Nuances of calculations for fastening PVC panels

It is extremely important to immediately purchase sufficient quantities of PVC panels. The fact is that different batches of plastic differ slightly in shades and, if necessary, it will be rather difficult to select parts that match the color of the cladding.

We calculate the materials as follows:

Determine the number of panels

For vertical mounting:

- measure the room and calculate its perimeter;

- we subtract from the obtained value the width of all door and window openings;

- divide the result by the width of one panel.

The end result is the number of panels to be purchased. It is assumed that the walls above and below the openings will be lined with scraps (panel length is usually 3 m).

PVC Wall Panels for Bathroom with 3D Effect Pattern

It is recommended to purchase several pieces additionally in case of damage to the material by negligence. For horizontal mounting:

For horizontal mounting:

- - according to the results of measurements, we calculate the area of the walls;

- subtract the area of all openings;

- divide the result by the area of one panel;

Add a stock of 10% - 15%.

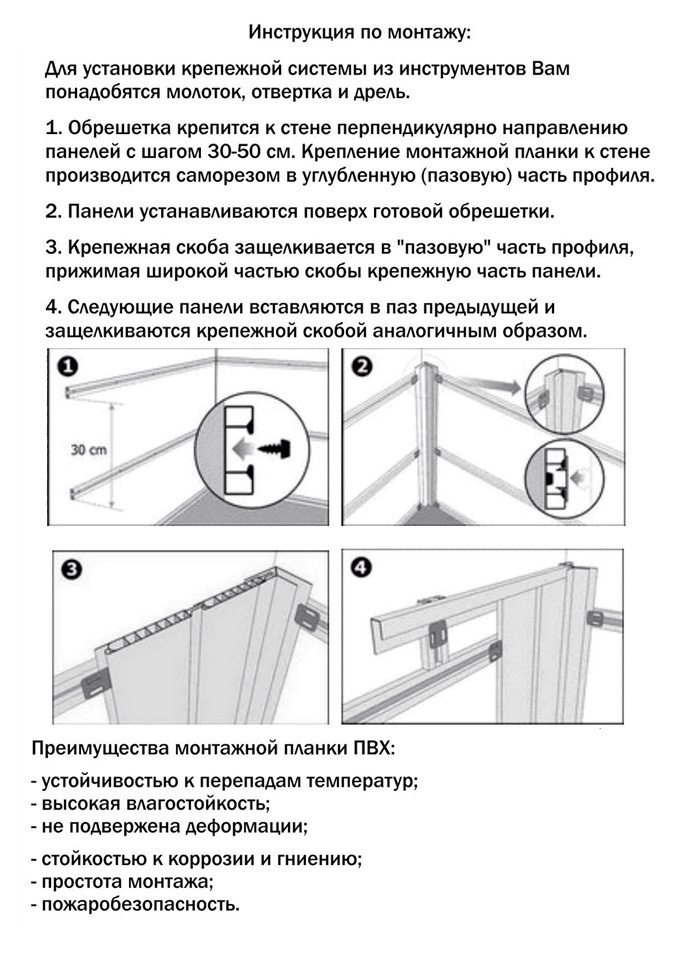

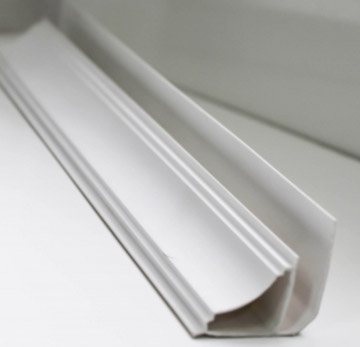

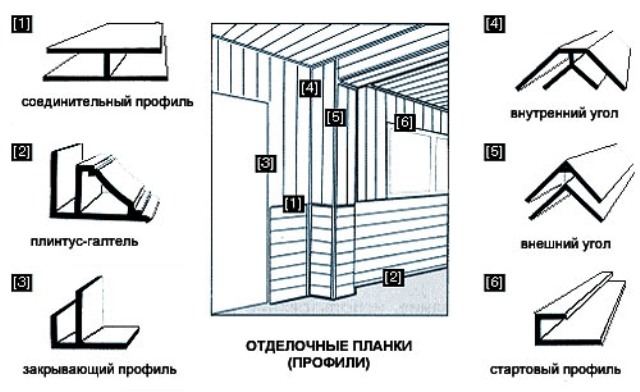

Determine the number of additional elements (moldings)

In general, you will need the following:

- inner corner: the total length is equal to the sum of the lengths of all vertical corners of the room plus the perimeters of the openings;

- a plinth that simultaneously plays the role of a starting bar: the total length is equal to the perimeter of the room minus the width of the doorway;

- ceiling plinth: the total length is equal to the perimeter of the room.

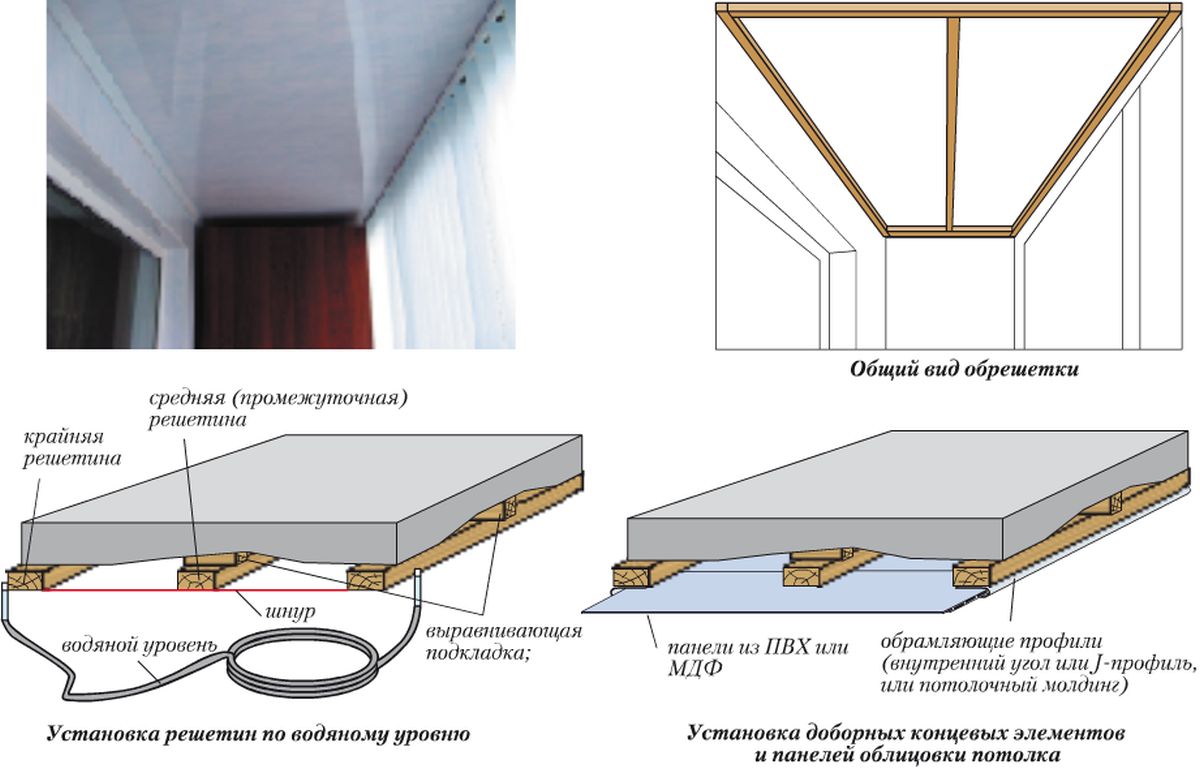

Installation of panels on a rough ceiling

For example, let's take a panel that mimics a slatted ceiling. The rough ceiling does not require any preparatory work.

