Installation technology

The advantage of chemical anchors is their high strength and ability to create high-quality surface adhesion. They can be used for dense and porous blocks. When installing this anchor, special injection is used, which is a polyester resin and a hardener.

When working with cartridges, a special gun is used. The resin and hardener in the cartridge are separated, they are in separate packages and are combined at the moment of extrusion. In the case when construction work is carried out according to project documentation, before starting installation work, specialists must check the conformity of the markings in the documentation and on the anchors themselves. The expiration date of the chemical solution is also checked before use.

Drilling holes

When installing mechanical anchors, builders prefer the diamond machine. If the drilling is done for a chemical anchor, a puncher is suitable for the work. In the process of drilling, the location of the reinforcement is taken into account, and if the drill hits it, the hole is drilled in another place.

The hole diameter must be drilled 2-3 mm larger than the stud diameter. Having drilled a hole of the required diameter and length, it must be cleaned of the formed dust. Untreated crumb will reduce the strength of the bond.

The size of the required screw is selected depending on the type of robot

The size of the required screw is selected depending on the type of robot

At this stage, work is needed:

- brush of the required diameter;

- construction vacuum cleaner;

- compressor.

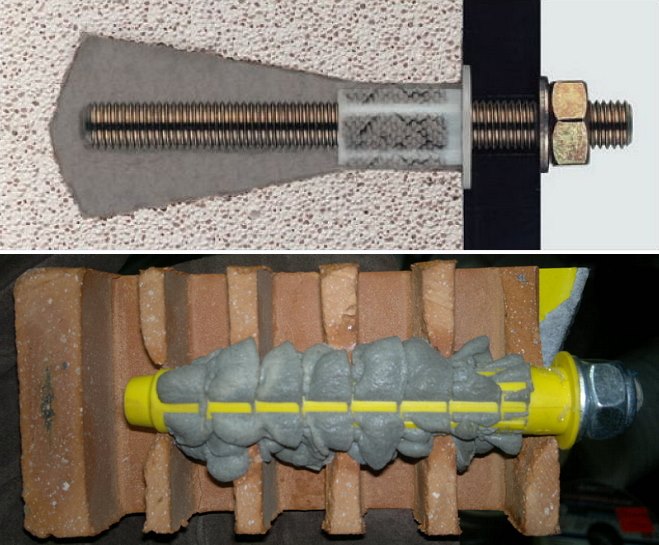

Installing the sleeve

If work is carried out on hollow and porous materials (aerated concrete, foam concrete, slotted brick), a mesh sleeve must be installed before pouring the connecting solution. It has the function of keeping the chemical in the hole until it solidifies. These sleeves are sold as prefabricated pieces or stockings and are available with special plugs.

Pouring chemical

Before pouring a chemical, you must read its instructions. In order to properly solidify the material, it is necessary to create a special temperature, the heating itself can be done with a construction hairdryer. The filling process takes place using a special dispenser gun. Pouring the substance with a gun into the hole should be squeezed 2/3 through the sleeve.

Stud installation

After pouring the mass, we immediately install the threaded rod. We bring it to the stop, after which we twist it several times in order to evenly distribute the chemical around the stud. Remove excess chemical before solidification. During the hardening process, the stud is not subjected to any stress.

Freezing

It is necessary to wait for the complete solidification process of the substance for the long-term operation of the anchor. The curing time depends on the temperature of the base material and averages 45 minutes. The lower the temperature, the longer the chemical solution will harden (in winter, it may take up to 6 hours). After hardening, start tightening the nut.

How to install an anchor bolt in concrete

The whole process is quite simple, the main thing is to correctly measure and implement everything as accurately as possible. But there are several nuances that need to be considered.

Practical tips for installing anchors in concrete:

- The strength indicator of fasteners is influenced not only by the anchor, but also by the quality of the base material (concrete in this case), proper preparation for installation, taking into account the material of the attached structure and the structure of the bolt itself.

- If a layer of finish is applied to the wall, the hole must be deeper, as the finish is usually less durable than concrete.

- It is advisable to take the drill 0.5 mm thinner than the diameter of the future hole.

- When working with a hammer drill, it is best to use a special carbide tip.

- Carefully read the instructions - the permissible force and the maximum number of revolutions must be indicated on the packaging with anchors.

- When screwing the anchor in, in no case should it be twisted until it stops, as the material may collapse.

