Application procedure: instructions

This type of primer is not applied with a roller; for a uniform distribution of the substance on the plane, a brush of 120 mm in diameter is bought.

Application process:

- Surface preparation: cleaning on dirt, dust deposits; defects are corrected with putty; the fungus is rubbed off, treated with an antiseptic; degreasing.

- Apply a brush, distribute the product over the plane.

- Wait until it dries completely, repeat the application.

- Rinse tools with warm water.

To avoid contamination of non-working surfaces, the bases are pasted over with masking tape. Furniture elements are covered with oilcloth.

If the substance thickens, then a little water is added, stirred until smooth. You can not make a very liquid consistency.

Useful video on the topic:

Application Tips

Before starting work, it is required to prepare the base - it is this stage that will guarantee the high quality, practicality and durability of the coating. The surface should be cleaned of stains of grease and various oils, with a special brush, you should scrape off dirt and dust, remove elements of previous coatings and mastic. Before the first application of soil, it makes sense to check the base for strength - for this, it is carefully probed and tapped, the identified problem areas are putty and leveled.

Mold, fungus, moss and other colonies of dangerous microorganisms must be treated with antiseptic fungicidal compounds.

Next, the composition is applied

Please note that the primer does not need to be diluted with water - Ceresit products are sold in a ready-to-use liquid form - you just need to stir them. The primer is applied with a brush

Paint rollers are not suitable for this. The composition should be applied in an even thin layer, trying to avoid the formation of puddles and drips.

The primer dries up to 6 hours. The cure rate largely depends on the room conditions, humidity and temperature indicators, the availability of ventilation and access to UV rays. The quality of the coating is checked experimentally - paint or glue is applied to a small area of the treated surface, and if the material dries unevenly, then another layer of primer is required.

Porous materials are in any case primed twice.

The use of Ceresit primers saves material consumption, improves the quality of the coating, and extends its service life. This is why these blends are the choice of professionals all over the world.

For the application of the Ceresit CT16 primer, see below.

The most famous products

Today in hardware stores, there are several options for a quartz primer to choose from. Each of them, having the same set of properties, still differs from their counterparts in additional components. Consider the most popular formulations:

Ceresite CT16. It is based on no solvents, therefore it is considered a safe primer. In addition, the substance adheres perfectly to smooth surfaces. The main feature is the possibility of adding a coloring pigment, as a result - obtaining a finished paint-primer for finishing. Ceresite is suitable for internal and external use at temperatures from +5, dries quickly. Depending on the base of the wall, the consumption of funds per 1 sq. m varies within 200-500 g.

Concrete contact. This product is produced on the basis of an aqueous dispersion of acrylic and latex. After use, the surface takes on a pale pink color. The advantage of the material is the ability to maintain breathability. Resistance to atmospheric changes makes it possible to use this material in outdoor work.The cost of the product is slightly lower than that of Ceresite.

Caparol Sylitol-Minera. The basis in this soil is quartz sand and potassium water glass. Manufacturers claim that tinting of the material is allowed, while the tool has proven itself well as a structural basis for coloring. The soil has increased consumption rates, as well as reduced vapor permeability. The product dries up within 12 hours, in addition, it is undesirable to use the composition in conditions of high humidity. The cost of such soil is higher than that of other analogues.

The main criterion for choosing a quartz primer is its low consumption, as well as significant decorative possibilities. After reading the material in this article, you can safely go to the hardware store for the train and start repairing. Use a primer both indoors and outdoors.

Application Tips

To get the most out of using this tool, you need to know how to use it correctly.

The following steps must be performed sequentially:

- Clean the surface to be primed from any foreign matter. This includes remnants of old paint and wallpaper, dust, dirt and any foreign objects.

- The working area is additionally leveled. If the defects are too large, it is necessary to plaster the surface. If they are insignificant, then you can get by with a simple grout using a special grater.

- If there are traces of mold, mildew or unknown damage on the surface, they must be cleaned by hand or removed with a special compound.

- Stir or shake the primer thoroughly. This will allow all active substances to be evenly distributed again throughout its volume.

- Using a roller on the handle or a wide paint brush, the primer is evenly applied to the entire work surface in one layer.

- If the working area has an increased level of porosity, then after the first layer has completely dried, another one can be applied.

- It is allowed to apply additional topcoats over the primer only after it is completely dry.

