Why USB drainage

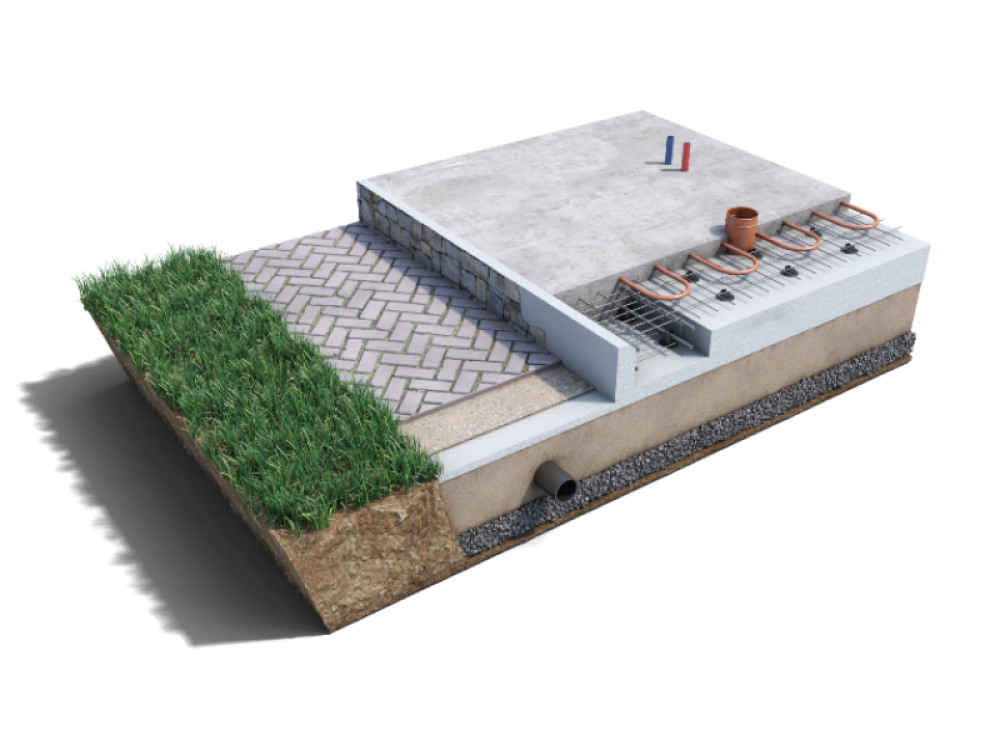

Another popular mistake in the construction of the USB is the refusal to drain. Meanwhile, it performs a very important function - it removes excess water from the foundation. Otherwise, the accumulated water during freezing and thawing will either increase or decrease in volume, thereby causing the soil to move. And this, in turn, may well cause deformations of the foundation itself.

It is important not to neglect the drainage system regardless of the type of soil and groundwater level.

