Types of fasteners

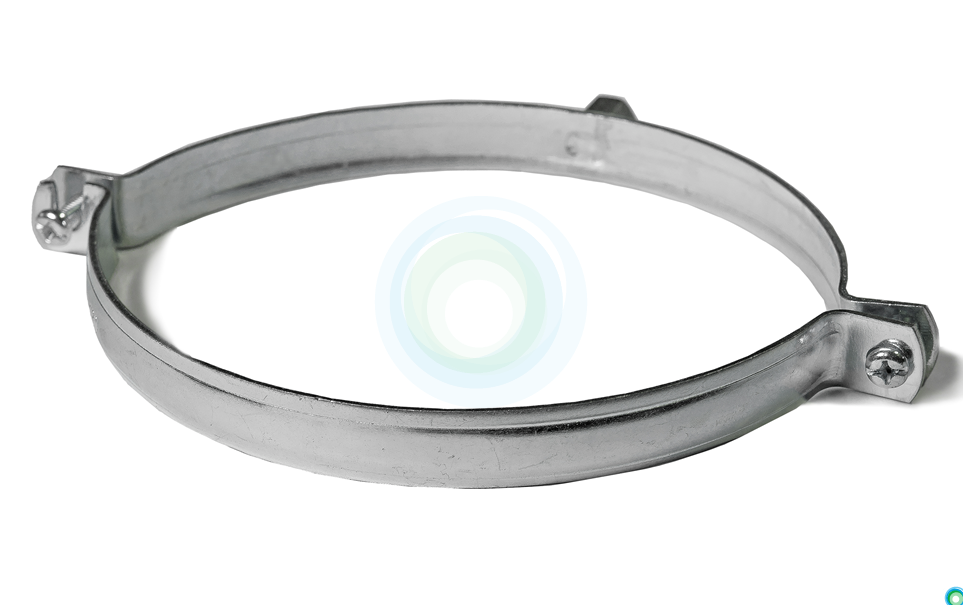

All clamps are divided into crimp and assembly clamps according to their design features. The first is a steel ring that is tightened on one side with bolts.

