Operating tips

There are several tips for using the XB-0277 to follow.

How to apply

Before application, prepare the substrate by removing rust and previous paint coat. Then - wipe thoroughly with a special product, removing dust and dirt.

Next is the process of diluting the enamel, which will require solvents P4 and P4A. The manufacturer does not indicate the exact degree of viscosity of the finished mixture, it all depends on the method of its application. So, to spray the enamel, you have to make it not as thick as when applied with a brush.

The agent is added to the soil gradually, after which it is thoroughly stirred.

The actual application of the primer XB-0278 can be done both by airless and pneumatic spray, and by a roller or brush. The hardening time of the layers depends on their order: the first one dries up in 1.5-2 hours, and the next - in 1 hour.

For more information on how to apply primer enamel, see the next video.

How to store

The temperature during transportation should not exceed 30 degrees. Care should be taken to protect the mixture from moisture or sunlight. The packaging must be tightly closed during storage. If all standards are fulfilled, the primer-enamel will be able to last up to six months.

Errors in use

Unfortunately, while working with the composition, some mistakes are made that should be avoided.

The most important thing is to apply only one layer in order to save the mixture. To obtain a high quality base, 3 coats should be applied, as mentioned above. If you apply only 1 layer, then most of it will be absorbed into the corroded area, and the remainder will not be able to provide adequate protection.

Another mistake is the use of a solvent that is not specified in the instructions - it may not be compatible with this primer, and the enamel will lose its quality.

It is also a mistake to apply the primer on a smooth base, since its composition is designed specifically for rusty coatings. Therefore, before processing a particular part, it should be roughened by special processing.

A matter of compromise

Shielding materials of an earlier development period are often inferior in their properties to their more modern counterparts. In most cases, the anti-corrosion properties of such products turn out to be slightly worse, and the overall service life is shorter. However, customers often “turn a blind eye” to these shortcomings due to the significantly lower cost of the protective material. These options are often resorted to by companies with a limited budget for work on corrosion protection of structures. It is worth noting that, if applied correctly, such compositions may well retain their protective properties for 4-5 years, which is a very good indicator that allows you to protect the metal from corrosion for a certain time.

