What is GML

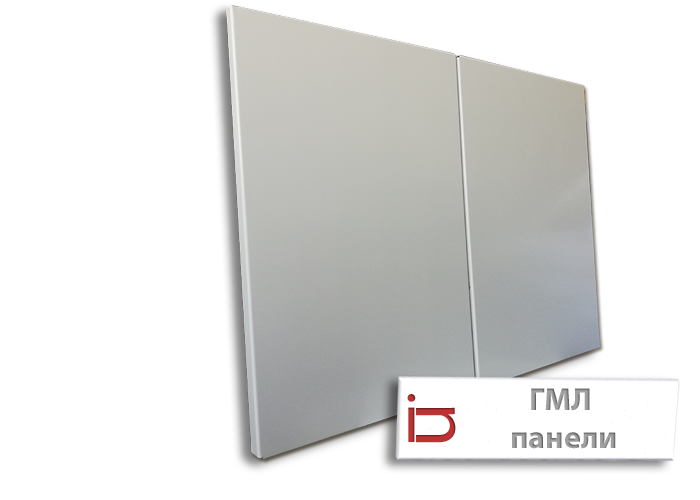

GML is a flat panel consisting of 2 main components: the well-known drywall and galvanized sheet on the front side. These gml panels are used for finishing the premises. Once installed, these panels do not need to be primed, putty or painted. The advantages of these panels are that they are quickly mounted to partitions and just as quickly dismantled.

Sheet metal with a thickness of about 0.55–0.7 mm in this case plays the role of a protective shell (it protects the drywall from damage, for example, upon impact), as well as the basis for the finishing polymer coating. For these purposes, use:

- galvanized steel (grades FePo3G, 08 Yu, 08 KP - with a zinc layer of at least 20 microns);

- sheet aluminum rolling;

- stainless steel (brands AISI 304, 430).

Stainless steel can be used in its pure form, and zinc and aluminum in most cases are covered with several technological layers on both sides: on top - a passivation layer, primer, polymer coating, self-adhesive protective film; bottom - passivation layer, primer, protective varnish / paint.

One of the following options is used as a material for creating a topcoat:

- pural, plastisol, polyester varnish, polyester;

- vinyl layer 0.5 mm thick;

- stainless steel sheet 0.5 mm thick.

The most common is polyester spraying with a thickness of 25 microns, as well as thermal painting with a mixture of polyester and epoxy resins with a thickness of about 130 microns. At high temperatures, polymer particles are sintered and polymerized on the surface of a metal workpiece (many are familiar with the so-called powder coating). Fused powder coating has good adhesion to metals, it can withstand abrasion, shock and bending effects; does not collapse under the influence of ultraviolet radiation and high / low temperatures (from -60 to +120 degrees). This coating is extremely resistant to corrosion.

The color of the coating can be any according to the international RAL catalog, but RAL 9002 and RAL 9003 are considered standard. As a rule, you can choose a matt, semi-matt or glossy surface.

The core of the gypsum board is made of plasterboard, which acts as a form-forming base and gives the product spatial rigidity and geometry stability. Depending on the specific tasks set, manufacturers use not only standard wall sheets - moisture-resistant, fire-resistant, perforated acoustic gypsum board, gypsum fiber (GVL) are enclosed in a metal wrapper. To create GML ceiling cassettes, lightweight plasterboard with a thickness of 9.5 mm is used. In accordance with the traditional dimensions of gypsum plasterboards, the dimensions of gypsum panels are obtained:

- width - from 600 mm to 1200 mm;

- length - from 600 mm to 4000 mm (more often 600, 900, 1200, 2500, 3000 mm);

- thickness - about 10 mm and 13-13.5 mm.

Within these limits, gypsum metal manufacturers can produce panels of arbitrary sizes to order.

The metal sheet is glued to the drywall with a special moisture-resistant glue, which provides greater bond strength, it is much more reliable than the drywall itself if you try to delaminate it. Note that a GML can be made to order, which will also be protected by metal from the back plane.

A sheet of metal covers the front of the panel and, with a radius of approximately 1.5 mm, bends around the edge of the drywall pasted over with cardboard. On one side, it forms a flange intended for installation.

In another design, there is a slightly smaller spike-eyelet (about 10 mm) on both sides; these are panels with an independent type of fastening.

What is the cost of gypsum metal and what does it depend on?

GMF is a fairly economical material, because produced in Russia using imported lines. When ordering it, manufacturers usually try to deliver it to the buyer as soon as possible.

The cost per square meter of a GM plate starts at seven hundred rubles.Further, depending on the properties required by the customer, it can increase:

- when ordering an unusual color;

- when it is necessary to use other types of drywall as the core of the board, for example, if the customer wants the material to be fire-resistant or water-repellent, or have sound insulation.

If you add up all the allowances, then the cost, at first glance, turns out to be not so low. But if we take into account that GMFs do not need preparation for installation and can be used immediately, and the sheathing process itself is extremely simple, then the benefits become obvious. One has only to estimate what the multi-layer structure created using conventional facing materials will cost, and add here the funds that will be paid to the workers, and the cost of gypsum metal no longer seems so great, and often even much more profitable.