Compliance with such a simple but important sequence of actions will ensure a high-quality work result.

Description and purpose

Betonokontakt (BK) is a universal tool for increasing the adhesion force of various substrates with a finishing layer. The components of the primer make it possible to use it for processing concrete structures, brickwork, painted surfaces, tiled walls, plasterboard sheets, wood, glass. Concrete contact is a polymer dispersion prepared on the basis of acrylic, to which quartz sand, cement, additives to increase adhesion are added. The liquid mixture is dispensed in buckets or barrels.

When performing repair and construction work, a universal primer helps to solve the following tasks:

- prepare concrete floor slabs for the installation of a wet screed or laying a self-leveling floor;

- prime the walls and walls before applying any plaster (cement, Venetian), especially if the finishing layer is thick;

- reduce porosity and strengthen the structure of drywall before painting, wallpapering, tiling;

- glue smooth finishing elements to glossy materials (even glass to metal);

- process the ceiling before whitewashing;

- preserve the plastered structures for the winter.

Helpful hints

Experienced craftsmen and builders recommend that you be very careful when choosing a primer. The choice of a specific product and a specific manufacturer will depend on the characteristics of the surfaces to which the primer will subsequently be applied.

The smooth surface of a concrete wall needs to be mixed with abrasive particles.They will roughen the surface, which will facilitate better application of subsequent finishing materials.

Metal surfaces must be coated with a special mixture with anti-corrosion properties. This will protect the metal from rust.

There are special water-based primers for wooden surfaces. They will preserve the wood as long as possible and protect it from rotting and increased moisture absorption. The primer mixture should contain substances that prevent the appearance of bark beetles and other pests. If new wood is treated with shellac, it will not release resin. This will help to avoid differences in shades in the future.

To work with drywall, you should use a deep penetration primer. This will help reduce the amount of absorbent material in the wall covering.

Apply putty before priming the mixture is needed for the best adhesion of all materials. But the primer applied over the putty will contribute to a long service life.

After applying the mixture, temperature drops should be avoided in the first 3 days after use. Otherwise, the entire coating may crack.

Some experts apply the primer mixture with a spray bottle. This will help novice craftsmen achieve a smoother application to the surface.

The old layer of plaster can sometimes not be removed. But before gluing the wallpaper, you need to walk on it with a mixture of deep penetration.

Some surfaces absorb a lot of moisture and are porous. To determine the required amount of funds for them, it is worth doing a little check. A piece of foam rubber is moistened in water and applied to the desired surface. In places where the liquid has absorbed faster, more primer will be needed.

The primer should only be applied to the surface from which mold and mildew has been thoroughly removed.

Walls must be primed before applying the topcoat. In this, the opinions of all experienced craftsmen are unanimous. Thanks to this technology, you get a durable coating that will last for many years.

How to choose?

In order for the planned finishing work to be performed correctly, reliably and efficiently, you must remember that:

- It is necessary to choose a primer based on the material used in the production of the working area.

- If the work will be carried out outside the building, the packaging must necessarily indicate that the primer mixture is moisture resistant.

- Before buying, it is necessary to study all the available types of primer and assess the volume and complexity of the upcoming work. Only after analyzing the information received, you can make a choice in favor of a particular product.

- If the primer will be applied to an already plastered surface, then first you need to check its porosity. To do this, wet a small area of the surface with water and note the drying time. If it is less than 3 minutes, then it is necessary to purchase a special strengthening primer mixture.

- It is necessary to take into account not only the material for making the working area, but also further actions with the primed surface. If the primer is not intended for further painting, then it cannot be used under the painted surfaces.

- Under the wallpaper, it is better to choose a white product with a maximum absorption level.

- You cannot use the formulations in the cold season at sub-zero temperatures, if the manufacturer has not indicated information about such a possibility.

- It is not recommended to use a primer mixture intended for the treatment of curtain and walls, when working with the floor, and vice versa.

Peculiarities

Ceresit primers are polymer-based water-dispersion mixtures. The components include a variety of additives that significantly improve the consumer properties of the soil.

Primers of this brand are widely used to prepare surfaces of various types: wood, porous concrete, brick, metal and plastic for finishing decorative finishing. The composition guarantees a high quality of work.

Advantages over other brands of primers:

- increases the adhesion of materials at the time of painting, wallpapering, plastering and ceramic cladding;

- reduces the absorbency of the coating, as a result, significantly reduces the consumption of paint and glue during subsequent work.