Step 1. Saturate the rough ceiling with antiseptic agents, let them soak and dry. It is advisable to make the vapor barrier with aluminum foil or plastic wrap. Fix the material with a stapler, carefully seal the joints with tape.

Fixing foil to the ceiling

Glue the joints with tape

Step 2. Measure the distance between the opposite walls of the room and cut the plinth, in the corners, the connection at 45 °.

Cut off the skirting board

Fix the elements to the wall with liquid glue, remove excess material immediately. Fix only three skirting boards, the fourth is placed after the panels have been laid. For a guarantee, you can additionally fix the back of the element to the ceiling with a stapler. Wait 2-3 hours for the glue to dry completely.

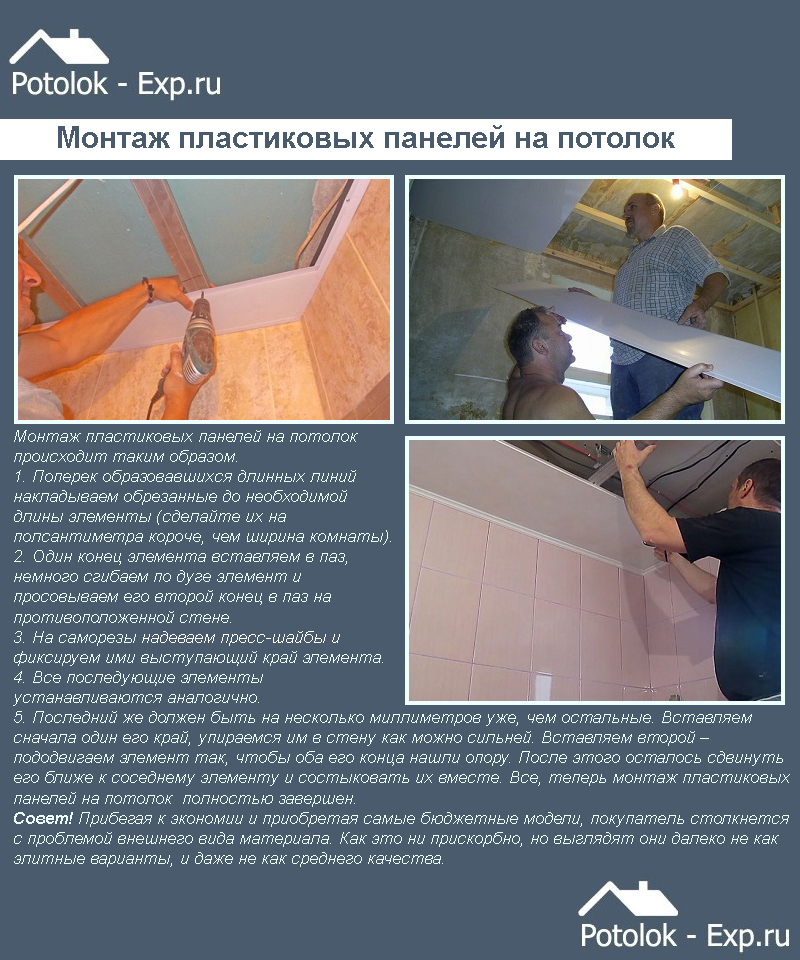

Step 3. Panels for ceilings should be several millimeters thinner than wall panels. Keep in mind that the panel can go two centimeters into each skirting board. Measure the length of the ceiling from edge to edge of the skirting board and add 1.5 cm to this value, the remaining 0.5 cm is left to facilitate installation. It is better to measure and cut each panel separately, this minimizes the likelihood of error.

Step 4. Recheck the dimensions and geometry of the ceiling. If there are minor deviations, then they will have to be gradually eliminated by changing the width of the gaps between the lamellas. The amount of change should not exceed two millimeters, otherwise the correction will become noticeable. If the architectural features of the ceiling allow, then align the panels in places that are invisible to the eye. Open areas will already have smooth joints.

Panels inserted into the skirting pile

Step 5. Insert the end of the panel into one skirting board, bend it slightly and insert the other end into the opposite one. Align the panel and tuck the long edge into the third skirting board.

Plastic guides help hide uneven panel edges

Step 6.Press the panels firmly together, secure them with a stapler. The tighter the locks converge, the stronger the connection. If the ceiling is not very even, then during the fastening of the panel, a gap may appear at the end between it and the plinth. To prevent this from happening, push the plastic trims into these places and only then fix it. Under the force, the plastic will be compressed to the required thickness, the gap will close. It is difficult to bend short slats. In such cases, make them one centimeter shorter, the width of the skirting boards allows it. The best option is to immediately install the panels on the wider side of the ceiling. During installation, do not use excessive force, do not damage the skirting board, do not scratch the walls, do not break the panel.

Installation of plastic panels

Step 7. After all the entire panels are installed, measure the width of the remaining uncovered ceiling. Cut the material to these dimensions using one of the possible methods.

Step 8. Using the method described above, insert the panel into two plinths, connect one edge to the lock. The rest will have to be fixed separately. There are two options. First, before installation, lubricate the reverse side with liquid nails and glue. The second is to drill a hole in one plane along the diameter of the self-tapping screw and screw the second plane to the ceiling with it.

Installation error

Step 9. Cut the base part from the fourth skirting board. Spread the remaining surface with liquid glue and attach to the wall in the proper place.

This completes the installation of the ceiling panels. Of course, during work, you need to leave space for electrical wiring, ordinary or spotlights. If, after installation, gaps are noticeable in some places, then they can be sealed with a sealant of the corresponding color.

PVC ceiling panels

Ceiling made of plastic panels

Technology for mounting PVC panels on the ceiling

Installation of pvc panels on the ceiling

Let's consider how to hem the ceiling with panels.

Material selection

First, of course, you need to choose the right material. The panels are available in a huge variety of designs and colors. They can be either monochromatic or multi-colored, have a glossy, matte or structured surface. You can find on sale panels, the surface of which imitates stone or wood, you can also choose mirror panels for the ceiling, in a word, you can choose your own version of the finishing material for each interior.

Panels differ in size and shape. The most common option is oblong planks, but square or rectangular panels are available.