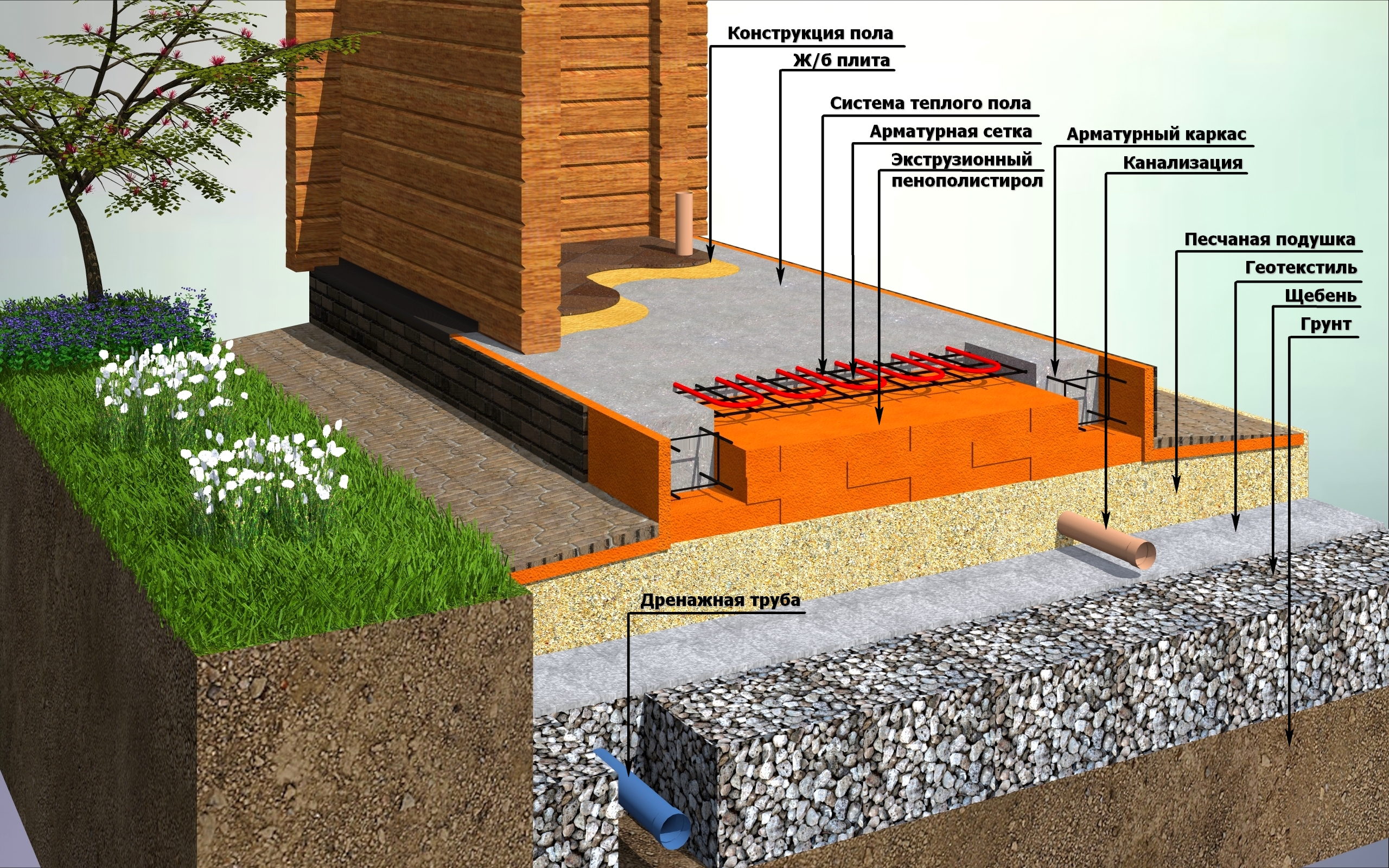

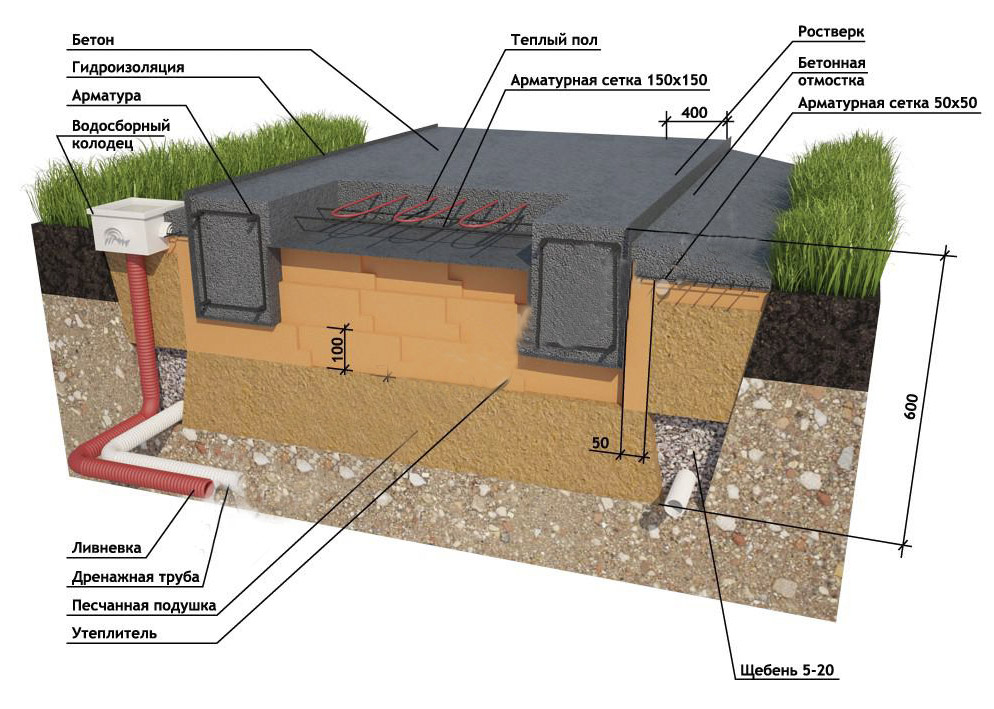

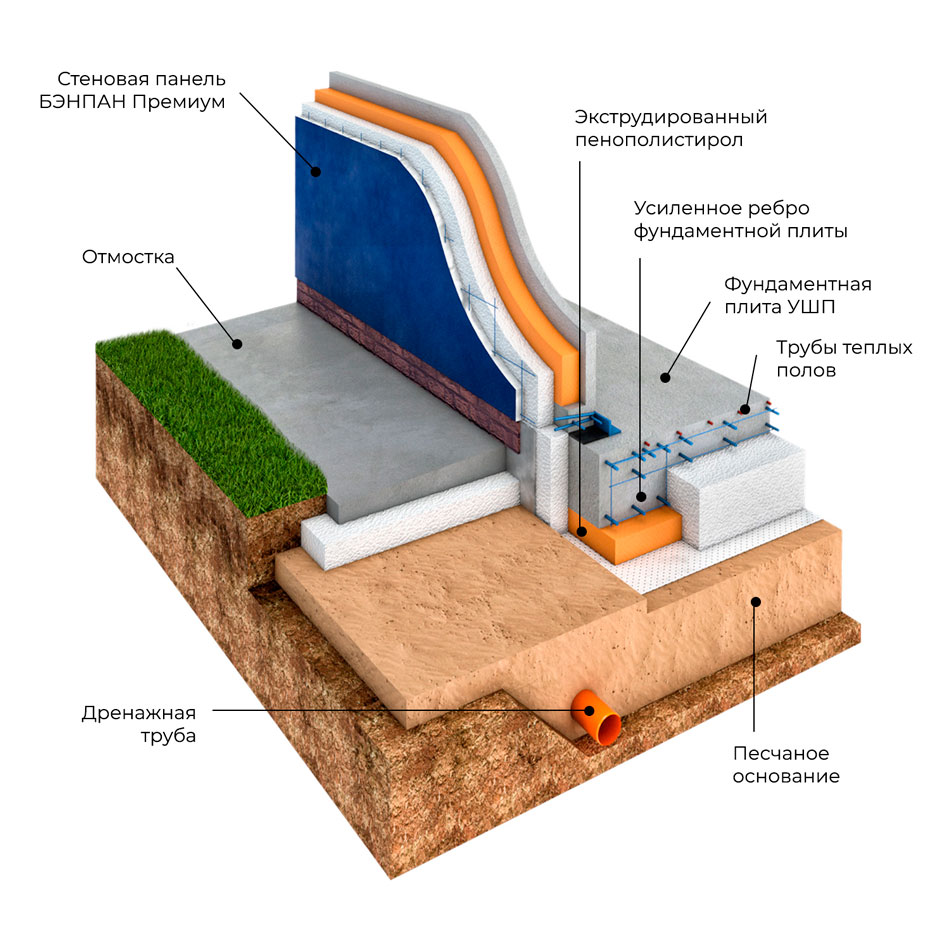

The construction technology of the USHP implies not only a drainage device, but also the presence of an insulated blind area around the house. Together, these measures drain water from the foundation and serve as a good prophylaxis against the effects of frost heaving forces.

