Mode of application

Before you start using the primer-enamel, it must be mixed well. The surface is freed from dirt, dust, flaking coatings, as well as rust, which has acquired a state of friability. The surface must first be degreased. If the base or products were painted with oil or alkyd paints, then it is necessary to clean it to a matt state. It is unacceptable to apply when the ambient temperature has risen above +30 degrees. Allow one hour or more between coats. As for the time of complete drying, this period lasts 2 hours.

Consumption rates per 1m2

All of the above characteristics have a positive effect on enamel consumption. But if the painting takes place in windy or sunny weather, the amount of paint used per m2 will double. Oil paint of light shades is applied in two layers, one will not be enough, as streaks and gaps will be visible. Therefore, choosing white, gray or yellow, enamel must be purchased with a margin.

Prepare your wall or ceiling surface before painting. First, wipe it with a damp cloth to remove dirt and accumulated dust. In order to save paints and varnishes, level the walls with putty and treat with a primer. The primer increases the adhesion (adhesion) and service life of the material.

As practice shows, the consumption rate of the material varies from 100 to 180 g. Also, professionals say that, on average, one kilogram cans are enough to paint 15 m2 of the prepared surface. Also, the consumption of PF 115 directly depends on the selected color pigment.

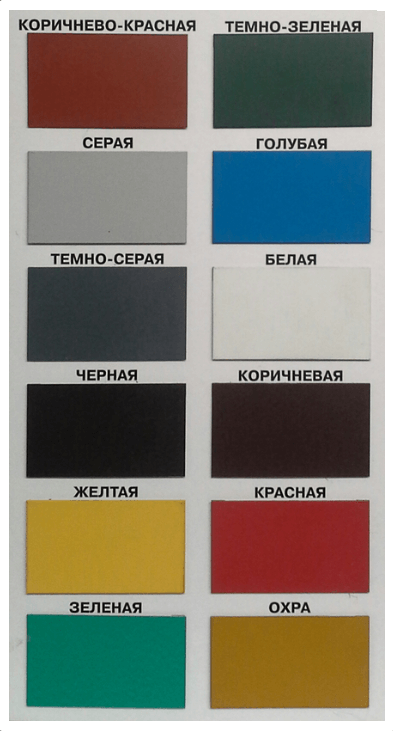

Table of approximate consumption of enamel PF-115 (depending on the selected color)

| Colour | What area is 1 kg of paint enough for | Paint consumption per 1m2, g |

| White | 7-10 m2 | 100-140 g |

| Yellow | 5-10 m2 | 100-180 g |

| Green | 11-14 m2 | 70-90 g |

| Blue | 12-17 m2 | 60–84 g |

| Brown | 13-16 m2 | 63–76 g |

| Black | 17-20 m2 | 50-60 g |

A spray gun is also suitable, thanks to a fine scattering jet, the enamel is applied evenly. Brushes absorb a lot of paint, which is why they increase the consumption of material several times.

When calculating the enamel consumption rates, add to the total amount the percentage of loss from the location of the surface. If the floor is painted, the paint will not drip and drip, but for walls and ceilings you will have to purchase material with a margin (approximately + 7%).

Do not forget that when painting a wooden surface, the paint will have to be applied in several layers, since wood, due to its uneven structure, absorbs a large amount of material. Consequently, paint consumption will increase. When covering metal surfaces, it is necessary to treat them from rust and dirt, and only then paint with the desired shade. In some cases, one layer is sufficient. Plastic is less whimsical.

If you buy more paint than you need, you can return it to the store within two weeks. To do this, the banks must not be printed; take a receipt for the goods and your passport with you.

Consumption for 1 m2

The calculation of the paint consumption on the surface must be done before purchasing to save time and money. The standard values are indicated by the manufacturer. The instructions are on the packaging.

Saving the composition largely depends on the correct preparation of the base. The opened enamel must be thoroughly mixed and diluted with special solvents or xylene, after which the surface can be prepared for application. To do this, it is necessary to remove dirt and rust from the base, after which it is necessary to thoroughly degrease it.In the case where there is a layer of previous enamel, such as oil or alkyd paint, it should be cleaned. It is forbidden to apply a primer-enamel over a nitro-containing coating.

It is recommended to apply the primer-enamel in 2 layers, taking a break for about an hour. When the composition is applied and dried, it can be coated with any paint and varnish material.

If you follow the application technology, the consumption of the composition will be about 80-100 milliliters per 1 m2. The number of layers depends on the need and desire of the consumer and can range from 1 to 4.