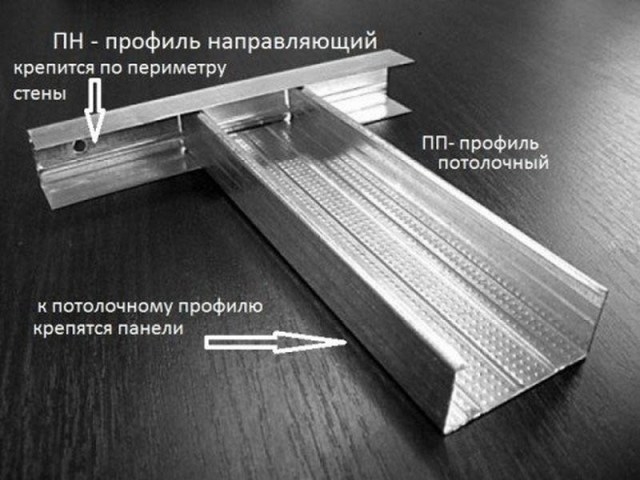

In addition to the panels themselves, you will need to purchase a profile for assembling the frame, hangers, dowels and screws for fastening.

In addition, you will need to prepare the following set of tools:

- Hammer drill or drill with impact attachment.

- Screwdriver.

- Construction level.

- Painting cord for marking.

- The square is metal.

Preparing for installation

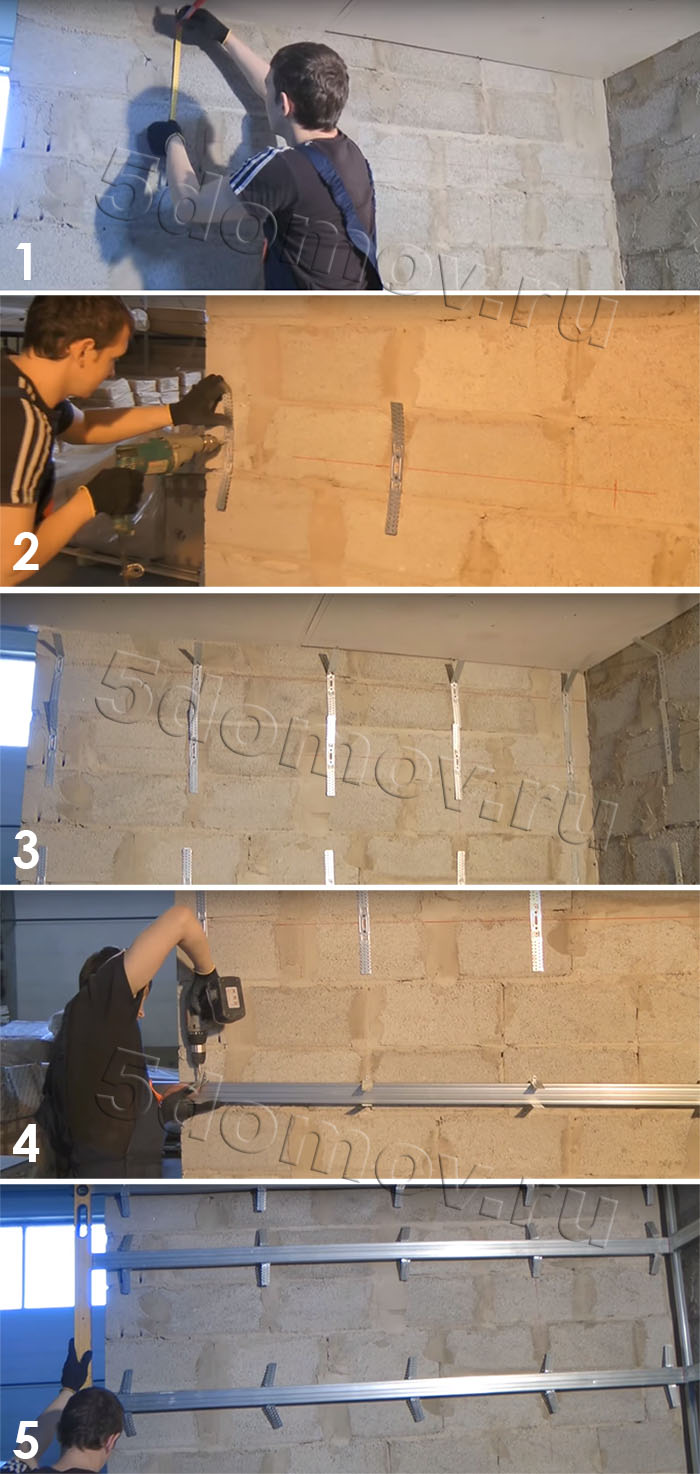

Lathing for installation of pvc panels

Ceiling preparation consists of removing the old coating and stripping loose plaster (see How to clean the ceiling from whitewash: effective options and How to clean the ceiling from water-based paint: practical advice). Before fixing the panels to the ceiling, it is possible to carry out measures for additional insulation of the slab or install a layer of sound insulation.

After that, they begin to markup, this is done like this:

- Height is measured at each corner of the room.

- Having chosen a smaller value, measure down 5 cm, this will be a horizontal level.

- This measurement is transferred to the rest of the walls and, with the help of a paint cord, the lines are punched out.

- Holes are drilled along the outlined line and the profile is strengthened.

Fastening panels

Fixing pvc panels to the ceiling

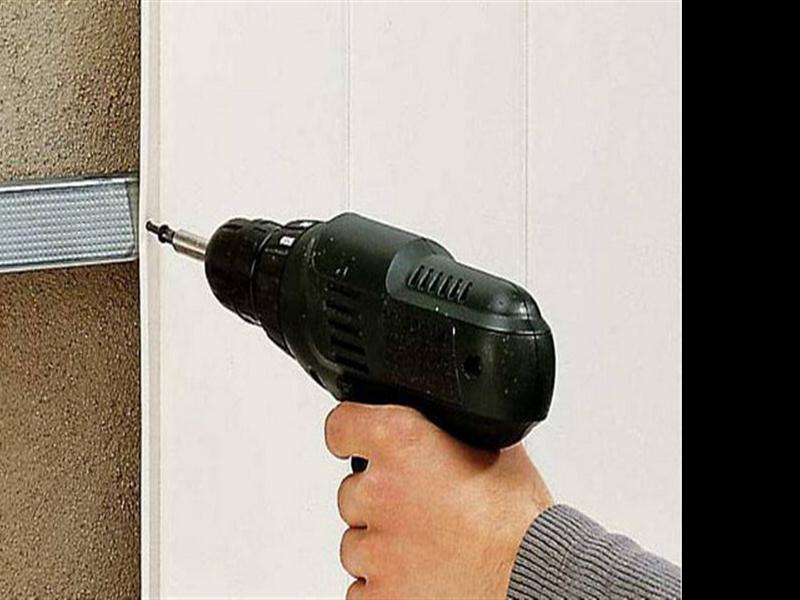

The panels are laid on the finished frame. This is not a very complicated process, the panels are fastened using self-tapping screws.

If there is a plan to put built-in lighting in the ceiling, which implies the installation of hidden wiring, then it is recommended to perform electrical work after the installation of the frame is completed, but before the installation of the panels.

Ceiling filing begins by installing the first of them in the starting profile. The panel is fixed with self-tapping screws, then the second panel is attached to it in the same way. Then the algorithm is repeated until the entire surface of the ceiling has been sheathed.