A little more about the nuances

The UWB device process is woven from parts. As in any construction site, each of them contributes to ensuring the durability of the entire structure. It must be remembered that laying concrete mix and working with glue-foam is possible only at positive temperatures.

There are other details to keep in mind.

So, for example, when laying reinforcement, it is important to knit it on the ground, and then, when transferred to a layer of XPS, install it on special stands, known in the professional environment as "chairs". Another important nuance concerns the laying of the concrete mixture - it must be vibrated, and also carried out over the entire area of the foundation (partial laying at different times is not allowed) in order to avoid cold joints

Vibration allows to improve the strength properties of concrete due to the fact that excess air bubbles are eliminated.

USP is one of the most energy efficient foundations

Attention to details and rules will allow you to build a foundation in a short time, which will become a strong and energy-efficient support for many years

Insulation loves to count

Calculation of the thickness of the heat-insulating layer is one of the most important stages in the construction of the USP. Sometimes, unknowingly or in an attempt to save money, builders reduce the thickness of the material

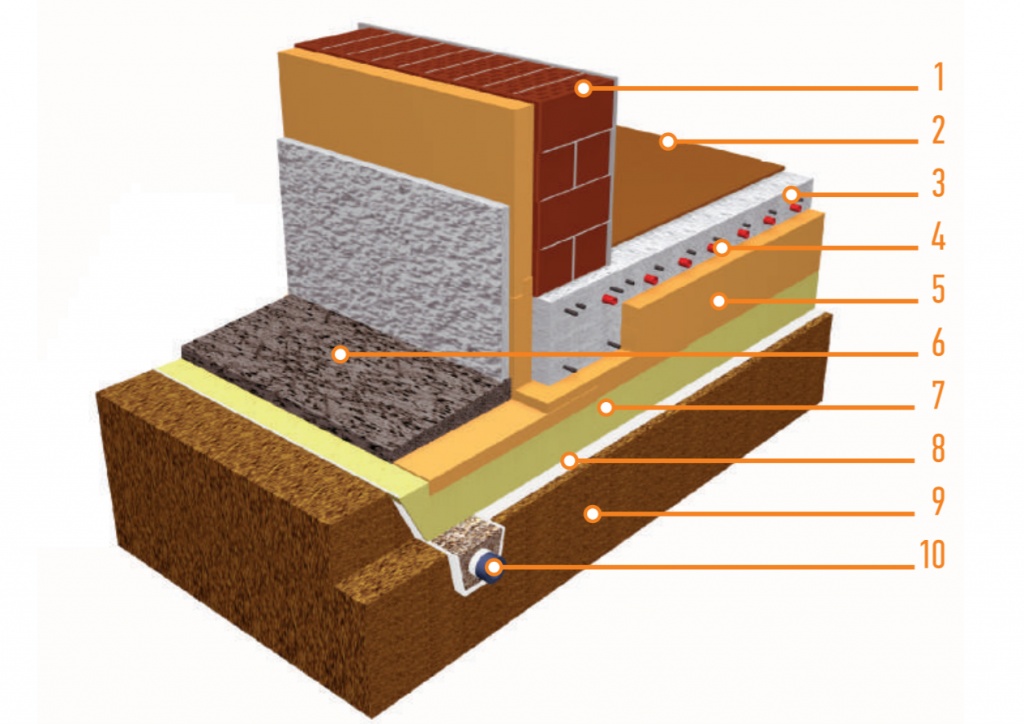

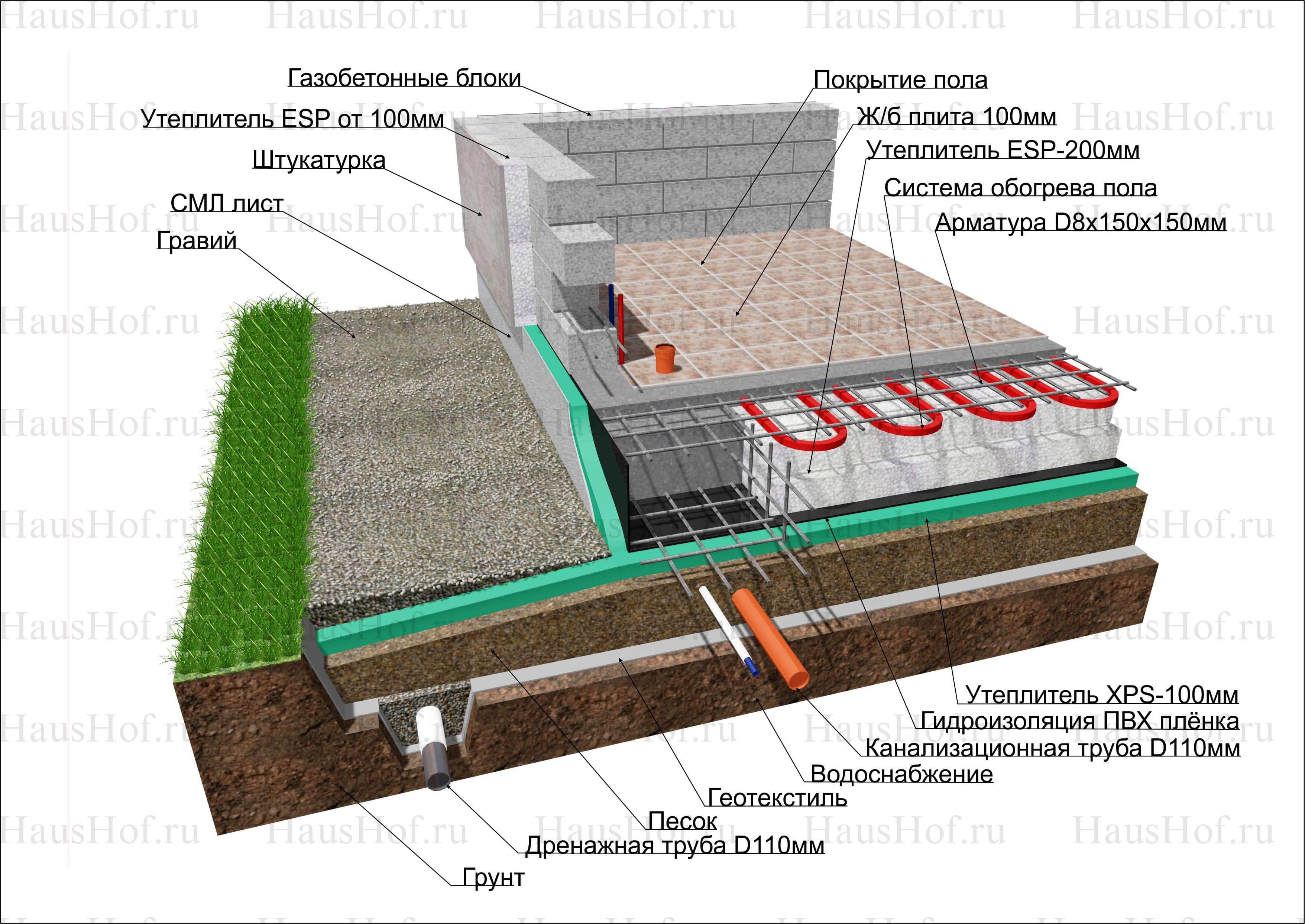

In this matter, it is important to understand that the presence of a heat-insulating layer is associated not only with heat engineering. The fact is that two-layer laying of insulation slabs allows, firstly, to reduce the thickness of the reinforced concrete slab, and therefore, to reduce the consumption of concrete mixture for its construction, and secondly, to form the structure of the foundation

It is with their help that a structure resembling an inverted glass is formed - with a reinforced tape around the perimeter and a reinforced plate on top.

