The consistency of the glue and its differences

By structure, two types of epoxy glue can be distinguished:

- Liquid glue is a gel squeezed out of a tube. Very simple and easy to use. You just need to squeeze the gel out of the tube and apply it to the surfaces to be glued. During operation, time is saved on mixing and preparation of the solution.

- Plastic mass - similar in consistency to dough or plasticine, sold in tubes. The necessary part of the plastic is cut off from the common piece and moistened with water. After that, you need to knead the product with your hands for a few seconds and apply to the parts to be glued.

There are also modified compositions of epoxy glue, their hardening temperature ranges from +60 to +120 degrees Celsius. This material is used for bonding metals and non-metals that are resistant to oils, fuels and other organic solvents.

Hot-hardening agents with temperatures from +140 to +300 degrees are considered especially strong. Such compositions are heat resistant and have high electrical insulating characteristics.

In addition to epoxy compounds used in manufacturing and industry, there are a number of universal epoxies used in everyday life:

- Moment is one of the most recognizable modern brands. Sold in any hardware store at a very affordable price. Packaging of goods is convenient for any craftsman: tubes with epoxy gel, plastic masses of 50 grams or reusable large-volume packages. The shelf life of such a product after opening the package is only a few months in a dry place with a temperature of no more than +25.

- "Contact" is ideal for gluing products that will subsequently be exposed to moisture. It is used for sealing joints in plumbing, pipe joints, gluing light shelves and decorative elements in the bathroom. The glue hardens in 2-3 minutes.

- "Cold welding" - suitable for joining metal elements, copes with the task for a few seconds. The mating level of the surfaces is identical to the effect after classic welding. After hardening, the edges of the metal product remain even, which is an additional advantage.

- EDP universal glue - used for fixing various surfaces, from glass and porcelain to metal. Experts say that this particular composition is optimal in quality and composition.

Cold welding - two sides of the same coin

Initially, the term "cold welding" was understood as the possibility of joining two metals without thermal effects. Pressure and plastic deformation were used to create deep molecular bonds. In the process of cold welding, two materials to be welded come together at the level of the crystal lattice and form permanent bonds. This method is especially useful when it is necessary to join two dissimilar metals that can deform when exposed to temperature.

This type of welding is used extremely rarely, since it requires special presses or vibration machines, and often both. Thermal welding is used more often, but the concept of "cold welding" was quickly adopted by manufacturers of special glue based on epoxy resin. Since we have decided to use this term, we will consider the main properties and scope of the so-called cold welding.

Why security measures are needed

This means that at least it is better to work with the material in the air, and not indoors.The first sign of trimethylamine poisoning is considered a sore throat, and it is at this moment that it is necessary to run to stop work, air the visit and drink fatty milk for a day. The substance has a pronounced odor, but in Poxipol it is veiled, therefore it is quite difficult to determine it and the body gets used to it in the same way as to carbon monoxide, so you need to take this issue seriously.

If you already had to work indoors, then you need to remember that evaporated trimethylamine is perfectly soluble in water, so you can use a "wet sink" with an air conditioner. It must be removed from the skin of the hands with citric acid; acids completely neutralize its toxic properties. The substance has a third hazard class, and the maximum permissible concentration is 5 mg per cubic meter.

Advantages and disadvantages

Among the advantages of Poxipol, users highlight the following:

- Versatility. The adhesive is suitable for restoring various objects and fixing various materials. But it is preferable to use Poxipol when working with metal, with which this product provides the most durable connection.

- Allows you to quickly restore damaged items. Poxipol eliminates the need to buy a new crane, as it provides strong metal adhesion for a long time.

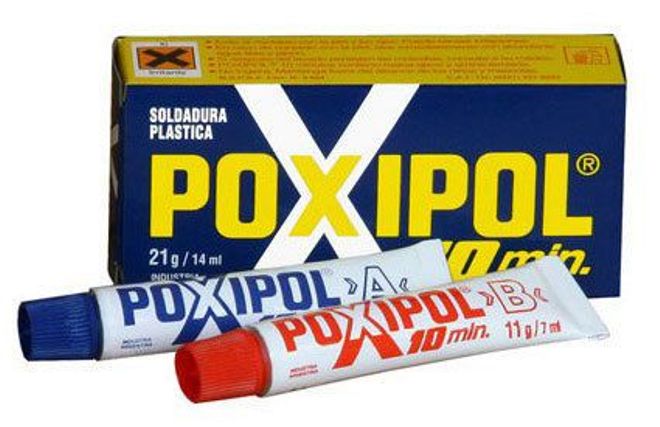

- Ease of use. To glue the damaged parts, it is enough to mix the components from two tubes, apply to the fragments and connect the latter together, pressing for 2-3 minutes.