The main difficulty of this work is that it is rather difficult for one person to hold the long panel in the desired position. Therefore, it is better to work with a partner or, as a last resort, to use supports assembled from a bar.

If the length of the panel is not enough, then it should be extended with a piece of the required length. To make the ceiling look more attractive, it is better that the transverse seams on the panels are not lined up, but staggered.

Main advantages and disadvantages

The advantages of plastic-based plates and panels include:

- increased resistance to moisture and chemicals;

- ease and convenience of installation;

- hygiene;

- fire resistance;

- long service life;

- resistance to mold and mildew;

- democratic price.

The disadvantage of such panels is their low resistance to mechanical stress; therefore, care must be taken when transporting and installing them. The strength parameters are influenced by the wall thickness, as well as the number of rigid ribs inside the slab.

It is simple to check the strength: for this you need to press your finger on the plate - if it bends, the material will be short-lived

The strength parameters are influenced by the wall thickness, as well as the number of rigid ribs inside the slab. It is simple to check the strength: for this you need to press your finger on the plate - if it bends, the material will be short-lived.

In accordance with the production technology, PVC panels are classified into two main types: printed and film.

This material also differs in the type of coating - with a shiny and matte texture. The main criteria for choosing panel products are colors and patterns, but there are a number of points that should be considered when purchasing lamellas. If the panels are packed, it is recommended to unpack them and examine each panel.

- Examine the slice. The strength of the material is indicated by a thick polymer coating on the back of the board and a bridge of sufficient thickness. You can navigate by weight, thicker panels are heavier.

- The plastic must be of the same thickness throughout the panel, no thickening or thin spots.

- Assess the shape: there should be no defects on the cells and edges.

- Check the outside of the pattern for quality and legibility. The presence of scratches and blurred marks is a reason to refuse a purchase.

- Purchase panels from the same batch, if this is not possible, match the pattern and color scheme so that the products do not differ in shade.

- When choosing, be guided by the purpose of the room to be finished.

Manufacturers offer several types of panel products:

- Classic lamellas, connected by groove-tenons, which are plastic boards.

- Sheet boards, similar to plywood sheets.

- A lining made of plastic, similar to thin wood panels of different colors.

When choosing a material, take into account the purpose and interior of a particular room. Plastic lining is a wonderful analogue of wooden panels, it is considered more resistant to heat loss

Sheet-type lamellas are used for cladding spacious rooms. Wall tiles are perfect for kitchens, bathrooms, corridors and other rooms, since they are easy to care for: dirt can be easily removed with a damp cloth or sponge.

The main advantage of plastic sheathing is its low price.The width of the panels is from 20 to 35 cm, the length is from 2.7 to 3 meters, and the thickness is in the range of 8-10 mm. Such parameters and reasonable price allow for cladding with plastic plates with minimal costs.

How important is the sequence of work in the repair of a one-room apartment and how to draw up a step-by-step plan: tips and tricks on how to make a full-fledged repair step-by-step for cosmetic and major home repairs. Read about which grout is better to grind the tiles in the bathroom in this article.

Calculation of the amount of material

The parameters of plastic panels are as follows: thickness ranges from 5 to 10 mm, width - from 250 to 500 mm, length - from 2700 to 3000 mm. Mounting profiles are available in standard lengths - 3000 mm.

First you need to calculate the area of one panel (multiply the width by the length), and then the area of the ceiling. The second number must be divided by the first, and then add 15% for pruning and stock. It is recommended to round the resulting figure to a higher number, so that during the work you do not have to buy additional material.

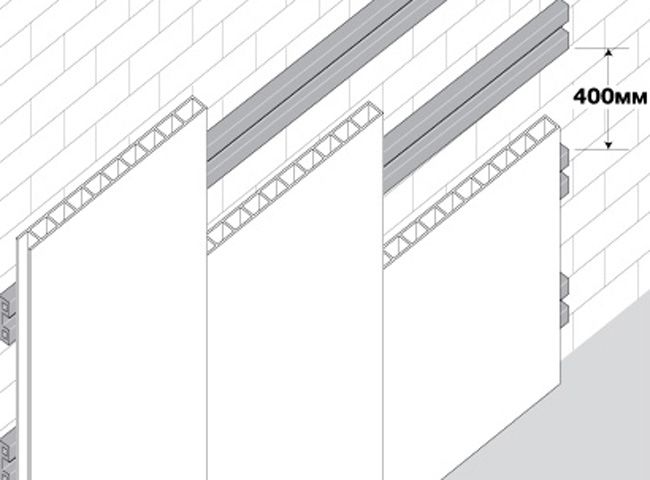

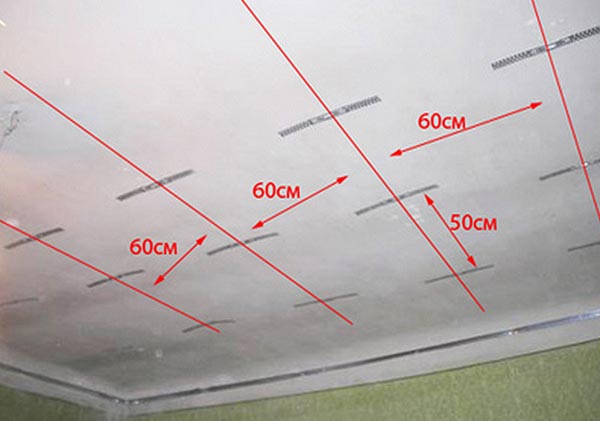

It is also very important to correctly count the number of metal profiles or wooden battens. For this purpose, you need to draw a proportionally reduced ceiling plan on paper.

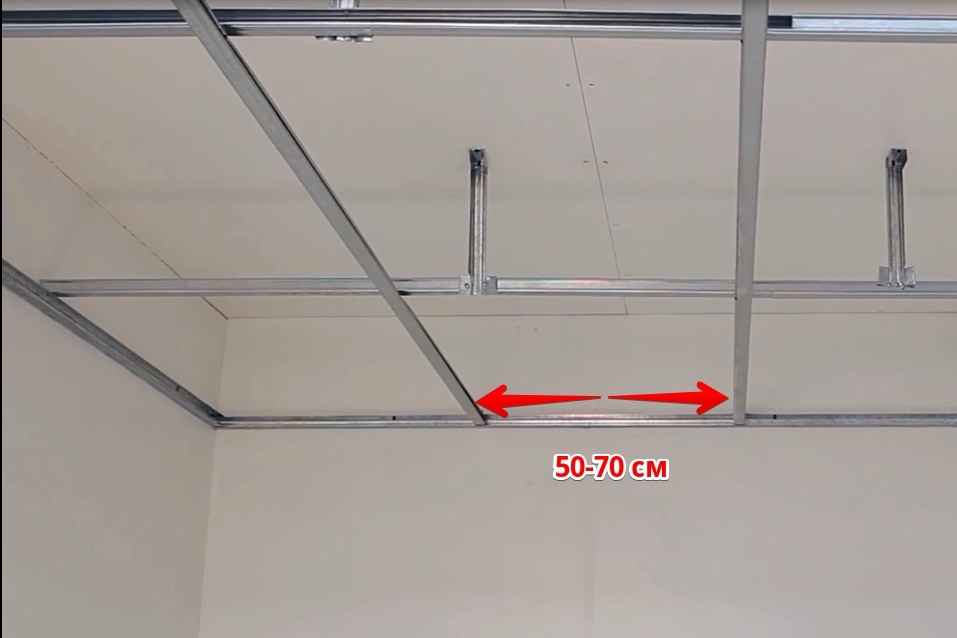

After that, apply longitudinal lines along one wall, set a distance of 400-600 mm between the profiles. Now it is easy to calculate how much material is needed for the entire room.