The best paint for rust 3 in 1

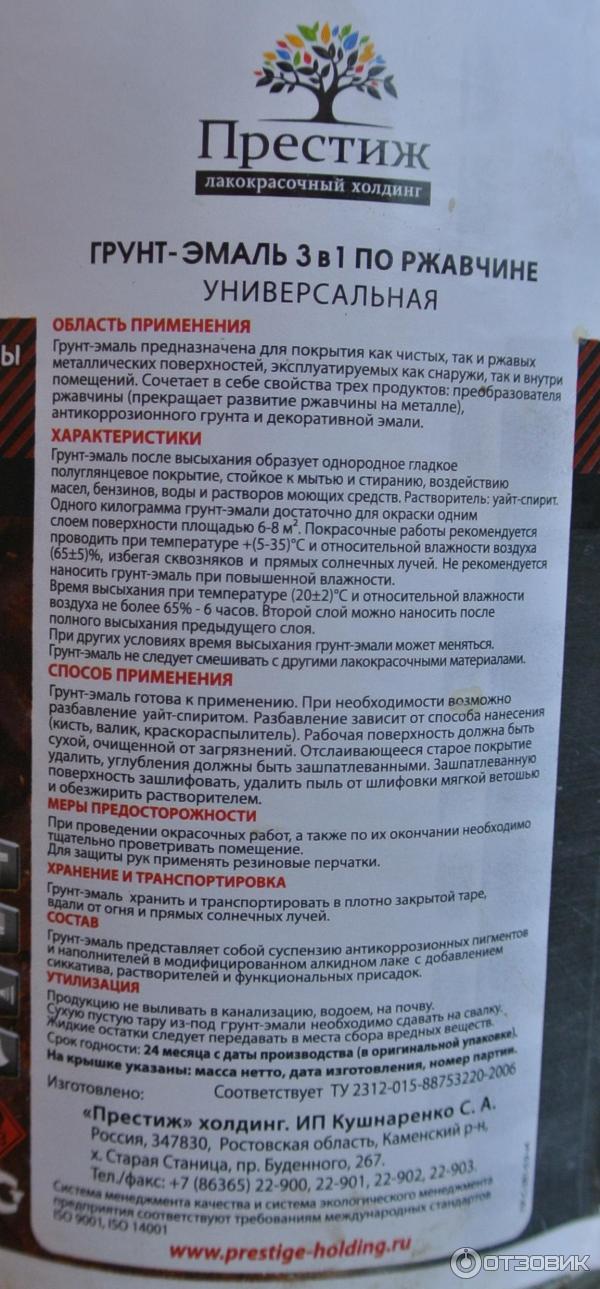

The presence of the "3 in 1" prefix indicates that the product works in several directions - priming, converting rust and decorating. Products of this type are resistant to any impact. After analyzing the reviews of consumers and experts, among a variety of products, two nominees with the best recommendations were selected.