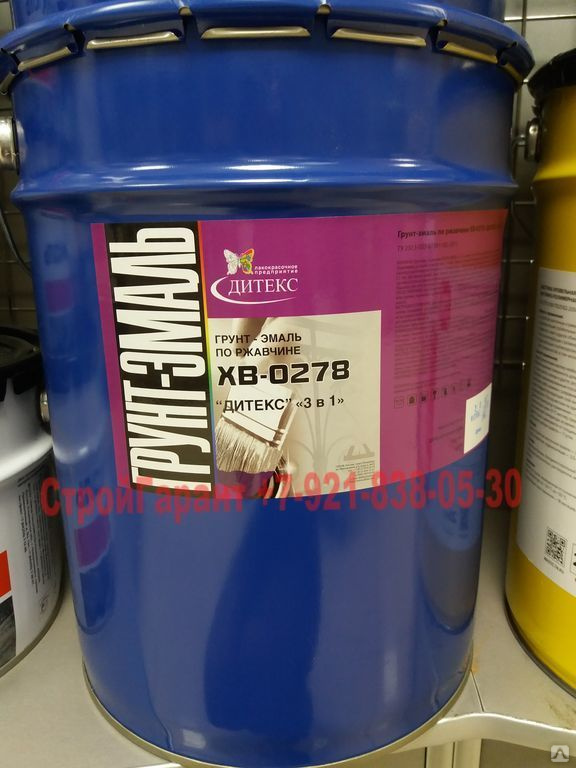

Primer-enamel XB-0278 - a universal protective coating

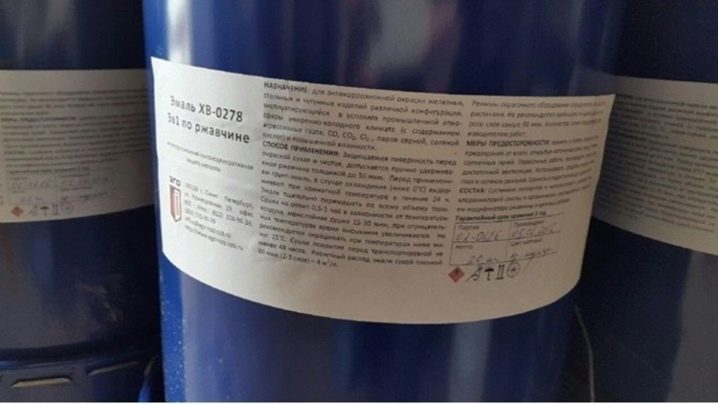

Enamel XB-0278 is used to protect any metal structures for domestic and industrial use (see also ep-0010). The versatility of this paint and varnish material allows it to be used for painting cars, all kinds of units operated in an aggressive environment and exposed to salts, gases, vapors and other chemical reagents with temperatures up to + 60 ° C.

Enamel can be used both in a complex coating with materials such as NTs, KhS, KhV, PF, EP, and as an independent protective coating. Before use, the enamel is diluted with R-4 solvent.

A distinctive feature of our primer enamel is that it can be use for coloring metal (steel, cast iron) surfaces with pieces of carbon deposits, as well as tightly adhered corrosion (rust up to 100 microns), exposed to an industrial atmosphere, including aggressive vapors and gases.