To find out the required number of profiles and suspensions, you need to draw a plan, where you indicate the distance between the structural elements, and then make a calculation

To find out the required number of profiles and suspensions, you need to draw a plan, where you indicate the distance between the structural elements, and then make a calculation

After completing the calculations, draw a line on the walls along the perimeter of the ceiling: here more rigid profiles will be laid that can hold the entire structure. This data also needs to be recorded. The number of dowel screws is calculated based on the number of profiles and the installation pitch of fasteners measuring 30 cm. It is also advisable to add a little for the stock. To reduce the cost of work, you can replace the metal profile with a wooden one, and the fasteners with staples.

If you are planning to install a ceiling plinth, then you just need to calculate the length of the perimeter of the walls. Such a profile, as a rule, has a standard length of 3000 mm, so at the end of the work a significant part of the material may remain.

Advantages and disadvantages

Plastic panels are a popular and common wall covering. They can be found in many shops that specialize in decoration materials.

Wide sheets and lining made of plastic are in great demand, because they have many positive qualities.

- First of all, it should be noted the durability of such finishing materials. In our climate, their service life can be more than 20 years.

- Such materials are durable. They are not afraid of dampness and moisture. In addition, they are not subject to rotting, as, for example, natural wood.

- Plastic panels do not require complex and regular maintenance. Dust and dirt do not accumulate on their surface. If the finish is dirty, then it will turn out to be cleaned with a regular damp cloth.

- PVC panels have sound insulating properties, so they are perfect for wall cladding.

- Using plastic panels, you can divide the space into functional zones.

- Plastic panels are lightweight materials that make them easy to work with. All processes can be handled without the involvement of assistants.

- Plastic is a very malleable material - it lends itself to various types of processing without problems. Therefore, in stores you can find PVC panels that have a variety of colors, textures, prints and ornaments.

- These finishing materials can be used in a wide variety of interior styles.The only exception can be only pretentious and pompous ensembles, in which extremely expensive and natural elements should be present.

- You can install plastic canvases both in a city apartment and in a private house.

- Various communications, such as electrical wiring, can be hidden behind the panels.

- It is quite possible to install PVC panels on walls with your own hands, since this process is not difficult and inaccessible. To do this, you do not need to stock up on expensive tools.

Of course, PVC wall panels are not ideal finishing materials. They also have their own weaknesses.

Let's consider them in more detail.

PVC panels are flammable. In case of fire, these materials burn quite strongly, spreading suffocating smoke in the room.

Many consumers note that after the installation of plastic panels, an unpleasant chemical odor remains in the room for a long time, which cannot be eliminated by ordinary ventilation. Of course, in this case, a lot depends on the quality of the purchased plastic.

PVC panels cannot be called "breathable" finishing materials

They do not allow air to move through the ceilings, and this is very important for sufficient ventilation in the room.

Plastic panels have voids in which various insects and parasites are often found.

PVC sheets are fragile material. They break when hit hard

It will hardly be possible to get rid of such deformations later - the material will have to be changed.

Knowing all the advantages and disadvantages of PVC panels, it will be easier to work with them. You will be able to avoid many mistakes during the installation process.

