Tips and tricks for use

When working with such a component as three-in-one enamel primer, it is recommended to take into account the following series of advice from experts:

- the best option for applying this substance is a medium-sized roller made of natural material;

- it is best to apply the primer in several layers, depending on the structure of the wall covering (2-4 layers maximum);

- when working, you should use not only a respirator, but also a protective suit so that the primer does not get on the skin;

- this kind of soil is thoroughly mixed for work, otherwise full penetration does not occur;

- These primer varieties are available from many companies, but those that are in high demand should be chosen.

Additionally, when working with the composition, it is required to take into account a number of tips regarding the procedure for using this substance.

Using an enamel primer as a primer

If this composition is used as a normal primer, then no more than two standard coats should be applied. Before work, it is required to thoroughly degrease the surface and dry it. In addition, the primer is best applied with a roller, and each layer is dried separately. Additionally, it is necessary to carry out all the work in stages.

Application as primer and enamel

In this case, two coats will not be enough, which will cause up to 4 separate coats to be applied. It is imperative to polish after application. In the case of this use case, full-fledged layers should be applied, while leaving a sufficient amount of time for the composition to completely dry before reapplying. In such a situation, it is advisable to spray the last layer from a spray gun.

Brief classification of primers by composition

Depending on what is included in the composition of the solution, the properties of the primer change. The following types are distinguished:

- acrylic;

- alkyd;

- shellac;

- silicone-acrylic;

- oil;

- epoxy.

Acrylic based

Acrylic compounds are water-soluble and practically odorless. They are fluid and penetrate deeply into the wood fibers. A noticeable film does not form on the surface, but the pores are also well clogged, and resin and tannin do not come to the surface. Acrylic dries well and quickly, therefore it is suitable for outdoor and indoor use.

The composition protects the tree from destruction and deformation, is compatible with antiseptic additives. It is considered universal, it is used for painting with various paints and varnishes.

Acrylic solutions must be applied in several layers so that they saturate the wood well and form a reliable layer. Because of this, the consumption is quite high.

Based on alkyd resins

Alkyd compounds form a thin film on the surface, which will protect the tree from external influences. They also strengthen the structure by binding the fibers together and closing the pores. Used for loose materials: fresh or old wood, chipboard.

It takes up to 10 hours for the primer to dry. For exterior decoration, it is necessary to choose a dry, stable weather so that the composition has time to dry out.

Silicone-acrylic

Solutions of this group penetrate deeply into the wood and retain its texture. After drying, the structure becomes dense and becomes water-repellent to its entire depth. After processing with a silicone-acrylic compound, you do not have to take additional measures to protect the wood from moisture.

Such a primer is used in the event that the walls will be exposed to dampness, for example, in basements or when decorating. It is also ideal for applications where the substrate is covered with opaque paint.

Shellac

The composition is used in the processing of conifers, since it neutralizes the effect of emitted resins. After priming, the risk of discoloration or deterioration of the paint material due to resin release is minimized. Also, the shellac agent prevents changes in the texture of the wood.

Primers of this type are excellent insulators and seal pores tightly. Thanks to the processing, the consumption of paints and varnishes is reduced several times.

Polyurethane and epoxy compounds

Used for any paint and varnish materials. They clog the pores tightly, preventing the wood from "breathing". On the other hand, the topcoat is flat and tight. These formulations are thicker than all other types of primers.

Use for residential premises with caution

Antiseptic primers

They contain antiseptic additives. They protect wood not only from bacterial infections, fungus and mold, but also from insects. Recommended for use in damp climates where the risk of rot is higher. It is also necessary to treat all wooden parts in cellars and basements with an antiseptic.

Drying oil

Used as a primer or stain. Often used under oil paints. The drying oil impregnates the wood by a few millimeters. Thanks to this deep penetration, it perfectly protects the material from rotting and moisture penetration. Also, after drying oil, the surface is very rough, which ensures excellent paint adhesion.

Styrene primers

After drying, a completely non-penetrating layer forms. The wood is obtained as if in "isolation". This ensures maximum protection against the weather. Styrene compounds are used for processing under enamels and oil-phthalic paints.