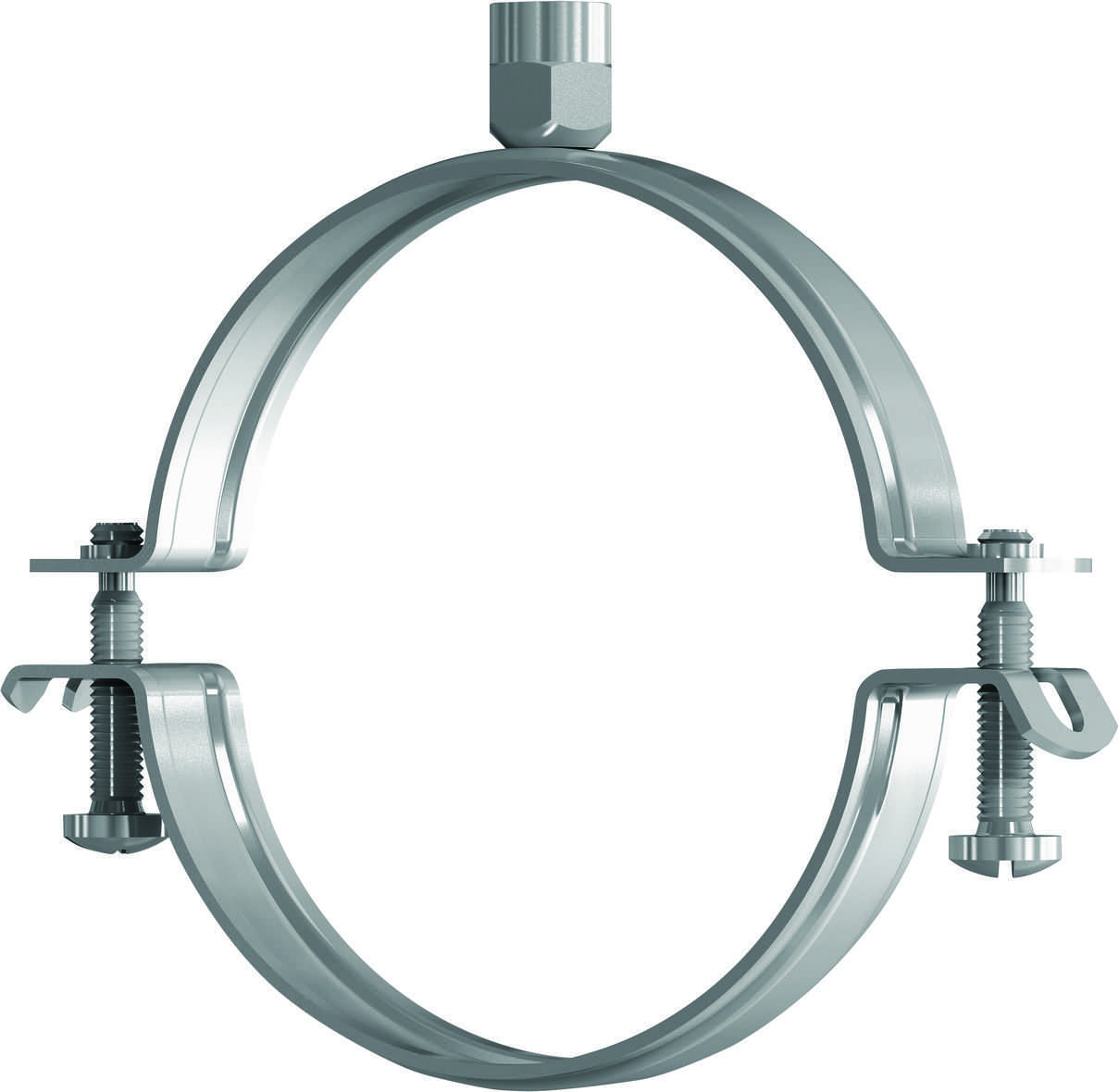

Mounting clamps are devices consisting of two half rings that are bolted together.

All clamps differ in the method of fastening:

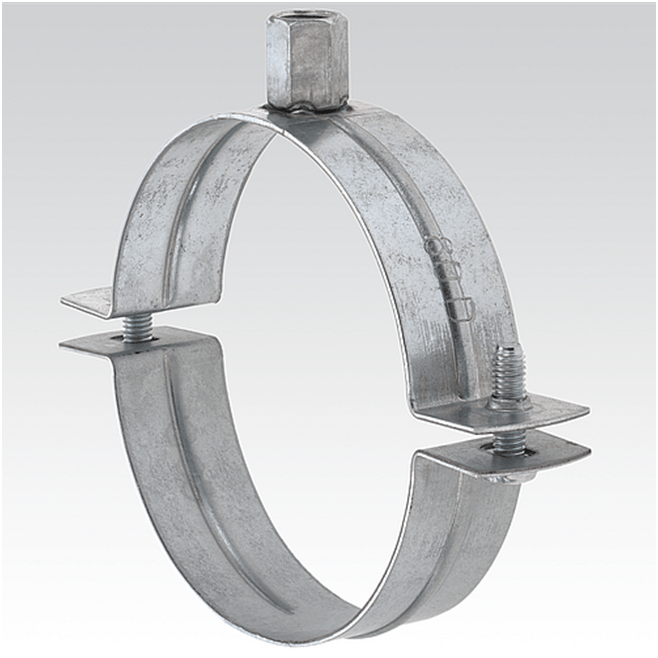

- To fasten the clamps to the ceiling, an anchor and a threaded rod are used, which is fixed on one side of the clamp, the other is fixed on the ceiling.

- The lateral fastening of the clamps fix the pipe with two pins to the enclosing structures.

- Wall clamps secure the duct to the wall surface with an adjustable or non-adjustable clamp.

In addition to standard clamps made of galvanized steel with or without a rubber seal, there are:

- band clamps, which are used to secure flexible small sections of pipe (nozzles) using stainless steel clamps;

- nylon parts for fixing flexible corrugated pipes;

- a clamp with a welded nut or a comb-nut and a rubber seal, consisting of two half rings, for fixing pipes to the wall or horizontal surfaces of the floor or ceiling;

- a clamp that is attached with a self-tapping screw to a vertical or horizontal surface;

- sprinkler clamp for hanging pipes, which is attached with a threaded rod to adjust the height of the duct attachment.

Characteristic

A clamp is a type of fastening that guarantees a reliable connection of plastic and metal air ducts to surfaces of various structures, including walls and ceilings. Clamps differ in width and diameter, they are plastic and metal. In the second case, they are made from stainless steel, alloyed composition, galvanized steel.

As a rule, it is a steel strip with a thickness of 1-3 mm. The width of standard products up to 40 cm in size is 2.5 cm, if the clamp has a diameter of 40–160 cm, this parameter can reach 3 cm. The most popular are inexpensive, but high-quality clamps with a diameter of 100 to 400 mm.