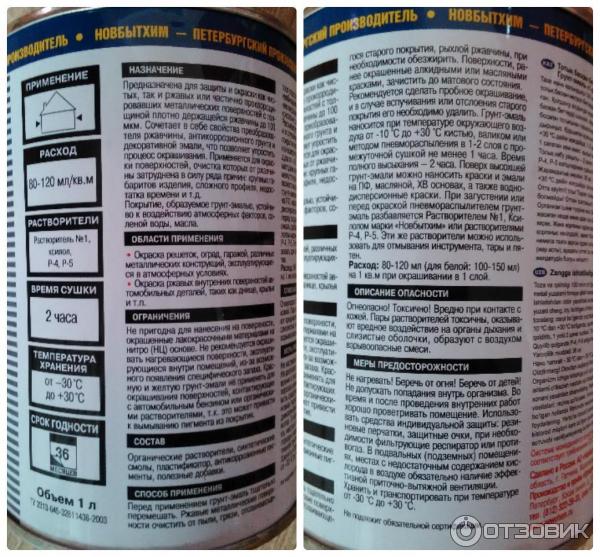

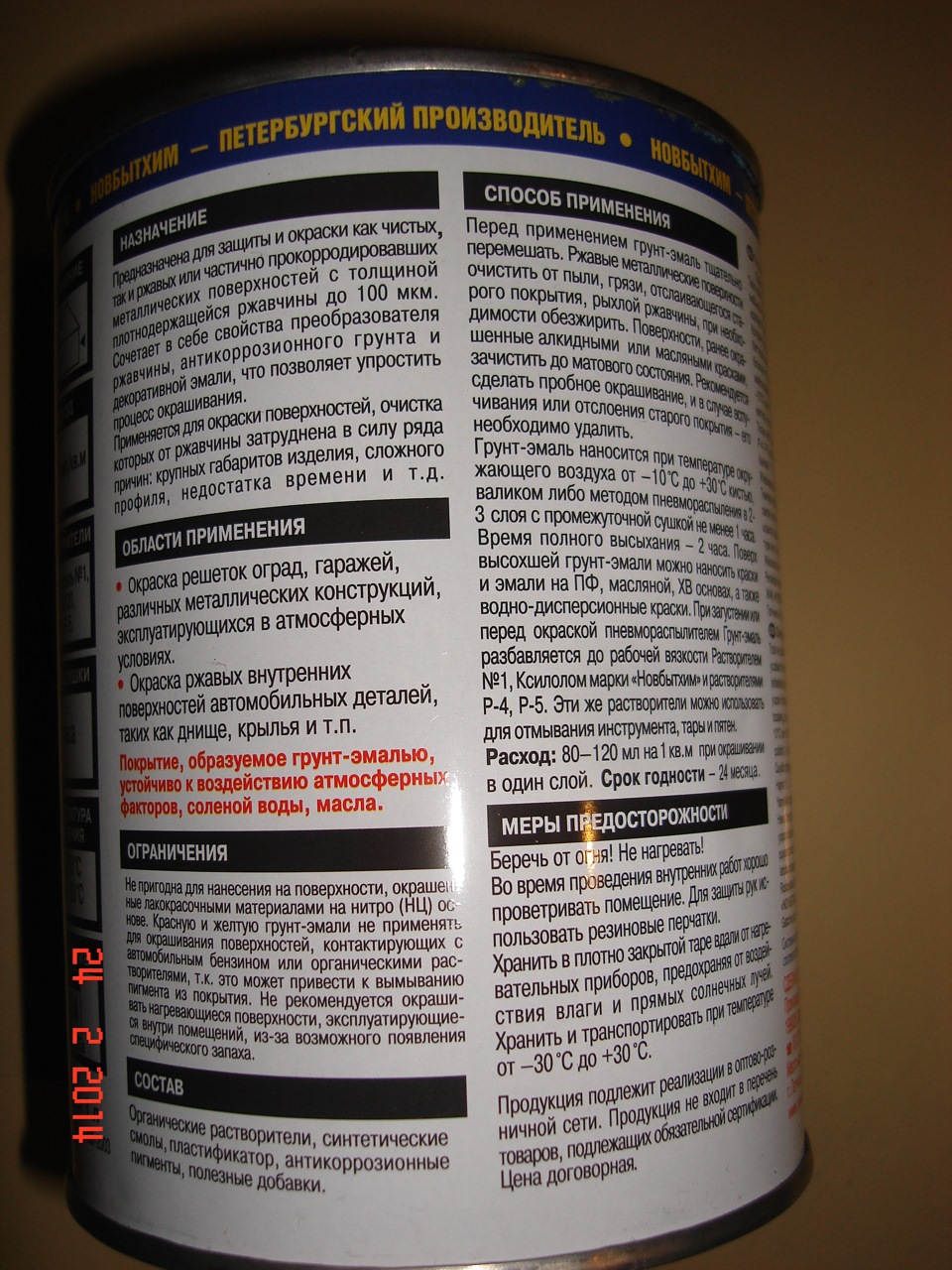

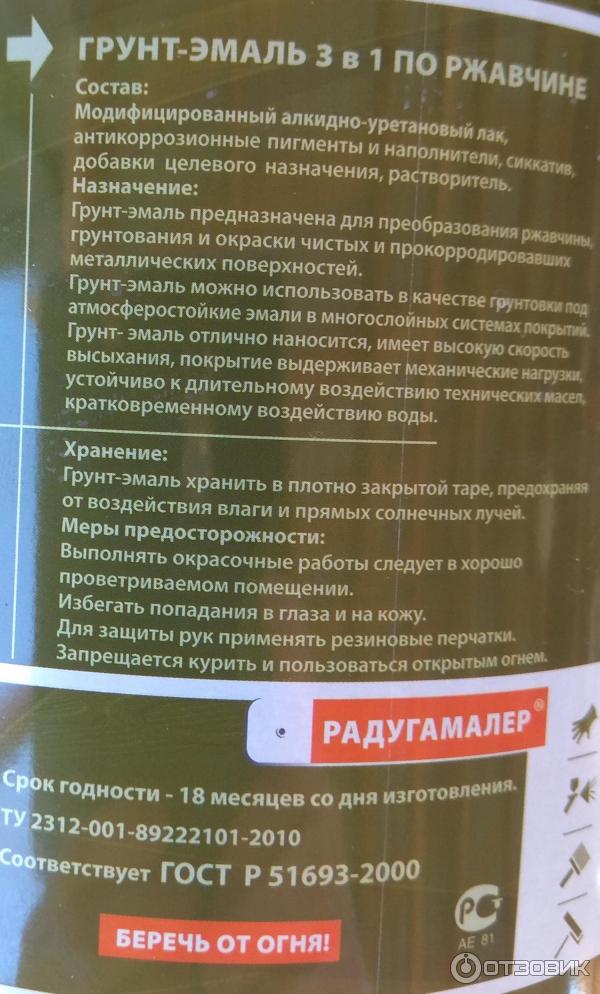

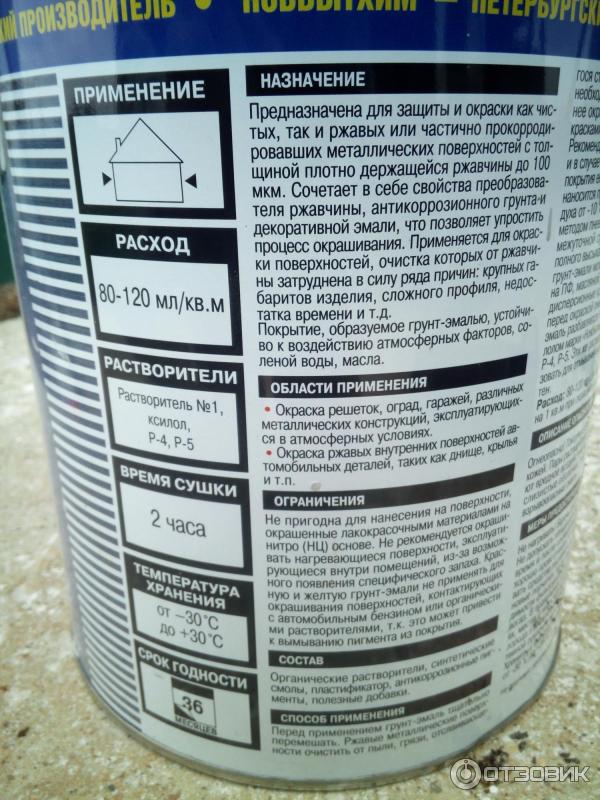

Novbytkhim primer-enamel

The paint "Novbytkhim primer-enamel" is intended for painting all types of surfaces. It is applicable both for new and already partially or completely corroded products. The composition of the product is represented by resins of synthetic origin, additives, solvents (organic) and anti-corrosion components. The product combines the qualities of an anti-corrosion primer, rust remover and topcoat. Its consumption is quite low - up to 120 ml per m² with a single layer.

Work can be started at an air temperature of -10 ° C. The coating is preliminarily cleaned from the existing detachments. If it was painted with oil or alkyd compounds, then cleaning to a matt state is necessary. A brush and roller are suitable for applying the composition. The paint also adheres well to pneumatic application. For best results, you need to put 2 layers. Intermediate drying should take at least 60 minutes. It takes only 2 hours to dry completely.

Dignity

- Fast drying;

- Resistance to different types of exposure and temperature extremes;

- High adhesion rates;

- Excellent decorative properties;

- Good hiding power.

disadvantages

Not suitable for heating surfaces due to odor.

Metallista

The paint on rusty metal in question from the brand with the myrrh name Tikkurila provides a 3-in-1 effect. Thanks to the wax included in it, it creates an increased protection of the metal from negative effects of moisturegiving it excellent water repellency. The structures covered with the composition will last at least a decade without renovation. Metallista is immune to the effects of fats, lubricants, industrial alcohols and turpentine, therefore, its field of application is unusually wide.

The manufacturer offers several basic shades for tinting, all in all, they can be created up to 32 thousand. The hardened layer can easily withstand heating up to 80 ° C while maintaining the original color. Drying of the applied composition until it comes off takes up to 2 hours. Thinner must be added to Metallista prior to use. It fits well on uncleaned surfaces without first applying a primer.