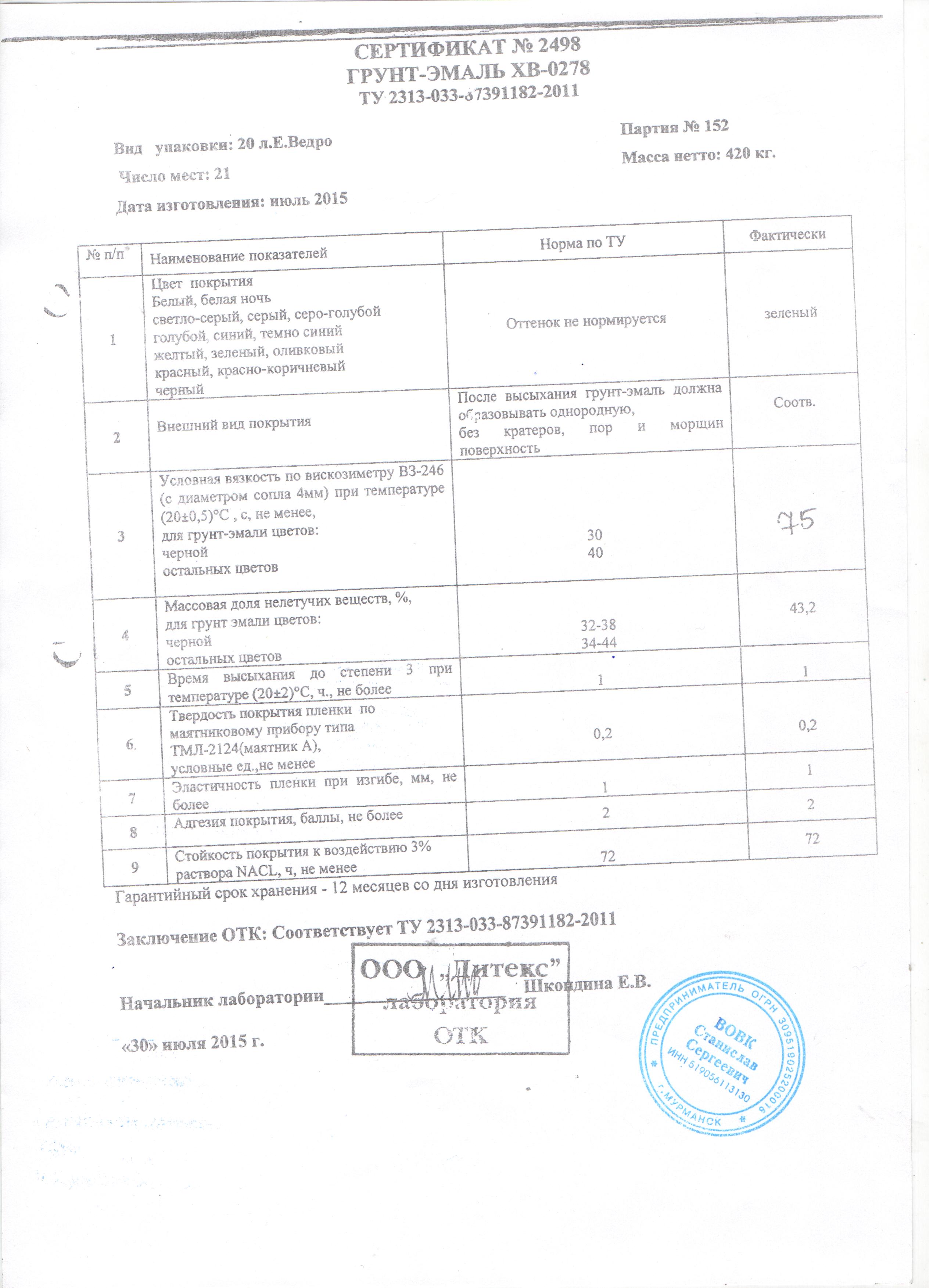

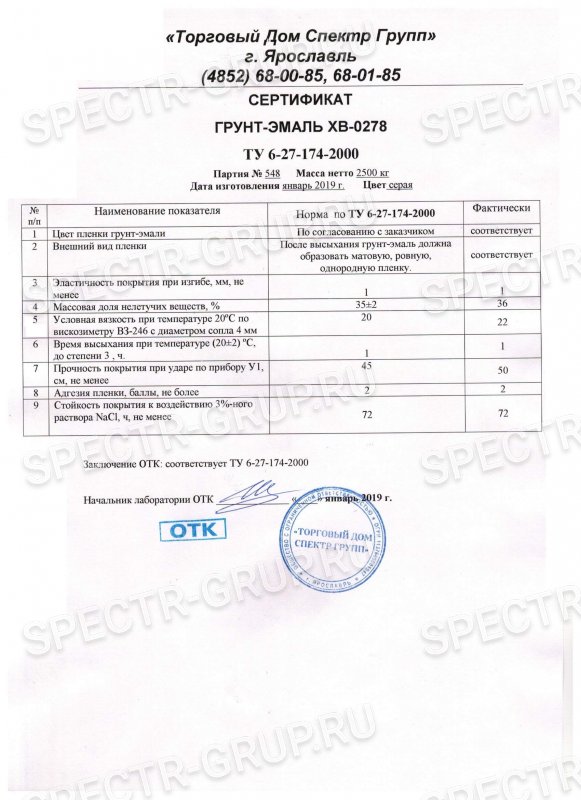

| Film appearance and color |

After drying, the primer-enamel hv-0278 forms an even, uniform, matte finish |

| Drying time of primer-enamel hv-0278 to degree 3 at a temperature of (20 ± 2) ° С, h, no more | 1 |

| Conditional viscosity of the primer-enamel hv-0278 according to the viscometer of the VZ-246 (or VZ-4) type with a nozzle diameter of 4 mm at a temperature of (20 ± 0.5) ° С, s, not less | 25 |

| Mass fraction of non-volatile substances,% | 40-45 |

| Theoretical consumption of primer-enamel per layer, g / m2 | 120-150 |

| Recommended thickness, microns

1st layer Subsequent layers |

20-25 20-40 |

| Recommended number of layers | 2-3 |

| Diluent | R-4, R-4A |

Application conditions and precautions:

Primer-enamel hv-0278 is applied to the surface by airless or pneumatic spraying, roller or brush, after thoroughly mixing until homogeneous, painting by dipping into the composition is allowed. Relative air humidity should not exceed 80%, ambient temperature from -10 ° C to + 30 ° C.

After the first layer of primer-enamel hv-0278 has dried for 2 hours at + 20 ° C, subsequent layers are applied with an interval of 1 hour.

