Designer's tips for using 3D panels

Finishes with large volumetric textures are better suited for spacious rooms, while small patterns can be used even for small rooms.

The embossed wall itself, even in white, is a fairly noticeable decor.

It is not always worth focusing attention on it even more, painting it too brightly, with exciting colors.

If brightly colored panels are used, the other walls should be as light as possible.

Visually, the 3D effect will be noticeable in any light. In addition, it changes depending on the viewing angle.

To make it more obvious and interesting, the pattern is often illuminated with wall, floor, ribbon or ceiling lights.

If the design involves the use of relief locally, as a separate art object, volumetric panels are perfect.

Many manufacturers offer ready-made options, but you can also combine tiles from any collection to your taste.

It is important to choose the right material in color and shape. Elements can be distinguished by ultra-modern design, then they will be an excellent addition to high-tech, modern, techno styles.

Classic motives are more suitable for historical styles. And almost invisible, light and unobtrusive can be used even for ethnic ones.

Wall panels are not only a decoration, but also a decor, so they should not be covered by bulky pieces of furniture, they are almost never supplemented with separate accessories.

Sufficiently deep textures are suitable for decorating living rooms, offices or classrooms, while gentle, soft and laconic ones look better on the walls of bedrooms or bathrooms.

In addition to a variety of colors, surfaces are matte and glossy, which is also important to consider when choosing a material. Glossy coating gives more optical effects, visually expands the space

Matt simply stands out with its texture, creating the necessary mood, complementing the atmosphere with coziness and tranquility.

Types of decorative wall panels

In fact, it is not enough to paste over the wall with any panels you like. Only those finishes that are correctly selected in size, texture and material will be able to achieve the desired result, complement, decorate the interior. Before you go for such design delights, you should familiarize yourself with the features of the existing options, their advantages, as well as disadvantages.

Gypsum panels

Gypsum panels are one of the most common, they are safe, non-toxic, resistant to temperature changes, provide additional noise insulation, and have a long service life. The possibility of coloring allows you to update the room in just a few hours, add new notes. During installation, a seamless surface can be achieved. In case of damage, sandpaper and putty will help to carry out a quick restoration.

Plastic

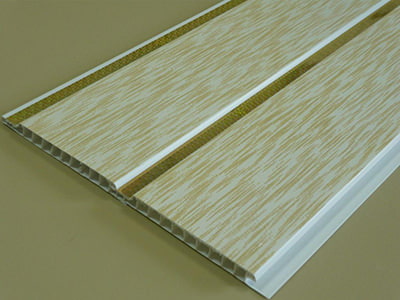

In the manufacture of PVC wall panels, technologies are used that allow you to create an imitation of many natural materials, including finishing stone and wood. Polymers also successfully imitate the texture of fabric or leather, and some collections include panels that are really covered with high-quality leathers or textiles. Plastic panels have no equal in a variety of colors and textures. The depth of the relief depends on the thickness of the material and ranges from 30 to 120 mm. Plastic tiles are lightweight, waterproof and easy to maintain.

Glass

This type of decoration appeared one of the last, has not yet had time to become very popular. Glass 3d panels for walls look very beautiful, have excellent quality characteristics, but not everyone can afford their cost. In addition, due to their heavy weight, they are not suitable for all walls, especially partitions.

Aluminum

Recently, they have been used with pleasure by both professional designers and ordinary homeowners who have decided to update the interior on their own. The finish is not afraid of exposure to temperatures or moisture, it is resistant to ultraviolet light, various alkaline environments. No further processing or staining is expected. Manufacturing technology allows you to experiment with texture and color. Due to their light weight, they can be mounted even on plasterboard partitions, but the panels are attached to the frame made of metal profiles, so they will take some area from the room.

Embossed MDF panels

Like the previous options, MDF panels can have a different texture, texture, color. They are made of a high quality compound that ensures stability and a long service life. However, they are not recommended for use in rooms with high humidity, for bathrooms, saunas, baths. Painted surfaces most popular with designers. A feature of MDF panels is the ability to use them not only as decoration for walls, but also for decorating partitions, furniture facades, doors.

Views

There are many types of panels, from textile to gypsum, therefore it is important to choose the right material and design walls for interior

Plastic

Due to moisture resistance, plastic panels on the wall are used in the shower, they are fireproof and have a long service life.