Permanent fixture: concrete dowel

The dowel is a spacer made of polypropylene or nylon, which is similar in function and operation to an anchor. It is not used independently, it is fixed in concrete with special nails or self-tapping screws. To strengthen the fixation, it is often performed with spikes or tendrils.

This type of fastening is used where there are no too heavy loads on concrete - fastening shelves, hooks for TVs, lighting fixtures. The dowels are hammered into the dowels, the screws are screwed in with a screwdriver or screwdriver. You will also need a regular hammer to drive in nails.

You can also find dowel nails designed for use with a power gun. Fasteners in concrete are made of metal, outwardly it is somewhat reminiscent of a bullet. It is relevant where you need to hang a large number of small items.

Concrete dowel: fast but strong

Nagels are those that are most often used to equip fasteners near the edges of a concrete wall. The fasteners do not require additional fixation, they are screwed into the hole, where a little epoxy glue is poured in advance. It is not necessary to drill holes - the dowel can be screwed directly into the concrete wall. If you still need to make a hole in the concrete, then it is better to choose a drill (a hammer drill can damage the wall).

Screw it in with a screwdriver - and after that it is no longer possible to unscrew the pin back. Therefore, the preliminary marking must be done especially carefully.

How to use?

Before installing an anchor, which belongs to chemistry, you need to carefully study the instructions for use. This allows you to take into account all the necessary nuances, for example, calculate the installation scheme and much more.

The first stage is the preparation of the borehole. On the basis, notes are made in the places where the fasteners will be mounted. Then a hole is drilled with a drill a maximum of 2 millimeters wider than the diameter of the stud. You need to hold the drill in a perpendicular position relative to the surface. The depth of the hole can be controlled with special stops, or by marking a mark on the drill. For future fasteners to be reliable, the hole must be cleaned of dust and dirt. The procedure is carried out using a special brush and a hand or construction vacuum cleaner - it all depends on the volume of work performed.

The second stage is the introduction of the adhesive mass. A nozzle is installed on the cartridge, and the whole structure is inserted into a special gun. First, squeeze out a small amount of the chemical composition, about 10 centimeters, to make sure that all the components are mixed evenly - you do not need to use them. The mixer spout is placed in the hole, then by pressing the trigger button of the gun, the mixture consumption is controlled. The veneer is filled to about 2/3 of its volume.

The third stage is the installation of a metal rod. To distribute the adhesive evenly inside the hole, the fasteners can be “pulled out” a little and then screwed in to the end. While the adhesive hardens, the position of the anchor can be controlled. It is possible to determine whether the mass has filled the hole or not by its appearance - if the glue comes out, it means that the installation is airtight.

The final step is to install and tighten the nut. After the solution has completely hardened, all materials and elements can be fixed. Tighten the nut with a torque wrench.Manufacturers in their recommendations indicate what maximum force should be applied when tightening the nut. It is not recommended to use a traditional key, as there is a risk of exceeding the force and deteriorating the material.

If there are breaks during installation, the mixer spout is not removed from the cartridge, but before continuing, it is changed to a new one.

Some builders are engaged in the preparation of the solution on their own. For this, epoxy resin is mixed, hardeners (UP-583), cement or gypsum mortar and a plasticizing agent (DBP or DEG-1). The resulting mixture is thoroughly kneaded. It is best to mix the solution in small quantities, then use immediately.

The following video describes the installation of chemical anchors.

Concrete anchors: weight and dimensions

The dimensions of the anchor bolts are determined by the material used and the purpose of the product. Each manufacturer is governed by general and internal standards. But there are parameters that are similar for all suppliers.

So, depending on the type of anchor, as a rule, the values of the diameter / length of the product look as follows (in mm):

- wedge: 6-20 / 40-421;

- spacer: 5-24;

- drive-in: 6-20.

The tables provide detailed information on the dimensions and total weight (in kg. 1 piece) of the demanded anchors for concrete, compiled on the basis of products from leading manufacturers (Hilti, Fischer, etc.).