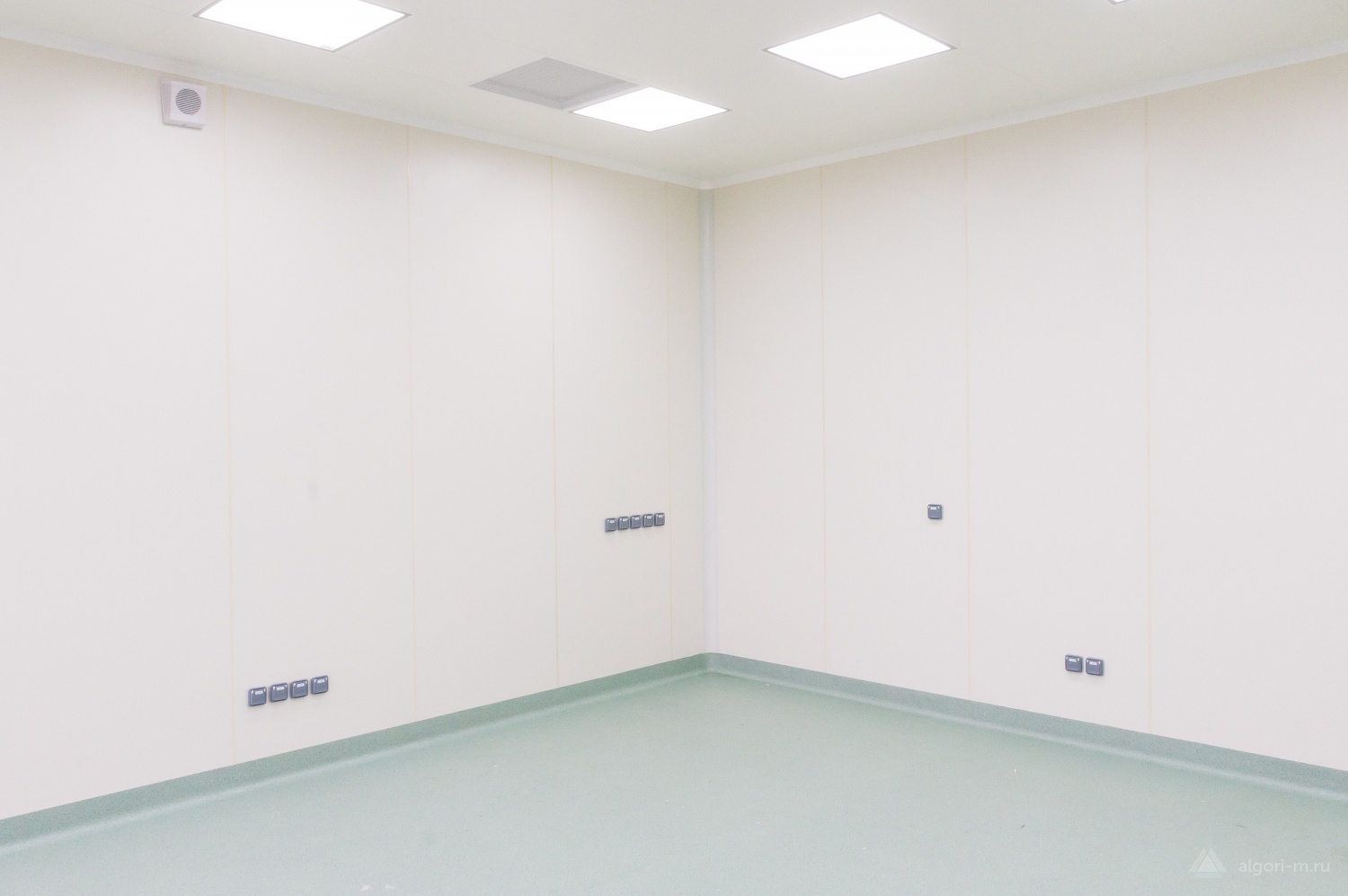

In the area of cleanroom cladding, gypsum plasterboards are at the forefront. The number of their competitors is minimal. In terms of practical and functional indicators, laminated plastic panels have gone not far from the GMF, but their initial price is almost twice as high. Other cladding options, such as laying tiles, painting walls with latex paints, gypsum vinyl, cannot be compared with GM panels, and do not have a sufficient set of qualities to be used in rooms where it is necessary to maintain a high level of cleanliness.

From all of the above, we can conclude that GMF is an advanced modern building material that has a number of unique qualities that put it one step above the traditional methods of surface cladding in clean rooms.