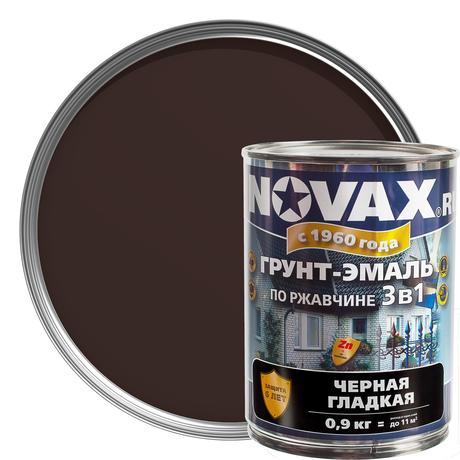

Appointment of primer-enamel for rust 3 in 1

The paint and varnish material is used to form a protective and decorative layer on metal surfaces, including those on which there are visible foci of corrosion damage (areas with continuous or punctate corrosion). Primer-enamel for rust - very easy to use, because performs the functions of several separate paint and varnish products at once (hence the name - 3 in 1).

The 3-in-1 Rust Enamel Primer combines the functions of three separate materials:

- converter of corrosion products;

- soil with anti-corrosion properties;

- finishing layer - decorative enamel.

Thanks to the synergism of the primer-enamel functions, it greatly simplifies the painting process. Instead of three layers of materials of different type and purpose (rust converter, primer, enamel), only one is applied, which combines all the properties, both protective and decorative.

When painting rusty metal, the rust layer should adhere tightly to the surface, and its thickness should not exceed 100 microns (or 0.1 mm).

The composition is often used for painting large-sized items, equipment and structures of complex configuration. It is also advisable to use it if you need to promptly carry out painting work.

Primer-enamel for rust 3 in 1 is used for painting new and previously painted metal gates, fences, gratings, garages, various equipment and structures used both inside and outside the premises (in atmospheric conditions).

The paint and varnish material has occupied a special niche in the automotive field. The composition is used for painting a car in order to protect some of its parts from destruction. Basically, the inner surfaces are painted, which corrode most quickly as a result of the aggressive influence of not only atmospheric phenomena, but also the mechanical action of sand and stones, dirt, salt from the roads.With 3 in 1 enamel primer, paint the inside of the wings, the bottom of the car.

It is permissible to use for the formation of a protective and decorative layer on products of their cast iron, stainless steel, some non-ferrous metals, such as copper, zinc, aluminum.

Application

Before applying the primer-enamel, the surface to be treated must be prepared: clean it from the peeling previous coating, remove large and loose foci of rust. After that, you should re-clean the product from dust and dirt and, if necessary, degrease with white spirit. All this will ensure the best adhesion of the primer-enamel, facilitate the work and provide a high-quality finish.

Before direct use, the composition must be thoroughly mixed. Depending on the complexity and size of the surface to be treated, enamel can be applied using a brush, roller or spray gun. Small parts can be dipped.

Before covering the entire structure, it is advisable to try painting a small area in order to assess the correct color selection and the quality of the finishing layer.

Average material consumption per m2 - 80-120 ml for one layer. The number of layers applied depends on the degree of protection and the desired effect and ranges from 1 to 4. Each manufacturer indicates on the packaging recommendations for the consumption of primer and the method of application to the product.

The drying time of the primer-enamel is short: to the “tack-free” stage - about 30 minutes, and the time of complete drying is about 4 hours. In order for the product to be resistant to salt, water and oil, it is necessary to withstand it before use for several days (up to 7 days).

In the open air, the process of drying the soil-enamel and removing the specific odor is faster than indoors. Therefore, manufacturers recommend painting the base outdoors or in a ventilated area.

For an overview of the Dali rust primer enamel, see the following video.

Varieties

There is a whole range of protective paints and varnishes. For example, alkyd-urethane enamels, often used for outdoor coating of concrete, metal and wood. A wide range of applications for epoxy enamel, characterized by durability and resistance to weathering - from flooring to painting external walls and roofs. Polyurethane enamel is renowned for its use on concrete and wood floors. Alkyd or acrylic enamel is renowned for its variety of types and versatility.

A variety of anticorrosive primer-enamels are used to protect metal from rust, have a complex chemical composition and are subdivided into:

- insulating;

- passivating;

- transforming;

- phosphating two-component;

- protectors;

- inhibitory.

Insulating primer enamel forms a layer that protects the metal from moisture and oxygen. It has increased heat resistance and is good for structures in the open air or in water. The passivating agent is capable of slowing down the corrosive process and is well suited for conditions with high humidity. Converters, which include phosphoric acid, interacting with rust, form a reliable phosphate film and partially reduce the metal. Phosphating two-component, in addition to phosphoric acid, containing and passivating substances, have excellent adhesion (adhesion) to the surface and are suitable for processing galvanized metals.