Klinovoy

| The size | PCS. in 1 kg | Weight 1 piece, gr. | The size | PCS. in 1 kg | Weight 1 piece, gr. |

| 6*40 | 100 | 10 | 10*150 | 12 | 85 |

| 6*65 | 67 | 15 | 12*100 | 11 | 94 |

| 6*95 | 50 | 20 | 12*120 | 10 | 104 |

| 8*50 | 46 | 22 | 12*135 | 8 | 133 |

| 8*75 | 30 | 34 | 12*150 | 8 | 139 |

| 8*80 | 25 | 39 | 16*105 | 6 | 179 |

| 8*105 | 25 | 41 | 16*140 | 5 | 220 |

| 10*65 | 17 | 60 | 16*180 | 4 | 275 |

| 10*80 | 15 | 71 | 16*200 | 4 | 320 |

| 10*95 | 13 | 79 | 20*160 | 3 | 383 |

| 10*120 | 14 | 74 | 20*200 | 2 | 500 |

| 10*130 | 13 | 78 | 20*300 | 2 | 738 |

Classical

| 6,5*18 | 189 | 5 | 12*130 | 13 | 83 |

| 6,5*36 | 115 | 9 | 12*150 | 10 | 110 |

| 6,5*56 | 80 | 13 | 12*180 | 8 | 130 |

| 6,5*75 | 58 | 18 | 12*200 | 7 | 147 |

| 8*40 | 75 | 14 | 12*250 | 6 | 188 |

| 8*65 | 45 | 22 | 12*300 | 5 | 219 |

| 8*85 | 37 | 28 | 14*100 | 12 | 86 |

| 8*100 | 31 | 33 | 14*120 | 12 | 88 |

| 8*120 | 27 | 38 | 14*150 | 9 | 118 |

| 10*40 | 36 | 28 | 14*200 | 7 | 163 |

| 10*60 | 32 | 32 | 14*250 | 6 | 195 |

| 10*97 | 25 | 40 | 16*110 | 7 | 160 |

| 10*125 | 17 | 61 | 16*150 | 5 | 240 |

| 10*150 | 15 | 68 | 16*180 | 5 | 250 |

| 10*180 | 12 | 87 | 16*220 | 4 | 260 |

| 10*200 | 10 | 100 | 16*250 | 4 | 290 |

| 10*250 | 7 | 150 | 20*151 | 5 | 248 |

| 12*60 | 20 | 51 | 20*200 | 3 | 405 |

| 12*75 | 17 | 61 | 20*250 | 2 | 500 |

| 12*100 | 15 | 67 | 20*300 | 2 | 568 |

Driven (steel and brass)

| The size | PCS. in 1 kg | Weight 1 piece, gr. | The size | PCS. in 1 kg | Weight 1 piece, gr. |

| M6 | 6 | 160 | M6 | 250 | 4 |

| М8 | 92 | 11 | М8 | 128 | 8 |

| M10 | 42 | 24 | M10 | 75 | 14 |

| M12 | 21 | 48 | M12 | 39 | 26 |

| М16 | 13 | 80 |

The chemical anchor is characterized by the size of the capsules. Their diameter can be 10-42 mm. The lengths are in range from 80 to 360mm. The package includes injection compositions with a volume of 150-825 ml. 1-2 mixers and an adapter may also be present.

Applications of chemical anchors

First, we list for which types of structural joints it is advisable to use a chemical anchor:

- in the construction of high-rise buildings

- when forming the foundation of prefabricated buildings even under difficult working conditions (humidity)

- during the construction of bridges: suspended, drawbridge, arched

- when fastening heavy concrete beams

- when fastening metal beams to a stone base

- when creating reinforcement outlets in monolithic construction

Most of the listed areas of application of chemical-based fasteners can be safely attributed to responsible construction, that is, the construction of structures, operated in the future by a large number of people or subject to extra loads.

Let us also consider more specific examples, where a chemical anchor is a reliable fastening in different directions of modern responsible construction:

- energy industry (nuclear power plant, state district power station, power transmission poles, transformers)

- mining industry (monorail roads, funiculars, ski lifts)

- airports (widening of runways and taxiways, fixing match and antennas for radio communications and navigation equipment)

- port construction (reconstruction and repair of quay walls, fastening of mooring bollards and bollards, locks, oil terminals)

- industrial equipment (rectification columns, conveyors, machine tools)

- prefabricated buildings (fastening load-bearing frames to strip foundations)

- industry of water parks, swimming pools and other water facilities

In addition, a chemical anchor is used for the construction of temporary structures, but requiring a certain strength, and the like:

- elevators (reconstruction of mines, fastening of elevator equipment, escalators)

- construction equipment (lifts, scaffolding, cranes)