What is GML

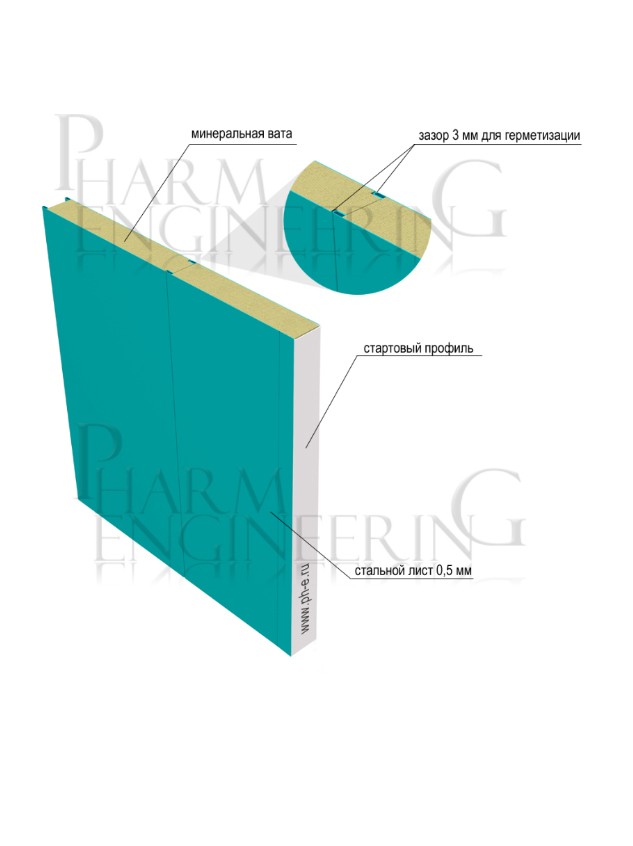

Gypsum sheet or panel (GML or GMP) is a flat multi-layer cassette plate, consisting of a front metal shell and a core made of the familiar plasterboard. This material is used as a finishing cladding for walls and ceilings indoors. GMF claddings are an example of absolutely dry construction, since they do not require any spackling, painting or priming after installation. They are quickly, without the formation of a large amount of garbage, collected, can also be easily dismantled. Below we will talk about installation in more detail, while we talk about the design of GM panels.

Sheet metal with a thickness of about 0.55–0.7 mm in this case plays the role of a protective shell (it protects the drywall from damage, for example, upon impact), as well as the basis for the finishing polymer coating. For these purposes, use:

- galvanized steel (grades FePo3G, 08 Yu, 08 KP - with a zinc layer of at least 20 microns);

- sheet aluminum rolling;

- stainless steel (brands AISI 304, 430).

Stainless steel can be used in its pure form, and zinc and aluminum in most cases are covered with several technological layers on both sides: on top - a passivation layer, primer, polymer coating, self-adhesive protective film; bottom - passivation layer, primer, protective varnish / paint.

One of the following options is used as a material for creating a topcoat:

- pural, plastisol, polyester varnish, polyester;

- vinyl layer 0.5 mm thick;

- stainless steel sheet 0.5 mm thick.

The most common is polyester spraying with a thickness of 25 microns, as well as thermal painting with a mixture of polyester and epoxy resins with a thickness of about 130 microns. At high temperatures, polymer particles are sintered and polymerized on the surface of a metal workpiece (many are familiar with the so-called powder coating). Fused powder coating has good adhesion to metals, it can withstand abrasion, shock and bending effects; does not collapse under the influence of ultraviolet radiation and high / low temperatures (from -60 to +120 degrees). This coating is extremely resistant to corrosion.

The color of the coating can be any according to the international RAL catalog, but RAL 9002 and RAL 9003 are considered standard. As a rule, you can choose a matt, semi-matt or glossy surface.

The core of the gypsum board is made of plasterboard, which acts as a form-forming base and gives the product spatial rigidity and geometry stability. Depending on the specific tasks set, manufacturers use not only standard wall sheets - moisture-resistant, fire-resistant, perforated acoustic gypsum board, gypsum fiber (GVL) are enclosed in a metal wrapper. To create GML ceiling cassettes, lightweight plasterboard with a thickness of 9.5 mm is used. In accordance with the traditional dimensions of gypsum plasterboards, the dimensions of gypsum panels are obtained:

- width - from 600 mm to 1200 mm;

- length - from 600 mm to 4000 mm (more often 600, 900, 1200, 2500, 3000 mm);

- thickness - about 10 mm and 13-13.5 mm.

Within these limits, gypsum metal manufacturers can produce panels of arbitrary sizes to order.

The metal sheet is glued to the drywall with a special moisture-resistant glue, which provides greater bond strength, it is much more reliable than the drywall itself if you try to delaminate it. Note that a GML can be made to order, which will also be protected by metal from the back plane.

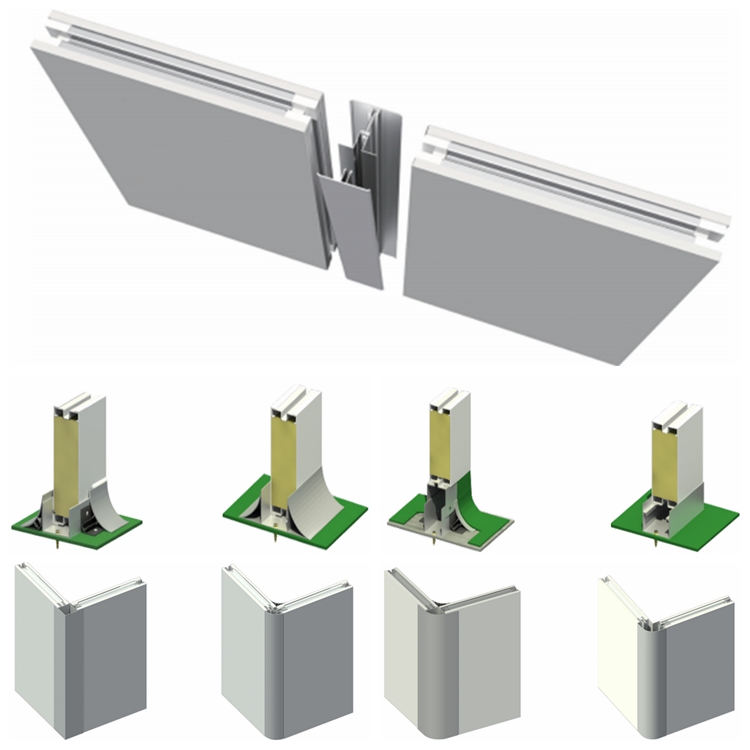

A sheet of metal covers the front of the panel and, with a radius of approximately 1.5 mm, bends around the edge of the drywall pasted over with cardboard. On the one hand, it forms a flange for mounting.

