Installation work

Since the panels that imitate the timber are lightweight and fairly easy to install, the exterior decoration of the house with panels can be done by hand. Anyone with the initial skills in using a screwdriver, level, saw and other household construction tools can do this work.

House insulation and lathing

House insulation and lathing

The work on finishing with panels for timber is divided into several stages. Let's consider step by step how to sheathe a house yourself:

- The preliminary stage includes the preparation of the surface for finishing. For this it is necessary to remove dirt and dust. The wall covering must be clean. You can do this with a vacuum cleaner. For a wooden house, the process of caulking the walls and surface treatment with antiseptics is performed.

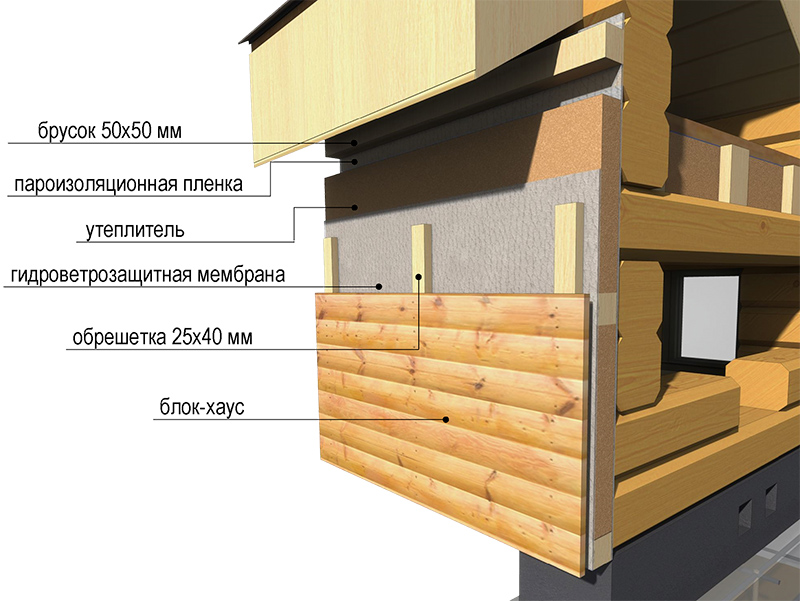

- Sheathing with imitation of a bar from the outside presupposes the presence of a crate. For this, bars with dimensions of 25 × 50 mm are used. They are mounted at a distance of 0.5–0.6 m. They attach the slats with self-tapping screws. If the surface is brick, then dowels must be used.

- We carry out vapor barrier of walls. To do this, we attach a special film to the crate, which performs the function of retaining moisture. The film should be laid with an overlap of about 15 cm. The joints must be glued with adhesive tape.

- We carry out thermal insulation. This is one of the important points for any wall decoration. You can use any type of insulation, both rolled glass wool and foam panels. It is necessary to lay the insulation on the vapor barrier between the battens of the crate. Additionally, we fix the insulation with the same tape.

- Then we proceed to the installation of panels of imitation of a timber finish, which is additional thermal insulation. You need to start from the bottom. Each subsequent panel is inserted into the lock of the previous strip and snaps into place. For additional fastening, each panel is neatly attached to the crate with wood screws. The hat must be slightly sunk into the panel so that it does not interfere with the installation of the next panel. After the installation is complete, the visible areas of the attachment must be covered with a mixture of sawdust and varnish, and after drying, sand with fine sandpaper.

- The work is completed by the process of covering the panels with special protective compounds and paints and varnishes.

As you can see, this is not a complicated process, and it is quite possible to do it yourself. You just need to be patient and make accurate calculations.

Installation of lining

Installation of lining

The nuances of mounting imitation of timber

Timber imitation panels are purchased hermetically packed. After the material is delivered to the work site, the packed panels must be opened and then laid out for a while in the air. You also need to take care that they are not exposed to direct sunlight. In this form, they need to be held for a couple of days. This procedure is carried out for the reason that during production the material is dried and immediately hermetically sealed. When the panels are removed, in natural conditions, they begin to strongly absorb moisture, and expand by several millimeters. If you start the installation immediately, then later the panel will lead, and the appearance will be irretrievably damaged.