- warehouse equipment (racks, conveyors, lifts)

- fastening of building structures (columns, consoles, balconies)

Examples of using a chemical anchor for repair work:

- reinforcement of structures (metal clips, injection of masonry walls)

- strengthening of foundations

- restoration of architectural monuments

It is advisable to fix hinged elements on chemical anchors that have certain installation requirements:

- ventilated facades

- road construction (noise screens, barriers, information boards, lighting masts, lying policemen)

- decorative elements (railings, canopies, lighting, stucco decorative elements)

- advertising structures (signs, banners, banners, roof installations)

As you can see, the chemical anchor is universal in application: for fastening solid structures and monolithic, porous materials; when working with structures made of concrete, brick, natural stone.

What is concrete anchor

Translated from German, an anchor means an anchor. This is a fastening element designed to fix an object to the base. In the case of concrete, carbon steel is used to make such products. To prevent the formation of corrosion, the bolts are coated with a protective layer of zinc-based alloy.

Metal anchors are used in cases of work with a base of high strength, hardness and fragility. These include concrete, stone, brick and plaster. At the same time, in comparison with screws and nails, the permissible mechanical load is noticeably different in a larger direction. This is important for fixing windows and doors, hanging furniture modules, household appliances, installing plumbing equipment, and utilities.

Structurally, the anchor is represented by a threaded rod and an expansion cylinder. Tapered lugs, rings, hooks or nuts with washers can be used as an option. After installing the fastening element, the petals open or solidify the working mass, which ensures reliable retention of the bolt in the technological hole without the participation of additional sealing.

Concrete dowel - fast but strong

Nagels, or as they are also called, concrete screws, are an indispensable tool for fixing everything you need in a rather difficult place for this - at the edge of a concrete wall. This fastener is dispensed with without additional fixation by directly screwing into the prepared hole, which must be drilled to remove dust particles. A small amount of epoxy can be poured into the hole to increase the strength of the attachment.

Using the dowel

Most dowel applications do without pre-drilling, since these fasteners are screwed directly into the concrete. If the preparation of the hole cannot be avoided, a drill is taken to create it, but not a perforator.

More powerful tools can destroy the wall. Screwing in is done with a screwdriver, after which it is almost impossible to get the pin out of the concrete, so it is worth taking measurements with all care. (See also Concrete Sealant: Features.)

The secret of selecting the necessary drill to create holes for placing any type of fastener is extremely simple: the values of their diameters must completely coincide. This means that the 8mm diameter anchor must be installed with an 8mm drill bit.

Dimensions and characteristics of anchor bolts

Initially, before choosing a pin, you need to know the dimensions, since the mounts can be of any size, caliber.

Groups of anchors by size: small - in section up to 8 ml / length up to 55; middle - up to 12/120 ml; large - with the largest dimensions D = 24 and L = 220 ml.

Foundation pins with different dimensions, their parameters determine 3 characteristics.

Let's decipher the markings M8 10 / 60-115: D slicing - M8, outer D = 10 (this D coincides with the D drill with which the hole will be drilled), the length of the pin is 115 ml, the thickness of the part is 60 ml.

All operational parameters of the anchors are indicated in the report card, this will be the mass, the limiting twisting and bending period, the least pulling power, rational overloads. In accordance with various data characteristics, the necessary models are selected and a sound connection is made to the concrete structures of the pin.

Feasibility of application

Chemical injection compositions and ampoules have a high cost, their purchase is advisable when working with hollow and porous concrete grades, in dense structures they are justified when mounted near the edge or in case of increased expected loads: breaking, vibration, weight. Anchors of this type support the weight of steel elements, consoles, columns, facade systems, equipment, fences, if necessary, they are used for additional fastening of reinforcing bars. When choosing this option, the quality of the base material practically does not affect the reliability of fixation, the products of Hilty, Fisher and their analogues are designed for operation in cracked concrete.

They are also advised to buy:

- In the absence of an accurate calculation of the dimensions of the hole.

- At high seismic and vibration loads on the object.

- If it is necessary to violate the recommended intervals: placement along the edge of the structure or next to an adjacent anchor. In contrast to standard concrete dowels, they do not have a thrust force.

- For operation in high humidity conditions (chemical composition reliably protects metal fasteners for concrete from corrosion).

- For installation in fire protection systems, the fire resistance of specialized types reaches 2 hours.