- Multiple layers of glue can be applied. This feature allows you to eliminate deficiencies after the completion of the repair.

- Transparent consistency. Due to this, after application, Poxipol remains invisible from the outside.

Poxipol has a wide range of applications and is non-toxic to both humans and pets. Among the disadvantages of the glue are low tensile strength, inability to withstand high temperatures and vibrations.

Precautionary measures

When buying cold welding, always pay attention to the production time. It is prohibited to use expired adhesive composition.

In addition to the lost properties, which are expressed in poor adhesion or its complete absence, you can expose your health and the health of those around you to great danger. Therefore, be sure to keep Poxipol out of the reach of children.

The contents of the first tube have a negative effect on human skin and mucous membranes. In case of contact with eyes, the product can cause a severe allergic reaction. The second component affects the entire human body in a negative way. It cannot be swallowed or applied to the skin. Just like the first, the composition can provoke allergic reactions. If, for any reason, welding gets on the skin, the affected area should be washed immediately with running water and immediately consult a doctor. After the adhesive has completely dried, it ceases to pose a threat to human health and life.

Bonding technology

You do not need a professional construction education or extensive experience to work with glue. There is nothing complicated in the implementation of installation operations. Using the mixture, you can glue brick, concrete, metal, fiber cement, granite, marble, ceramics, glass, porcelain-faience, wood and some types of polymers other than those indicated on the package. Instructions for using Poxipol are as follows:

- 1. The surface to be treated is cleaned of foreign objects and treated with an antifungal liquid. No primer is required.

- 2. Dilute the required amount of glue, and prepare all the tools that may be needed in the process.

- 3. Smear only the surface of the element to be connected with glue and press it firmly in the right place. It is enough to hold for 1-2 minutes.

- 4. On average, hardening lasts 10-12 hours, but experts recommend not touching the treated area for at least one day, so that the glue is fixed as much as possible.

- 5. After complete solidification, any manipulations can be performed with the element, such as painting, drilling, grinding, curly cutting. According to its properties, the glue joint will be stronger than brick, concrete and any cement mortar.

The technological operation is very simple, but do not forget about the safety measures

It is very important to use protective gloves during work, since if it comes into contact with the skin, it will no longer be possible to wipe off the glue. If you use it to glue two fingers together, then only surgical intervention will help to separate them painlessly. So the matter is very serious and security requirements should not be neglected.

So the matter is very serious and you should not neglect the safety requirements.

Instructions for the use of glue

For reliable fixing of parts, it is important to prepare well both bonded surfaces. First, they remove dirt, debris, dust off. Further, degreasing is performed by washing with soapy water, wiping with acetone, alcohol, special degreasers (depending on the type of material)

Before applying the glue, you need to make sure that the surface is completely dry - so the adhesion will be much higher

Further, degreasing is carried out by washing with soapy water, wiping with acetone, alcohol, special degreasing agents (depending on the type of material). Before applying the glue, you need to make sure that the surface is completely dry - this way the adhesion will be much higher.