Separately, it is worth mentioning the protective properties of the primer. The deep penetrating mixture of this brand helps to improve the properties and quality of any surface. The active components of the composition penetrate into the fibers and stick their particles together both from the outside and from the inside. Due to this, the surface is strengthened and its destruction is prevented. The use of primers helps prevent deformation on any surface other than non-absorbent surfaces. They also prevent the destruction of decorative finishing materials that are applied to the surface treated with the composition.

The primer reliably protects the surface from dust settling - cover it with a compound and see how it shines. Its use prevents a thin layer of leveling compounds from drying out and the formation of bubbles on its surface.

In other words, the use of the Ceresit primer results in material savings, increased durability of the finish and a favorable indoor climate.

The advantages of the mixture also include environmental safety - the coating does not contain harmful and toxic substances, there are no solvents in its composition, therefore it is absolutely safe for use in residential buildings and apartments.

It is noteworthy that the company has established the production of spiral frost-resistant compounds by adding special components, which made it possible to use the primer in the winter season, even in unheated rooms. By the way, the use of primers produced by this company does not change the vapor permeability of the base, so they can be used in areas equipped with heating. It is a truly versatile compound that is equally good for use in high and low temperatures.

The disadvantages of the mixture are associated with its cost, but if you look at it, the pricing policy is very profitable. The composition is sold in containers of 1, 5 and 10 liters and with an increase in volume, the cost per liter decreases, therefore, when carrying out large volumes of work, you can significantly save on its purchase.

Scope of application

Installation of insulating materials, painting, gluing vinyl, non-woven or paper wallpaper, laying floor leveling compounds and lining with slabs - this is not a complete list of finishing works that require the use of Ceresit primer. With the help of this mixture, you can significantly compact the base, and after the soil dries out, the strength of the treated surface will be increased, but air circulation will remain at the proper level. This property of the composition is especially important when it comes to laying steam and waterproofing indoors.

The use of these mixtures is quite popular when carrying out construction and finishing works.

This type of soil is used for the following surfaces:

- concrete;

- gypsum;

- cement;

- ICE and chipboard;

- drywall;

- gypsum fiber;

- paint and varnish coatings.

Its functions are also wide:

- reducing the moisture content of absorbent surfaces before laying the tiles;

- surface preparation for applying plaster and floor mixes;

- preliminary preparation of the coating before installing thermal insulation or painting;

- processing of porous concrete, plasterboard, cement plasters, as well as chipboards.

Despite the similarity of CT 16 and CT17 for facade work, it is worth giving preference to CT17 soil. The reason is its versatility.As you know, outdoor work is carried out in several stages - this is priming, and plastering, and painting. In this case, the primer is used in each of the stages listed. There is no doubt that it is more profitable to purchase a single universal deep penetration mixture than to buy many different formulations for each separate stage of work.

Types and characteristics

Primer Concrete contact is available in the following varieties:

- acrylic;

- water-dispersive.

Acrylic (polymer) primer is environmentally friendly, safe to use, used for various types of work (indoor, outdoor). After processing, the panels allow air to pass through, provide a comfortable microclimate in the room. Polymer components in the composition prevent the occurrence of mold and mildew.

Water-dispersion agent is optimal for gypsum plasterboards, monolithic concrete, wooden floors, plastic blocks. The mixture is applied before painting ceramic tiles, before plastering the ceiling with toning or gluing paper or vinyl wallpaper. The finishing material helps to highlight the structure of untreated wood and brickwork.

Types of building mixtures also differ in the size of quartz grains. Some varieties are used for indoor work, others for external use or universal

The technical characteristics of the building material are as follows:

- Environmentally friendly components - the primer does not contain harmful ingredients, does not have strong odors. You will not need to use protective equipment for hands, respiratory tract.

- The composition is resistant to alkaline components and aggressive environments.

- Good air permeability of the composition ensures constant oxygen circulation, prevents mold and unpleasant odors.

- Resistant to mold, parasites, fungi.

- Drying of products at an average humidity is 2-3 hours.

- The service life is about 70-80 years.

- During construction work, the temperature should be maintained at + 5 ... + 35 ° С, the optimum humidity level reaches 60-80%.