Reducing the thermal insulation layer simply will not allow you to cope with this task. In addition, thanks to the thermal insulation plates, the entire heat flux goes into the room, and not into the ground.

Installation technology of insulated Swedish plate

Reinforcing metal mesh is installed strictly according to the level

Before starting construction, it is necessary to carry out all the necessary calculations and research. Based on their results, the possibility of using an insulated Swedish plate on the site is determined. Problems during the operation of this material may arise due to non-observance of the installation technology.

The work is carried out in a specific sequence:

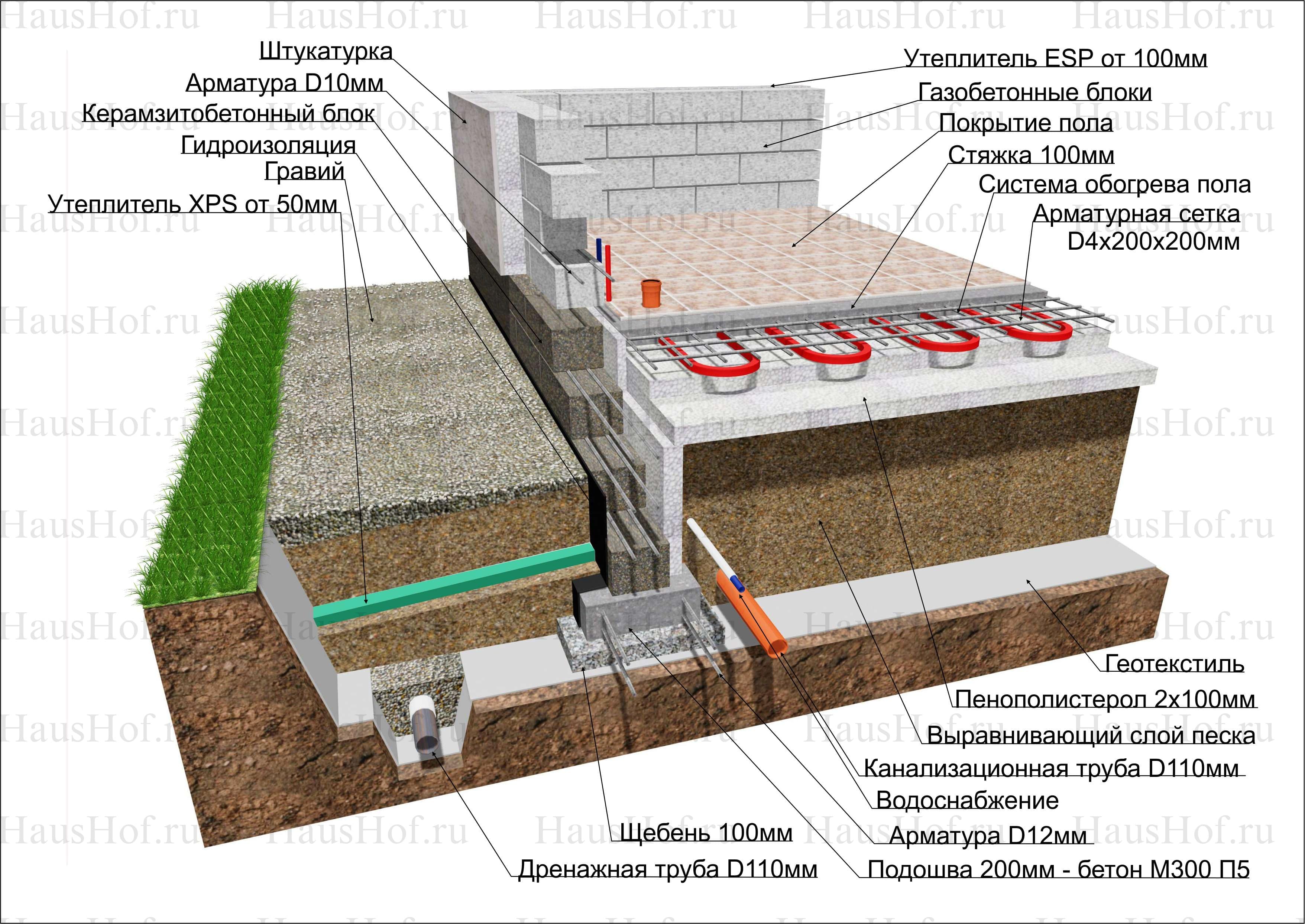

- soil preparation;

- laying geotextiles;

- installation of mortgages;

- the device of a pillow of their sand and gravel;

- installation of formwork;

- waterproofing;

- laying insulation;

- reinforcement;

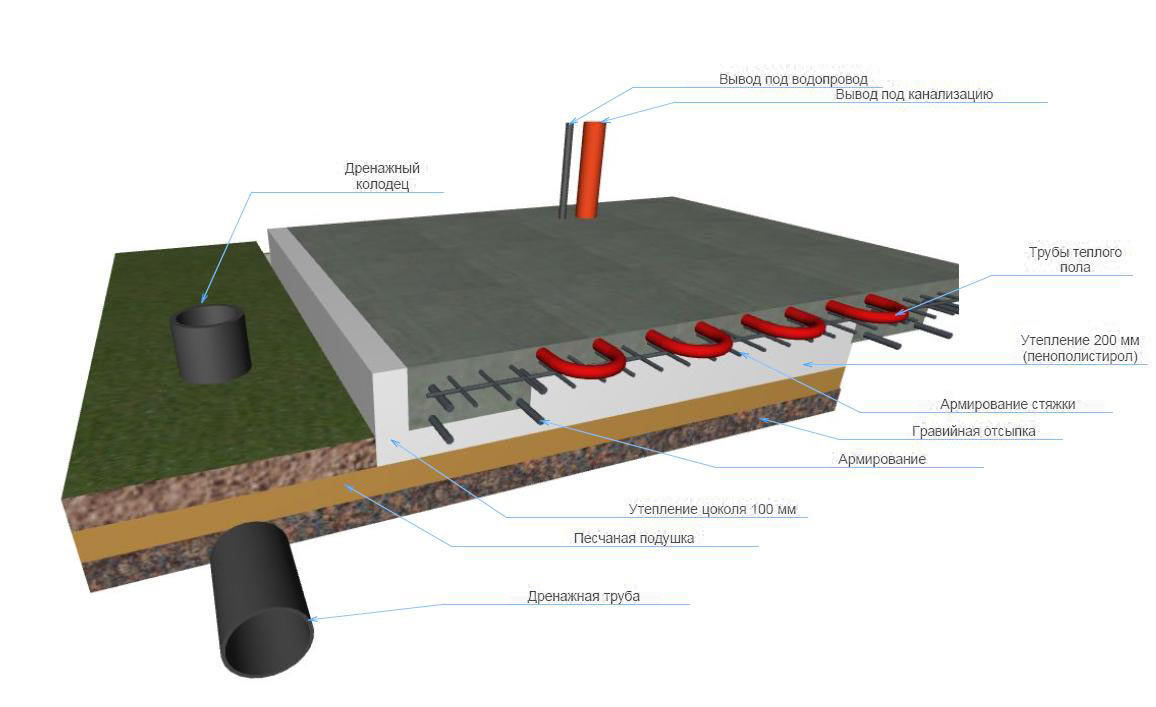

- the device of the "warm floor" system;

- frame installation;

- pouring the foundation and blind area.