Begin to attach panels always from the bottom up. Moreover, it is placed so that the groove is located at the bottom, and the spike is at the top. This arrangement prevents dust and dirt from getting into the groove of the panel.

Particular attention is paid to the installation of the first panel, which is mounted at a distance of about 10 cm from the lower level.Before attaching the first panel, the level of its installation is carefully checked.

The quality of further finishing depends on the quality of fastening of the first panel. The clad house with panels should not have distortions.

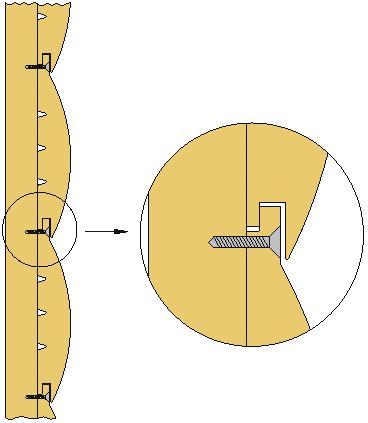

It is best to use special brackets to fasten the panels to the battens. Of course, you can use screws, screws, and nails. But all this simply replaces the staples if they cannot be purchased. When using fasteners, it is necessary to screw them in at an angle of 45 when installing into the locking surface, and at an angle of 90 when installing through the panel.

It is necessary to carry out work in certain climatic conditions. The weather must be dry. The temperature can be below zero. According to the rules, the minimum temperature can reach minus 15. But it is not recommended to carry out work on painting panels with varnish-and-paint agents under such conditions.

Finishing the bath with warm plaster

An alternative option for finishing the facade of the bath is warm plaster, which is a solution based on cement, expanded clay crumbs, perlite sand, powdered pumice and granular foam.

Facade plaster has many advantages:

- high sound and heat insulation characteristics;

- good adhesion to any type of substrate;

- installation without the use of reinforcing mesh. Exceptions are deformed sections of the facade;

- resistance to decay, combustion, mold formation, insect infestation and other pests;

- does not require preliminary leveling of the surface.

The disadvantages of the material include the following:

- impressive weight;

- high price;

- limitation on the thickness of the decorative layer - the permissible thickness is not more than 5 cm;

- the need for a finishing primer and painting;

- the need to strengthen the foundation of the structure.

The plaster is applied to the cleaned surface by hand or machine. Each subsequent layer is applied after the previous one has completely dried.

In which rooms can it be used

Imitation of a bar is used for walls and ceilings. It is a textured living material that has a number of advantages. It allows you to create the feeling of a wooden house in the interior of one or all rooms. Wood allows the coating to breathe, some varieties generally purify the air.

False beams are used in the design of the interior space of apartments, country estates, private cottages. It will perfectly complement the corridor, living room, bedroom, nursery, office. Some breeds can be used in the bathroom, kitchen, balcony, loggia. In general, the material is versatile, compatible with absolutely any room.

In the kitchen, using imitation of timber, you can sheathe both the walls and the kitchen backsplash, but additional wood processing will be required. Different colors will allow you to emphasize the severity or warmth of the space.

What it is?

Timber imitation is also called false beam. It is a material that can be used for cladding both outdoors and indoors.

Today, there is an artificial imitation of a bar made from wood waste with the addition of plastic, as well as a solid wood option, which is especially popular with consumers. It is worth considering in more detail.

It is a planed board, processed from 4 sides, and made in the form of a processed wooden bar. The thickness of such material is up to 35 millimeters, and the width can reach 260 millimeters. The material of manufacture is coniferous and deciduous wood. The profile in this case is the trapezoid, and due to this, the smoothness and evenness of the base is achieved.

For the best joining, the edges are processed in a special way, this allows you to reliably protect the insulation from the effects of negative climatic conditions and humidity. The fact of what material a product is made of determines its density and characteristics.

Features of cladding with siding (or metal block house)

Before starting work on insulation and siding, the walls of the house are strengthened, the cracks and cracks formed are closed. The design of such a facade depends on the quality and external characteristics of the material.

Modern manufacturers offer a huge selection of panel types, various colors and textures for any taste. Many people wonder what is better block house or siding?