3-d panels

They create a unique interior due to the volume and 3-d effect on the walls. The texture is painted in different shades (glossy or matte) with acrylic paints, or covered with veneer.

Gypsum

Gypsum wall panels are very durable and provide sound insulation. They are lightweight, but they look monumental in the interior. There are imitations of stone, wood, volume and high relief.

Wooden

Wooden ones are the best option for a house or apartment because of the environmental friendliness of the material. For protection, they are impregnated with wax.

Pictured is a large living room with wood paneling and classic English-style interiors.

Bamboo retains heat and is less susceptible to change when exposed to moisture.

Veneered

Veneered look like solid wood, it is a thin cut of wood glued to an MDF or chipboard board. It is often used in the interior and is an affordable option for wall decoration.

Cork

Cork has a characteristic texture and a unique pattern that is suitable for the interior of the house. The cork retains heat, allows air to pass through, and creates sound insulation.

In the photo there is a tiled cork cladding, which creates additional soundproofing of the living room.

Fiberboard, MDF, chipboard

Fiberboard, MDF, chipboard are sheet and tile. This saves assembly time, it is convenient to lay out the drawing and combine colors. Fastened with glue or clamps.

MDF panels are pressed and glued with natural resins, retaining heat and creating sound insulation.

Fiberboard is not suitable for the bathroom, but it is resistant to changes in humidity in the room.

Particleboard chipboard is less durable and subject to deformation under the influence of changes in humidity or temperature in the room.

Rack panels are connected by grooves and attached to the crate, they are made of chipboard, MDF and other material.

In the photo there is a slatted wall cladding in the interior of a modern kitchen, which coincides with the design of the apron above the work table.

Soft

Soft ones are made of fabric, leather, felt, felt and are filled with a soft filler (synthetic winterizer, foam rubber). Suitable for a living room with a karaoke system, children's room. You can decorate one wall or part of it.

Mirrored

Mirrors are suitable for ceilings and walls, they will increase the space and reflect the light. There are glass and mirror-coated panels. The panels are more flexible and weigh less than glass.

Leather

Leather panels do not accumulate dust, like other soft panels, the wall is protected, the room is insulated. They are easy to keep clean.

Vinyl

Vinyl ones retain the pattern and will fit the interior of a loggia or balcony. They transfer moisture, are made in different colors and patterns of wood, stone, are attached to the crate.

Polyurethane

Polyurethane ones are smooth, embossed, combine 2-3 colors or a composition. Elastic, good shape, porous and lightweight.

In the photo, the wall is finished at the head of the bed with soft polyurethane in the interior of the blue-white bedroom, where the color balance is observed.

Advantages

When choosing one or another material for interior decoration, it is important to familiarize yourself with its pros and cons. To decide whether it is worth revealing the ceiling surface with MDF panels, it is necessary to study its positive properties.

So, several characteristics are attributed to the advantages of products.

- Reliability and long service life. Subject to the rules of installation and operation, the material can last at least 10 years.

- Excellent sound insulation properties. The installed panels will "muffle" the noise from the neighbors upstairs.

- Good thermal insulation performance. The material is able to retain the heat in the room for a long time and prevent the penetration of cold from the street. This property is especially valuable for owners of private buildings and owners of apartments located on the upper floors.

- Easy installation. No special skills are required to install the panels. All work can be done using the tool at hand. Installation is easy to do with your own hands, without resorting to the services of hired craftsmen.

- Cleanliness of finishing activities. To install MDF panels, in most cases it is not necessary to dismantle the old coating or level the surface. Finishing with such material refers to "dry", without dirt and debris.

- No risk of mold or insects inside the products.

- Easy maintenance. If the panels are dirty, just wipe them with a damp sponge or soft cloth. Contamination is easily erased from the surface of the cladding without the use of specialized products.

- Affordable cost. MDF boards are an inexpensive material that anyone can afford to revet the ceiling.

In addition to the above advantages, the panels have an attractive appearance. Curly, painted, laminated: the assortment of materials is varied, so you can choose a product for any interior style.

An example of wall decoration with MDF panels

Let's consider one of the options for panel wall decoration in more detail, namely, the installation of MDF sheets. Step-by-step instructions will help you figure out how to make a wooden crate correctly and fix the selected material on it.