Glue preparation method

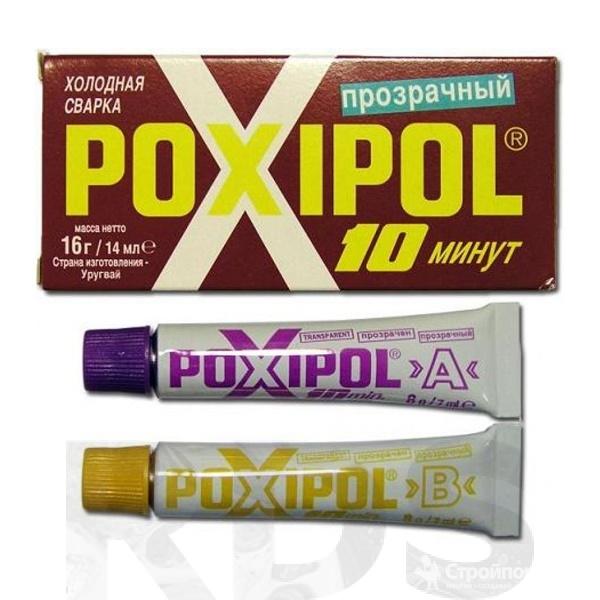

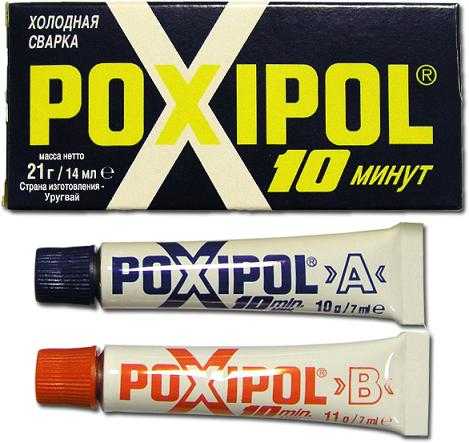

It is necessary to mix the two components of Poxipol glue strictly before work, otherwise the composition will quickly harden and deteriorate. It is necessary to perform the following actions:

- put the required amount of component A (epoxy resin) on a plate or in a disposable cup;

- add the same volume of composition B (hardener), that is, the proportion will be 1: 1;

- mix the glue well so that it becomes homogeneous, you should not devote a lot of time to the process.

At the end of the work, the tray plate must be cleaned by scraping off the glue residues, it is reusable and will be useful for the next application of Poxipol.

Bonding products "Poxipol"

After the glue has reached a uniform consistency without lumps, you can start bonding the parts. One of the working surfaces is well coated with glue, then strongly pressed against the second part. Withstand 60-120 seconds for initial setting, if necessary, adjust the position of the parts during the first 5-10 minutes. The product is left for a day, after which it can be used.

Useful tips for using Poxipol are as follows:

- to seal joints, pits, cracks, and other defects, it is better to use a small construction trowel or knife dipped in cold water, with which the glue is spread;

- when repairing leaks on containers, tanks, the composition is also applied with a spatula, but already a little thickened, or they take opaque plastic-like glue with their hands, stick to the problem area;

- if small steel shavings are introduced into the glue, the mass will become more resistant to mechanical stress and will be able to withstand even the vibration of the products;

- the most favorable temperature for working with glue is + 18 ... + 22 degrees, in which case the composition hardens evenly;

- often it is required to apply two layers of glue, in this situation you need to wait until the first is completely dry and only then do the second.

Remains of glue in the tubes do not need to be thrown away, they can still be used in the future.

It is only important not to swap the caps, screwing them in the correct order. If the epoxy resin in the package thickens a little, put the tube in hot water or closed on the radiator before use.

Adhesive Precautions

Adhesive Precautions

Epoxy can negatively affect the skin, mucous membranes, causing irritation and allergic reactions.The hardener is even more harmful to the skin, it must not be allowed to come into direct contact with the body. If any component or their mixture gets on the skin, wash it with plenty of soap and water. Eye contact or swallowing requires urgent medical attention!

After drying, the composition is harmless to humans, but while working with it, you must observe safety measures: wear glasses, gloves, a respirator, and ventilate the room well. It is better not to use expired glue. It should be stored only out of the reach of children and animals. It is strictly forbidden to repair elements of gas equipment with Poxipol!

Poxipol cold welding provides exceptional bonding performance across a wide range of products. It will become an indispensable tool at home, in the workshop, for repair work. The effectiveness of the glue has been proven in practice, it does not lose its popularity among users.

Disadvantages of Poxipol Cold Welding

- Low melting point, which is about 120 degrees Celsius;

- The packaging capacity is only 16 grams, which is often insufficient;

- Narrowed field of application due to limitations in technical parameters;

- Quite a long solidification time, which is inferior to competitors;

- Users note a relatively large number of rejects in the supplied mixtures;

- Low tensile strength, which excludes the use of glue for critical joints that are exposed to mechanical shock and vibration loads;

- The need for thorough preparation of the surface by cleaning it from oil and grease, otherwise nothing can not stick together.