The material is flammable! Avoid work near open sources of fire. Primer-enamel painting is carried out in well-ventilated rooms, wearing rubber gloves and using PPE.

Avoid getting the primer xv-0278 into the respiratory and digestive organs!

Transportation and storage:

Primer-enamel ХВ-0278 can be transported by any type of transport, the air temperature during transportation should not exceed the established limits: from -30 ° C to + 35 ° C. It is also necessary to comply with the conditions that will ensure the safety of the container and protection from atmospheric precipitation.

During storage, it is necessary to exclude direct sunlight on the material, the same applies to moisture. The material in a tightly closed container should be stored in closed rooms at temperatures from -25 ° C to + 30 ° C.

Manufacturer's warranty:

JSC "PKF Spectr", subject to all the stipulated conditions of transportation and storage, gives a guarantee for the compliance of the material with the requirements of TU 2312-007-60414707-2013. Warranty for primer-enamel XB-0278 - 6 months from the date of production. After the warranty period of the material has expired, before using it, it must be checked for compliance with the requirements of TU 2312-007-60414707-2013, only after the compliance has been established, the material can be used for its intended purpose.

Articles about the material:

Primer-enamel XB-0278 - anti-corrosion protection in a limited budget

Paints and varnishes and compositions, just like any things, are not alien to constant renewal. The chemical industry does not stand still, offering specialists all the new, more perfect ingredients.

Read more →

APPLICATION

Surface preparation

Metal surfaces are cleaned from loose rust, dirt, dust and degreased.

Application methods

By pneumatic spray, brush, dipping.

Application conditions

Before use, make sure that the primer-enamel is well mixed and homogeneous throughout the container.

If necessary, before use, the primer-enamel can be diluted to a working viscosity of 18-20 with R-4 solvent.

The prepared primer-enamel is applied to the surface at a temperature from minus 15 ° C to 30 ° C

To exclude moisture condensation on the surface of the workpiece, the surface temperature must be at least 3 ° C above the dew point.

After the layer has dried (1 hour at 20 ° C), subsequent layers are applied.

To wash the instrument, you can use the solvent R-4, R-4A, a mixture of acetone and toluene.

Precautionary measures

The material is flammable! Do not work near open sources of fire.Perform work with good ventilation, wearing rubber gloves, using personal protective equipment

Avoid inhalation and digestion. If the material comes into contact with the skin, wash it off with warm water and soap. Store the primer indoors, excluding direct sunlight and moisture at an ambient temperature of minus 30 ° C to + 30 ° C.

This information is based on our laboratory test results and practical experience. As we update it and improve the materials, we reserve the right to change the above information without further notice.

Preparation for application

It is recommended to remove loose rust from the surface before applying the enamel coating. You should also remove the remnants of paint and varnish materials that are present on the metal.

When performing work, the following recommendations must be taken into account:

- use dry spray method only if properly trained;

- use those solvents that are suitable for the primer-enamel (the list is indicated in the instructions);

- do not use the painted product until the end of the drying period of the primer;

- apply enamel to a rough surface (otherwise the primer will not be absorbed).

In addition, it is recommended to clean the surface from dust, dirt and traces of grease. If it is necessary to paint smooth metal, the material is pre-processed with fine abrasive sandpaper. This will help increase the adhesion. It is also not recommended to apply less than one coat of the product. In this case, after processing, only rust deposits will be removed. Together with the corrosion, the primer will also go away. That is, as a result, the product will be unpainted and unprotected from the appearance of rust.

Execution of works

Before starting painting, the primer-enamel must be mixed with the solvent R-4 or R-4A. Also, compositions P-670 and P-670A are suitable for this tool. It is impossible to mix the primer-enamel with other solvents. This is due to the fact that the product prepared in this way will dry longer. And it is forbidden to use white spirit with this primer.

The proportions for the dilution of the solvent and enamel are not indicated by the manufacturer. The viscosity is determined based on how the product is applied (roller or brush requires a more viscous product than when spraying). You need to add the solvent in a large volume, constantly mixing with the primer.