The modern facing material of the blockhouse is made of galvanized steel with a special coating, it imitates the construction of wooden logs.

These panels differ from conventional siding precisely in that they are an exact imitation of a timber frame.

Blockhouse is a good material that is ideal for indoor and outdoor decoration.

Manufacturers offer a wide range of panel colors and shades, which in turn allows you to create a unique exterior at home.

If there is a question of siding or corrugated board when choosing a material for facade cladding, it is most rational to give preference to the first option.

Siding for exterior wall decoration of the house has the following set of advantages:

- excellent soundproof and heat-insulating properties;

- the construction of the frame for the installation of the panels provides natural air movement, thereby allowing the walls to “breathe”;

- fire safety;

- simplicity and high speed of panel installation;

- for facing in this way, preparatory work is not required;

- no need for maintenance;

- resistance to weather and seasonal changes.

Summing up, it is worth noting that both finishing options have the right to occupy the first positions in the list of high-quality and effective facade materials for arranging the facades of private houses.

Convex or rectangular outer surface is an individual choice according to your taste and aesthetic expectations.

What, unambiguously, pleases, is the same cost of finishing with siding or metal block house. The same quality of the facade structure and durability in operation.

Varieties

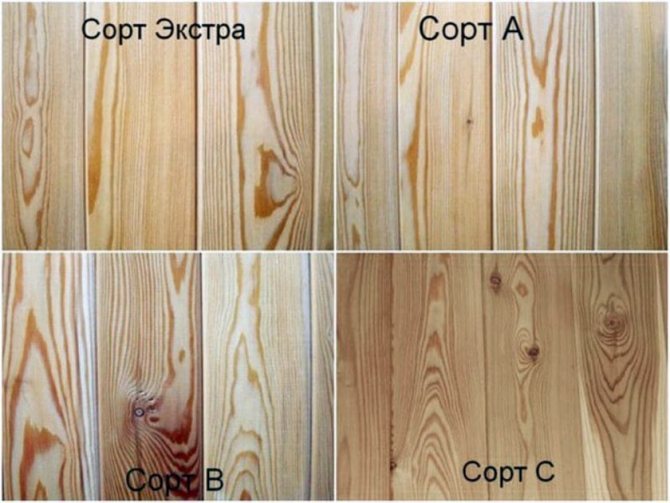

All wood products are divided into quality grades, depending on the number of knots, on the presence and size of cracks, resin pockets, outgrowths and wane.

The main grades are, in order of decreasing quality of the material:

- Extra;

- ;

- B;

- C.

There are also mixed varieties:

- Prima (between Extra and A);

- (between A and B);

- BC (between B and C).

Comparison table of varieties of timber imitation

| Name of wood defects and processing defects | Front surface | |||

| Variety "Extra" | Variety "Prima" | Grade "A" | Variety "AB" | |

| Knots grown together, healthy, dark | Not allowed | Tolerance. Ø up to 1/3 of the width not ≥ 1 pc. at 1mpg | Allowed | Allowed |

| Partially fused healthy knots, incl. cracked, eyes | Not allowed | Tolerance. Ø up to 1/5 of the width not ≥ 1 pc. at 1mpg | Tolerance. Ø up to 1/4 of the width not ≥ 2 pcs. by 1 mpg | Allowed |

| Non-fused knots | Not allowed | Tolerance. Ø up to 10mm not ≥ 2pcs. per product (if there are no other knots) | Tolerance. Ø up to 1/5 of the width not ≥ 1 pc. at 2mpg | Allowed |

| Knot holes, rotten, rotten, tobacco knots | Allowed on the edge of the spike - when assembled, they are closed with another part | Allowed on the edge of the spike - when assembled, they are closed with another part | Allowed on the edge of the spike, if during assembly they are covered with another part | No admission. holes from fallen knots, the rest is tolerance. |

| Sprout, core, blue, wane, fringe, rot, cancer, stepson | Not allowed | Forgiveness admission. up to 2x20mm not ≥ 1pc. on the product, the rest is out of tolerance. | Forgiveness admission. up to 5x50mm not ≥ 2pcs. on the product, the core is not allowed. on the floor board, tolerance. | Forgiveness admission. up to 8x70mm not ≥ 2pcs. for the product, admission. blue for 30% of the product, core tolerance, the rest is not tolerance. |