Poxipol scope

Poxipol transparent cold welding is used for home bonding of plastic parts, small metal parts that have broken, containers in which cracks and holes have formed. All this can be restored thanks to this substance, without using any other devices. The composition can be used in many places that are not subject to high stress, but are difficult to bond with other glue. Due to its structure, it is practically invisible after application. Can be used as cold welding for ceramics.

The mixture can also be used for decorative restoration. If you need to close up a small part of any product, then it is enough to knead the material and use it as plasticine. There are only up to 100 grams of material in a package, so we are talking about relatively small operations. Even in a plastic state, cold welding keeps its shape, and after solidification it becomes even possible to process it, if there is such a need.

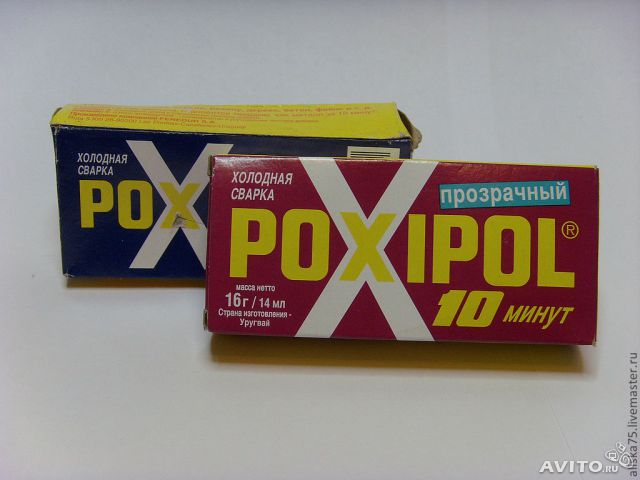

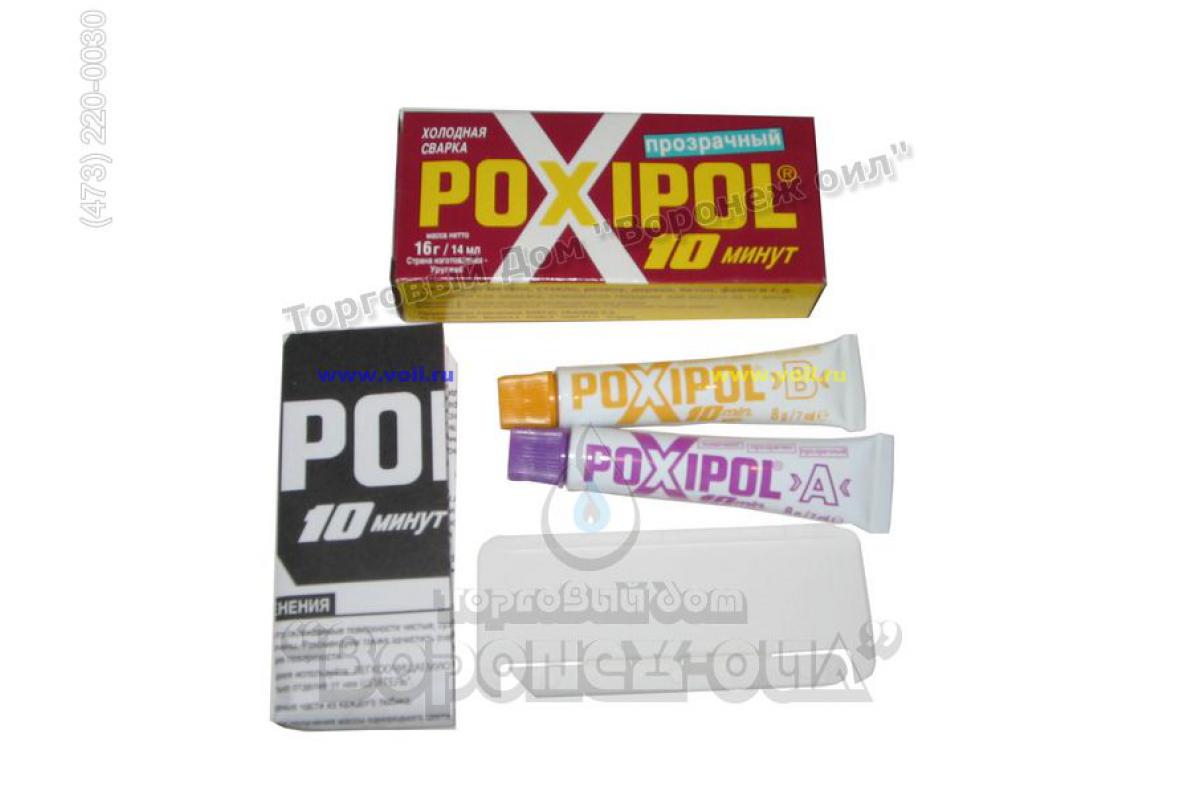

Poxipol types

This cold seal comes in one variety. These are two components in separate containers. The substance weighs 16 grams per package. Given that the quality of this brand is not at the highest level, this is quite enough.

Poxipol Cold Welding Specifications

Poxipol Cold Welding Specifications

|

Specifications |

Meaning |

| Maximum shear force of the connection, N |

993 |

| Average shear stress, MPa |

2,2 |

| Shear test, N |

237 |

| Peel stress, MPa |

5,4 |

| Primary hardening time, hour | |

| Time of preservation of the plastic state, min | |

| Full solidification time, hour |

Features of Poxipol application

The Poxipol cold welding instructions must be strictly followed, since otherwise the mixture may remain in a plastic state and the connection will not occur, or it will be of such poor quality that everything will have to be redone. The first stage involves thorough cleaning of the surface, even if the work is carried out with wood or plastic. By using a solvent and other substances, you should get rid of grease and debris so that nothing interferes with the connection.

Then you need to measure out the same amount of each of the components.

Application of two Poxipol components

This is followed by a thorough mixing process, during which you need to get a homogeneous mass. There should be no solid particles, lumps of undissolved substances and other negative elements. The entire mass must be a homogeneous material. When kneading, the temperature rises, which helps to change the physical state of the material.

Thorough mixing of Poxipol components

After that, you can apply the resulting composition to the surface. If gluing is going on, then the materials should be pressed, and if the defect is being repaired, then you just need to wait.