The nuances of fastening to concrete

For the installation of a chemical anchor you will need a rock drill or other type of drilling tool, a wire brush for dust cleaning, a pump or pneumatic equipment for blowing out, a gun and a mixer. The procedure for fastening to full and hollow concrete is different. In the first case, diamond drills are often used to prepare the hole, the walls need to be roughened. The cavity is cleaned with a brush and blown with air at least 4 times; it is not recommended to use water at this stage.

The resulting hole is filled by 2/3, after which the installation of metal fasteners is carried out (most often by inserting or scrolling). The next step is the time delay specified in the instructions (approximately - 20 minutes), and only then the final fixation of the bolt is allowed. It is necessary to take into account the high speed of solidification of the chemical composition; at any breaks, the spout is wiped and closed with a cap.

Hollow and slotted concrete requires a slightly different approach when installing an anchor. The hole preparation process is no different. But before the filling stage, a plastic or metal sleeve (mesh or perforated) is inserted into it. Its purpose is to save the mixture; in its absence, the consumption increases significantly. Regardless of the type of concrete, it is not recommended to rinse the hole with water, this negatively affects the adhesion properties.

Mounts cost

| Anchor marking | Manufacturer | Short description | Volume, l | Price, rubles |

| HIT-HY 100 330/2 | Hilty, Liechtenstein | Standard chemical adhesive anchor for anchoring in concrete | 0,33 | 1530 |

| HIT-HY 100 500/2 | 0,5 | 1850 | ||

| HIT-MM PLUS 330/2 | Low-cost hybrid composition based on uranium-methaacrylate | 0,33 | 645 | |

| HIT-MM PLUS 500/2 | 0,5 | 840 | ||

| HIT-ICE | For fastening at low temperatures | 0,3 | 2640 | |

| HIT-RE 500-SD | Epoxy adhesive for installation in cracked concrete, restoration of heavy reinforcement | 0,33 | 3100 | |

| 0,5 | 3340 | |||

| HFX | Ruler in solid cartridge for use with standard nail tools | 0,275 | 1120 | |

| FIS V 360 S | Fischer, Germany | Two-component vinyl ester injection for universal use | 0,36 | 1390 |

| FIS EM 390 S | The same for underwater installation | 0,39 | 1470 | |

| FIS VS 300 T | With extended setting time, recommended when working in high temperature conditions | 0,1 | 640 | |

| FIS VW 360 S | For anchor application in winter, working range - from -15 to +20 ° C | 0,38 | 1160 | |

| KEM-VE 10 | Sormat, Finland | Vinylester capsule anchor with thread size M10, suitable for underwater installation | 90 | |

| KEMLA М12 | The same, on a polyester base (increased pull-out load) | 190 | ||

| BIT-PESF | BIT United Ltd, UK | Adhesive anchor for aerated concrete, gas silicates, foam blocks. It is characterized by high viscosity | 0,3 | 660 |

Installation nuances

Now let's figure out how to assemble a chemical anchor with your own hands.

There are two ways, apart from the option with a metal sleeve, which is suitable for hollow bricks.

First of all, we drill a strictly perpendicular hole for mounting the anchor.

- Then, using a brush, a small brush or an ordinary medical pear (enema), we remove all remaining debris and dust from the inside.

- We fill the hole about 3/4 with an injection solution - it is no longer needed, since it will be squeezed out when installing the rod.

- We screw the fastener into the glue, observing its centering and level. We stop when we reach the mark on the thread. Carefully remove excess mixture.

- The solution remains to dry for the time specified by the manufacturer of the composition.

- Once dry, weights can be hung on the threaded fastener and secured with a nut.

Reinforced connection

Reinforced connection

The next method is technically not very different, but it creates a stronger bond - it is suitable for more porous materials.

To implement it, you need a metal stop for the drill, so as not to destroy the edge of the block.

- We drill a hole, having previously installed the limiter;

- Once the desired depth is reached, the drill begins to make circular movements to create an expanding cavity inside, as in the picture above.

- Otherwise, the installation is similar - we clean the hole from dust, fill it with a hardening mixture, insert the fixing rod, wait for it to dry.

As you can see, anchoring aerated concrete blocks is not such a difficult task, and given the softness of this material and the ease with which it is drilled, the work is often done even easier and faster than with classic dowel screws on concrete. For a more detailed acquaintance with the chemical anchor, we recommend that you watch the video in this article.