Dignity

- Creation of an insoluble base;

- Delaying the formation of corrosion;

- Eliminates the need for preliminary preparation of the base;

- Double chemical formula;

- Convenience of working with any tool.

disadvantages

- Implementation in small volumes;

- The need for tinting;

- Not a very large number of ready-made colors (four).

Enamel is sold in small containers - from 400 ml to 2.5 liters.

Properties and application of primer enamel

Primer-enamel from Novbytchim has a very wide range of applications. It can be used for protective and decorative finishing of glossy, matte and rusted metal surfaces. Primer enamel 3 in 1 for hammerite rust?

The composition is in demand in everyday life for painting various fences, garages, gates, doors, safes, window bars, furniture, etc.In addition, it is used to process bridges, power transmission lines, and agricultural machinery.

Primer-enamel is used for painting products, the cleaning of which from rust is difficult for any reason: due to large dimensions, complex profile, lack of conditions.

The composition is suitable for treating rusty internal surfaces of cars: underbody, fenders, etc. After drying, the enamel forms a coating that is resistant to salt water, mineral oils, as well as to sudden temperature changes (withstands operation in the range from -45 ° C to + 60 ° C).

Metal and rust paint is a versatile 3-in-1 product combining the properties of an anti-corrosion primer, rust converter and decorative enamel. Another plus is the fact that the composition is diluted with water, does not have an unpleasant odor and does not emit harmful volatile substances.

The manufacturer does not recommend using a primer enamel for finishing heating surfaces that are planned to be used indoors.

Surface preparation

The peeling coating is removed from the previously painted surfaces with a scraper, and then cleaned with a steel brush. Contaminated items are washed with a solution of washing powder, rinsed and dried.

Oil and grease stains are removed with a cloth dipped in white spirit.

Also recommended on previously painted surfaces make a test application of the enamel primer. In case of swelling or peeling of the old coating, remove it with a special remover.