Necessary tools for work:

- jigsaw;

- building level;

- plumb line;

- roulette;

- screwdriver;

- construction stapler;

- hammer, pliers;

- construction pencil or marker.

This is the minimum set of tools that will help you to do the installation of MDF panels on the wall with your own hands.

Finishing process step by step:

Wall preparation - removing the old coating, cleaning the surface, treating it from mold if necessary, sealing joints and cracks, priming. After the surface is completely dry, you can proceed to the next stage;

A crate is mounted on the prepared wall. For horizontal panels, the frame guides must be vertical, for vertical ones - horizontal;

If the wall needs to be leveled with lathing, hangers are used;

The step between the guides is 50-60 cm. The vertical is marked with a plumb line, the horizontal - along the level;

The first guide is fixed at the edge of the wall (in the corner or from the floor) using dowels and self-tapping screws. The following bars are attached in the same way, but each guide is checked again with a level or plumb line;

When using suspensions, threads are pulled from above and below between the extreme guides - beacons along which the remaining parts of the crate are attached;

Insulation is installed between the sections of the crate, if necessary;

Communications such as wires and cables are also laid inside the crate, taking into account the places for sockets and switches;

To fix the first panel, you must again use a level or plumb line;

The panel is attached to the corner of the wall with a thorn, fixed on this side with several self-tapping screws;

On the other side of the panel, at the point of attachment to the lathing guide, clamps are inserted into the groove and fixed on the lathing with small nails or staples

It is important that the head of the fastener does not interfere with the fastening of the next panel;

The spike of the next panel is inserted into the groove of the previous one and is checked against the level in order to eliminate backlash in the connection. Its groove is also fixed with clamps;

The last panel is cut to the width so that it fits into the groove of the previous one, but leave a gap of about 5 mm in the corner

It is fixed with self-tapping screws.

For such a finish, it is necessary to use decorative corners and skirting boards, which will hide the fastenings of the initial and last panels and give the wall a complete look.

Glue the corners on liquid nails

Glue the corners on liquid nails

In those panels that fall into the locations of switches and sockets, it is necessary to pre-make holes for these elements. If necessary, you can give the location of the communications rigidity using small pieces of timber fixed around the perimeter of the hole under the panel.

Inserts for sockets and switches

Inserts for sockets and switches

It is not difficult to finish the wall with the help of panels with your own hands, the main thing is to have the necessary tools, at least minimal construction skills and a clear understanding of the procedure.

Step-by-step video tutorial:

Varieties of wall panels

Finishing types

Depending on the shape, panels of the following types are distinguished:

• slatted type-setting - are oblong planks made of wood, chipboard, PVC, fiberboard or MDF. These interior wall panels are 240 to 370 centimeters long, 12.5 to 30 centimeters wide and 0.8 to 1.2 centimeters thick. The panels have grooves and spikes to connect to each other. Installation of cladding in horizontal and vertical orientation is allowed;

• tiled type-setting - are squares with sides from 30 to 98 centimeters long. Such wall panels are great for creating mosaics, because each of them has its own color and texture. Coating material - MDF, fiberboard, PVC and chipboard. To connect the plates, grooves and inserts are used;

• sheet - better than others have proven themselves when decorating large walls. The sizes of their sides can vary from 122 to 244 centimeters with a thickness of 0.3 to 0.6 centimeters. Unlike other materials, wall panels are made only of wood or resin-impregnated fiberboard.

Rack type panels of various widths

The methods of fixing the plates are different. So, slatted typesetting panels for wall decoration are fixed on the crate, tiled - with the help of clamps or adhesive. Glue is also used for fastening sheet panels, and the seams between the covering elements are masked with moldings. How to install PVC on the ceiling yourself? watch the video and read here.

Classic paneling solutions

When finishing with plastic panels with your own hands, you need to take into account not only the type of coating elements, but also the material of their manufacture.

Wooden products are considered reliable; they are made from wood species such as alder, maple, oak or cedar.

Sometimes the finish has a wax coating, due to which it can be used in rooms with high levels of humidity. Since wood wall cladding panels are environmentally friendly, they are recommended for use in residential areas.

