a tube with an inner diameter slightly larger than the diameter of the cap, put it on the cap. Pour glue inside. When the glue hardens, unscrew by the tube.

The remnants of a bolt or a stud without a head can be unscrewed as follows: cut the left thread in the remaining body, drip a moment with glue, screw in the left tap, leave for an hour. Drop oil on the main thread and also leave for an hour. Unscrew when the glue has set. If the remnants of a self-tapping screw are stuck in the wood, it is easier to close this hole and install other fasteners nearby.

How to unscrew a bolt with stripped edges?

It is very good if there is space around the problem connection that allows you to use tools such as an adjustable wrench or pliers for untwisting.

Bolt with stripped edges for a screwdriver

If access to the bolt with torn edges is limited, then you can make a notch on the bolt head with a chisel or using a grinder. After that, you need to try to unscrew it with a screwdriver, and if it does not give in again, then put the screwdriver at an angle to the stuck bolt and hit it with a hammer, trying to create a rotational movement (counterclockwise).

Bolt with a protruding head for an internal hexagon or sprocket

Such a bolt can be unscrewed:

With a flat screwdriver, having previously made a notch on the head of the bolt with a hacksaw for metal or a grinder (it is important to cut with absolutely vertical walls so that the screwdriver does not jump off during the unwinding process);

Using a TORX sprocket of a suitable size (chosen so that the splines do not go into the hole for the hexagon, but it is not too large). Such an asterisk should cut through the head of the bolt with slots, entering tightly into the head itself

Then you should unscrew the bolt with a jerk to avoid breaking the sprocket spline. It is not necessary to use TORX sprockets with holes in the center for this manipulation, as they break off when driven.

With a drill, drill and a set of special extractors (sold in construction and auto dealerships). To do this, drill a hole strictly in the center of the bolt, carefully hammer an extractor of a suitable size into it, and then unscrew it together with the bolt with pliers. This will be easy, since the extractor has the opposite threading direction to the bolt.

With a reversible drill and a left-hand drill, the diameter of which should be slightly smaller than the damaged bolt. First, a small hole is made with an ordinary thin drill, and then we put a drill of left rotation into the drill and turn on the drill in the inverse rotation mode.

Allen bolt

Such a bolt can be unscrewed:

- Using a file to get the next hex size (in this case, the bolt can even be reused);

- With a TORX sprocket of a suitable size;

- With a flat screwdriver, after making a notch on the head of the bolt with a hacksaw for metal or a grinder;

- With the help of an extractor, which is screwed directly into the hexagon hole.

Steel connecting rod bolts

Such a bolt can be unscrewed:

- With an extractor of a suitable size;

- Using electric welding. To do this, you need to insert and weld an unnecessary hexagon that matches the size of the bolt. It should be noted that this method is only suitable for bolts made of steel.

Alternative methods

One such method is to weld a nut onto the broken part of the rod. It is quite effective if part of the bolt is located above the surface of the part. To implement this method, you need a hammer, a welding machine, a grinding tool (manual or mechanical), a nut of the required size.

At the initial stage, preparatory work is carried out. They consist in processing the remaining part: stripping, removing traces of corrosion and degreasing. Using the tool, fix the nut in the center of the rod. With a welding machine, they weld it to the top. The assembled structure is carefully unscrewed from the hole.

This method is used if the reason for not unscrewing the bolt is accumulated corrosion or the so-called welding of the bolt to the body of the part. Various solutions are used to implement this method. They are composed of acid (such as sulfuric acid) and various additives. Recently, the special composition WD-40 has gained wide popularity. In many cases, it becomes a good helper for the problem of unscrewing "difficult" or broken bolts. It is advisable to use this composition with all considered methods, except for thermal, since it is quite flammable.

We drill out a piece

The most time consuming method is to drill out the broken bolts. It should be used only in extreme cases when other methods will not work. There are several reasons for this. Firstly, high accuracy of the work carried out is required, since the likelihood of damage to the thread is very high. Secondly, it will not be so easy to break the bolt, it will take time and several drill sizes.

If there is no skill in such work, the most acceptable option would be to use a thin drill first, and then a larger diameter. The point of the method is to select a size that will be as close as possible to the size of the stud. After the work has been done, the bolt fragment must be removed with a magnet.

Star bolt

You can unscrew such a bolt in the same way as unscrew a nut with torn off edges. The main ways of unscrewing stubborn bolts and nuts were discussed in great detail earlier by us, and now we can summarize all those methods that are suitable for such a screw. So, if your sprocket bolt has ripped edges:

- The easiest way is to use an extractor. The well-proven remedy will not let you down this time either. Make a hole in the leg of the fastener, fix a suitable extractor there and carefully unscrew the jammed bolt. As we can see from this article, a set of extractors of various diameters is a really necessary thing on the farm if you regularly do such assemblies and disassembly.

- Use the gas wrench. This adjustable wrench will grip the bolt tightly, and you can remove it in a few turns. This method is good because you don't need to buy a separate tool. There is a similar adjustable wrench in almost every home.