- The composition has neutral acidity, does not react with alkali, and prevents oxidation of metal surfaces.

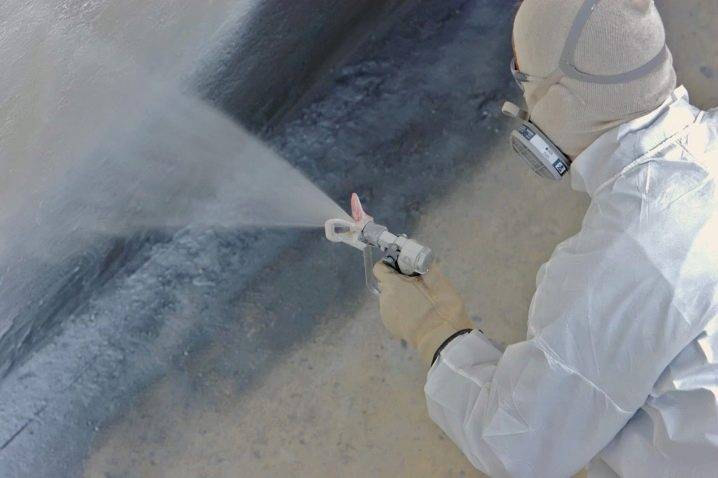

The mixture is intended for manual or mechanical application (spray gun, compressor or aerosol cans).

Composition

When deciding the question Concrete contact - what is it, the composition of the material is taken into account:

- Cement or Portland cement.

- Finely dispersed quartz filler - gives a rough texture to the primer, improving the quality of adhesion to the surface.

- Polymer components (acrylic dispersion, etc.) - the ingredient improves the adhesion of the mixture.

- Technological fillers and additives - impart waterproof and antibacterial characteristics to the composition.

- Dyes - give the necessary shade to the mixture, are hypoallergenic, do not contain harmful components. Pastel colors are included as standard, suitable for different interiors.

Consumption

Consumption of primer Concrete contact per 1 m² depends on the size of the grains of sand and the degree of porosity of the surface to be treated:

Application procedure

Ceresite coating of vertical surfaces requires compliance with certain requirements for pre-treatment and work order, as well as temperature conditions during application and drying.

When preparing walls for using a primer, the first step is to remove all unnecessary from the surface:

- wipe off dirt and dust with a wet cloth;

- oil stains must be degreased;

- gently scrape off drips of paint or cement;

- if there is a fungus, then it must be cleaned off and the surface treated with antifungal agents.

The present cracks and pits must first be filled and allowed to dry for 3 days.All defects must be cleaned, peeling and poorly adhered parts must be chipped off, damage must be plastered.

The surface prepared in this way should not be wet or damp. The product is applied with a special brush or soft brush over the entire surface. If the concrete contact is applied unevenly, the subsequent materials will not adhere well, which will negatively affect the appearance of the coating. If necessary, after one layer has dried, a second can be applied.

Peculiarities

The Ceresit primer is distinguished by its ultra-high permeability and ideally strong adhesion not only to the base of the working surface, but also to the top decorative layer. Therefore, it not only secures them separately, but also securely connects and holds together.

The competent approach of the manufacturer to the manufacture of primers allows you to endow them with additional special and important qualities. For example, there are primers with anti-corrosion functions or with the ability to inhibit harmful microorganisms.

Using the Ceresit primer, you can simultaneously solve several problems at once: leveling the surface, improving its adhesion, clogging the pores on the working surface and giving it an attractive appearance. Achieving these goals is possible thanks to a unique and well-thought-out composition.

Also, due to the leveling of the surface, the absorbency of the working area of the finishing materials decreases. That is why all its parts are evenly colored in the future, and have the same color.

We can safely say that without a primer, high-quality finishing work is simply impossible. And in order to precisely achieve the best result, the manufacturer offers several types of this coating today.

Manufacturers

In market conditions, there are many firms that produce concrete contact. Despite the fact that the manufacturing technology is similar, the composition may include various components that affect the cost of the product. Consider examples of concrete contact from the most common manufacturers.

Knauf

The concrete contact of this company has a finely dispersed composition based on fine-grained quartz sand. It is worth considering that the composition is not waterproof. Most often used for smooth surfaces before subsequent coating, forms a roughness.