Popular products made of fiberboard - a material consisting of woody plant fibers. They are also safe for human health, resistant to high humidity, but deteriorate in direct contact with water. In turn, facing panels made of chipboard for interior wall decoration are similar in appearance and qualities to wood. This is due to the fact that chipboard is a compressed waste from wood production. The disadvantage of this material is the poor tolerance of sudden changes in temperature and humidity conditions.

Panels made of MDF are highly resistant to almost any environmental factors. Fiberboards are produced by using the dry pressing method, therefore they are not afraid of moisture and mechanical stress. It is recommended to decorate the walls with MDF panels, such as those rooms where conventional materials are short-lived or ineffective.

All the types of panels mentioned are recommended for use in residential premises. With proper care, their service life will be more than 10 years. Wooden wall panels for wall decoration have a particularly long service life: if they are made of high-quality wood, they will retain their original appearance for several decades.

Panels from new materials

The panels made from gypsum vinyl are renowned for their reliability and durability. The material of their manufacture is a modification of drywall, and is similar in properties. Plastic panels for walls for interior decoration, which are not demanding on operating conditions and are easy to maintain, also demonstrated their best side.

New products on the building materials market are glass panels and 3D panels. The former are intended for applying photographic drawings to the surface of the walls, the latter have an unusual texture with a hypertrophied relief. 3D panels are made from all of the above materials, as well as from aluminum.

Wall decoration with plastic panels is allowed in residential, commercial and public institutions. This coating is often used in schools and kindergartens because it is considered environmentally friendly. In turn, glass panels are as safe as plastic and are able to withstand significant mechanical stress, but are less common because they are more expensive. The same goes for the increasingly popular 3D panels.

3D panels create an unusual effect

Use in different rooms

In the interior, a gypsum panel can become part of any room, even in a bathroom, moisture-resistant options seriously change the space.

In the living room

The living room or hall is the most demanded area for gypsum mix panels

In this room, it is important to create an atmosphere of relaxation, pleasant for the gathering of the whole family in the evening. Plates easily fit into any style of the living room, without conflict with other interior elements

If the living room is made in a classic style, then the panels are chosen such that an association with stucco arises.

Reliefs with wavy elements, geometric shapes, and abstraction are developed in modern living room interiors. The choice of pattern and shape should be subordinated to the already created interior conditions. If the room has a lot of plant motifs, sophisticated forms, plates with clear and strict geometry are unlikely to be in tune with the image of the living room. But each case is individual, therefore you need to try, experiment, arrange "fitting" in special programs. Sometimes even paradoxical solutions turn out to be the most successful.

In the bedroom

More often in the bedroom, the area at the head of the bed is made out with panels.There are also ample opportunities in color: it all depends on the preferences of the owner, someone sleeps well only in a bright room with light textured accents, someone needs darkness, depth of shades for a restful sleep. And the panels are ready for any options.

If the bedroom is large, you can create an antique style in it, which is perfectly built precisely due to such decorative elements as gypsum panels. But it is undesirable for the relief of the panels in the bedroom to literally cut the eyes. The best is a project in which the design is subordinated to the use of shades of the same color or adjacent colors. It is believed that this is a very good interior idea for the nervous system.

In the kitchen

In the kitchen space, gypsum panels are used less often, since high humidity prevails. But, firstly, you can use panels with moisture-resistant impregnation, and secondly, remove the panels from the cooking zone as much as possible. And if they decorate the wall of the dining area, and even in a really spacious kitchen, it will be an interesting and stylish option. If the panels are coated with enamel paints of the desired shade, they can be wiped clean with a damp cloth. In any case, such an option for a huge number of people is much more interesting than a boring tile.

In the corridor

If the corridor is small and narrow, the gypsum panels may not take root here - they will further emphasize the modest size of the space. But there is a solution: these are panels with imitation of a carriage coupler. In a classic corridor, such slabs look very organic and stylish. It is difficult to immediately understand whether this is a real leather tie or an imitation of it.