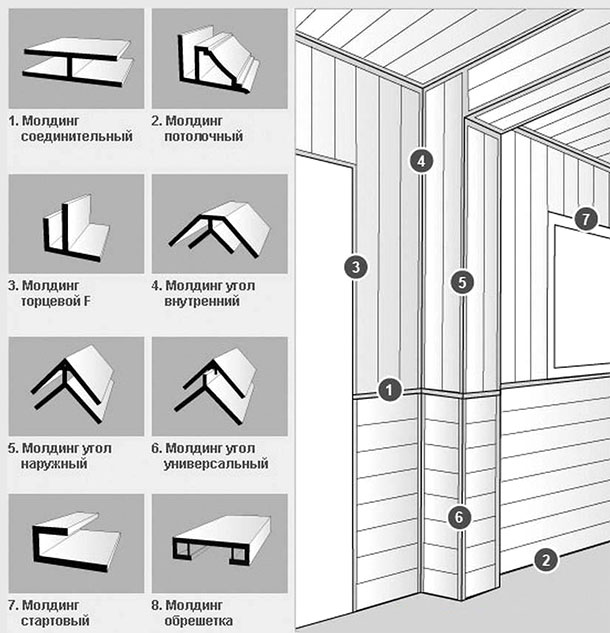

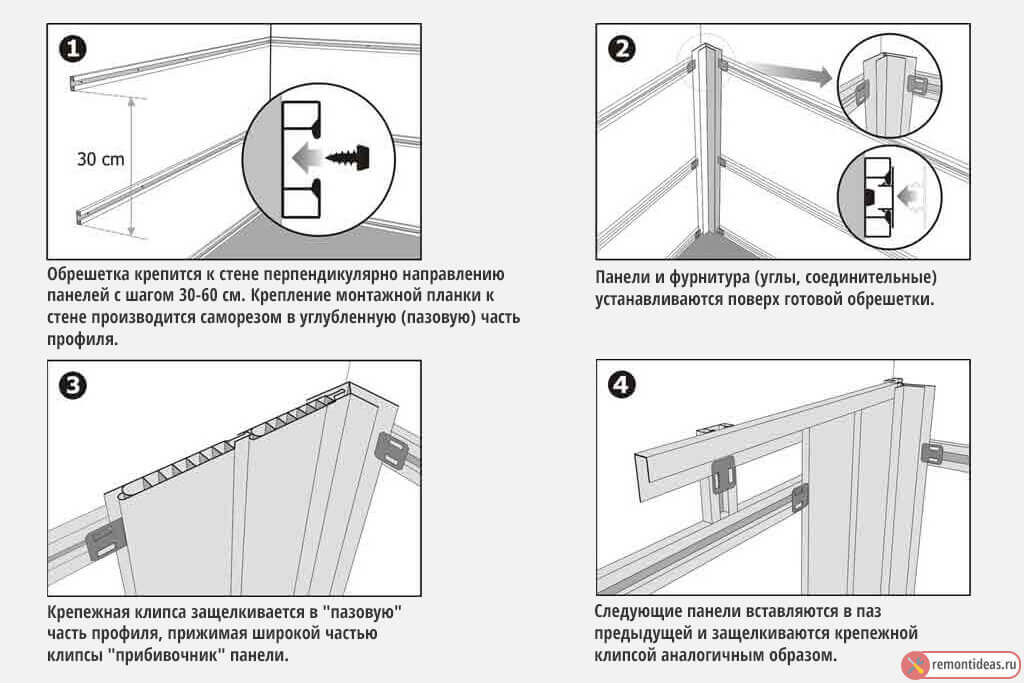

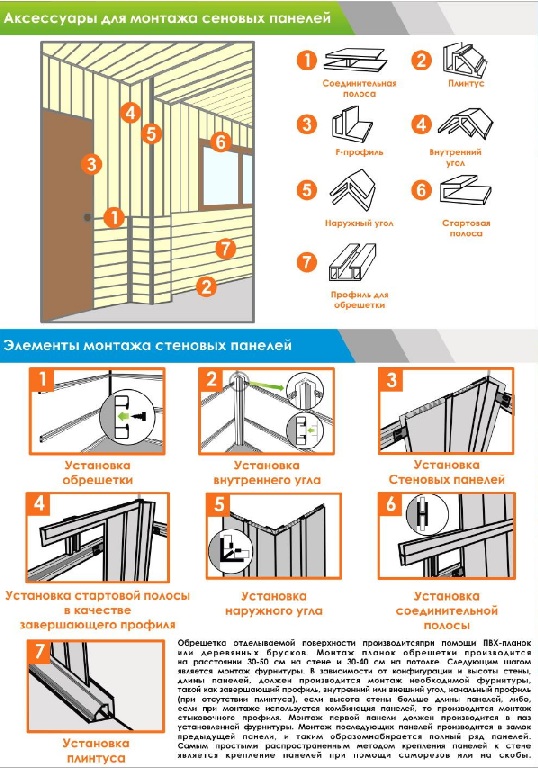

2 Preparation for installation - to level the surface or make a frame?

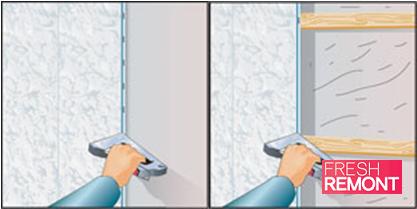

There are two ways to install the panels: gluing directly to the wall or fixing to the frame. The first option requires flat surfaces. If there are protrusions with a height of more than 5 mm, they are knocked down. Hollows, when there are few of them, are not so scary - they will hide under the trim. The base is pre-treated with a primer to increase adhesion.

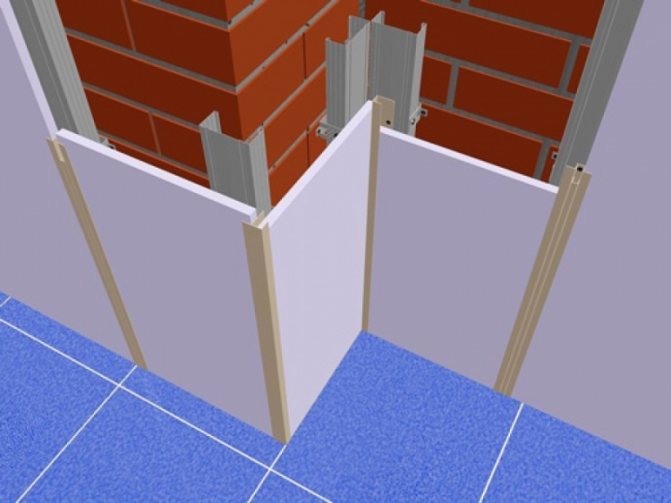

When the irregularities are large, which is especially typical for corners, it is easier to make a frame than to correct defects. For manufacturing, a metal profile for drywall or wooden slats is used, which are pre-treated with an antiseptic and antifungicide. This option is also convenient because the sheathing will hide pipes, wiring, if it is open, or a room in a new building. Thermal insulation is installed under the panels, if necessary.

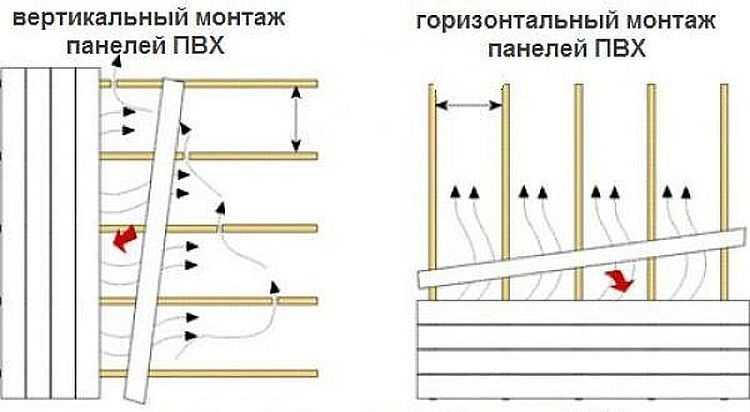

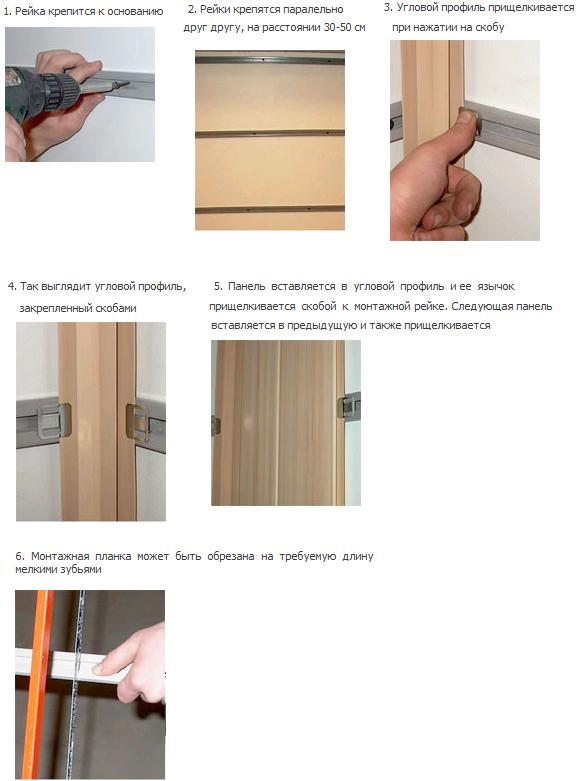

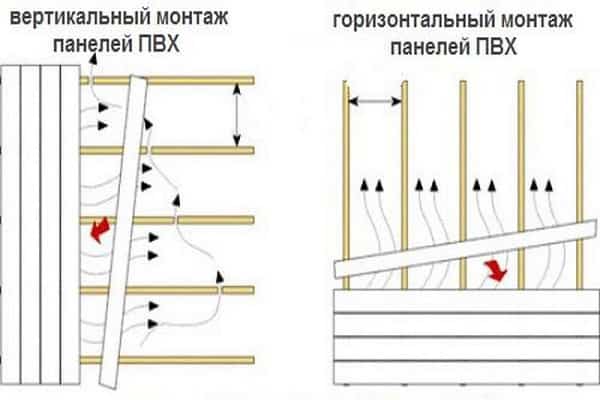

The lathing is installed perpendicular to the location of the finishing material. On the walls, vertical placement is preferable - less dirt and moisture will get into the seams. They start from the ceiling, having determined at what height it will be. If you plan to lay wiring under the casing, other communications, install lamps, there should be enough space for their location.