Concrete contact Prospectors

It is used for surfaces made of dense materials that do not absorb moisture well. Due to the latex in the composition, it increases the strength of the surface after processing. Differs in drying speed, about 2 hours, economically consumed.

Ceresite

Contains polymers, coloring pigments on a water-dispersion basis, is absolutely non-toxic. Makes the base vapor and moisture resistant. Dilution with water, use of a roller is not allowed. Applicable only for indoor work.

Axton

It is a dry mixture that is diluted with water before use, mixed thoroughly. High quality primer for construction and finishing works. The primer is used for uncleaned rough surfaces. The only drawback is the high consumption of the mixture, which is 300 g / m2, dries up within 3 hours.

So, we figured out what concrete contact is used for. The use of a universal, reliable soil greatly simplifies repair and construction work. Concrete contact provides high performance properties of walls, facades, ceilings. Allows to carry out finishing, decorative work of external and internal surfaces.

Why do you need a primer

The impregnation of walls with special compounds has a specific purpose. Loose and free-flowing surfaces become stronger, and smooth and dense surfaces acquire the required degree of roughness.

In both cases, priming ensures more reliable adhesion of the base and the next layer of finishing materials (putty, paint, wallpaper, etc.).

And if antibacterial properties are present in almost any impregnation (there must be a corresponding inscription on the label), then the quality of the walls affects the choice of a specific type of product. Let's take a closer look at how to process porous and dense substrates.

Views

Ceresit primers are presented in a wide range - universal compositions for deep penetration, concrete contact, concentrate mixture, antifungal primer and others. Let's dwell on the most popular varieties.

CT 16

Ceresit CT 16 is widely used for external and internal works. The primer strengthens the substrate and increases adhesion. The mixture includes a special color scheme, due to which the surface after processing acquires a super white color and can be used under thin light wallpaper or paint.

The primer of this modification is available in the form of a thick liquid. Its structure includes an aqueous dispersion of acrylic-based polymers, enriched with mineral fillers and pigments. The active component of the primer is quartz sand of the finest fraction - this increases the surface roughness and improves adhesion.

Characteristics:

- The primer is used at positive temperatures in the range of 5-30 degrees Celsius. The drying speed is 3-6 hours, and the material consumption is 0.3-0.5 kg / m2.

- The primer is available in white, but the unique composition parameters allow the use of tinting - this is very often used when working with decorative plasters - the base does not shine through and the color scheme looks perfect.

- The ability to reduce the moisture content of the surface is distinguished.

- The mixture is sold in a ready-to-use form; it does not need additional preparation.

CT 17

The main component of CT17 soil is an aqueous solution of synthetic resins. The primer has a yellowish tint. It is used at t from 5 to 30 degrees Celsius, dries about 4-6 hours. Material consumption depends on the type of surface and averages 0.1-0.2 kg / m2

CT17 is applied to concrete, gypsum plasters, cement coatings and masonry substrates. The price of a package of 10 liters of a primer of this modification in 2017 was 600 rubles.