On unpainted products made of steel and ferrous metals, paint 3 in 1 from Novbytkhim is applied without preliminary priming. It is only necessary to make sure that the surface is free of dirt.

When working with galvanized metal or aluminum, glossy surfaces are ground to a matte texture, dust from grinding is removed. Then the product is washed with water and dried. Before painting, apply one coat of Hammerite Special Metals Primer or similar products from other manufacturers, for example: Grit Metal or Rostex Super (Tikkurila).

Rusty metal surfaces are cleaned of loose and fragile fragments with a metal brush or sandpaper to a solid base. The surface is washed with water and dried. No preliminary priming is required in this case.

The best hammer paints for rust

Hammer paints form a specific rough coating, creating the effect of hammering. At the same time, the enamel perfectly protects against moisture and temperature extremes. After evaluating the technical characteristics and feedback from specialists, 2 winners were selected that met the necessary requirements.

Hammerite

… I used enamel to paint a metal door to appreciate the strength of the hammer effect. Hammerite well masks irregularities that have arisen during the operation of the canvas, and creates a visually effective coating ...

Expert opinion

Another best paint for rust protection for both exterior and interior work. It adheres well to surfaces with signs of rust due to its high adhesion rate. The enamel creates a smooth coating with excellent water repellency even on rusty, unprepared surfaces and fully cures within 2 hours after application. The product has excellent thermal stability, maintaining its integrity even when heated (up to 80 ° C).

Hammerite is designed to protect ferrous metal only. It contains corrosion inhibiting components - alkyd varnish, sunlight-resistant pigments and functional additives. It is allowed to start painting when the air is warmed up to 5 ° C with a roller, brush or spray, which allows you to choose the most convenient tool in each case. After applying the base coat, wait at least 5 hours.The manufacturer offers 11 shades.

Dignity

- Resistance to aggressive factors;

- Ease of application to areas of corrosion;

- Doesn't require preparatory work;

- Suitable for outdoor and indoor work;

- Lead free.

disadvantages

- Not low cost;

- Dilution requires Hammerite Thinner.

Zip guard

It is a urethane rust paint designed for metal surfaces, but it is also suitable for concrete and wood. The enamel may be used directly in areas with signs of corrosion. At the same time, it is not required to carry out any actions to clean up the affected areas, except for those only cases when there is a swelling of the old coating - they must be removed.

In the production of Zip Guard, the Ziprust technology is used, which allows you to apply a layer without prior use of primers. Enamel can be used for interior and exterior works. It is a one-component formulation and creates a corrosion-resistant coating due to a combination of soil properties, anti-corrosion ingredients and finishing compound.

Dignity

- Protection of all types of surfaces, not just metal;

- No surface preparation required;

- Suitability for outdoor and indoor use;

- Creation of a resistant coating with anti-corrosion properties.

disadvantages

- Before painting, you need to grind glossy surfaces;

- Dries for a long time.

Composition and specifications

A hammer or other primer has a good effect when used on metal surfaces. All properties are available due to the composition of this substance, which includes the following components:

- first of all, this substance contains an alkyd varnish, which promotes adhesion to the surface;

- there are various functional additives to reduce the effect of sand on the structure;

- in addition, the components of this solution contain special enzymes, as well as organic and inorganic fillers;

- among other things, organic fillers and auxiliary pigments are present in the structure of this coating.

As a rule, the main purpose of pigments is to give the composition a certain shade. Often, this kind of enamel with a primer effect is black, which is why its use is widespread in practice. Depending on the aerosol filling and production technology, such a dye has a specific purpose. Most often it is anti-corrosion protection of a metal surface.

Consumption per 1m2

Before considering how much this version of the composition dries, it is necessary to clarify the consumption of this enamel per 1m2. In this case, the following indicators are established:

- as a rule, with correct and rational application, a layer of 0.1 millimeter is formed;

- if we talk about a single-layer coating, then 130 to 140 grams of the composition are consumed per square meter;

- provided that the application technology is not followed, and in addition a brush or roller is used, the consumption may increase to 200 grams.

It should be understood that all of these values are prescribed by the paint manufacturer and are not always true in practice. In this case, the consumption of the composition during normal use can vary from 130 to 250 grams.

Advantages and disadvantages

This type of paintwork has a number of positive and negative qualities. Let's consider in more detail the main advantages of coverage:

- such a composition dries out quickly enough;

- there is a necessary protective property for the surface;

- little existing corrosion is eliminated;

- relatively low cost;

- there is no need to buy different materials for work;

- can be used for any purpose.

Despite a number of advantages, there are also some disadvantages. Small temperature range for operation. At high humidity, the composition slowly solidifies.If used as a full-fledged coating, polishing is required.

Advantages and disadvantages

Let us consider in more detail the advantages and disadvantages of the material that are common to all manufacturers.