Working principle and application

Concrete is a porous material, heterogeneous in structure. And in the places of attachments, various forces appear - for twisting, bending, shearing, shearing, compressing, pulling out. Their concrete anchor takes over, spreading together with the supporting structure.

Basic principles of concrete anchors:

- At the moment of interaction of the base material and the anchor, a friction force appears - the thrust is performed with dowels, metal collets.

- When, at the anchorage depth, the material gives resistance to bending or crushing - due to the collet bushings on the fastener, the curved shape of the rod, expansion.

- Loads at the point of contact between the base and the bar are compensated for by shear stresses during embedding or gluing - this is how smooth, adhesive anchors work.

Anchors for concrete can be of different designs, different types, sizes. They are made of special steel in accordance with GOST, covered with a layer of anti-corrosion agent. The rod can be 6-20 millimeters in diameter and up to 220 millimeters long.

Any anchor includes the following parts:

- The bolt itself

- Taper with a layer of thread inside

- Sleeve with special cutouts

Anchors perform a constructive or load-bearing function. The load-bearing function is realized in cases of joining floor slabs, beams, columns, balcony consoles, staircases and flights, finishing and wall panels, engineering equipment, communications, hoods, ceiling lamps, etc. Also anchor used for installation log on concrete or hollow floors. They attach electrical equipment and hinged furniture to the walls.

Structural fasteners are used to resist the displacement of parts of the assembly, if their stability is guaranteed by their own weight, and anchors are also relevant for straightening in construction.

Varieties

Among the fasteners for concrete anchors are something akin to heavy artillery. Their purpose is to fasten structures of rather heavy weight to the walls. They are often used as fixing elements for window and door frames, lighting devices, with their help, reinforcement in concrete is also anchored.

All products operate according to the same principle: screwing in a special fastener leads to the expansion of the product, which ensures tight fixation of the anchor in the wall. Anchor fasteners can be of several types and have different sizes, below we will consider them in more detail.

Reinforcement anchoring table in concrete based on stud diameter

Hammered

- The name suggests: this concrete anchor is hammered into a hole in the wall, which is pre-drilled for this with a hammer.

- Make sure to clean the hole and remove dust and debris from it.

- After that, what was required to be fixed in this place is hung, and a special stud is screwed into the anchor, which is fixed with a nut.

The material for the manufacture of most of these anchors is galvanized steel, the price depends on their length and diameter. It happens that multifunctional MTA fasteners also belong to the group of driven anchors.

Reliable anchor for aerated concrete

Wedge

The difference between such anchors from devices from the previous group is that the part does not need to be hung before fixing the stud, and there is no need to clean the anchor hole from dirt. The necessary part is fastened directly to the anchor, after which it is fixed with a nut.

In the photo - installation of the anchor in wedge-type concrete

This group of hardware also includes stainless anchors and electrogalvanized anchors. Their heads have the ability to sink into the material that they fix.

PFG

- Designed to work with low quality concrete structures and in cases where fixation is carried out in the ceilings and walls of old houses.

- This fastener has a large expansion area compared to other types of such hardware.

- It works like this:

-

- the main part of the anchor is driven into the wall;

- the necessary part is attached to it with a bolt.

How to install an anchor in concrete with your own hands

There are PFG anchors that secure cables or ropes. The end of the stud of such an attachment is a ring, which can also be used to fix the chandelier. Anchors, the end of which looks like the letter "L", are mainly used for fastening water heaters.

Chemical

Its principle of operation is similar to that of glue:

- Before using such fasteners, the drilled hole in the wall is carefully cleaned to insert the ampoule with the adhesive.

- A hairpin is screwed into it, and the whole structure is left alone for a while. The composition can dry out within a few minutes or several hours.

The curing time is influenced by the ambient temperature. Do not load the chemical anchor until the adhesive is completely cured. A feature of these products is that no internal stress is created in the wall, and this reduces the likelihood of its destruction. Shown below is instructions for surface mounting. (See also How to Drill a Concrete Wall: Features.)

How to install a chemical anchor for aerated concrete

You can also meet other types of anchors. For example, there are embedded or fasteners such as rod clips. They are usually used in the construction of apartment buildings.