The technical specifications for duct clamps always include parameters such as the required pipe crimp diameter, compression force, material of manufacture and the device for fixing to the pipe.

The clamp is the best way of fastening, and there are several reasons for this:

- mounting products have the simplest, but effective and wear-resistant fastening mechanism;

- due to its compactness, the clamp is easily installed and, if necessary, replaced;

- in fact, nothing is known about cases of spontaneous disconnection of the clamp.

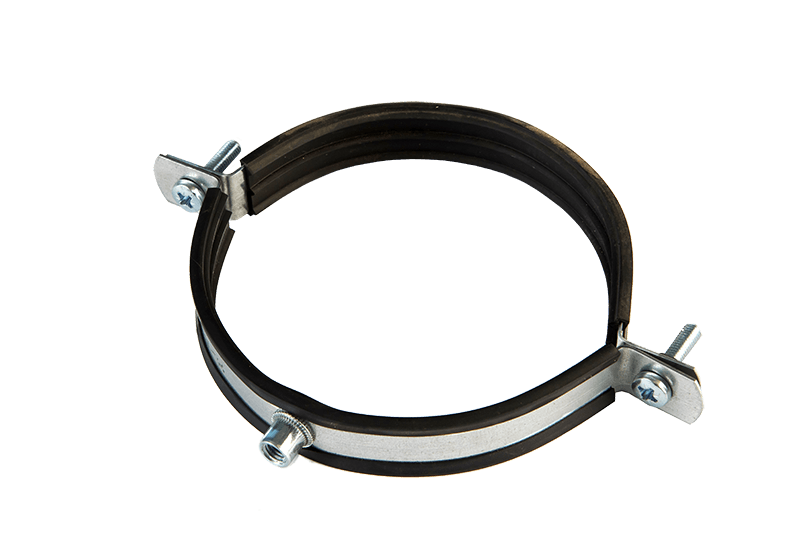

We add that, in addition to reducing vibration, sound insulating properties and resistance to UV rays, rubberized fasteners are immune to critical temperatures and aggressive chemicals.

Appointment

Basically, the clamp is necessary for mounting ventilation and fixing the pipe in a variety of (including inclined) positions. But, along with this, it is needed for tight joining of the duct fragments. If the clamp is equipped with a rubber gasket, it also reduces the vibration of the air exchange structure and the noise level by 10-15 dc. Moreover, there is no harmful chlorine in the composition of such a sound-insulating insert.

Such convenient and durable clamps for air ducts with a circular cross-section are necessary when installing main, conventional and suspended air exchange structures, but are also used in the installation of systems in private houses.

Specifically, mounting products with a central location of fasteners are used only for horizontal and circular ducts. But there are clamps with side fastening, which are additionally fixed with threaded parts - such clamps are suitable for vertical and horizontal connection of air pipes. Crimp models - parts for fixing individual parts of air ducts.

Installation of ventilation ducts occurs with the additional use of such devices with clamps: rods, adjustable and non-adjustable suspensions, threaded studs, turnbuckles.

Views

Several types of clamps differ in their design, method of fixing, but there are also non-standard types of products.

We list two main groups.

- Crimping devices - made of a narrow steel strip, have a round shape, when fastened, they are bolted on only one side. They are used for hermetically sealed connection of air ducts with a circular cross-section, provide an insert for vibration damping. The wide crimp type of the piece ensures a strong connection in the case of a chimney installation.

- Mounting clamps are two semicircular metal strips, bolted together and equipped with a vibration-damping rubber insert. In turn, they are also subdivided into categories:

- device with a mechanism, adjustable distance between the channel and the wall;

- wall clamp without an adjusting device;

- mounting clip for spacers, the three parts of which are bolted together.

Thus, the fasteners are fixed to the walls by means of a clamp, which in some cases can be adjusted. If you need to fix the pipe on the side surface, then two studs are used, in the case of a ceiling, you will need to prepare a threaded rod and an anchor.

However, when installing an air exchange system, other non-standard types of attachment devices are also used:

- a ventilation clamp equipped with a rubber profile and a self-tapping screw, the latter fixes the element to the ceiling and wall, it is needed for the installation of ventilation and chimneys;

- nylon product, the main purpose of which is to secure corrugated pipes;

- for free suspension of air ducts, the splinkler type of clamps is relevant - the height of the structure can be changed by means of a threaded stud;

- tape fasteners are applicable when working with flexible sections of the pipeline, it is produced mainly from stainless steel and has clamps from the same material;

- a product with a comb-nut welded to it, which allows you to suspend structures to different surfaces.