| Resin pockets | Not allowed | Tolerance. up to 3x50 mm not ≥ 1 pc. by 1 mpg | Tolerance.up to 5x70 mm not ≥ 1 pc. by 1 mpg | Allowed |

| Mushroom heart spots, browning, sapwood, false kernel | Not allowed | Tolerance. in the form of spots and stripes up to 30% of the product area | Tolerance. up to 30% of the product area | Allowed |

| Blind cracks | Not allowed | Allowed up to 1х100mm | Allowed up to 1mm in width, total length up to 1/3 of the product length | Allowed |

| Mechanical damage (tearing, snatching, gash, dent, chipping, scuffing, chipping) | Small tears up to 1mm or 5x7mm chip, depth are not allowed. up to 3mm, in a quantity of 1pc per item | Small tears up to 2mm or chips 5x15mm, depth are allowed. up to 3mm, in a quantity of 2pcs per item | Tolerance. sizes up to 5x10mm and depth. up to 3mm, no more than 1pc. by 1 mpg | Tolerance. sizes up to 10x20mm and depth. up to 3mm, no more than 3pcs. by 2 mpg |

| Uneasy | Allowed on the edge of the spike with a width of not ≥ 3 mm and a total total length of 25% of the length of the product | Allowed on the edge of the spike with a width of not ≥ 3 mm and a total total length of 25% of the length of the product | Allowed on the edge of the spike with a width of not ≥ 3mm and a total total length of 25% of the length of the product | Allowed up to 10% of the product area |

Also, any imitation of a bar, regardless of the grade, is not allowed:

- Through holes on the lamellas, formed as a result of knots falling out;

- Sagging in places where it will be visible after installation;

- Mechanical damage (chips, dents) on the front side of the product;

- Resin pockets larger than 7mm;

- Fringe on the edges, visible after finishing;

- The moisture content of the boards is more than 13%.

Types of waterproofing materials

Waterproofing materials can be liquid, in the form of a film (membrane made of polymer or mineral filler) or roll.

Each material differs in its properties.

For external wall cladding, sealants are chosen, but only if the area is not large.

The anti-corrosion mixture contains a resinous product (bitumen) and is applied to walls only if metal structures are to be installed.

For walls in the bathroom or kitchen, use a waterproofing coating.

Compositions of coating waterproofing for walls:

- Cement mortar.

- Acrylic solution.

- Silicon solution.

- Crystalline liquid.

As for the film membrane, it protects the walls from dampness. Made from synthetic rubber, PVC, polypropylene. The membrane film is corrugated.

Sheathing a house with imitation timber - step by step instructions

Timber panels imitating timber, used for both external and internal facing of the house, are one of the highest quality and environmentally friendly finishing materials. With their help, you can radically transform your home from the inside and outside, beyond recognition, while avoiding large material costs.

A building faced in this way can be quite difficult to distinguish from a solid solid wood, and installation work is not particularly difficult.

The main stages of fastening

The entire workflow for installing panels can be conditionally divided into several main stages, performed according to certain rules:

The entire workflow for installing panels can be conditionally divided into several main stages, performed according to certain rules:

Step 1: Acclimatization. The cladding of the house begins with an imitation of a bar with its preliminary adaptation to the environment within 2-3 days; for interior cladding, this period is usually doubled. If you ignore this stage, it is fraught with warping of the material and even the appearance of cracks on it.

Step 2 Insulation of the building facade. The process of preparing an external wall for cladding usually consists in eliminating the existing shortcomings, fixing the battens and applying steam and heat insulation layers. This stage can take place in parallel with the previous one to save time.

Step 3: processing wood panels Boards should be thoroughly impregnated with special protective compounds that quickly and deeply penetrate into the wood.

Particular attention is paid to the connecting elements - grooves and spikes

Step 4: finishing the surfaceFastening an imitation of a bar on the wall usually begins from the ground in a horizontal direction, with the spike located at the top, and the groove at the bottom.

The material can be attached to the crate in different ways: with the help of small nails, screws or clamps - special connecting brackets.