In another design, there is a slightly smaller spike-eyelet (about 10 mm) on both sides; these are panels with an independent type of fastening.

Where are gypsum panels used?

Walls and ceilings made of gypsum metal in their technical and operational characteristics differ significantly from all other finishing options, therefore the scope of application of the GML is more specific. Let's first outline the main features of the material.

The planes lined with gypsum sheets are completely sealed. As a result: the air masses of the room do not come into contact with the materials of the rough walls and ceilings, there is no diffusion of substances through the body of the panels. There are no leaks and overflows if the pressure inside the room jumps sharply (for example, if the doors of a clean room are opened with excess pressure).

Matt and semi-matt walls and ceilings do not create glare even in strong side lighting, therefore they do not interfere with the work of the staff.

Due to the fact that the joints of the panels are sealed with a sealant, the fasteners are hidden, and all the corners are rounded - dust, moisture, and various kinds of dirt have nowhere to accumulate.

The seams remain flexible, so the system can be used correctly even in seismic areas. For the same reason, this cladding is highly resistant to vibrations generated by equipment, as well as the overpressure that is generated inside "clean rooms" in order to maintain a stable air composition.

The outer polymer coating of the GMF does not emit any aerosol particles into the air, it can withstand regular exposure to disinfectants such as, for example, alcohol, 6% hydrogen peroxide and 3% chloramine. Most importantly, it is free from porosity or significant roughness that could trap moisture, microbiological and chemical contaminants. Such characteristics of the polymer coating fully comply with the requirements of GOST R ISO 14644–4–2002 “Cleanrooms and associated controlled environments. Part 4. Design, construction and commissioning ”. Thanks to the precious metals (silver ions) contained in epoxy-polyester powder, the finish coat has a pronounced antibacterial effect on many pathogens of hospital infections, which can settle and grow even on flat surfaces.

GMF cladding systems can be easily integrated with all components of cleanrooms (pass windows, doors, locks, lighting and ventilation devices, internal and external communications).On the gypsum metal, overhead and built-in wiring products are easily mounted and sealed, technological holes and openings are organized, for example, for installing exhaust or heating grilles.

Flammability, flammability, smoke-generating ability, toxicity - gypsum metal tolerates fires very decently, significantly increases the chances for people to leave the building on time (classes G1, B1, D1, T1, respectively).

So, clean rooms are where gypsum cladding reveals itself in all its glory. Clean rooms are called rooms with strict environmental control when it is necessary to minimize the amount of foreign and harmful particles: anaerobic bacteria, dust, inert chemical and aerosol vapors. In addition, in such environments, pressure, humidity, and temperature can still be regulated.

Most often, this is the medical industry - the organization of birth, intensive care, operating units. Naturally, you cannot do without a stable environment in research laboratories. Also, a clean room lined with plaster metal is used in several dozen industries, where foreign substances can significantly affect the quality of products. For example, it is believed that up to 70 percent of cleanrooms are used to create pharmaceutical and microbiological products, electronic components (especially semiconductors), and micromechanical devices. Increasingly, GMF can be found in food processing plants.

In fact, these panels are not only suitable for clean rooms. Due to its high strength characteristics and excellent moisture resistance, gypsum metal is successfully used for finishing garages, car washes, warehouses and workshops. Connoisseurs of the laconicism of the high-tech style immediately noticed this material, especially since, in addition to RAL colors, it became possible to create a coating “imitating a tree”, “marbled”, “metallic”, etc. centers, clubs, restaurants, and even used in apartments and cottages.