- Focus on the head of the bolt. If there is enough space around the bolt, make a cut on its head with a grinder or a hacksaw. In this notch, you can rest a screwdriver or chisel and turn the bolt, hitting its free end with a hammer or other convenient tool.

We have considered the options for loosening bolts and nuts that are available for use by any home craftsman. Of course, the methods used in professional workshops or in car services remained outside the scope of the discussion. However, they constantly use equipment that will come in handy at home once or twice. And it costs a lot of money. Professionals use to loosen bolts with stripped edges:

- Wrench.

- Stud runner.

- Specialized extractors.

However, if you have such situations no more than once a year, then there is no particular point in purchasing special tools.

Rusty nut

Another problem that is familiar to motorists (and not only) is a rusty nut and / or thread. In this case, you should not make a heroic effort to unscrew the fasteners. Your edges will simply "merge" and another problem will be added to the boiling thread. If, after a couple of attempts, it is not possible to unscrew, try the following methods one by one:

- Use a wrench to tap the bolt. There is a chance that the rust will crack and the nut can be unscrewed.

-

Fill the compound with kerosene and wait. It will corrode the rust, after which it will be easier to unscrew the rusted nut. But during this operation, you must not smoke, turn on welding, be near an open flame.

- Warm up the nut. The metal will expand, making it possible to unscrew it. The trick is to keep the nut warm and the bolt shank cold, so heat up quickly. To do this, use a construction hair dryer or open fire (be careful with this). If the screw is small, you can take a powerful soldering iron, heat it up to the maximum temperature, then quickly warm up the junction.

-

This method will (almost) destroy the nut, so it should only be used in hopeless situations. Grooves are made on the edges (using a metal saw, grinder, file).They rest against this groove with a flat screwdriver, giving it a direction in the direction of unscrewing. They knock on the handle with a hammer. If there is at least a couple of moves, maybe it will turn out to be unscrewed.

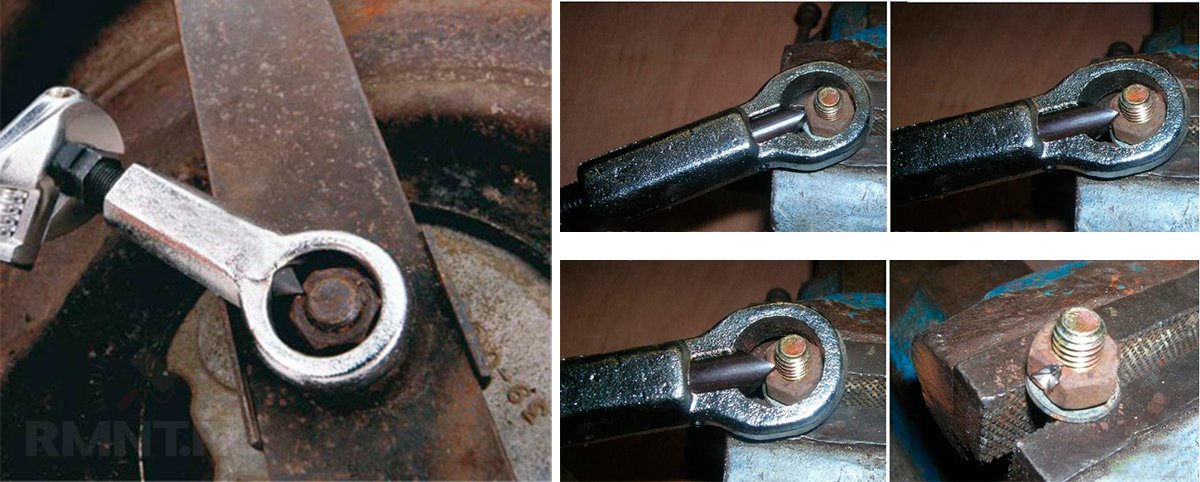

- Use a special puller (pictured above). With the help of a bolt, the pin rests against one of the faces, after which you can try to move it from its place. Due to the fact that a lever can be put on, it can work even in very difficult situations.

You can also fight rust with a lubricant. Try to fill the joint with a flowing multi-purpose grease (available in cans of WD40). After waiting a couple of hours, we try to work with a key. It didn't work - we try other methods one by one.

![[instruction] how to unscrew a broken bolt: 100% working way](https://flwn.imadeself.com/33/wp-content/uploads/7/6/9/76997ab8e05de9eee6338e1a9f19dc4f.jpg)

![[instruction] how to unscrew a broken bolt: 100% working way](https://flwn.imadeself.com/33/wp-content/uploads/2/4/8/2484cf485c95cd0c7953e854e1a1f56c.jpg)

![[instruction] how to unscrew a broken bolt: 100% working way](https://flwn.imadeself.com/33/wp-content/uploads/0/2/3/0232f3b145d3c557583f5f67d0a6b22d.jpg)