Parameter table for chemical bonding

Types of anchor tanks

Depending on the number of installation work, options of various sizes are used:

1.Capsules - glass or PVC ampoules with a divided cavity for the components: resin, hardener. Application features:

-

- The volume of the chemical mixture allows one bolt to be anchored into the concrete surface.

- Optimal dimensions are indicated on the packaging.

- After the introduction of a steel insert into the drilled hole, the integrity of the capsule is violated, mixing and hardening of the ingredients occurs.

- From an economic point of view, it is advisable to use if the plans include a small number of elements.

- Kits consisting of a capsule and a threaded rod make it easy to select the inserts.

2. Cartridges - injection compositions with a volume of 100 to 1500 ml. Features of this anchor:

- Resin and hardener are contained in a tube, separated by a sealed baffle, or in two containers held together.

- The price includes one or two mixer nozzles, in the cavity of which the components are mixed until homogeneous.

- HILTI anchors are additionally equipped with an extension tube for filling deep holes.

- To perform injection, it is necessary to use a dispenser (pistol) of mechanical, pneumatic, electric (accumulator) action.

- The use of mixtures in large containers is beneficial for professional construction work.

- Changing the dispenser will allow you to continue working after a long break.

Specifications

The quantities that determine the operating conditions of systems based on chemical compositions:

- Base material - concrete surfaces with different porosity, strength, degree of load and deformation.

- The permissible temperature range of concrete, cartridge is the gap in which the hybrid anchor and its components remain functional.

- Minimum and maximum depth is a range that will provide an even distribution of dynamic, weight loads.

- Curing time.

- Recommended branded fasteners.

| Anchor | Manufacturer | Concrete characteristics, strength | Concrete temperature, ° C | Anchorage depth, mm | Curing time, hour | Fasteners |

| FIS VW 300 T | Fisher | Unstretched, cellular, hollow, foam concrete, strength C12-C60. | -15 ‒ +20 | 70 ‒ 175 | 0.5 ‒ 12 | Stud FIS A, with female thread RG MI, mesh sleeve FIS H. |

| HIT-ICE | Hilti | Dry, water-saturated, no cracks. C20-C60. | -23 ‒ +32 | 60 ‒ 480 | 0.5 ‒ 36 | Stud HAS, HAS-R, HAS-HCR. |

Anchor installation technology

Stages and nuances of installation:

1. Marking the concrete surface for boreholes according to the dimensions indicated in the building specification.

2. Drilling. The difference between the diameters of the threaded mount and the drill is 2 mm.

3. Removal of cement dust. The hole is cleaned alternately, in several steps, with a compressor or a hand pump, a brush. Washing is allowed when using chemical compositions for moisture-saturated concrete.

4. The capsule anchor is inserted into the cavity. The use of injection for concrete has the following features:

- Insert the cartridge into the extrusion gun.

- Squeeze a portion onto any surface.

- After making sure that the mass is homogeneous, fill the hole in concrete 2/3 of the hole size with a two-component mortar. For deep holes use extension tubes or sleeves.

5. Installation of threaded elements using a drill, manually until it stops. Install larger studs with a conductor. Additionally, the following are used as mortgages:

-

- Armature.

- Female threaded bushing for bolt fixing.

- Mesh sleeves for walls made of bricks and aerated concrete.

6. Part of the adhesive composition with sufficient filling of the hole should protrude onto the concrete surface. Otherwise, the stud must be removed, additionally injected, and the installation of the threaded fastener must be repeated.

7. Fasten, ensure the immobility of the connection until the adhesive mass hardens.

Chemical anchor cost

| Manufacturer | Name | Composition, temperature regime, ° C | Volume, ml | Price, rubles |

| Hilti | HIT-RE 100/330 | Epoxy

-40 ‒ +70 |

330 | 1700 |

| HIT-HY 200-A 330 | Urethane methacrylate

-40 ‒ +120 |

0.33 l | 2980 | |

| HIT-MM PLUS | Urethane methacrylate

-40 ‒ +50 |

330 | 710 | |

| HVU M8X80 capsule | Urethane methacrylate

-40 ‒ +72 |

138 | ||

|

Fisher |

FIS HB 150 C | Vinylster

-5 ‒ +40 Underwater application |

145 | 1012 |

| FIS PM 360 S | Vinylether

-5 ‒ +40 |

360 | 1650 | |

| Capsule

FHB II-P M8x60 |

Vinylester

-5 ‒ +20 |