Installation methods

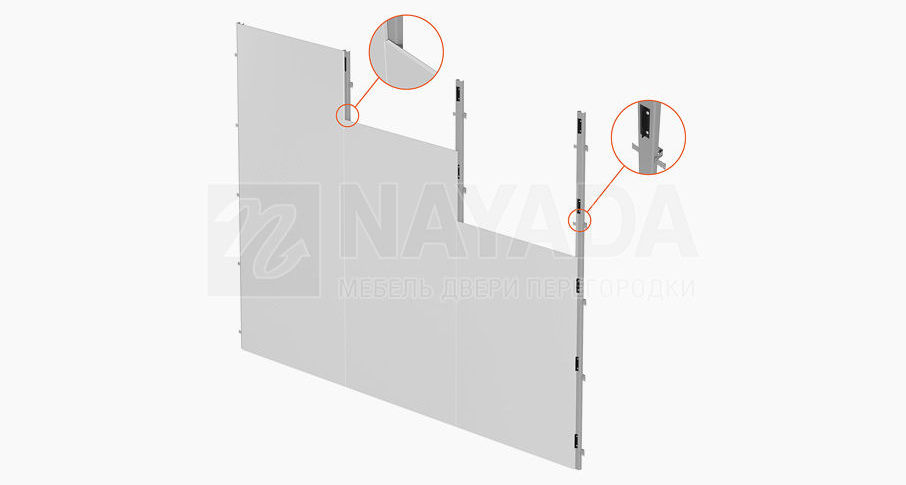

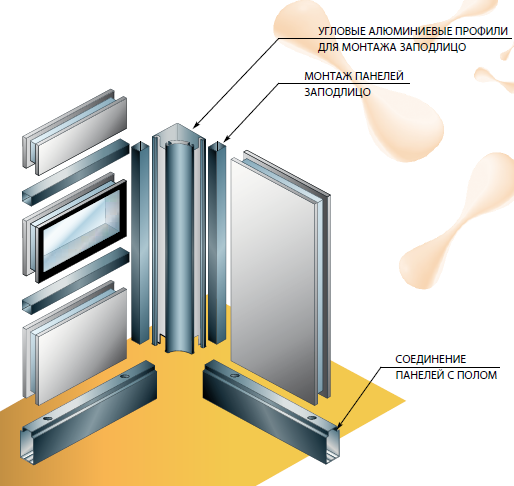

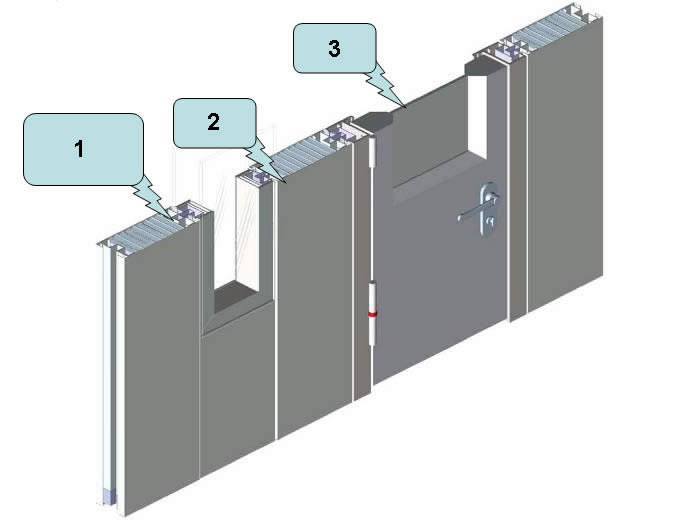

There are two methods of installing gypsum panels that are practiced today.