Applying components to the device to be glued

The setting time here is higher than that of other brands and is at least 10 minutes. With a change in temperature, this indicator can increase. The final solidification will occur in a day, and the primary one in an hour.

Manufacturer

The manufacturer of this cold welding is the Uruguayan company Poxipol.

It is interesting: Block house - features and scope

Glue hardening time

By and large, the consumer is interested in how long the glue dries, what tensile strength and what temperature it can withstand. All this is indicated in the characteristics. For example, it is written right on the package that the solidification time is ten minutes, although in fact the composition polymerizes and completely hardens in 24 hours, and trimethylamine stops emitting harmful fumes only after 78 hours.

However, according to the results of publicly available tests, complete curing of the composition occurs only after 48 hours. Trimethylamine in its pure form is a very toxic substance, it is especially dangerous in the form of vapors, about which not a word is written in the instructions. If so, let's look at the security measures first.

Application area

Instructions for use and technical characteristics of this glue are fully posted on the manufacturer's website. It describes in detail in what areas it can be applied, what properties it has.

So, he glues metal, plastic, wood products. Also porcelain stoneware, porcelain, faience, marble, concrete. More rubber and glass. By the way, you can find out about other effective brands of adhesives for metal here

Perfect for home repairs in workshops, designing all kinds of crafts. Assembly, fixing, joining of furniture interiors made of wood or metal. It is especially recommended for objects experiencing rather heavy loads. Remember this. Let's say - slats and crossbars of beds, crossbars at stools. Legs of tables, chairs, armchairs.

Repair of wooden or metal doors and windows, hinge attachment. Leaky tanks, water tanks. Filling and repairing cracks in the sink, bathroom, toilet. Fastening handles of hand tools. Almost the entire list, from a heavy hammer to a light mop. Bonding marble and granite blocks.

For the restoration of stucco, concrete, plaster or marble monuments. Securing a variety of fittings. For supporting in walls to hang heavy objects. In summer cottage gardening, installation of fasteners for hanging objects, tools and massive decorations.

Patching radiators made of non-ferrous alloys and fuel tanks on cars or motor vehicles. Also other everyday things. Boat frames or car bodies. Reinforcement and joining of seams in vehicles. Restores threaded connections. Docking and renovation of garden furniture from basic materials used.