Protectors are equipped with metal particles, when dry, they form a strong metallized coating, are economical in consumption and are recommended for processing products in contact with water. Inhibitors are distinguished by deep adhesion to damaged metal, high anticorrosive properties, increased consumption and are well suited for decorative painting.

In terms of their composition, many of the above means are of the type of so-called 3-in-1 primers, which will be discussed below.

Purpose and application

Such a type of paint and varnish coating, as a primer enamel for rust 3 in 1, in practice, is often used for certain complex tasks. This type of coating has the following main and additional purposes:

- Spetsnaz primer enamel for rust is mainly used for the treatment of metal surfaces.

- Rust primer is often used in the automotive industry, as well as in modern mechanical engineering.

- Rust paint can also be used in certain areas of the industry, including food.

- This coating is used for metal fences and any other metal outdoor structures.

- If necessary, this composition can be used to cover other options for structural elements.

In practice, such a composition can be used for other specific tasks, however, the basic properties will not appear, as is the case with painting a car or other metal elements.

Composition and specifications

Some primer enamels compare favorably with others in ease of use due to their multicomponent nature. They contain, in addition to solvents, various pigments and fillers, three main groups of substances:

- rust converters;

- anti-corrosive primer;

- outer decorative layer.

Therefore, these paints and varnishes are called primer-enamels 3 in 1. And due to the homogeneous and unique consistency, instead of three successively applied layers, only one is required to be applied. The owner of 3 in 1 enamel is exempt from the cost of primers and putties. Some of their other attractive features can also be noted:

- heat resistance of the finished layer (withstands the range from + 100 ° С to -40 ° С);

- evenness of the treated surface;

- immunity of the coating to inorganic and organic substances (mineral oils, weak solutions of salts, acids and alkalis, alcohols, etc.);

- no need for thorough preparation of the painted surface (complete removal of rust is not required);

- relatively low consumption and good hiding power (ability to cover the color of the surface);

- fast drying (within about two hours) and durability of the coating (up to 7 years outdoors, up to 10 years indoors).

The consumption of such enamels is 80-120 ml / m2 (one layer). The thickness of one layer is approximately 20-25 microns (0.02-0.025 mm). There is about a kilogram of composition per seven square meters of surface. Externally, the coating is a thin continuous and uniform uniformly colored film. Suitable surfaces for painting are products and surfaces made of stainless steel, cast iron, some non-ferrous metals such as aluminum, copper and zinc.

In the composition of rust paints, among other elements, various fillers can be presented. Some protector enamels may use metal particles to create strength and texture in the final finish. For example, the so-called hammer paint for rust is known, which contains aluminum flakes, which, when dried, create a texture reminiscent of the effect of hand hammering on sheet metal.

Peculiarities

When using such a primer of the PRESTIGE brand or any other manufacturer, you may encounter a number of peculiarities. Consider the main nuances when working with paints and varnishes:

in order to meet the minimum flow rate, you need to correctly approach the choice of a suitable tool;

when working, it is important to use a respirator, since there is a high toxicity of the composition;

before applying such a coating to the surface, it must be prepared, otherwise the effect will be minimal;

this substance quickly solidifies only at low humidity, which is why it is required to select the appropriate atmosphere;

this variety is suitable for use on any surface, however it behaves best directly on metal.

Given a number of these features, it is possible to correctly and efficiently use such a substance for structural elements and other surfaces that need appropriate protection.

Properties and technical characteristics of primer-enamel for rust 3 in 1

Among the properties of this material are the following:

- triple effect of use (transformation of corrosion products, increased adhesion due to the priming action, the formation of a protective and decorative paint and varnish coating);

- the ability to apply primer-enamel directly over the rust layer;

- resistance to atmospheric corrosion (weather resistance), water resistance;

- resistance to aggressive influence of mineral oils, salt water, weak solutions of some alkalis and acids;

- fast curing;

- a fairly small consumption of enamel with good hiding power;

- the protective layer can withstand sharp temperature fluctuations, ranging from -45 ° C to + 100 ° C, while the elasticity of the coating is not lost;

- painting can be carried out at temperatures up to -10 ° С;

- ease of application, good painting characteristics, etc.

3 in 1 rust enamel primer is very easy to use. Painting is carried out in several ways of applying paints and varnishes: dipping, spraying, roller, brush.

The optimum thickness of a single-layer protective coating (a thickness gauge is used to determine the thickness) is 20 - 25 microns, with a two-layer painting - 40 - 50 microns. The number of protective layers is from 1 to 3, depending on the purpose and the desired effect.