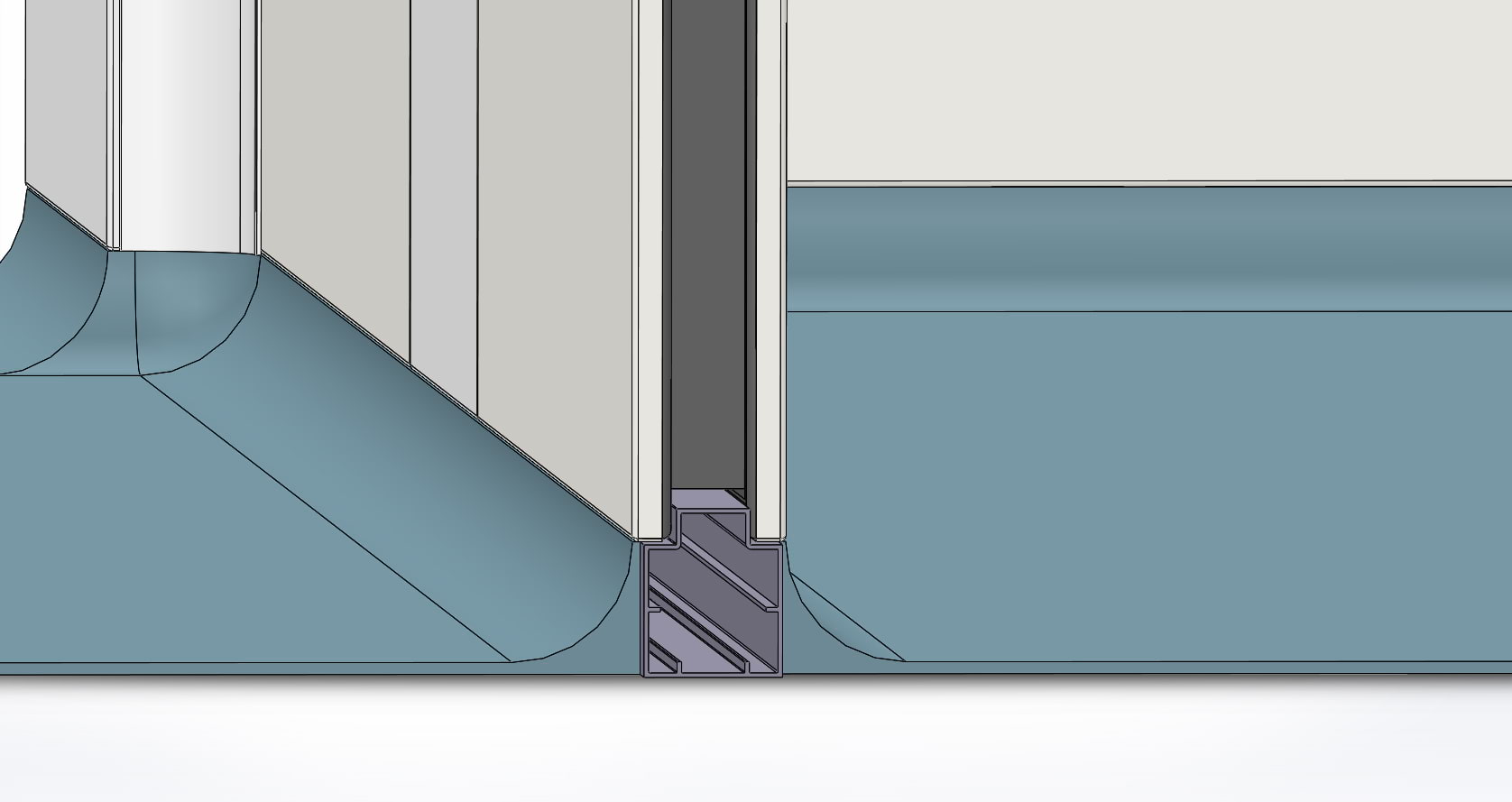

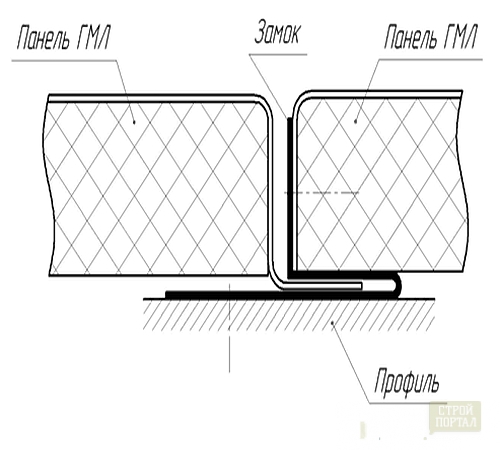

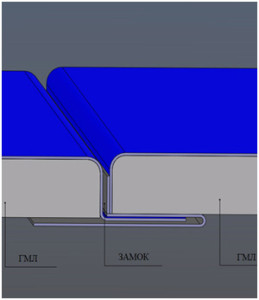

- Independent. This method involves joining the sides of the panels butt-to-joint or overlapping. When installing panels in this way, a gap will always form between them, which can be bridged using a special profile. The main advantage of the independent installation method of GM panels is the ability to dismantle each individual panel.

- Stationary. This mounting method is more acceptable. It implies a strong joint of the studs and a reliable connection of each groove. A feature of the method is the installation of special locks on each panel using self-tapping screws, which ensure the connection and fastening of the product to each other.

Each of the above methods are practiced, and they have something in common - the need to seal each joint. In the process of independent installation, when the gap width reaches 8 mm, a special silicone figured seal is used to seal the joints. And if the installation is carried out by a stationary method, and the seams are no more than 2.5 mm, use a sealant, silicone.

You can find out about the features of the gypsum plasterboard type GMP-S from the video below.

GML ST / GML FR gypsum panels

Gypsum panels are designed and recommended for use in clean rooms of the medical, electronic, food, microbiological, pharmaceutical industries, hospitals, laboratories, as well as other branches of the modern economy. GML panels are easily mounted into a frame profile, have an impeccably smooth surface, are non-toxic, non-flammable, ideally combine with all elements of the wall structure, can be made to any individual format and painted in any color from the proposed color card. Therefore, wall fences with a GML base are optimal for creating clean rooms in any branch of medicine and industry.

In favor of GMLPANEL gypsum panels is the fact that they allow you to form practical wall structures, including all the elements necessary for a clean room: ventilation, heating, lighting, engineering and technology and others. With a certain fastening system, each wall block, as well as its components, can be easily dismantled (for replacement, repair, transfer)

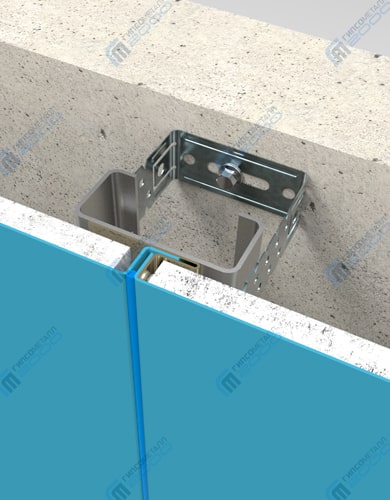

To ensure that the wall railing does not accumulate dust, special attention is paid to the docking mechanisms and fastening systems. If the cleanroom is designed once and for all, you can limit yourself to the standard (kleimer) fastening mechanism

In other cases, it is advisable to choose a U-shaped fastening profile, which provides instant installation-dismantling of the GML panel

The cladding, in addition to finishing the walls, performs heat and sound insulation functions. The fastening technology eliminates the possibility of dust accumulation in panel joints and seam spaces. All fasteners and joints are hidden. GMP panels are manufactured by GMLPANEL LLC under the GMLPANEL trademark according to TU-5284-002-84316168-2013 and are certified for compliance with the requirements of GOST ISO 14644 and GOST R 52539

How plaster metal panels are mounted

Gypsum sheets are installed on main walls and ceilings, and are also used for cladding frame partitions. As a rule, GMFs are mounted on metal subsystems, but it should be noted that they can also be fixed on a solid wooden or plastered wall. If the fixing is made on a mineral base, then it must be perfectly aligned, fixing is done using expansion dowels with a diameter of 6 mm.

The frame for walls made of GMF is assembled from a galvanized profile CD and UD (wall thickness 0.5–0.7 mm), using straight hangers. The rules for organizing the frame are fundamentally no different from those that are used when working with traditional GCR. The main technological nuances can be found in the article "Plasterboard Walls". Just note that it makes no sense to place the racks more often than 600 mm along the axes. In addition, horizontal arrangement of CD carriers with the same pitch is allowed. It is not necessary to place frame profiles under all joints of the sheets - that is, jumpers are not needed.