Restoration of vases, flower pots, large porcelain items, gardening fountains. Bonding of concrete pipes for gutters or storm gutters. Plastic drainage systems. As you can see, the possibilities are great.

Instructions

Before proceeding with gluing parts, it is necessary to carefully prepare the working surfaces. This requires removing mechanical debris, as well as washing and degreasing the elements using a special solvent.It is necessary to combine the contents of the packages in equal parts and mix the composition thoroughly. Mixing time is usually 10 minutes. The resulting mass should be homogeneous and free of lumps. When mixing the components, the temperature of the resulting mixture increases significantly.

Then you should apply the resulting product to one of the surfaces and press the parts tightly against each other. To eliminate leaks in containers, you need to apply glue to the hole or crack and leave it at rest until it dries completely. You can adjust the location of the parts within 10 minutes after applying the mixture, and it is recommended to use the glued thing a day after installation.

When using Poxipol cold welding, the following precautions should be observed:

it is necessary to exclude contact with the skin and mucous membranes;

in case of contact of the skin of the hands with uncured glue, wash the contaminated area with soapy water, and then rinse with warm running water;

if allergic reactions occur, it is recommended to consult a doctor;

after complete drying, the product does not pose a danger to human health;

when buying cold welding, you should pay attention to the expiration date, since it is forbidden to use compositions with an expired date.

Advantages and disadvantages of Poxipol

The popularity of this brand of glue is due to its excellent adhesive properties. The seam is durable, does not collapse over time. The advantages of Poxipol are as follows:

- preservation of the joint volume after drying, the possibility of applying an adhesive layer of any thickness;

- the use of glue on any materials (even on different structures, density), no damage and corrosion when applied to most types of plastic;

- water resistance, oil resistance, scratch resistance;

- the possibility of applying on vertical, horizontal bases with a continuous and dotted method;

- ease of mixing and ease of application;

- fast setting and short time to full hardening;

- the ability to use for indoor and outdoor work;

- lack of solvents in the composition, the possibility of using in residential premises, children's institutions;

- lack of traces, stains, streaks after drying;

- availability for sale in almost all hardware, hardware stores;

- simplicity and clarity of instructions for use.

The disadvantages of Poxipol glue include its low tensile strength. Therefore, you should not use the glue in conditions where parts are exposed to vibration, other movement, deformation, and high mechanical stress. The quality of adhesion decreases if the surface is not properly prepared, which can also be attributed to the disadvantages of the glue. Another disadvantage is the risk of damage to some materials (teflon, polypropylene, polyethylene), this glue cannot be used on them. Other disadvantages:

- higher price compared to domestic adhesives;

- low melting point;

- short pot life after dilution;

- the need for mixing components;

- too small packaging (if there is a large amount of work).

Features of Poxipol glue

Poxipol epoxy glue has a number of features that must be taken into account when working with it:

We glue the plastic with Poxipol glue (click to enlarge)

- when dry, it does not increase or decrease its volume;

- they can work under water. For the glue to harden, air access is not necessary;

- the time for complete solidification depends on the ambient temperature. In 24 hours the glue is polymerized at a temperature of 20-24 degrees. An increase in temperature will increase this period, and a decrease will reduce it;

- completely solidified composition lends itself to processing with emery, it can be drilled and threaded. You can start these works within an hour after gluing;

- with Poxipol glue, you can safely work on vertical surfaces - due to its thick pasty consistency, it does not drain.

Watch a video about this glue:

Instructions for use

If it is not possible to thoroughly process the surface for applying glue, it is permissible to start work without preparation. In this case, adhesion will decrease, since the penetration of the mixture into the structure of the coating will interfere with contamination. To improve the quality of adhesion of the surface with Poxipol, the instructions for use should be studied before performing work. Sequencing:

Contamination is removed. If the coating is heavily soiled, it should be rinsed under water and then dried thoroughly. A brush is used to remove dirt from small cracks.

The surface should be moderately rough. If you plan to glue glass coatings, you must treat the material with contact adhesive

This will improve the adhesion of the resin to the surface.

It is important to protect the structure from mold. To do this, you should treat the surfaces with an antiseptic.