The indisputable advantages of primer-enamel over classic protective coatings (meaning primer GF-021 and enamel PF-115) include the following points:

- Surface preparation when using an anti-corrosion compound is greatly simplified. Its application does not require a thorough cleaning of the areas affected by rust and additional surface treatment with a special modifier, followed by its neutralization with a soda solution. The primer-enamel can be applied even to residual rust, it is enough to remove the peeled coating and loose corrosion formations from the treated surface.

- The decorative and protective properties of the material are noticeably higher than that of alkyd coatings. Alkyd-urethane varnish, acting as a binder, has greater hardness, wear resistance and is less susceptible to moisture and aggressive media than alkyd varnish used in primers such as GF-021 and PF-115 enamel.

To ensure reliable anticorrosive protection within 5 years, it is necessary to apply one coat of primer of the GF type and two coats of PF-115 enamel, while the primer-enamel should be applied in two coats. When applying three layers, the service life of the decorative and protective coating increases to 7 years.

- The use of the material can significantly reduce the time spent on painting. It should be recalled here that the primer GF-021 dries up within 12 hours, and one layer of PF-15 enamel is completely polymerized in 24 hours. Thus, to obtain a protective coating it will take: 12 + 24 + 24 = 60 hours.

One layer of the composition at an ambient temperature of 20C does not exceed 6 hours, which allows complete painting work in 12 hours.

- All components of the protective coating (rust modifier, primer and enamel) are in one can, which greatly simplifies their application and reduces the amount of tools required.

The main, and perhaps the only drawback of primer-enamel is their high cost, however, upon closer examination, this drawback turns out to be rather doubtful. The fact is that the estimate of painting work takes into account not only the price of the material. It also takes into account the cost of preparatory work and the application of each, separately taken, layer.

When using this composition, the preparatory work is greatly simplified, and the protective and decorative coating itself is applied not in three, but in two layers, therefore the total cost of the work differs slightly.