Consumption of primer-enamel for a single-layer coating is from 80 to 125 ml / m2. With an increased viscosity of the composition or before pouring into the spray gun, soil-enamel for rust 3 in 1 is diluted to the required viscosity using a solvent, xylene (or their mixture). The amount of thinner used should not exceed 10% of the total mass of the paint and varnish material.

The drying time of a single-layer protective coating at a temperature of 20 ° C "to touch" is 30 - 35 minutes, and to a degree of hardness 3 (control is carried out using a non-destructive testing device - hardness tester) - about 4 hours under the same atmospheric conditions.

The appearance of the coating is a homogeneous continuous film, the degree of gloss is at least 75%.

The service life of the protective coating is:

- for indoor use - at least 10 years;

- when operating in atmospheric conditions, temperate climates - up to 7 years.

The stability of the coating formed with the help of a primer-enamel against rust 3 in 1 to the static effect of 3% saline solution, oils and water - 7 days.

What is an alkyd primer

Alkyd soil is one of the most demanded mixtures, because it has excellent characteristics and has a huge number of useful properties.

Alkyd soil is one of the most demanded mixtures, because it has excellent characteristics and has a huge number of useful properties. The products can be used for processing a wide variety of substrates, including glass, metal, wood, and plastic. It helps to protect the surface, make it smoother and increases the adhesion rate with the finishing material several times.

Benefits of an alkyd based primer

The main advantages of the material include the following:

High strength of the mixture.

Does not rub off after completely dry.

Helps to close resinous knots, which do not become visible even after several years.

Any paint, glue and putty will adhere very well to a surface treated with an alkyd primer.

It can be used for processing a wide variety of surfaces or applied to the base that was previously painted.

The material can be used even at sufficiently low air temperatures.

It has a composition that is completely safe for human health, so the mixture can be applied without the use of any special protective equipment

In this case, it is important that the room is ventilated during the work.

To remove primer from other surfaces, use an inexpensive chemical called white spirit, which can be found at any hardware store.

Of course, alkyd primer also has some drawbacks, but they are quite insignificant and if you apply the mixture to the base correctly, they will be completely invisible.

Application

The product contains polymers that can fill small cracks and pores. Due to this, it is possible to achieve the maximum indicator of surface protection. Alkyd primer helps to extend the life of wooden buildings, especially when used with alkyd paints or liquid wallpaper. A huge advantage of the material is that it is compatible with almost all building and finishing mixtures, which makes it truly versatile in use.

Slaven quick-drying anticorrosive primer-enamel

|

Slaven primer enamel is an independent one-component coating that combines the properties of a rust converter, primer and enamel. Thanks to a specially developed binder formula and high-tech additives, the primer-enamel has high protective and decorative properties, does not exfoliate, does not form sediment and films on the surface. The primer enamel provides long-term protection for metal surfaces exposed to weathering.

Purpose: primer-enamel is used as an independent coating with good adhesion to the painted surface and ease of application. Slaven primer-enamel can be used for painting chassis and suspension of cars, forged furniture, windows and window bars, metal structures, doors, concrete and wood surfaces, rigid PVC. It does not require a preliminary application of a primer, it can be applied to a surface with partial corrosion, stops further corrosive destruction of metal. The coating of the primer-enamel is weather-resistant, resistant to abrasion and detergents, and has high impact resistance.

Technical details.

Ingredients: varnish based on modified alkyd resin, anticorrosive pigments, fillers, solvent, drier, special targeted additives.

Application method: clean metal surfaces from rust and scale, wooden surfaces from dust and dirt. Before use, the primer-enamel is thoroughly mixed. To the required viscosity, dilute with a solvent (GOST 10214-78, GOST 1928-79), xylene (GOST 9949-76, GOST 9410-78) or a mixture of these solvents with white spirit (nefras C4 155/200) in a 1: 1 ratio according to mass. Primer-enamel is applied to the prepared surface with a brush, roller, paint sprayer or by the method of jet dousing, dipping.

Consumption: Consumption of primer-enamel, depending on the color, 80-120 g / m2.

Drying time: the drying time of a single-layer coating at a temperature of + 20oС and 65% relative humidity is no more than 6 hours. After drying, it forms an even, homogeneous semi-matt coating, resistant to temperature changes from - 45 ° C to + 60 ° C.

Tool cleaning: after use, rinse the tool with solvents or white spirit (nefras C4 155/200).

Packing: 0.5kg, 1.1kg, 3.2kg, 20kg

Expiration date: 2 years from the date of manufacture in a tightly closed manufacturer's container. |