Such a measure will prevent the destruction of wooden structures. Other materials are more resistant to microorganisms.

Glue is applied only to the part that will be attached.

Cooking method

The contents of tube A and B are mixed in an amount sufficient to fill the damaged area of the coating. This must be done immediately before performing work. If the mixture is prepared in advance, it will harden, lose its properties upon repeated mixing and will not provide sufficient adhesion.

The resin and modifier are mixed until a homogeneous mass is formed. The layered structure of the material can lead to a deterioration in the quality of adhesion of the adhesive to the surface. You can learn how to properly glue parts using the cold welding method from the instructions. You will need equal amounts of resin and modifier.

How the gluing process works

The instructions for using the cold welding method are simple:

- After taking the same amount of resin and modifier, these substances are mixed for 10 minutes.

- It is not necessary to apply glue to both joining surfaces. This is not necessary, in addition, the mixture will be consumed in excess. It is recommended to glue one of the parts.

- Having connected the surfaces, they are held in this position for 2 minutes.

- Check the quality of the connection. When necessary, the position of the parts is corrected.

If the surface area to be treated with the adhesive is large, a construction trowel can be used to apply the mixture. This will speed up the completion of the repair.

How long does the glue dry

There are 3 stages of modification of the structure of the mixture after application:

- 2 minutes after surface treatment - this time is allotted to correct the position without the risk of losing the properties of the glue;

- 10 minutes - at the end of this period of time, the glue sets, therefore, if damaged, the seam loses its properties, the strength decreases;

- 24 hours after treatment is given for complete drying.

If in the area where the glue is applied, it is planned to process, install fasteners, it is recommended to withstand a little more than 1 day. This will provide higher strength. Moreover, the likelihood of expansion of the suture connection, its compression and deformation is excluded.

Basic properties of Poxipol

Now about the properties and characteristics of the material. The table shows the laboratory data of the manufacturer Acapol itself and the data presented here is very convincing.

In practice, this is expressed in the widest use of glue, both an adhesive and a void filler, cold welding for sealing holes. Judging by the feedback from users, in the material, after it has completely solidified, you can freely drill a hole and cut a thread. Of course, one should not hope that cold welding is an analogue of conventional welding, nevertheless, as a glue for metal, Poxipol works very well.

The main characteristics that affect the scope of application of two-component glue can be described as follows:

- the material is dielectric, does not transmit and does not conduct current;

- withstands temperatures up to 120 ⁰C;

- the thickness of the layer does not affect the strength of the connected elements;

- after hardening, it does not deform and does not flow from surfaces;

- resistant to moisture and fuels and lubricants;

- well processed after hardening with any locksmith tool;

- complete drying time - 48 hours, preliminary drying occurs within the first 30 minutes after application;

- the life time after mixing the components is from 3 to 6 minutes.

Therefore, subject to careful handling and compliance with safety rules, Poxipol is an indispensable tool both for finishing work and for repairing any type of equipment. Good job everyone!

Bonds metal, glass, rubber, wood, concrete, earthenware and other materials. It is applied as a putty, it becomes as hard as metal. Can be drilled, tapped. Poxipol does not change its volume, does not deform. Does not break: tough but flexible. Can be used at temperatures up to 120 degrees Celsius.

Poxipol does not contain solvents. Can be applied in any layer thickness. Cold welding Poxipol hardens even under water. It is used in cold weather without heating and additional pressure. Cold welding is resistant to acids, solvents and chemicals. Does not change its properties over time, does not rust. Moisture and heat resistant. It does not change in a tube, it can be stored indefinitely.

Application

It is used for gluing wall hooks and brackets, for repairing a boat, sealing leaks, strengthening the handle of knives, gluing broken dishes, glass, repairing toys, installing instruments in a laboratory, gluing aircraft models, aquariums, repairing furniture, fixing fallen tiles on walls, strengthening floor tiles ...

And also putty car fenders, repair fishing rods, fill up holes in the water supply system, in aluminum sheets, repair concrete floors, make fasteners and guides, fill up holes in metal and concrete containers, fill up cracks in pools, carve wood and metal, fill voids in casting, filling cracks, sealing cisterns and tanks.

Type of

Epoxy adhesive.

Appointment

- It is used for gluing, repairing and filling voids, cracks, irregularities.

- For gluing wall hooks and brackets, mirrors.