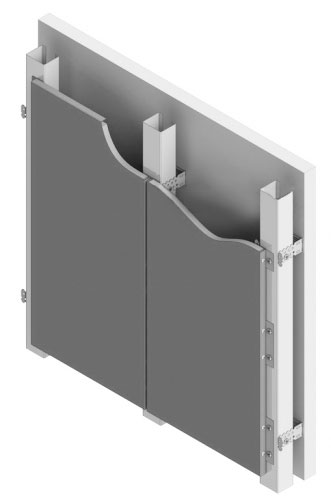

Fastening of panels to racks or planes can be carried out in one of two ways, depending on the type of flanging of the edges of the metal sheet:

- independent

- stationary

In any case, all fasteners are hidden in the area of the seams. No self-tapping screws with sweat, which are recessed into the body of the panel, are not used here.

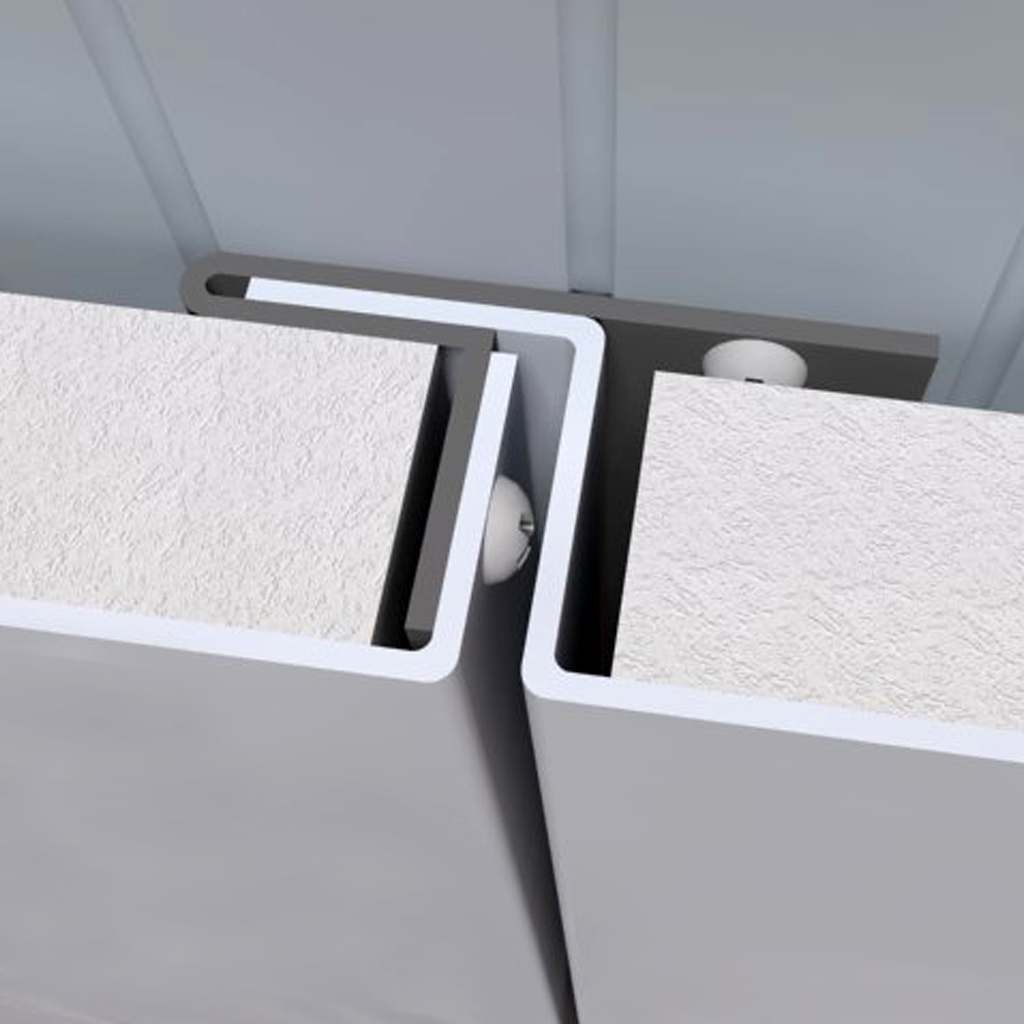

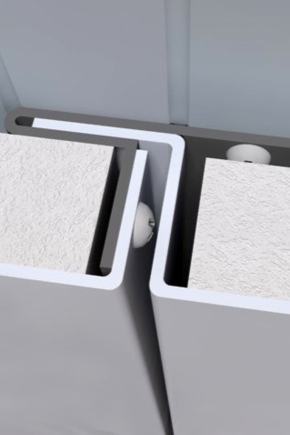

With an independent mounting method, each panel can be quickly dismantled separately. In this case, on each side of the gypsum sheet there are sides, during installation they are joined or superimposed on each other (then the fastener, screw or dowel, double metal passes through). A distinctive feature of this method is a large gap, which is closed with a special elastic profile.