Guaranteed quality

The production of panels is carried out in accordance with the latest German developments. A multi-stage control system for all processes has been introduced, the quality management system is certified according to ISO 9001. All this allows us to produce 3D gypsum panels with a unique porcelain effect - due to an increase in the density of the material, bubbles do not form in it, the surface is even and does not stain hands. The use of our own strong molds for casting guarantees the ideal geometry of each finished product, so that you can create monolithic compositions of unlimited sizes without visible seams and noticeable transitions. The relief depth is guaranteed to be the same for every panel in the same collection.

Can be used in any interior

You can buy decorative panels for your home, office, shop or other object, made in the style of baroque, art deco, minimalism, steampunk, hi-tech and more. Our catalog includes a wide range of products that can be used alone or in combination with wood, leather and other decor. At the same time, in any interior, our panels remain the center of attention and create a positive atmosphere. Depending on the wishes of the customer, the craftsmen during installation can paint the products in any color from the catalog.

Security

We produce 3D gypsum panels for walls from safe premium quality gypsum, free from alabaster, plasticizers and other foreign substances. Our products are environmentally friendly, do not increase the background radiation, unlike most concrete products. Artpole panels are non-combustible (fire hazard class KM0), therefore they can be used even in places of fire evacuation.

Ease of installation

Decorating with Artpole panels does not take much time: perfect geometry, detailed instructions and light weight significantly reduce the labor costs of the craftsmen. Thanks to the repetition of the decor on the back side, our panels weigh less (they can be held with one hand), reduce the load on the floors, so there is no need to spend time on additional reinforcement during finishing. A number of models from our range can be mounted on any base, without prior preparation. The ideal geometry allows the panels to be laid in a monolithic sheet without seams, creating exclusive decors.

If you still have questions about Artpole 3D gypsum wall panels, ask our specialists at one of the free phone numbers. You can familiarize yourself with the collections presented on the site in our company stores in Moscow or at partners in different cities of Russia and other countries.

TECHNOLOGY: In the summer of 2012, a new Russian production of gypsum panels ARTPOLE was opened. When creating the technological line, the latest German developments were used, allowing to obtain gypsum panels with the effect of "Porzelan Plaster" (gypsum with a porcelain effect), which have no analogues in the world. The technology was implemented in cooperation with leading Russian specialists from the Mosstroy Research Institute.

ABOUT THE PRODUCT: In this catalog we present new collections of 3D decorative wall panels for interior decoration Artpole, made of plaster using a unique German technology.

Wood panels for wall decoration: varieties and classification

There are many wood finishing materials on the construction market, which are classified according to the characteristics:

There are many wood finishing materials on the construction market, which are classified according to the characteristics:

- The form. Slats and plates. Reiki is 2.5-3.7 meters long. The width is also different. Collect slats using spikes, grooves. Installation is carried out in different ways: horizontally, vertically, diagonally. The slabs are square. They will pave the wall from the floor to the middle? And also used as a separate insert.

- Material. Facing material is made of natural wood, fiberboard, chipboard, MDF.

The cladding has a different cost. It depends on the material being made - it will be a valuable wood species or particle board.

Rack decorative

These are long slats, up to 3.7 meters long, up to 30 cm wide, their thickness is different. They are made of wood, PVC, fiberboard and other materials containing wood shavings.

Use slats for finishing small rooms where there are many projections (corners). If the decoration is light colors, its application visually enlarges and brightens the room, the corridor.

Fixing the slats horizontally - stretches the room in length, vertically - the high ceiling is visualized. Installation is carried out on a frame base with staples or self-tapping screws.

Natural wood

Facing material made of various types of wood is appreciated for its unique pattern, shades and play of colors, as well as for its warmth and comfort. During processing, the wood is handled carefully in order to preserve the textured pattern and shade. In most cases, the panels are not painted, but covered with a colorless varnish for expressiveness and protection from external factors.

Wood material can be called capricious - it does not tolerate moisture or sudden changes in temperature. Constant exposure to hot air is also unacceptable. Humidity and temperature should be optimal.

Fasten the cladding to the created lattice of metal profiles or wooden slats.

Pressed panels

Cladding made of pressed wood shavings is not toxic today. Thanks to new technologies, the composition does not include phenolic glue. The production takes place under great pressure. The pricing policy has not changed. The panels are still available to the middle class and perfectly decorate the premises.

Cladding made of pressed wood shavings is not toxic today. Thanks to new technologies, the composition does not include phenolic glue. The production takes place under great pressure. The pricing policy has not changed. The panels are still available to the middle class and perfectly decorate the premises.