At the required distance from the main floor, a mark is made, and then, using a level, lines are drawn along the entire perimeter of the walls. A guide profile is installed along them. It should be fixed on dowels with self-tapping screws. The mounting plate is fixed on these rails. This is a plastic corner that has a groove for the ceiling plinth. After its installation, a gap remains, where the PVC lining strip will subsequently enter.

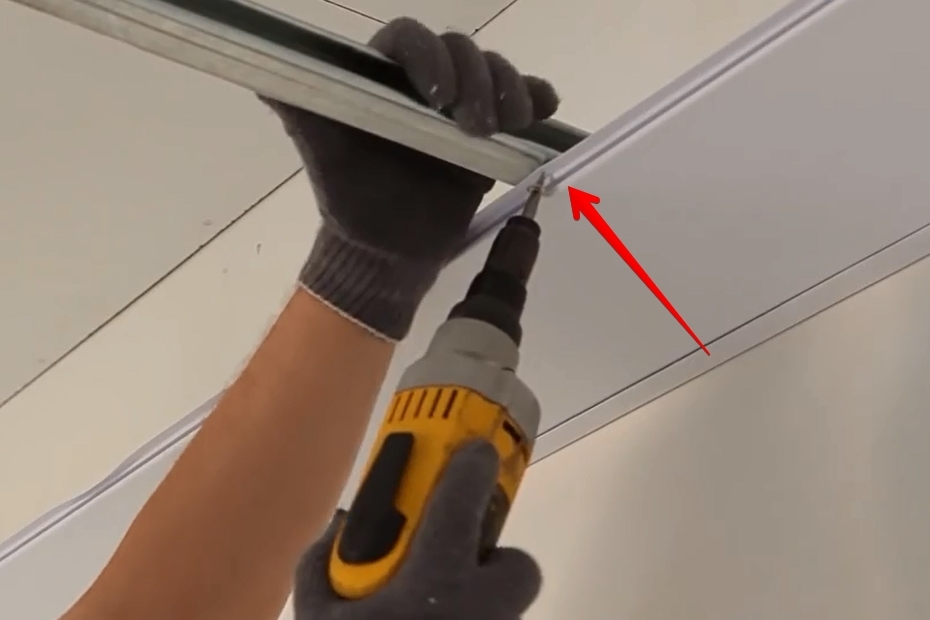

Next, place a metal profile on the ceiling. In this case, the work with wooden beams is inconvenient and difficult, since the structure will be suspended, for which a special mount is used. They retreat 10 cm from the wall, draw a parallel line along the entire length, do the same from the opposite side. Through 40-50 cm, mark the places for the installation of the ceiling profile.

To speed up the process, a chokline is used - a thin, durable cord covered with dry paint or colored chalk. Suspensions are fixed along the lines every 50–70 cm.Ceiling profiles are introduced into them, the edges of the fasteners are bent and fixed with self-tapping screws. Previously, a fishing line is pulled from both ends of the guide rails, and intermediate profiles are set along it in the same plane. Watch the video for installing the frame on the ceiling.

On the wall, the first cross member of the frame is installed at the floor itself, the subsequent ones are placed at a distance that is on average 40 cm.If the surface is uneven, the position of the wooden bars is adjusted with linings, and the metal profile - with the help of suspensions. It should not be forgotten that the lathing is also arranged around windows and doors along the entire perimeter.

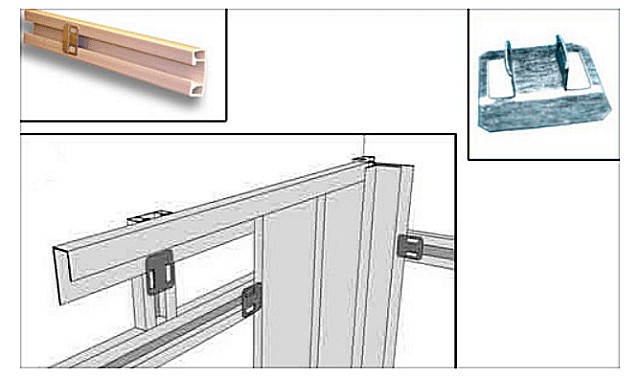

The installation of the frame ends with the installation of moldings, in which the corner joints of the facing lamellas are hidden. The gap with the floor is closed with a plinth. If desired, choose a model with a box, inside which the electrical wiring is hidden. Fixation is carried out on self-tapping screws along a metal profile or using mounting brackets, nails, if the lathing is wooden.

Panel selection

The durability and aesthetics of the finish will entirely depend on the quality of the PVC panels. Here are some things to keep in mind when choosing this material:

PVC panels are ceiling and wall

It is important not to confuse them, since the ceiling cladding is less durable and if fixed to the wall, it is likely to crack even with a weak accidental impact.

The thickness of the plastic is of decisive importance. In high-quality panels, this parameter is 2 - 2.5 mm, in low-quality panels - 1.5 mm

To check, you can wrinkle the panel in your hands: if the outer walls are easily pressed through, and the stiffeners are bent, then it is better to look for a better option.

The strength of the panel depends on the frequency with which the stiffeners are cast in it. A high-quality product with a width of 250 mm usually has 29 ribs, a low-quality product only 20.

Plastic must live up to its name, that is, it must be plastic. It depends on the presence of special additives in its composition. Unscrupulous manufacturers seek to save on this, as a result of which their products tolerate deformation worse. Checking method: you need to bend the strip, which is part of the lock along the edge of the panel (to snap another panel)

When released, the strip should easily return to its previous position, and no trace should remain at the fold.

Pay close attention to the appearance of the panel: any deformations, pattern defects, inconsistencies in shades, scratches are unacceptable. The contours of the stiffeners should not be guessed under the front surface.

It is imperative to check the accuracy of the geometric parameters.

Take two panels and snap them to one another. The seam should be perfectly flat, that is, have the same width along the entire length. It is useful to repeat the experiment with several pairs of panels.

Poor quality plastic emits toxic volatile substances. First of all, it can be recognized by its strong chemical odor. But in any case, you should trust only well-known brands and buy only certified products: odorlessness is not a 100% guarantee of safety.

Embossed panels are more difficult to keep clean than smooth ones, so it is best not to use them in the kitchen or hallway.

How to choose the right panels

There are many panels on sale and it is not easy to make a choice. It is recommended to build on the type of room that you intend to decorate.

If it is a bathroom or toilet, give preference to smooth, moisture-resistant materials. Embossed surfaces are more difficult to clean. Lime deposits can appear on them, which will be impossible to clean without the help of aggressive chemicals. And this will cause irreparable damage to the appearance of the finish.

For the corridor, solid shock-resistant materials are suitable, since frequent contact with the walls in a small room is inevitable. Textured surfaces are appropriate here - imitation of leather, wood or natural stone. On a non-uniform surface, small abrasions and scratches are not visible.

For the corridor, solid shock-resistant materials are suitable, since frequent contact with the walls in a small room is inevitable. Textured surfaces are appropriate here - imitation of leather, wood or natural stone. On a non-uniform surface, small abrasions and scratches are not visible.

For a loggia or balcony, durable wear-resistant panels are suitable. It is better to use smooth planks here. They are much easier to care for than rough ones. And there is always plenty of dust on the balcony. To neutralize the effects of exposure to ultraviolet radiation, it is better to choose lamellas of light shades.