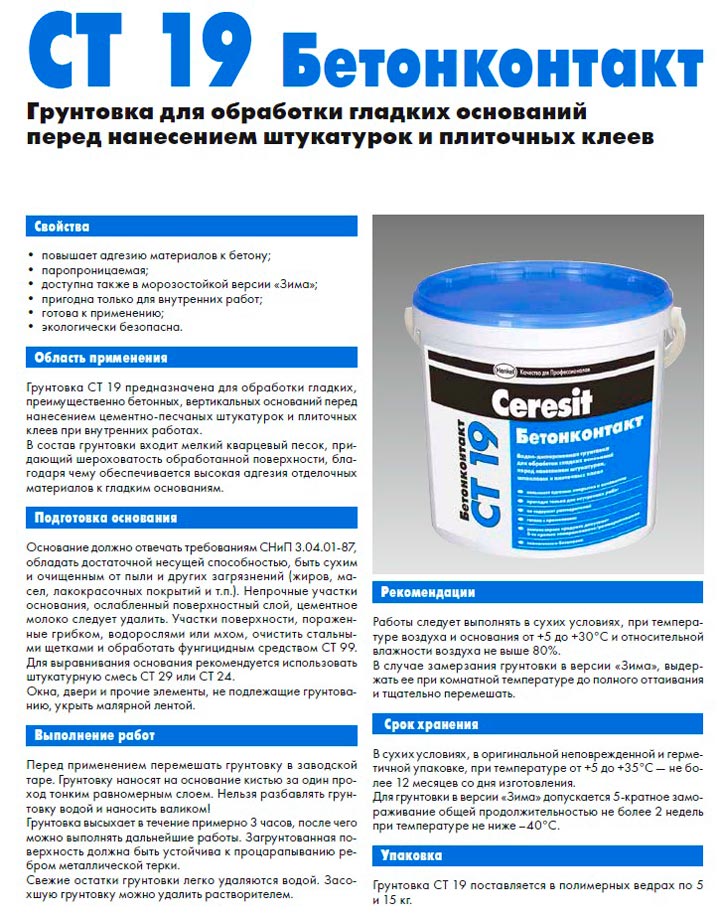

ST 19

It is a concrete contact used for concrete surfaces. The mixture is called adhesive because it significantly improves the adhesion of the concrete base to plaster, putty, glue and other materials. IN 10 However, the coating is suitable for impregnation and other substrates: cement, tiles, plasterboard, gypsum fiber and others.

The primer is effective at temperatures from 5 to 35 degrees, the drying speed is 4-6 hours, its consumption is in the range of 0.1-0.2 kg / m2. It is produced in buckets of 5 and 15 kg, the cost of the latter was 1200 rubles in 2017.

IN 10

Another popular type of formulation from Ceresit. This mixture is used strictly for interior work for decorative finishing. It ensures an even distribution of glue or paints, reduces their consumption, and also binds dust and increases adhesion. The composition is applied to concrete and cement-gypsum bases, the material shows itself well on brick, as well as all types of plasters and putties.

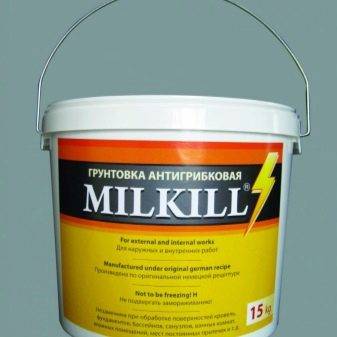

ST 99

It is a special anti-fungal primer. It is used to prevent the appearance of microorganisms, and in high concentrations - to destroy existing mold, moss and lichens. The mixture has high fungicidal properties due to the antiseptic components in its composition. In addition, the primer is safe, environmentally friendly, does not leave streaks and provides a high-quality surface finish. Used when working with concrete, plaster and brick. This is a concentrated formulation, therefore it is diluted with water, as a rule, in a ratio of 1 to 3 or 1 to 5.

Antifungal primer provides maximum protection in aggressive conditions of high humidity and temperature fluctuations.The cost of one liter is about 350 rubles (according to 2017 data).

Concrete contact or "regular" primer

It is wrong to compare these two types of impregnation, because they are intended for different walls.

Primer concrete contact

Smooth, slightly porous substrates (cast concrete, ceiling slabs, previously painted, etc.) have a very weak degree of "adhesion" with subsequent finishing layers. Therefore, the surface must first be prepared.

For this, a special concrete contact is used. Outwardly, it is a pasty mixture of polymers with quartz sand.

The composition is applied to previously cleaned from dust, dirt and degreased walls. Works can be carried out with a wide paint brush or roller

The walls treated with concrete contact become roughened, which significantly increases the level of adhesion. A leveling finish (cement plaster, gypsum plaster, etc.) or tiles perfectly fits on such a surface.

But the composition with quartz sand is not suitable for wallpaper or painting - such a coating will not be able to hide the roughness.

Deep penetration primer

For porous, loose and loose surfaces, use a deep penetration primer. It is a white liquid with a specific odor.

She recommended to process foam block, cement-based or lime-based plaster, gypsum blocks and walls made of other highly absorbent materials. The soil tends to penetrate into the depth of the base by 2-10 mm. or even 15 mm.

It is more convenient to apply impregnation with a roller, and use a brush to treat corners and various recesses. To achieve a greater effect, in some cases, it is recommended to re-treat the wall with deep penetration impregnation.

After complete drying, you can proceed to wallpapering, painting, plastering or other planned work.

Universal primer

For walls that do not require special processing, a universal composition is suitable. Outwardly and in smell, this impregnation is very similar to a deep impregnation primer, but differs in properties.

The agent penetrates to a shallower depth, but the treated area is made stronger and will provide a stronger connection with other finishing materials.