Experienced builders advise using nails. The fact is that the density may change slightly under the influence of a temperature drop, and nails, unlike self-tapping screws, do not impede some movement of the board.

However, when using them, you should strictly follow the ideally even direction of laying, because when gaps are formed, there will be no possibility to disassemble the structure.

Step 5: finishing coat. Despite the fact that each panel has already been treated with protective equipment, at the end of the workflow, the procedure should be repeated. With the further operation of the building, such work is recommended to be repeated every 5 years.

Technological secrets of installation

Professional builders do not hide that the technology of house cladding with imitation of a bar has its own secrets, on which the final result often depends:

Professional builders do not hide that the technology of house cladding with imitation of a bar has its own secrets, on which the final result often depends:

- For the exterior cladding of a building, it will be much more practical to use wider panels. Thus, the total amount of work will be significantly reduced, and the appearance will most accurately convey an imitation of a real solid bar.

- To ensure ventilation of the entire structure, a small free space of about 50 mm should be retreated from the beginning of the installation work.

- When finishing toning the material, the seams and joints of the panels should be carefully processed. Otherwise, when climatic conditions change, the wood can dry out, and all the flaws will be visible at a glance.

- During internal work, the walls of the house should be prepared for installation more carefully, and the process itself must be taken much more carefully, because there are many complex planes here.

- The outer cladding is made with materials from coniferous wood, while for the inner one is more often used boards from deciduous trees.

- Wide wooden panels can visually reduce the interior space of the room.

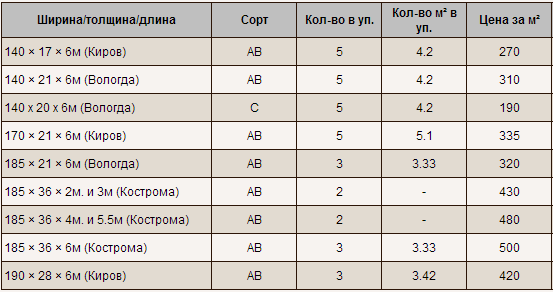

Approximate cost of finishing work

Imitation of a bar is considered one of the most inexpensive finishing materials, especially when compared with solid log cabins. However, the final cost of cladding a house with imitation timber will depend on indicators such as:

- Wood species (coniferous or deciduous);

- Total area of work carried out;

- The original dimensions of each panel (narrow or wide);

- Material grade (A, AB, B, C);

- Profile geometry.

Approximately 250 - 500 rubles. per square meter:

Of the listed points, it is the tree species that will have the greatest impact on the total cost, on which the service life largely depends. For example, oak is considered the most expensive material due to its high strength and reliability.

Stopping at the facing of the house with imitation of timber, you will end up with a beautiful, presentable, and most importantly, environmentally friendly and safe building.

Choice of materials

How to decorate the facade of a house from a bar? It is more convenient to sheathe a wooden case with materials that are easy to attach. Therefore, they choose lining, block house, imitation of timber, thermal panels, etc. The main condition for cladding is the presence of ventilation in the walls, which is created due to the gap between the wall and the finishing material. When using facing materials (bricks, tiles, plaster), they try to create ventilation holes so that the wood does not end up in thermal insulation. If the walls don't breathe, mold and mildew will form inside.

The building materials market is always ready to offer a suitable material for the exterior decoration of a wooden house. Options are chosen based on their capabilities and requests.Any building material has advantages and disadvantages:

- Imitation of a bar is an environmentally friendly material that allows you to decorate and insulate a house after standing; has unique characteristics of wood, since it is made from coniferous trees; resistant to external factors due to the resin content. The disadvantages are that there are too dense knots, increased fire hazard;

- Wooden lining is a wood material that preserves all natural properties; has high wear resistance with proper surface treatment; increases the steam exchange functions of the bar. Disadvantages: requires periodic processing and coating;

- Block house is one of the varieties of lining with imitation of a rounded surface of a log; easy to install; often ready-made structures are made from such material. Disadvantages: like other natural materials, it is susceptible to moisture;