There are no such problems in the living room, moreover, smooth plastic strips can reduce the cost of the interior of this room. Therefore, textured 3d panels are appropriate here, in the form of a spectacular composition on an accent wall.

There are no such problems in the living room, moreover, smooth plastic strips can reduce the cost of the interior of this room. Therefore, textured 3d panels are appropriate here, in the form of a spectacular composition on an accent wall.

It is important to pay attention to the quality of the finishing elements. Check the products for chips, deformations, the number of cells inside - the strength of the casing, the quality of the lock connection depends on this

Preliminary calculations of the amount of material required

In order to avoid acquiring surplus and re-visiting the store, the first thing to do is to determine the optimal number of lining needed for finishing. The material can be mounted vertically or horizontally, depending on personal wishes.

When performing a horizontal installation, the area of the room is measured with the removal of the openings of windows and doors. The resulting number must be divided by the area of 1 panel. In this case, spare products should be purchased at least 10%, as the amount of scraps increases. In addition, it is required to count the number of rails, which will be used to equip the lathing and as fasteners. First of all, the height of the walls must be divided by the step of the frame. Basically, this indicator reaches 50 cm, after which it must be multiplied by the perimeter of the room. The resulting value indicates the length of the rails in linear meters. Having made measurements of the height of the corners, and multiplying the resulting number by their number, the full footage of the corner profiles will be released. The perimeter of the openings of windows and doors should also be added to this indicator.

Glue mounting

If the walls are flat enough, then work can be carried out without using the frame. Liquid nails are used as fasteners.

When choosing an adhesive, you need to pay attention to its composition. It must be free of solvent

Otherwise, the lining will simply collapse.

Preparation

When decorating the walls with PVC panels with your own hands occurs according to the glue option, then the preparation of the walls is most carefully approached. It will not be enough just to remove the excess - it is necessary to completely clean the surface. And in some cases, create a new layer of putty. And be sure to apply an antibacterial primer.

Pasting

The whole process should be fast enough, and all movements should be verified. The fact is that it will be almost impossible to correct the shortcomings. That is why this method requires some skills.

Installation of plastic panels on glue

So:

- The primer coat should dry well. After all, plastic finishing cannot be carried out on a wet wall. Nothing will hold.

- The glue is prepared according to the instructions. When canned compositions are used, they are thoroughly mixed beforehand.

- For work, use a special gun, roller or brush. The area of application of the adhesive composition should not exceed two structural elements.

- The corner piece is installed first. A lining is inserted behind it and pressed against the wall. This should be done without unnecessary effort, and even more so - point clicks. It is very easy to damage the cellular structure of the material.

- So, sequentially, they paste over the entire area with plastic with their own hands. At the end, the finishing moldings are fixed.

- Now comes the turn of decorative elements.

Wall paneling can also be done on adhesive tape. This method is not yet so sealed, so you should not trust it. And the point lies precisely in the tape used. Its quality does not always correspond to the required parameters.

Of course, each master can offer his own variations, which certainly deserve respect. But, when real experience is insignificant or completely absent, then it is better to follow the proven path, even if it takes a little longer. After the first success, it will become very clear: how to sheathe the walls with plastic.

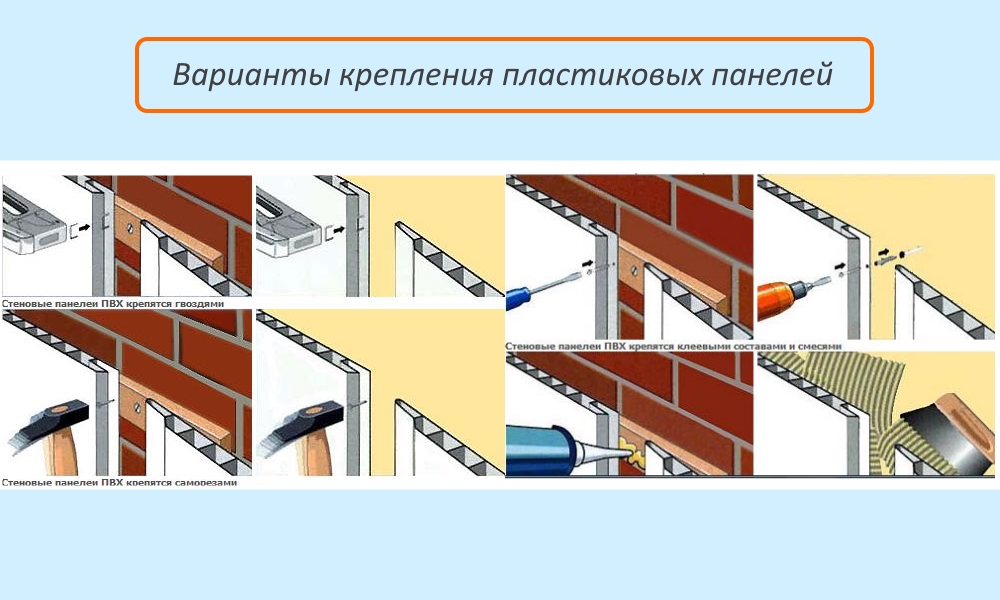

Panel mounting methods

Wall cladding with PVC panels can be carried out using several technologies, this, first of all, depends on the type of wall, the quality of its finishing and the functional load that the structure bears. These types of fasteners for PVC panels include:

- Fastening products to wooden blocks that are fixed to the wall. This installation method is suitable for craftsmen who want to save on building material, since wood is much cheaper than any other part. In addition, it is much easier to attach the panel to the tree; it is enough to use screws with a sharp end. The structure of the lathing itself is assembled by twisting the bars with self-tapping screws to the wall through the hangers;

- Fastening wall panels to the lathing made using a metal profile. The scheme of the frame device is similar to the wooden one, the difference is that for a more accurate result, the bearing profile is inserted into the starting guide, which is fixed at the beginning of each wall;

- Fixing panels directly to the wall plane by gluing it with assembly glue or liquid nails. Installation of PVC panels in the bathroom directly on the wall without wooden guides is carried out only in cases when there is no doubt about the evenness of the coating, and when it corresponds to the zero level. This factor greatly affects the quality and result of the work, since on an uneven wall, PVC panels will have bumps and irregularities, and their locks will not exactly adjoin each other, therefore specialists rarely use the method of laying products without crate.

Fastening without frame

The panels themselves come in different sizes, so you need to choose how to fix them based on this indicator. Also, when making such a decision, it is necessary to take into account the humidity in the room, since the wooden block absorbs moisture well and can rot from its excess, in such rooms it is necessary to use the installation method on metal profiles.

Conclusion

Lamels have different widths, when choosing this parameter, consider the size of the room. It is recommended to install wide elements only in large rooms, the shorter the wall, the narrower the panels should be.

The width of the panels is selected taking into account the size of the wall

Do not decorate walls in subzero temperatures, such conditions may not affect the physical properties of finishing materials, but they always have negative consequences for performance

Pay attention not only to materials, but also to working conditions. In an uncomfortable master, it is difficult to accurately observe all technological nuances