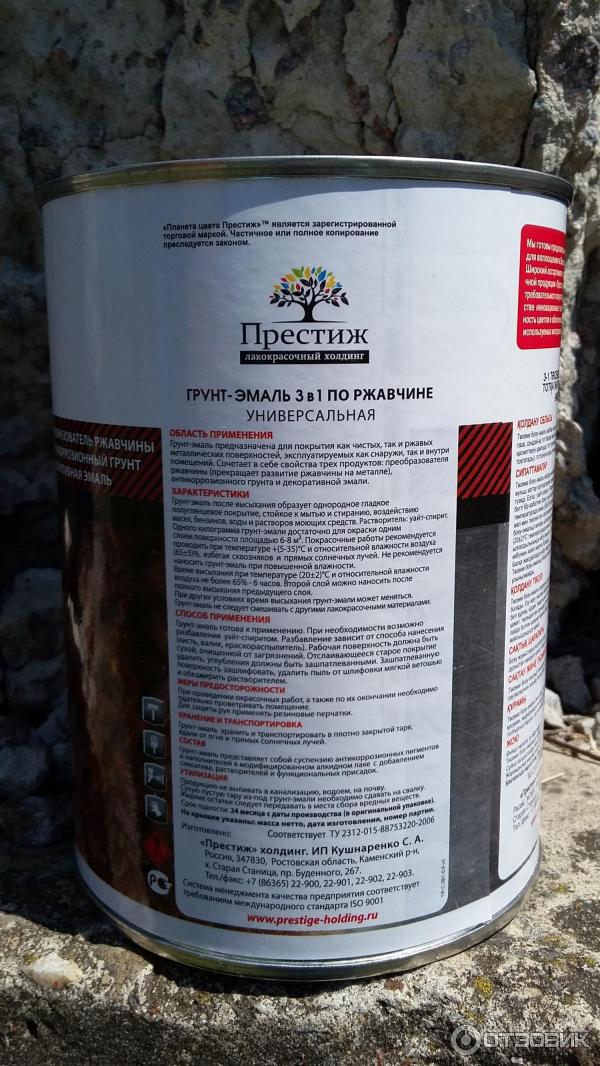

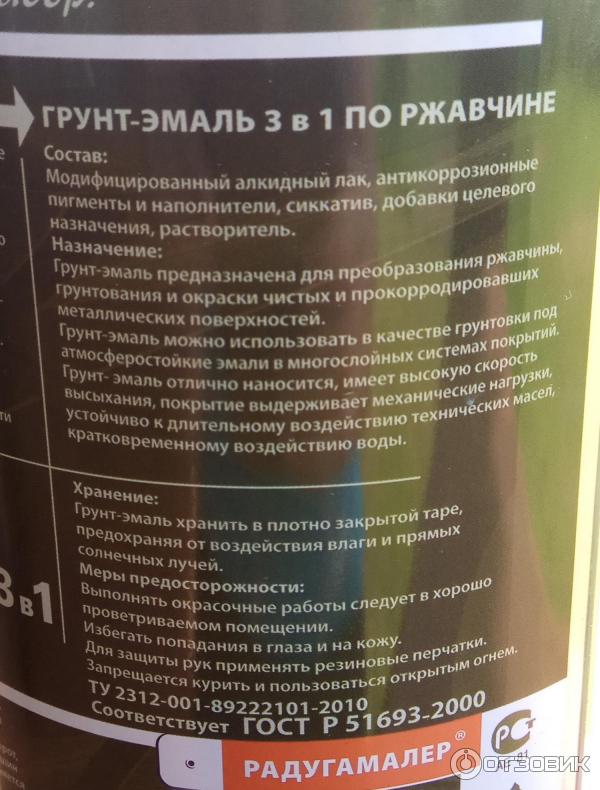

3 in 1 rust primer - what is it

Three-in-one primer-enamel is a coating for metal that combines decorative and protective functions. Consists of rust-neutralizing anti-corrosion additives, primer and paint enamel.

Three-in-one primer-enamel is a coating for metal that combines decorative and protective functions.

Three-in-one primer-enamel is a coating for metal that combines decorative and protective functions.

Scope and technical characteristics

They are used for painting various metal mechanisms, buildings, as well as products: fences, gates, fences, pipes, profiles, car bodies. Primer-enamel 3 in 1 is suitable for painting surfaces on rust with a layer of no more than 100 microns. Batteries and other heating surfaces are coated with enamel with special heat-resistant additives. Metal structures that are constantly in a humid environment are painted with a three-in-one composition with special plasticizers to avoid destruction and oxidation.

Enamel components:

- Anti-corrosion ingredients that neutralize corrosion, preventing its further appearance;

- Alkyd-urethane varnishes are a binding ingredient, thanks to which the paint dries quickly;

- Enamels give the metal well-groomed, nobleness, resistance to outside influences;

- Solvents provide an optimal consistency.If the enamel has thickened, it is diluted with white spirit, solvent;

- The elastic properties and durability of the enamel are given by plasticizers and other components, which the manufacturer adds to the composition.

Main technical characteristics:

- Primer-enamel allows you to paint metal quickly, without unnecessary complications, gives a spectacular appearance for a long time;

- 3 in 1 rust enamel is available in various shades. Manufacturers offer a wide rich palette: metallic, glossy, matte.

Batteries and other heating surfaces are coated with enamel with special heat-resistant additives.

Batteries and other heating surfaces are coated with enamel with special heat-resistant additives.

Service life of the protective coating

Subject to all stages of application, the service life of painted products located in the building is more than 10 years. For street structures exposed to various adverse external influences - 7 years.

Subject to all stages of application, the service life of painted products in the building is more than 10 years.

Subject to all stages of application, the service life of painted products in the building is more than 10 years.

Application

Before applying the primer-enamel, the surface to be treated must be prepared: clean it from the peeling previous coating, remove large and loose foci of rust. After that, you should re-clean the product from dust and dirt and, if necessary, degrease with white spirit. All this will ensure the best adhesion of the primer-enamel, facilitate the work and provide a high-quality finish.

Before direct use, the composition must be thoroughly mixed. Depending on the complexity and size of the surface to be treated, enamel can be applied using a brush, roller or spray gun. Small parts can be dipped.

Before covering the entire structure, it is advisable to try painting a small area in order to assess the correct color selection and the quality of the finishing layer.

Average material consumption per m2 - 80-120 ml for one layer. The number of layers applied depends on the degree of protection and the desired effect and ranges from 1 to 4. Each manufacturer indicates on the packaging recommendations for the consumption of primer and the method of application to the product.

The drying time of the primer-enamel is short: to the “tack-free” stage - about 30 minutes, and the time of complete drying is about 4 hours. In order for the product to be resistant to salt, water and oil, it is necessary to withstand it before use for several days (up to 7 days).

In the open air, the process of drying the soil-enamel and removing the specific odor is faster than indoors. Therefore, manufacturers recommend painting the base outdoors or in a ventilated area.

For an overview of the Dali rust primer enamel, see the following video.

The best rust paint for outdoor use

Paints and varnishes of this group protect metal surfaces from water and other factors. The leading properties, on the basis of which the selection of nominees was carried out, was the preservation of the characteristics declared by the manufacturer at peak temperatures, resistance to loads of various types and full coverage of the base. These requirements are met by 2 representatives of the group.

Kudo

Kudo 3-in-1 Primer Enamel creates a dense matte finish. It is suitable for working exclusively with ferrous metals, but it can be used for painting both new and corroded surfaces. The composition is based on alkyd varnish. In addition, it contains synthetic resins, as well as xylene, coloring particles, corrosion inhibitors, dimethyl ether and methyl acetate. Due to the minimal odor, the product can be used indoors.