Purpose and scope

When deciding what the contact mix is used for, the recommendations of the manufacturers for the types of products indicated on the packages (for walls, floors, external structures) are taken into account. The primer mixture does not absorb moisture, allows finishing with decorative plaster.

What surfaces to apply?

The composition forms a rough coating on the surface with abrasive particles that provide easy and strong adhesion to plaster and putty. Grains of sand or crystals provide a support for a decorative finish layer for difficult substrates.

In addition to decorating buildings inside and outside, Betonokontakt can be used to arrange flowerpots for flowers and other garden tools.

The list of materials for surfaces includes the following coatings:

- non-porous concrete with a smooth surface - panels in concrete buildings, columns in monolithic buildings in modern buildings;

- ceramic slabs - you do not need to remove old slabs before decorating, you can process it with a mixture and carry out decorating work;

- wood - the primer is applied to fragments of wood before plastering, the wood must be thoroughly dried;

- metal surfaces - it is required to process the coating with a layer of building mixture.

Do I need to apply on top of oil paint?

The mixture is allowed to be used over the oil colorant, but it is recommended to remove the paint, because the compound may come off with the old coating. If it is not possible to remove the old paint, it is required to carry out finishing work in the following sequence:

- The coating is degreased.

- The smooth surface is treated with abrasives (coarse sandpaper or metal brush).

- Notches are made with an ax or chisel.

- The next step is dust removal with a vacuum cleaner or sponge.

- A layer of primer is applied.

- The surface is dried.

- Then it is processed again.

- After drying, plastering, puttying or laying of ceramic plates is carried out.

Description

Adhesive primer "Betonkontakt"

For the treatment of smooth surfaces prior to the application of plasters, putties and adhesive mixtures

Properties

- increases the adhesion of the coating to smooth surfaces

- increased resistance to water

- solvent-free

- For interior and exterior use

- ready to use

- dries quickly

Application area

Application area

Ceresit CT 19 primer is intended for treating smooth, dense, absorbent and non-absorbent substrates before applying repair plasters, putties and adhesive mixtures inside and outside buildings. Can be applied on concrete substrates (including evacuated concrete), mosaic floors, lime, cement-lime and cement plasters and screeds, paint coatings (strong, with high adhesion), stone and ceramic tiles, surfaces with residues of hard-to-remove adhesives. Ceresit CT 19 can also be applied to plasterboard, chipboard and OSB. The primer contains a quartz filler, which gives a roughness to the treated surface, thereby ensuring high adhesion of finishing materials to smooth substrates. The Ceresit CT 19 primer significantly reduces the hygroscopicity of the primed substrate, which prevents the subsequent materials from drying out too quickly. For surface strengthening and impregnation of porous, highly absorbent substrates, Ceresit CT 17 should be used.

Primer developers

This composition has about a dozen variants of the name: Betokontakt, Concrete-contact, Betonokontakt, contact-soil, soil-contact, etc. The inventor of this primer is the German company FEIDAL. In any case, this is precisely what is indicated on their official website, and since no one has yet disputed the information, this fact can be considered true. The original name is Betokontakt, in Russian - Betokontakt. Among the people, "Betonokontakt" has taken root more, since it is most often applied to concrete. So, strictly speaking, the original is the composition of only this company.

Feidal was the first to market a primer to improve adhesion on poorly absorbent substrates

However, any company that produces building mixtures has a similar composition with the same or very similar name. Most likely, the name changes are intentional so that no charges can be brought.

In general, it is not so important for the consumer who came up with this composition. It is important that he fulfills his functions

How the primer works

The main component of this material is quartz sand, which improves adhesion between the wall plane and the finish. The sand has a fine dispersion, it is well and evenly applied to the surface as part of the soil. Additional components of the product vary, but they are often available as water-dispersible formulations.

Quartz primer has a number of advantages, including:

- Strengthening the surface properties and smoothing it. After the measures taken, plaster or paint is applied much easier.

- Fast drying. After distributing the product along the wall, it comes into contact with the material of the plane - the quartz grain helps to increase the drying rate.

- Reliability. Thanks to special filling dry components made of organic substances, the wall structure is additionally strengthened and retains its technological characteristics for a long time.

- Pressure resistant. Quartz soil is in demand due to its good resistance to atmospheric pressure, so that it can be used in various operating conditions.