This product is applied in the same way as any other paint. For small areas, you can use a brush or roller. When painting large items, it is recommended to use a spray gun or spray gun. In some cases, the enamel is applied by dipping items into the prepared mixture. But this option is suitable for small structures.

It is recommended to process metal surfaces at temperatures from -10 to +30 degrees. The humidity level should be 55-80%. The first coat of primer dries at room temperature within 1-2 hours. The metal can be re-processed only after the applied coating has completely dried.

After painting, the material must not be bent or subjected to mechanical stress. Because of this, the integrity of the protective layer will be violated. The enamel, as noted above, does not tolerate bending loads.

Description and features of the composition

Primer-enamel is a universal product intended for painting metal surfaces, including those covered with a layer of rust. The basis of the product is made of perchlorovinyl, alkyd and epoxy resins. The product also contains corrosion inhibitors, rust converter, pigments and plasticizers.

> This enamel can be used as an independent coating, which is applied in three layers:

- The first acts as a rust converter, which stops and prevents the development of corrosion.

- The second one plays the role of a primer, which not only provides anti-corrosion protection, but also increases the adhesion properties of the metal.

- The third acts as a decorative coating that also protects the material from external influences.

It is forbidden to use XB-0278 for processing non-ferrous metals. Moreover, this primer does a good job of protecting the car body from corrosion.

Primer-enamel is recommended for surface treatment with a layer of rust up to 70 micrometers thick. In this case, the material requires an additional layer of paint. The coating obtained after metal processing has the following characteristics:

- elastic;

- solid and durable;

- resistant to exposure to aggressive gases and solutions (therefore, suitable for use in industrial plants);

- tolerates contact with salt solutions heated to a temperature not higher than +6 degrees;

- the protective properties are maintained in moderate conditions for four years.