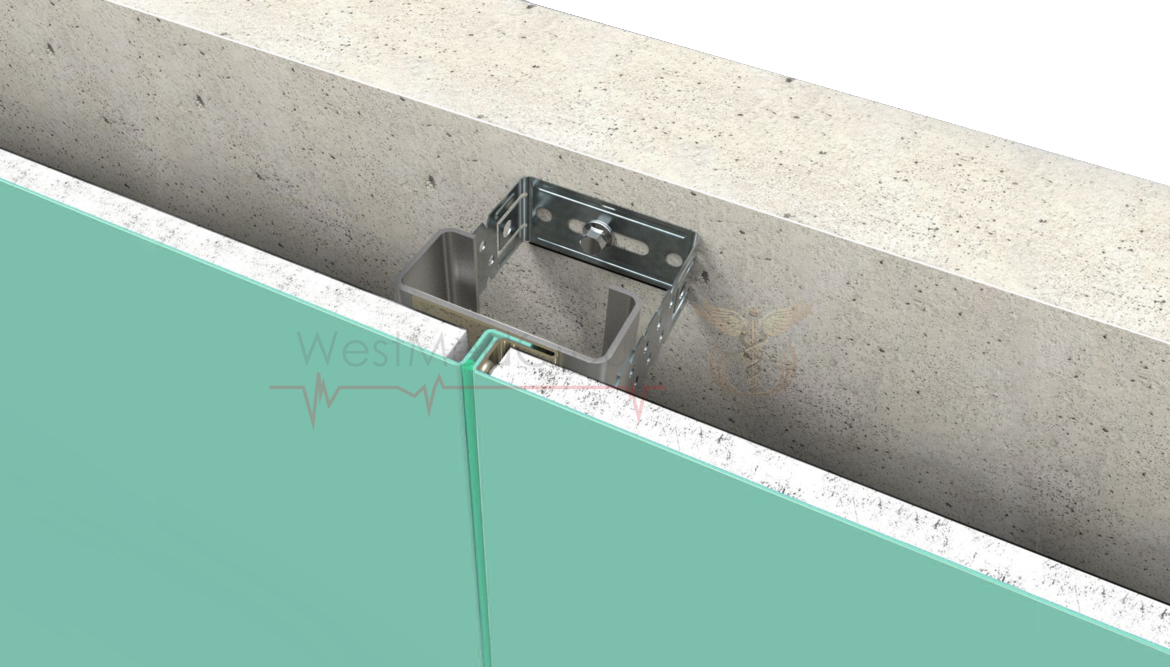

When using a stationary fastening method, the plane is assembled according to the thorn-groove principle, like a lining. First, metal locks are attached to the sidewall of the panels, which are also powder-painted. For wall panels, 2 pieces are used per linear meter, for ceiling panels, 3-4 locks are installed per meter of seam. Fixation of the lock to the end of the GML is carried out with self-tapping screws for metal (or holes are drilled and blind rivets are used).

Then the plane is assembled similarly to a plastic lining: the groove-lock petals are fixed on the supporting base (self-tapping screw, rivet or dowel), the spike of the next panel is inserted into the groove of the previous one and everything is repeated.

Whichever method of installation is used, the joints of the panels must be sealed.A large gap of 8-10 mm, which is formed with independent fasteners, is closed with a shaped sealing profile made of medical silicone. Thinner joints (2–5 mm) remaining during permanent installation are filled flush with the plane with one-component silicone sealants. The sealant should be neutral cured, sometimes containing fungicidal additives.

Gypsum sheets intended for ceiling cladding can also be fixed to profiles with rivets or self-tapping screws, but more often they use installation without mechanical fasteners in order to have quick access to the inter-ceiling space where utilities are laid. Some models of GML ceiling cassettes have an enlarged flange perpendicular to the front plane, which snaps into a special frame element. It is called a stringer comb. Suction cups are used to pull the cassette out of these clamping profiles.

Ceiling panels with sides 600x600 or 600x1200 can be embedded in a subsystem with T-shaped profiles (Armstrong type).

The inner and outer corners, the adjoining walls and the ceiling, the adjoining walls to the floor, the end end of the slab - all these zones are covered with framing elements. In order to exclude places in which cleaning and disinfection can be difficult, internal and sharp corners are completely excluded from the structure, therefore the extensions have a rounded cross-section. The rounding radius is usually in the order of 70 mm. The framing elements are supplied in lengths of 3 meters, as a rule, they are made of aluminum, powder-painted. Some manufacturers offer co-extruded hard non-toxic PVC add-on elements (they have a colored outer layer).

How much is gypsum metal

The main elements of such systems are manufactured in Russia using European equipment, so the GMF is a fairly economical solution, and the delivery time for ordered products is minimal. The price for gypsum panels starts at 700 rubles per square meter. The price will increase by about 10% if you want to order a custom color. The price tag will change if special requirements are imposed on the panels. For example, increased fire resistance, sound insulation or moisture resistance will require the use of other types of drywall as a core. Then the cost of the GML square also changes - 800, 1500, 1800 rubles per m2, respectively.

It seems that this is more than other finishes cost, but it should be borne in mind that gypsum panels are completely ready for use, and they are very easy and quick to install. If you calculate the cost of a multi-layer cake that has to be created when finishing surfaces with many traditional materials, as well as the money that must be paid to the contractor for the work (usually each operation is taken into account), then the GMF is often even more profitable.

As for the finishing of clean rooms, there are very few competitors for gypsum-metal systems. Somewhere at a similar level in terms of practicality and efficiency are HPL panels made of high-pressure laminated plastic, but the cost per square meter starts from one and a half thousand rubles. Tiles, latex painting of plastered walls, gypsum vinyl cladding - these finishes do not compete with GMF in terms of functionality and performance and cannot be used in high-purity rooms, therefore it is useless to compare them.

rmnt.ru, Igor Maksimov