Kudo is considered a very good rust on metal paint, combining the properties of its inhibitor, adhesion promoters and finishing coat. Thanks to this, the product allows you to form durable protection in a short time frame. It is allowed to start work at 10 ° C. The enamel is sold in a spray can.Thanks to its aerosol format, it allows high-quality staining in the most problematic areas for access. Coloring is carried out in layers, but the second layer is allowed to be applied only after 15 minutes. It takes 2 hours to fully cure.

Dignity

- Easy application;

- 3-in-1 effect;

- Excellent covering ability;

- Good adhesion performance;

- Eliminates the need for special surface preparation.

disadvantages

Not suitable for light metals.

If, when working with Kudo, the second layer was not applied within two hours, then the work will need to be continued only after two weeks.

Dali

Dali paint is a modern 3-in-1 rustproof primer. It is recommended for new and already corroded metal surfaces. Before processing them, you need to make sure that there is no detachment in the affected part. If there is one, then the product will need to be pre-brushed with a metal brush, removing swollen areas.

Dali is recommended for indoor use due to the absence of a pungent odor. The product is allowed to be used on surfaces made of cast iron, stainless alloy steel, non-ferrous metal, galvanized metal. It is allowed to start painting with the onset of heat, when the air warms up to 8 ° C, after preliminary degreasing and drying the coating. The expense of the product is small: to apply one layer on an area of up to 18 m², you will need about 1 kg.

Dignity

- Glossy finish;

- Application directly to the corroded layer;

- Resistance to temperature extremes and atmospheric influences;

- No brush marks remain;

- Anti-corrosion protection combined with a decorative effect;

- Super durable.

disadvantages

- Application in 2-3 layers;

- Final drying within 7 days;

- Not a budget price.

To dilute paint-enamel for rust, xylene and solvent can be used, but in an amount of not more than 10% of the total weight.

Specifications

There is an opinion that you can prepare the primer-enamel yourself by mixing the primer with the paint you like. However, the result is likely to be disastrous, because mechanical mixing will only worsen the properties of both the primer and the enamel. It's all about a special production technology for the production of primer-enamel, thanks to which the primer layer will adhere to the surface of the product, and the finishing lacquer layer will remain on the surface. For this purpose, various additives and additives are introduced into the composition.

Manufacturing technology of multifunctional primers gives them excellent qualities.

- Resistant to temperatures. It is recommended to apply the primer-enamel at a temperature of 20 ° C - then the drying temperature declared by the manufacturer and the properties of the material will be reached. But if necessary, you can use it even at sub-zero temperatures. And the applied and dried primer-enamel retains all its properties at temperatures from -45 ° C to + 100 ° C.

- Density and elasticity of the finished coating. When applied correctly, cracks will not appear for several years.

- Low material consumption. Compared to classic varnish-and-paint materials, the consumption of primer-enamel will be about 30% less, even if the coating is applied in several layers.

- Atmospheric resistance. Primer-coated products are resistant to sun, moisture, salt and oil, making this material ideal for refreshing outdoor interiors.

Hammer paint is a type of traditional primer enamel. Metal powder is additionally added to its composition, and the treated surface looks like a blacksmith's processed - hence the name of the paint. It can be unmistakably identified by its textured "pebbled" surface and metallic sheen. It is also applied to rust, combining the functions of a primer and enamel.

Metal additives make it more difficult to spray paint and requires a brush or roller.Also, on vertical surfaces, metal particles may move downward, which will worsen the original appearance of the product. But when applied using the technology, hammer enamel looks very impressive on interior items.

Conclusion

Painting metal surfaces with the above-described primer enamel is a work in which a unique material is used. It is intended for metal structures, including large-sized ones, which are operated in atmospheric conditions. We can also talk about products with a complex profile, the cleaning of which, for some reason, can be difficult.

Additional Information: Paint primer enamel for rust in consumption per m2

- Moisture resistance

- Wear-resistant coating

- Corrosion protection

- Oil resistance, petrol resistance

- resistance to mineral fertilizers

- Resistant to detergents

- Conditional viscosity at (20.0 ± 0.5) ° С according to the VZ-4 viscometer - not less than 20 s

- Drying time to degree 3 at (20 ± 2) ° С - no more than 1 hour

- Consumption of primer-enamel, depending on the color and method of application - 120-150 g / m2 for a single-layer coating.

- Due to its technical characteristics, it provides high physical and mechanical properties.

Designed for long-term anti-corrosion protection of metal surfaces of equipment and structures, including those exposed during operation to elevated temperatures from -60 ° C to +350 ° C, operated in a marine and industrial atmosphere UHL1, including in conditions of high humidity.

Enamel primer is used as a primer for concrete and wooden floors, protects metal structures from rust, prevents corrosion, transforms existing rust. Enamel 3 in 1 is suitable for painting surfaces made of wood, concrete, metal and is used for both indoor and outdoor use.

If the metal coating was previously painted with oil or alkyd paint, then it is better to clean it to a matte appearance. In addition, in order to further reduce paint consumption, experts recommend doing a test painting. This procedure will help you to see the areas of detachment and bulging, and if necessary, remove them.