- Vinyl siding is a lightweight, practical material that is resistant to weather conditions; available in different colors; budget option compared to natural wood. Disadvantages: does not always withstand loads, gaps may appear between the elements at high and low temperatures;

- Metal siding - imitates wood materials while remaining a fireproof material; the colors and shape are different; minimal surface care; easy to install, does not require a foundation. Disadvantages: does not allow the exit of the vapor formed in the walls;

- Thermal panels - made of high quality concrete with practically no water; the product does not crack, withstands low temperatures and retains heat; have a unique design solution, imitating brick, tile, stone, etc. Disadvantages: can be destroyed by moisture;

- Decorative brick - provides a high level of thermal insulation; durable and reliable material in a variety of shades. Disadvantages: requires a reliable foundation and sufficient roof overhang;

- Facade stone - used more often for laying paths; made of natural stone, therefore it is expensive; fits on walls according to the principle of tiles; withstands any temperature extremes, moisture resistant, but allows the house to "breathe". Disadvantages: expensive, requires professional skill when laying;

- Facing tiles - made from baked clay; for outdoor work, choose a frost-resistant product with a moisture-repellent coating; comes in different configurations and colors. Disadvantages: for laying on a timber requires preliminary leveling of the walls;

- Fiber cement panels - made using the latest technologies from cement, reinforcing fibers, mineral fillers; resistant to loads and temperature extremes; come in different colors or are painted after installation. Disadvantages: in the absence of ventilation, they retain the escaping moisture, exposing the wood to rotting;

- Plaster is a simple and affordable material that allows you to level any walls; gives the house a modern look; you can choose any color that is added to the finished mixture; the most resistant are acrylic paints. Disadvantages: tightly closes the wooden wall, making the room unventilated.

Having decided on the appropriate type of material for cladding a house from a bar outside, they prepare everything necessary for finishing work. If you plan to do everything yourself, make sure to purchase a sufficient amount of materials, as well as have the necessary tools and accessories on hand. Decorating the walls in a house from a bar will require work at a height, so you must adhere to safety rules in order to prevent industrial injuries.

Features of choice

There are a wide variety of options for siding imitating timber on the market. The price of materials can be significantly different.To save money, experts recommend buying panels directly from the manufacturer in order to avoid markups from construction stores. But first of all, you need to choose high quality material. For this, individual points should be taken into account.

The humidity indicator should not be higher than 15 percent, otherwise it may threaten the façade warping during operation. The groove in the panel serves to ventilate the façade and helps to prolong the appearance of the panels.

The width of the siding is also important to the appearance of the building. To make it look like a natural timber, the width should be about 100 millimeters. Very narrow panels look cheap, and wide ones look sloppy

In addition, you need to pay attention to the quality of the lock connection. Its evenness and smoothness are important, as well as the absence of defects and damage.

And it is also necessary to choose the right decorative elements. It is they that increase the wear resistance of the surface, and are also responsible for the attractiveness of its appearance. Therefore, you need to choose quality products.

Before performing work, it is necessary to calculate the material and its components. To do this, you need to measure the walls, window and door openings. The area of the openings will not be covered with a false beam, so it must be subtracted from the total so as not to purchase unnecessary finishing materials.

Interior trim with false beams

Imitation of timber in the interior is a popular decoration material. It fits well with traditional styles as well as modern ones. Imitation of a bar for interior decoration is used in two versions:

- monolithic. In this case, all walls in the room are sheathed with false beams. The result is a monolithic one-piece panel. Such a coating is distinguished by high indicators of strength and reliability;

- combined. Combined wall cladding is a combination of imitation of timber as in the photo with other finishing materials: wallpaper, fabric, tiles.

Combined finishing is an opportunity to let your imagination run wild and come up with stylish solutions for the interior of the premises. She is more popular.

Current design styles with imitation timber

False beams are used in the following design directions:

- Art Deco. The main emphasis of the style is placed on multi-level ceilings made of imitation of timber, geometric ornaments, expensive fabrics, an abundance of light;

- minimalism. The peculiarity of the interior is simplicity, brevity, multilevel lighting;

- country. Country is a tree, comfort, home atmosphere. The main elements of the interior are rural color, old furniture, discreet shades.