The technology of thermal insulation with a Swedish plate begins with accurate measurement in order to be able to remove the top layer of soil to the required depth. To do this, you do not need to perform grandiose work and apply additional equipment, this is a fairly simple job.Then you need to lay geotextiles. The next stage begins with the installation of mortgages. They are necessary for the supply of sewerage systems, water supply, heating and electricity. A layer of gravel is laid on the geotextile, and then a second layer of sand and everything is compacted tightly. The total thickness of the layers should be at least 30 cm. Then the formwork is installed from the fiberboard plates and the waterproofing layer is laid.

Insulation (expanded polystyrene) is laid on a sand cushion.

As a heater, XPS or EPS 100 mm expanded polystyrene can be used. It fits under the base of the foundation. Additionally, the penoplex is installed on the side parts of the USP foundation of the insulated Swedish plate. The next stage is the installation of a reinforcing mesh, it is attached to metal supports. The "warm floor" system is attached to the fittings, which includes the routing of pipes in the floor along the beacons. Then the pipes are connected to a manifold - a special distributor of coolant flows in the heating system with a sealed expansion tank. The pipes must first be inflated with air. If this is not done, then they can deform after pouring with concrete.

Then the reinforcement cage is installed and the screed is poured. After that, everything is carefully tamped, leveled and left for 5 hours until solidification, only then the formwork is removed

When working with a heat-insulated Swedish stove, according to reviews, it is extremely important not to make a mistake and thoroughly observe the technology. Any deviation from the instructions can be fatal, and it will no longer be possible to redo the error.

In order to understand all the intricacies of installing an insulated Swedish plate, see the video below. It will help you avoid ridiculous mistakes:

Some points to consider when installing an insulated Swedish plate:

- correct connection of communications;

- connection to the collector;

- control the work done before pouring concrete;

- revet the finished foundation.

It is necessary to calculate in advance the location of the water supply, sewerage and electrical cables, because after the end, it will be extremely difficult to change something, and sometimes it is impossible at all. You also need to check the horizontal position of all pipes according to the marks. After installing the pipes, a collector is connected, which is mounted on metal rods.

After installing the pipes, the system is checked for leaks under pressure. The so-called pressure testing of the heating system is carried out. Intermediate control before pouring concrete is needed so that mistakes can be corrected in time. Before pouring the screed, visible debris is removed from the working surface. Then all the pipe leads must be closed with plugs so that the concrete does not get inside. After pouring, finishing work is carried out: the concrete surface is tiled or covered with plaster.

Rules for choosing a heater for USP

When choosing thermal insulation for USHP, first of all, it is worth paying attention to the compressive strength indicator. Considering that the insulation will be subjected to colossal loads, it must retain its shape and properties throughout the entire service life.

The material laid in the stiffeners is under pressure from the foundation itself and the supporting structures of the house.

In most cases, XPS (extruded polystyrene foam) is used for UWB insulation. It is a durable material with a low coefficient of thermal conductivity, resistant to aggressive environments, not afraid of water

Almost zero water absorption is fundamentally important, since the material is under load in humid conditions throughout its entire service life. Let's not forget that the insulation in the construction of the USP is laid directly on the ground, and a concrete slab is mounted on top of it, which also has a certain moisture

But extruded polystyrene foam, depending on the scope of application, has different strength characteristics.The one that is actively used for floor insulation will not be suitable as USP thermal insulation. There are special grades designed for use under increased loads. Example –XPS CARBON ECO SP. It has a particularly high compressive strength of 400 kPa at 10% deformation and 200 kPa at 2% deformation.

Thus, the wrong choice of insulation entails several serious problems. The first of them is the loss of thermal insulation properties due to wetting, this is if a material that can absorb moisture is selected. And the second problem is related to the destruction of the insulation, if its strength is lower than that required by the technology.