Facing material is produced in various colors, with patterns or "wood imitation", monochromatic.

Some of them are covered with colorless varnish, while others can be painted on their own, giving individuality and achieving the desired result.

You can mount the material on a rough base in three ways: frameless: on glue, self-tapping screws and a frame.

Artificial panels on the wall under the tree

The cladding is made of polyvinyl chloride. Painted to match the color of the tree. The textured drawing can be exactly the same as a tree in section. These panels are used for finishing wet rooms, balconies, corridors, living rooms in private houses, loggias and attics. In the place where natural wood can swell or crack, PVC will retain its original appearance for a long time.

This material has a generally rack-and-pinion shape. Fasten it to glue, frame base.

Self-adhesive panels

Self-adhesive panels are made of PVC and MDF. They are easy to install (without dirt, dust, without reducing the space of the room), and they are also durable.

Self-adhesive panels are made of PVC and MDF. They are easy to install (without dirt, dust, without reducing the space of the room), and they are also durable.

The material has a number of features, among which the influence of moisture is unimportant, improved sound insulation, durability without loss of appearance. Different in shape, rail, square

Mount on the entire wall or partially, chaotically

They are different in shape, rail, square. They are mounted on the entire wall or partially, chaotically.

The manufactured material is safe for human health.

What are the panels

Manufacturers offer a wide range of 3d slabs, because wall panels are made from various materials that have their own advantages and disadvantages.

- Gypsum panels. Flexible and plastic gypsum allows you to realize a wide variety of patterns and textures, and a wall composed of several such panels seems to be solid, since the gaps between them can be easily covered with the same gypsum imperceptibly. In addition, this material is paintable. The disadvantage is the significant weight of gypsum panels compared to plastic or MDF.

- Plastic panels. Considered a budget option. In addition, they are moisture resistant and lighter. Wall panels made of plastic lend themselves to painting, and their installation is quite simple: they are attached to the wall with glue or a metal frame. The downside is their flammability, which makes it impossible to use 3D wall panels in the living room interior directly next to the fireplace.

- MDF panels. They are made from wood fibers by gluing. The material is environmentally friendly and reliable, but much cheaper than wood. Differs in high performance and reliability. It is used to decorate rooms with a humidity of not more than 80%. Embossed panels made from compressed wood fibers are attached to the wall with brackets. The advantages include high noise and heat insulation. Wall panels made of MDF can be painted and laminated. Of the minuses, we single out the need for careful care for them, since over time it loses its appearance somewhat.

- Bamboo panels. Materials made of natural wood are also popular. The most commonly used for the manufacture of volumetric decorative slabs is bamboo. Low cost, environmental friendliness, ease of installation and excellent appearance open up many opportunities for using bamboo 3d panels in the interior. However, unfortunately, such panels are short-lived and have low moisture resistance, so they are not very suitable for a bathroom or kitchen. They are usually used in bedrooms or living rooms.

- Aluminum panels. The volumetric image on the surface of aluminum plates is obtained by perforation, and on top is covered with a special film that serves to protect the panel from corrosion. Therefore, aluminum wall panels are sufficiently moisture resistant. In addition, they are fire resistant and very durable. Therefore, it is permissible to use aluminum 3d wall panels in the interior of a living room with a fireplace. This material does not require special care and practically does not get dirty, however, this luxury is worth it.

Room interior with 3D panel

Room interior with 3D panel

Squares in 3D panel

In order to make it easier to decide on the choice of panel material for your interior, we will give their comparative table:

|

Gypsum |

Plastic |

MDF |

Bamboo |

Aluminum |

|

|

Ease |

— |

+ |

+ |

+ |

+ |

|

Moisture resistance |

— |

+ |

+ |

— |

+ |

|

Fire resistance |

+ |

— |

— |

— |

+ |

|

Durability |

+ |

+ |

— |

— |

+ |

|

Price |

Depends on the complexity of the drawing |

Average |

Average |

Low |

High |

|

Mounting |

Self-tapping screws |

Adhesive or metal frame |

Brackets |

Glue |

Special profiles |

Living room interior with 3D panel

Living room with 3D panel

Bedroom with 3D panel