- For the repair of boats, toys, furniture, plumbing, fishing rods.

- For sealing leaks, concrete floors.

- For strengthening the knife handles.

- For bonding broken dishes, aircraft models, glass, aquariums.

- For mounting instruments in the laboratory.

- For fixing broken tiles on the walls.

- For strengthening floor tiles.

- For filling car fenders and bumpers.

- For sealing holes in plumbing, in aluminum sheets, in metal and concrete containers.

- For fasteners and guides.

- For sealing cracks in swimming pools.

- For carving wood and metal.

- For filling cavities in casting, cracks.

- For sealing cisterns and tanks.

Types of surfaces

Metals, ceramics, rubber, glass, concrete, fiber-reinforced concrete, wood, rigid plastics (plastics), except for polyethylene, polypropylene, teflon (polytetrafluoroethylene).

Construction adhesives are increasingly used in interior decoration. They have become an excellent alternative to standard cement based mixes. Modern substances are much better at coping with the tasks, meet modern safety requirements and have incredible durability.

Poxipol glue is one of the most demanded materials today. Its performance properties are legendary. And the majority of construction companies give preference to him when purchasing consumables.

Instructions

- Before the composition hardens, it can be leveled with a spatula or knife, having previously moistened them in water.

- If the mass is not squeezed out or is squeezed out with difficulty, slightly heat the tubes.

- Do not change the caps on the tubes.

- In case of frost below 10 degrees C, the components may harden, leave the tubes for some time at room temperature or in a pocket under your clothes and POXIPOL will be ready for use without losing its properties.

- When filling large voids or gluing large parts, use rebar (pieces of wire, metal mesh or fiberglass). Apply several coats at intervals of 40-50 minutes for best results.

Some results of laboratory tests "POXIPOL" 10 min. metallic and transparent.

Note1: These characteristics are valid at a temperature of + 23 degrees C +/- 2 and an equal amount of each of the two components.

Note 2: The data provided is for informational purposes only. They were obtained using methods developed by Akapol. The company is not responsible for test results obtained by third parties.

.

|

Options |

"POXIPOL" 10 min. metal |

POXIPOL 10 min. transparent |

| Working time (mixture life) |

3-5 minutes |

4 - 6 minutes |

| Initial Drying Time (100 microns) |

5 - 10 minutes |

5 - 10 minutes |

| Shore D hardness in 1 hour |

Over 66 units |

Over 66 units |

| Shore D hardness in 48 hours |

Over 78 units |

Over 76 units |

| Density |

1.50-1.60 g / cc |

1.16-1.26 g / cc |

| Spreadability |

Absent |

Absent |

| Tensile strength (emery iron) |

Over 800 N / sq.cm |

Over 800 N / sq.cm |

| Impact resistance |

Good |

Good |

| Shear strength iron (emery) |

Over 1600 N / sq. Cm |

Over 1600 N / sq. Cm |

| -aluminum |

Over 400 N / sq. Cm |

Over 450 N / sq. Cm |

| -bronze |

Over 250 N / sq. Cm |

Over 350 N / sq. Cm |

| -copper |

Over 170 N / sq. Cm |

Over 300 N / sq. Cm |

| - galvanized steel |

Over 250 N / sq. Cm |

Over 230 N / sq. Cm |

| -lead |

Bonding strength is higher than the strength of the bonded material |

|

| -polyvinyl chloride (PVC) solid (over another contact adhesive) |

Over 180 N / sq.cm |

Over 180 N / sq.cm |

| -polyester, glass fiber reinforced |

Over 150 N / sq. Cm |

Over 150 N / sq. Cm |

| -tree (pine) |

Over 500 N / sq. Cm |

Over 500 N / sq. Cm |

| Temperature resistance (depends on thickness and volume) |

Not less than 80 degrees WITH |

Not less than 60 degrees. WITH |

| The solidified product is not affected in any way by the following media |

Water, environment |

|

| The cured product is extremely weakly influenced by the following media | sodium oxide hydrate (5% -47%), hydrochloric acid (5% -20%), nitric acid (5%), phosphoric acid (5%), acetic acid (5%), mineral oil (SAE 20W40), food grade vegetable oil, detergents, gasoline, plasticizers (DOP), toluene, etc. |