Decorating different rooms with imitation of timber

For each room, designers are advised to choose your own false beam:

- living room. The living room is a spacious and bright room for which the color and texture of the selected material is important. In this case, its mechanical characteristics play a second role. For the living room, you can use boards of both light and dark shades. It is better to trim small rooms with a light bar with a monosyllabic pattern, spacious ones with dark materials with pronounced patterns;

- kitchen. In the kitchen, meals are regularly prepared, which causes the room to fill up with vapors. Therefore, it is necessary to choose strong blocks for its lining, which will not deform under the influence of fat, moisture, steam. Designers advise making a choice in favor of a plain light beam with an unexpressed pattern to make the kitchen more harmonious;

- bedroom. Here you can use various options for false beams in colors, strength and patterns. In the bedroom, almost all solutions look restrained and impressive.

- the corridor. For cladding of walk-through rooms, it is better to dwell on a material of a light shade without a complex pattern.

It is worth carefully studying the photo of interior decoration with imitation of timber in order to choose the best option for decorating your home.

Basic qualities

Imitation timber is a material that has recently entered the construction market. Previously, this function was performed by lining made of wood or plastic, which could imitate natural material. But if we compare modern material with its predecessors, then it should immediately be noted that it is produced in certain sizes, which are: 0.65–2 m in width, 2–4 m in length. It is this size that is considered optimal for external cladding work. houses with irregular shapes and a large number of corners.

So, the positive parameters include:

- It is a fairly environmentally friendly material. For its production, wood is used, which has a breathable effect.

- It has a special type of lock, it weighs a little, so it is easy to install.

- It is used for wall decoration from any material.

- Relatively low price and a large palette of colors.

- Durable enough. If you carry out the installation correctly and operate it in the future, it can last up to thirty years.

- Acts as additional thermal insulation of the home.

Along with the positive characteristics, the main disadvantages should be noted:

- The house, finished with imitation timber, has a high degree of flammability. Despite the fact that manufacturers are quite serious about the treatment of material with special anti-combustion compounds, imitation of a bar is easily subject to fire. In this case, it is necessary to treat it annually with special solutions, otherwise the material will burn, blacken and crack.

- The need to carry out periodic application of varnish or paints and varnishes.

- Compared to the price of the timber imitation itself, components, corner and other decorative elements are quite expensive.

How to make outdoor decoration

You can do the cladding of the facade of a residential building with your own hands if you use high-quality siding. It can be easily assembled in a short time, providing reliable protection to the walls of the cottage.

All work is conventionally divided into stages:

- preparation - the wall surface will need to be thoroughly cleaned of existing dirt and dust. To do this, you can use a conventional powerful garden vacuum cleaner. Also, the base should be covered with an antiseptic to prevent the risk of infection by fungus or mold;

- installation of the lathing - a vertical lathing is mounted on the base, adhering to a step of 60 cm from bars measuring 25x50 mm. If the wall is wooden, self-tapping screws are used for mounting the lathing; if it is brick or built of cinder blocks, holes must first be arranged in it and dowels must be hammered into them;

Lathing

Lathing

- vapor barrier of the base - over the lathing, you need to fix the vapor barrier film with an overlap, and glue the resulting joints with construction tape;

- thermal insulation of the base - insulation in rolls or mats of 10 cm in thickness is suitable. The insulation material is laid directly on the vapor barrier layer between the crate. Next, a vapor barrier film is again attached to the insulation material, which is additionally fixed with tape directly to the crate. The joints are glued again;

Imitation of timber is laid on a vapor barrier film

Imitation of timber is laid on a vapor barrier film

installation of panels and decorative elements. Performed on the crate, moving from bottom to top. Each element must be inserted into the groove of the previous one until it clicks. Additionally, the facade is fixed with small screws or thin nails. The screw cap needs to be slightly drowned into the panel, then cover it with a mixture of sawdust and varnish, wait until it dries and clean it with a fine sandpaper;

Fastening the material should start from the bottom

Fastening the material should start from the bottom Fixing scheme for imitation of timber

Fixing scheme for imitation of timber

finishing painting of panels - if the material does not have a topcoat, it must be covered with an antiseptic and painted. Then it will retain its attractive appearance for a long time.