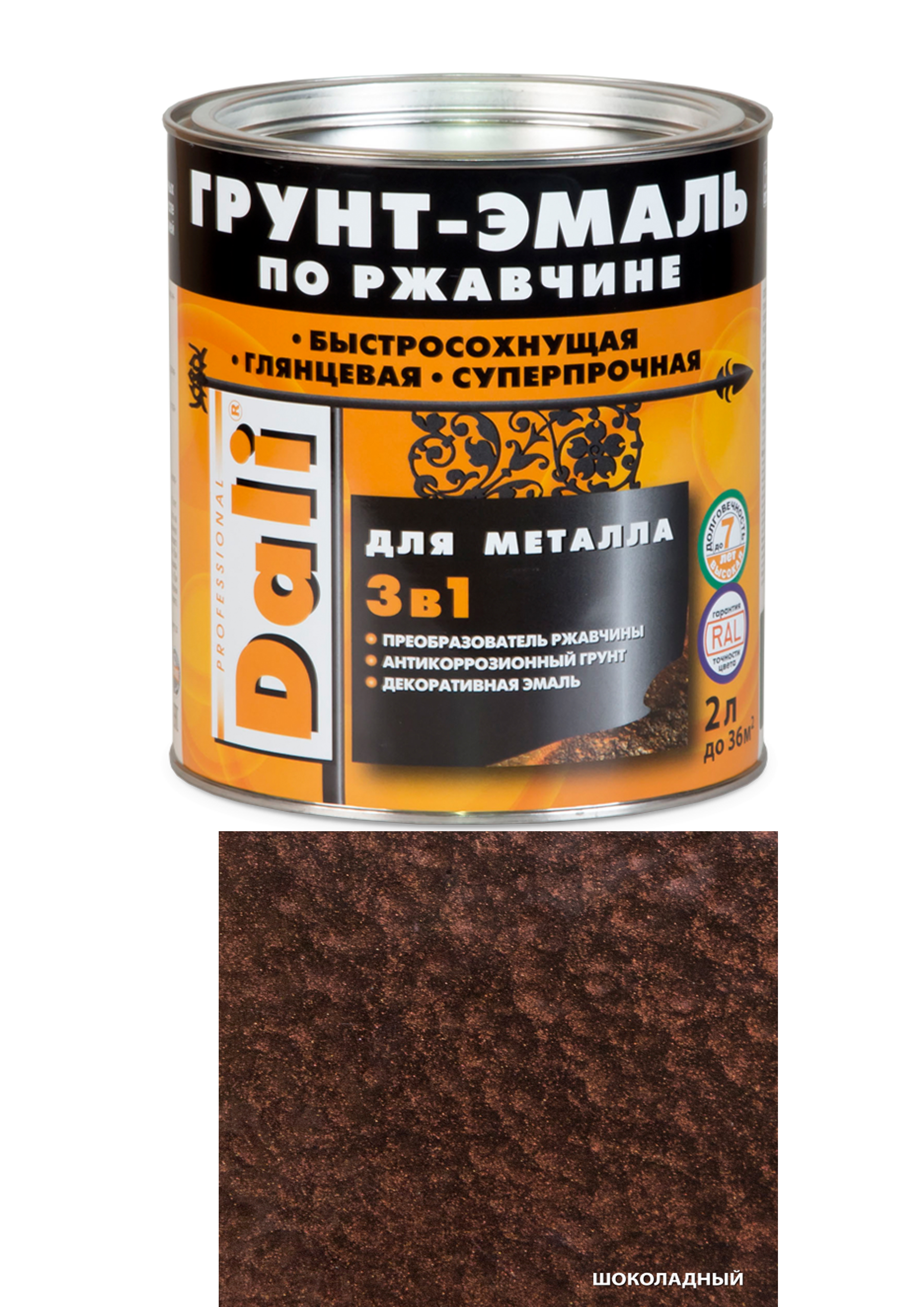

This enamel can have any color. Popular shades are yellow, white, brown, black and gray. But if necessary, at the request of customers, other colors can be mixed in production by adding appropriate pigments to the original resins.

Major mistakes when using

Most often, users make the following erroneous actions when working with a primer:

- Applying only one layer. Some, to save money, apply only one layer of the product - this is the wrong decision. Two or three coats are required according to the instructions to ensure the proper finish. Part of the enamel will be absorbed into the rust, while solid components remain on the surface. Achieving a good protective film will not work.

- Dry spray. This method is suitable if an experienced specialist will perform the work, and the equipment will be specially configured. Otherwise, the adhesion and durability of the coating will decrease.

- The use of an unsuitable solvent. You can use only those tools that are indicated in the instructions and are compatible. Other solvents will disrupt the properties of the enamel and will dry for a long time. White spirit must not be used for the primer!

- Early use of the product. After finishing the coating, wait until the complete polymerization occurs as the solvent and the primer itself dry. The film quality will otherwise be impaired.

- Application on a smooth surface. To ensure good adhesion (adhesion), the surface must be rough but free from contamination. The enamel is specially designed for rusty surfaces. Smooth materials should be roughened beforehand.

Observing all the tips and performing staining strictly according to the instructions will allow you to preserve the integrity of the products for a long time, protect them from corrosion.

Features and Benefits

Primer-enamel XB-0278 is a product with a unique composition. It has not only the properties of enamel, but also a primer and rust remover. The mixture can be applied on completely rusted or corroded substrates.

In the case of a three-layer application, the structure can be used even at sub-zero temperatures. The composition in such conditions will be able to perform its functions for 4 years, and its appearance will remain for 2 years. There are also more durable products with a service life of up to 15 years, however, they are very expensive.

The primer XB-0278 is used to paint both cast iron and steel, and surfaces with a large amount of scale. The thickness of rust can be 70 microns, while the composition will perfectly cope with its purpose, regardless of atmospheric conditions, the presence of emitted vapors or gases, chemicals or salts.

XB-0278 is perfect for painting surfaces that are difficult to clean for one reason or another. These include curbs, fences, iron bars or metal garages.

Some mechanics use a primer for light car repairs as well.Enamel is applied to parts that do not require decorative finishing.

XB-0278 has a very wide range of areas of operation, the product is universal and suitable for many jobs. It can be used to paint household or industrial structures, devices exposed to gases, various chemicals or reagents.

With this enamel, you can make an excellent base for a refractory surface.

The affordable price of the product is a big plus. For a liter of XB-0278, you will have to pay only 120 rubles.

The primer has a fairly wide color palette. The assortment includes enamels of brick, gray, black, yellow and blue colors. Thus, you can save money on the purchase of paint and time - on its application.

Additional recommendations for use

Primer-enamel XB-0278, the characteristics of which were presented above, should be applied at an ambient humidity that does not exceed 80%. If we are talking about coloring products, then dipping them into the composition is permissible. After applying the first layer, it should be left for 2 hours at a temperature of +20 ° C. All subsequent layers are applied at intervals of 1 hour.

It should be remembered that the material is flammable, therefore it is unacceptable to work with it near open sources of fire. Painting is carried out in well-ventilated areas, the technician should wear rubber gloves and use personal protective equipment. The primer-enamel XB-0278 gray should not get into the digestive organs, I should inhale the paint.

Applications

You can use the primer-enamel XB-0278 for painting:

- various metal structures, both at home and at industrial facilities;

- machines and installations that are constantly in contact with aggressive substances and vapors, water, reagents;

- metal covered with a layer of rust;

- cast iron, steel and iron, including areas where there are traces of scale or carbon deposits;

- large metal structures, including complex shapes;

- car parts.

Also, this primer is used to prepare the base, on which a refractory layer is then applied. If necessary, the enamel is used to paint reinforced concrete structures, including fences, walls and curbs.

Composition and specifications

The primer-enamel is made in accordance with the conditions of GOST: its composition and technical characteristics are fully certified and meet all the necessary quality standards.

The main ingredient of the mixture is perchlovinyl resin, which is used for the manufacture of parts that often interact with aggressive phenomena, as well as for the production of paints and varnishes with protective properties.

Primer-enamel has high technical characteristics. The level of conditional viscosity is ВЗ246, the amount of non-volatile substances is 35% in a multi-colored and 31% in a colorless composition. The tool is quite economically consumed: only 150 grams per 1m². The composition dries up in just an hour. After hardening, a dense, uniform and matte film is obtained.

The adhesion of the resulting film is 2 points, and the coefficient of efficiency of the rust converter is 0.7.

TU 2313-033-87391182-2011

| Type of | One-pack material based on perchlorovinyl, alkyd and epoxy resins. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recommended application | For painting clean metal surfaces (except for non-ferrous metals), as well as for surfaces that are difficult to clean for a number of reasons: large-sized products, a complex profile of the surface to be treated, the presence of scale and tightly adhering rust (layer up to 75 microns). It can also be used for car repair painting, for priming rusty surfaces, underbody, fenders and other parts that do not need decorative painting. | ||||||||||||

| Description | Primer-enamel XB-0278 can be used as an independent coating when applied in 2-3 layers (the first layer acts as a rust converter, if any, stopping the further development of corrosion on the metal; the second - as a primer, providing adhesion and anti-corrosion properties of the coating; the third - as a protective and decorative coating) and in a complex multi-layer coating with various enamels and varnishes. In this case, the primer-enamel can be applied on surfaces with a thickness of corrosion products up to 70 microns, and is covered with a finishing enamel (varnish). The resulting coating is elastic, has high hardness and strength, it is resistant in the atmosphere of industrial enterprises, to the effects of aggressive gases, vapors and salt solutions with a temperature not higher than + 60 ° C. In complex coatings, primer-enamel is used in various climatic zones. A coating of three layers of primer-enamel retains its protective properties for at least 4 years in a temperate climate. | ||||||||||||

| Certification | Certificate of state registration, valid throughout the territory of the Customs Union. | ||||||||||||

| Specifications 1 practical consumption depends on layer thickness, application method and conditions, surface roughness, product shape and color 2 single layer thickness on a vertical surface depends on the degree of dilution of the material, temperature, application method, surface roughness and product shape |

|

||||||||||||

| Diluent | Solvent R-4, toluene | ||||||||||||

| Cleaning tools | Solvent R-4, toluene | ||||||||||||

| Warranty period of storage | 12 months from the date of production |